Fixing structure for flying shear blade

A technology of blades and flying shears, applied in the field of fixed structure of flying shears blades, can solve the problems of high frequency of bolt breakage and difficulty in taking out bolts, and achieve the effect of simple and reliable structure, convenient replacement, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

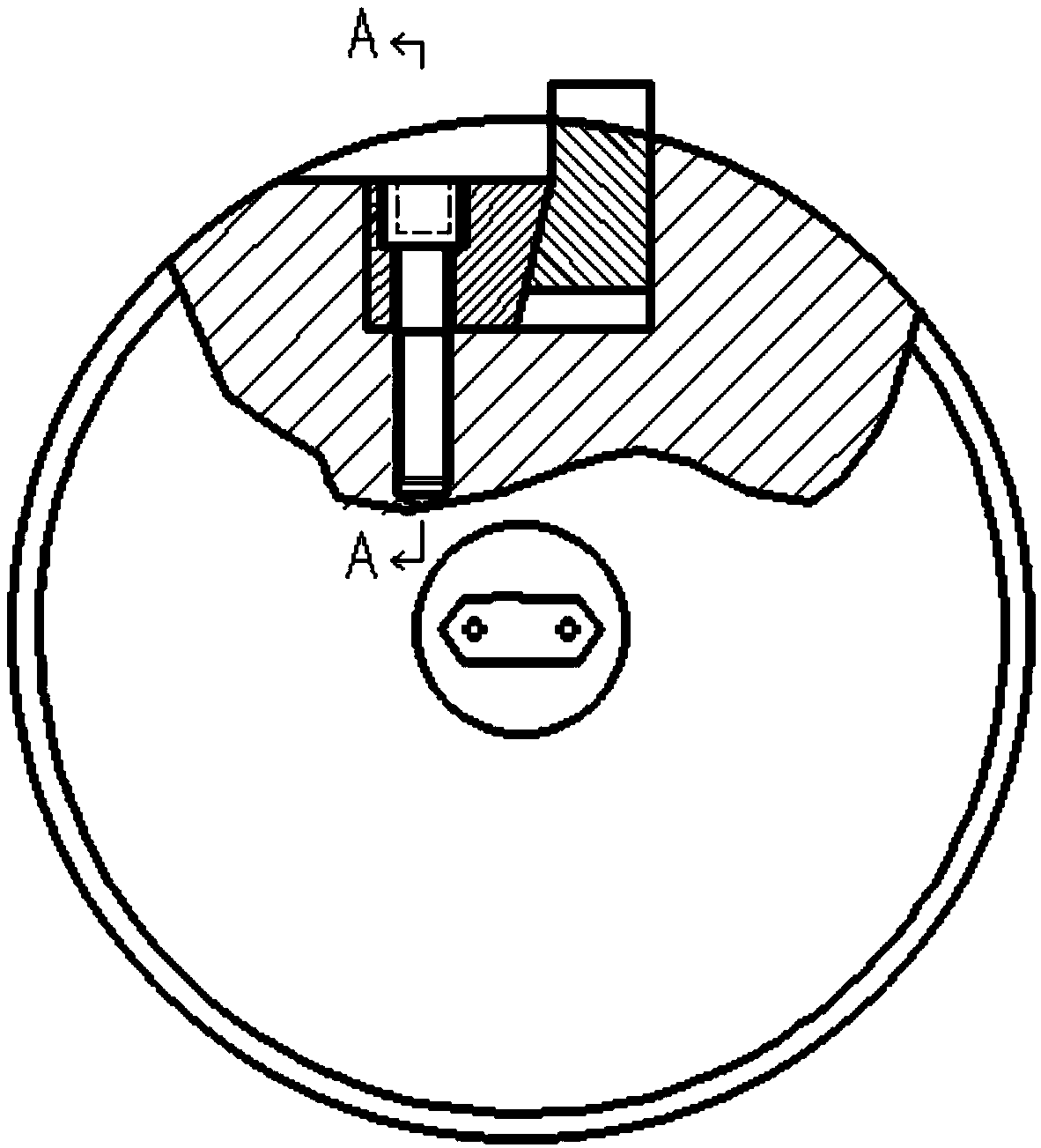

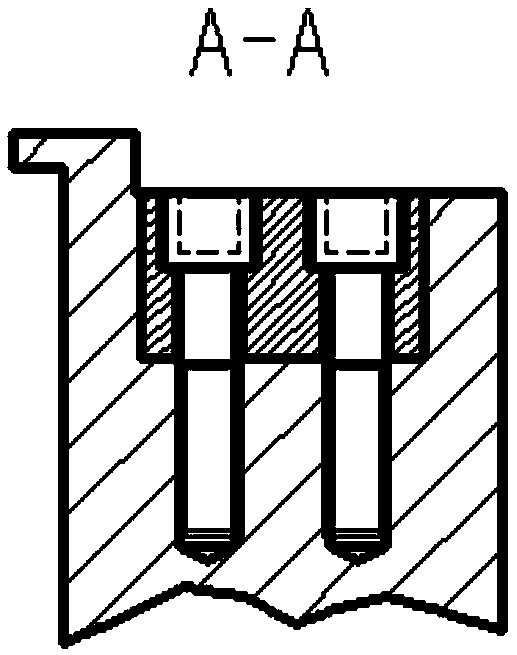

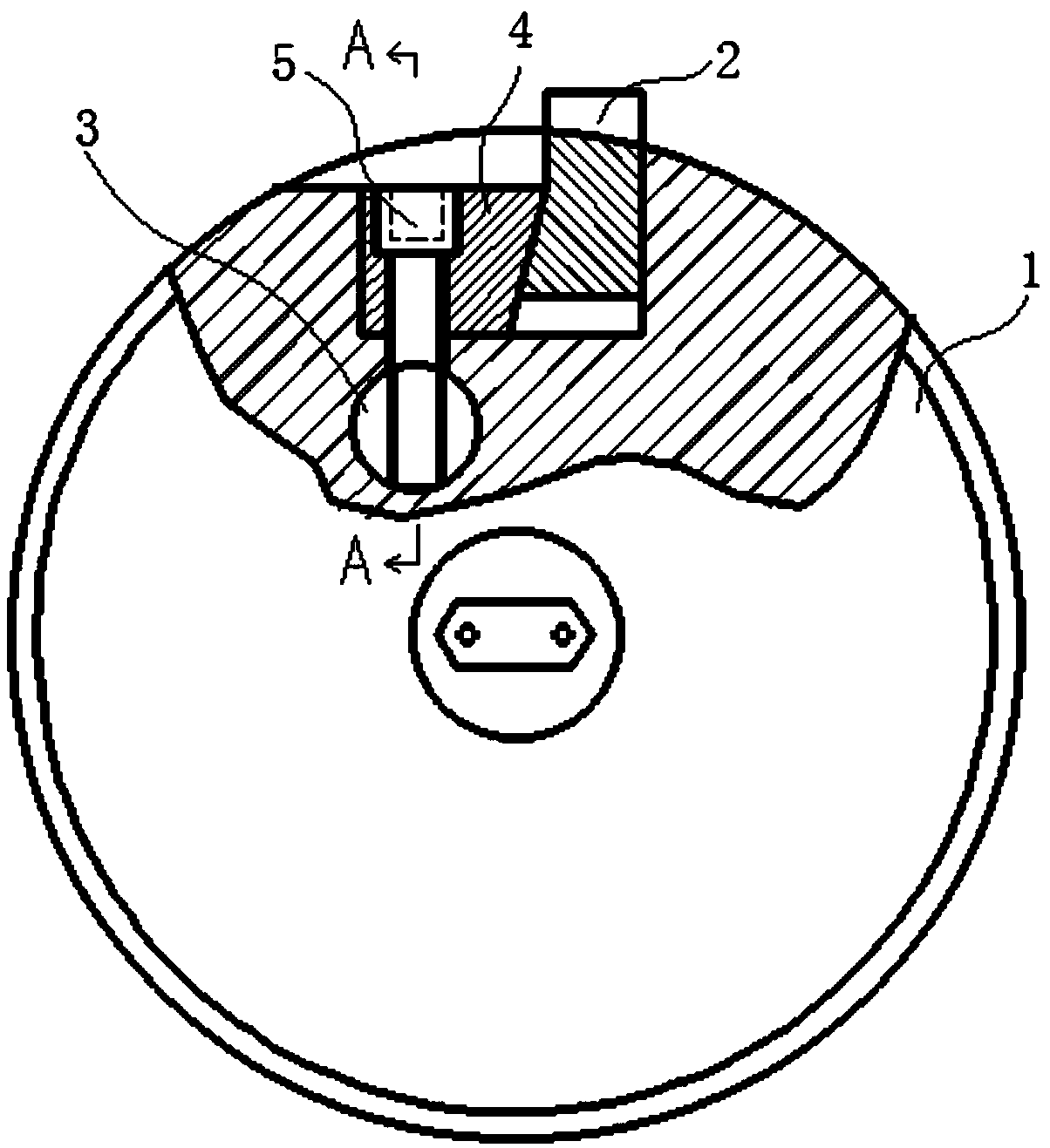

[0025] Such as Figure 3-10 Shown, a kind of fixed frame of flying shears blade comprises cutter head body 1, blade 2, pin shaft 3, briquetting block 4, fastening bolt 5, and described cutter head body 1 is provided with blade 2 and briquetting block 4 The installation notch, the blade 2 is squeezed and positioned in the installation notch of the blade 2 by the pressing block 4, the pin shaft 3 is sleeved on the cutter head body 1, the pin shaft 3 is located directly below the pressing block 4, and the pressing block 4 and pin 3 are fixedly connected by fastening bolt 5.

[0026] Wherein, a pin shaft installation hole is provided on the lower part of the installation notch on the cutter head body 1, and the pin shaft installation hole is a through hole, and the pin shaft 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com