Wooden board cleaning and clearing device

A cleaning device and cleaning technology, applied in wood processing equipment, cleaning methods and tools, pretreatment of molding materials, etc., can solve the problems of flying wood chips, not reusing wood chips, and affecting the respiratory health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

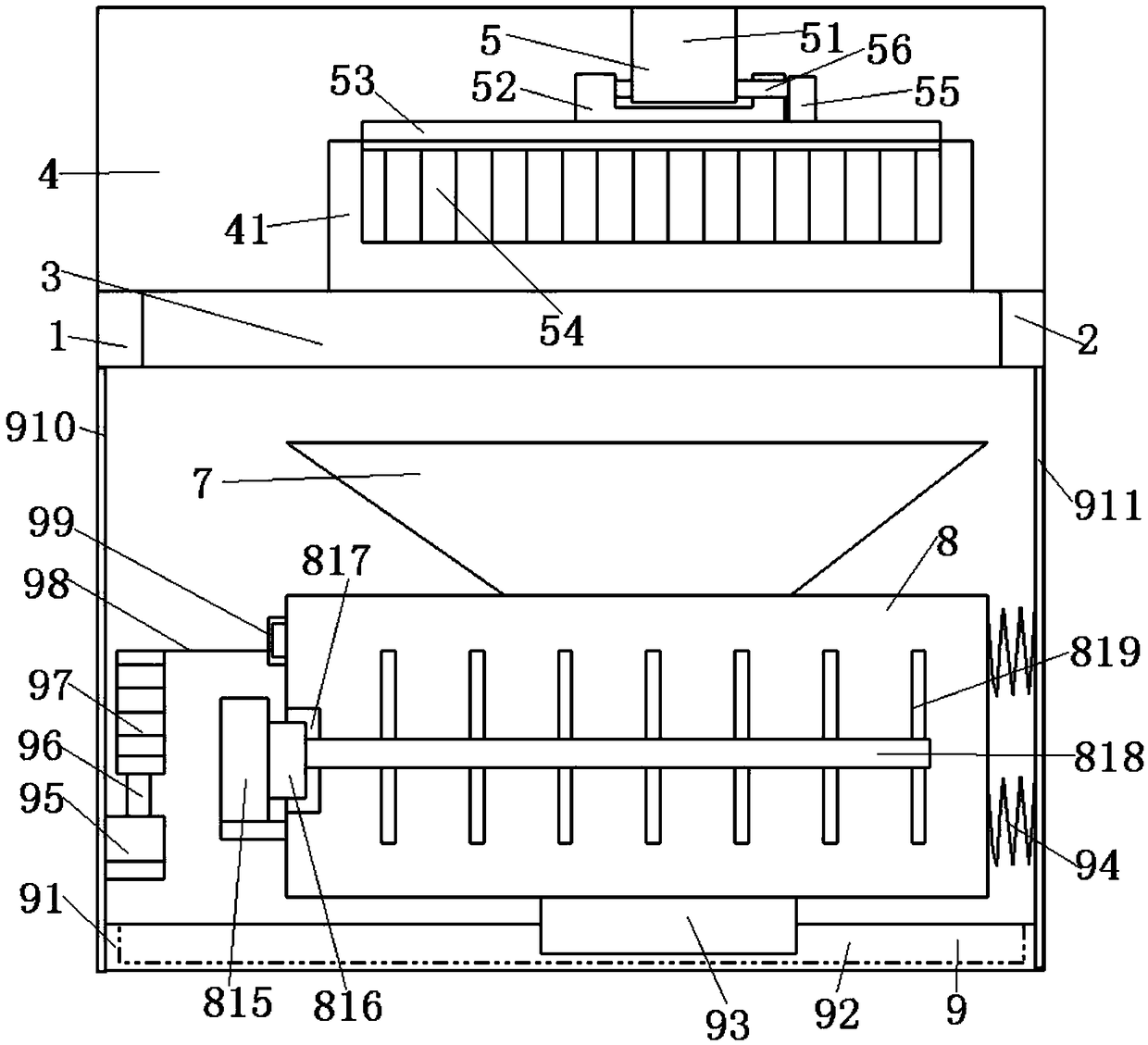

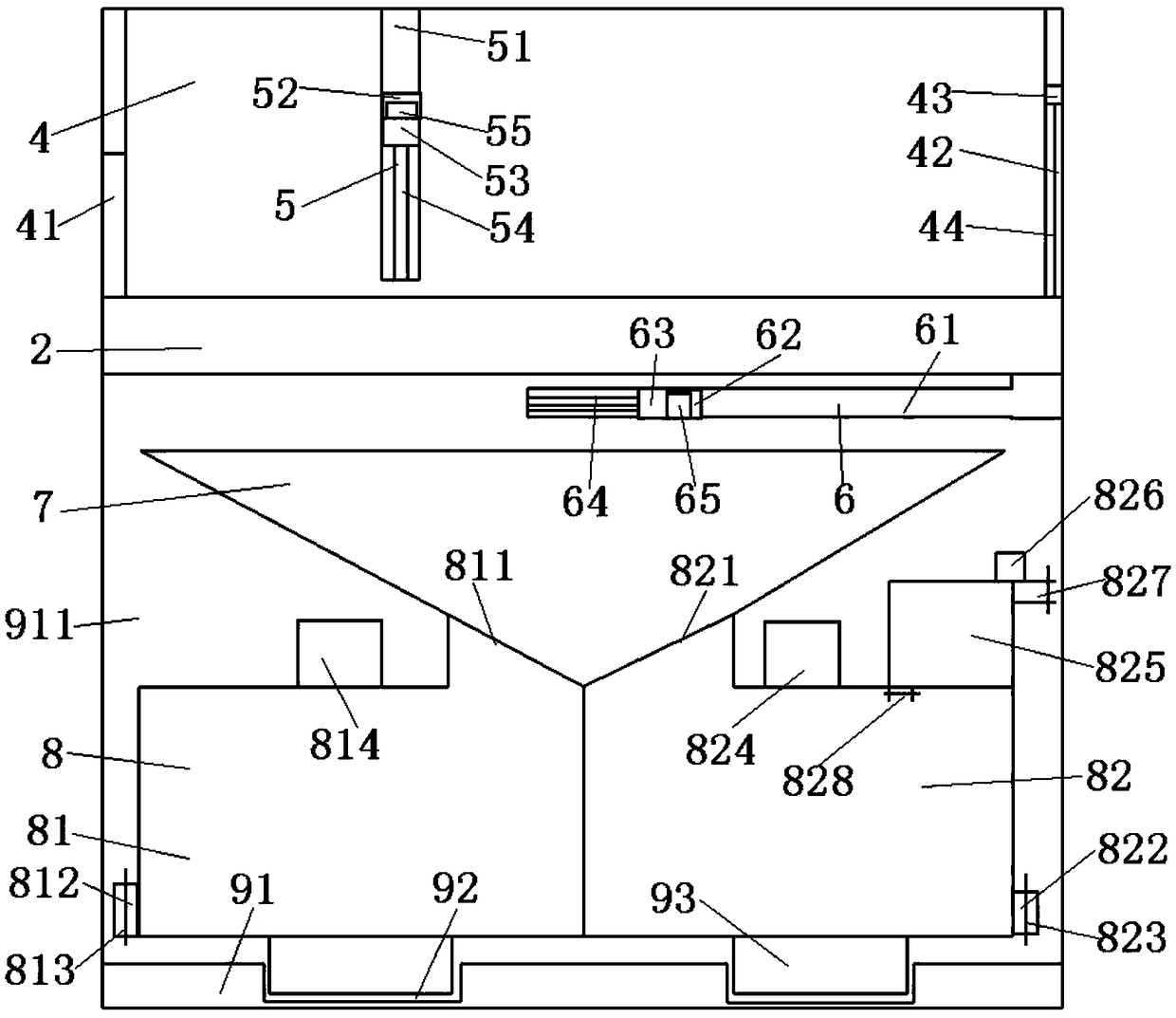

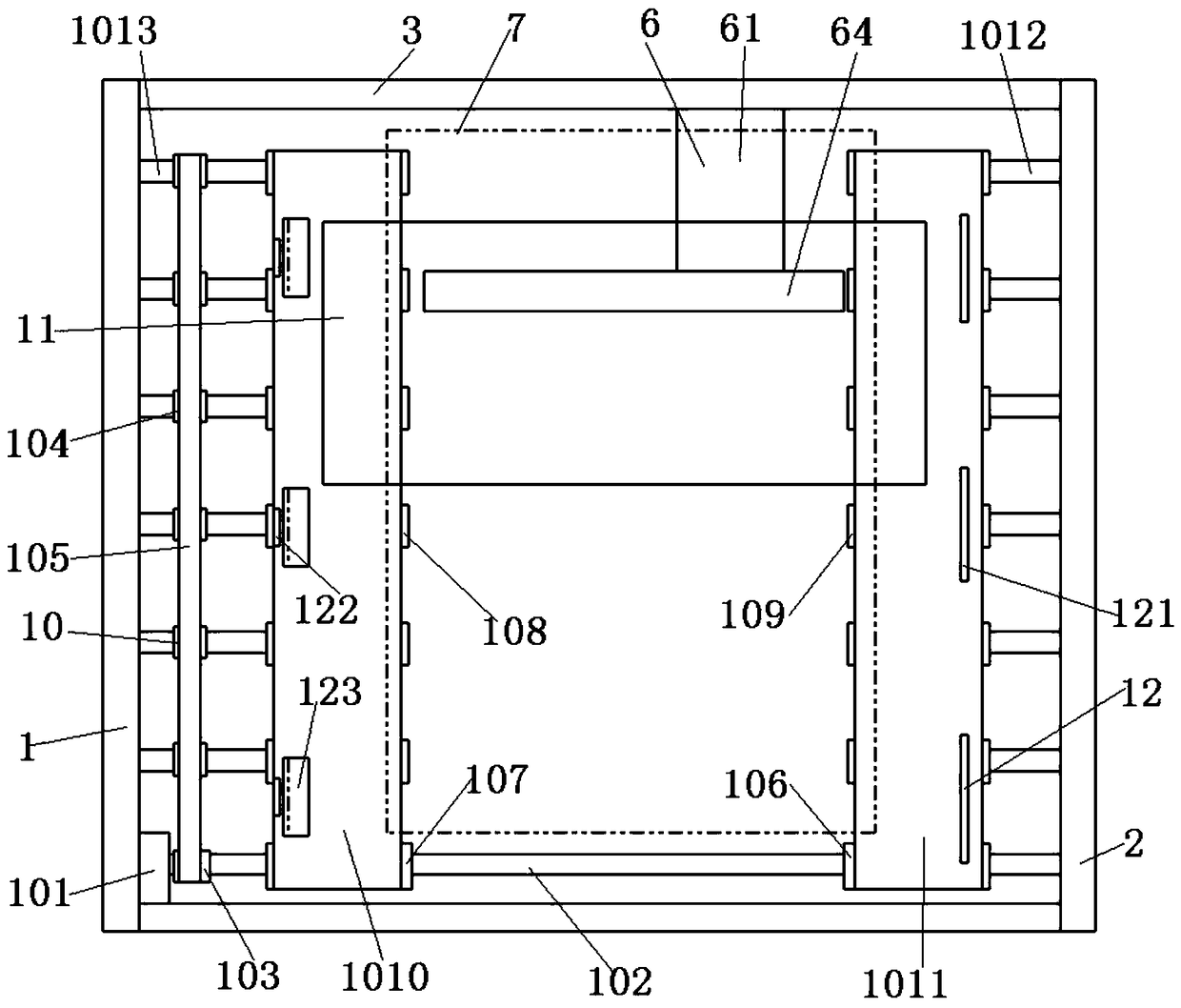

[0028] A wooden plate cleaning device, comprising a first fixed rod 1, a second fixed rod 2, a connecting fixed rod 3, a protective cover 4, an upper cleaning component 5, a lower cleaning component 6, a hopper 7, a processing box component 8, Shake component 9, transmission component 10, plate 11 and clamping component 12 left and right, the two ends of the first fixed rod 1 connect the second fixed rod 2 by connecting the fixed rod 3, connect the lower cleaning component 6 under the connected fixed rod 3, the second A transmission assembly 10 is arranged between the first fixed rod 1 and the second fixed rod 2. The transmission assembly 10 is provided with a plate 11 and a protective cover 4. An upper cleaning assembly 5 is arranged inside the protective cover 4. A receiving hopper is arranged below the transmission assembly 10. 7. A processing box assembly 8 is connected under the receiving hopper 7, and the processing box assembly 8 is connected with a left and right shakin...

Embodiment 2

[0038]A wooden plate cleaning device, comprising a first fixed rod 1, a second fixed rod 2, a connecting fixed rod 3, a protective cover 4, an upper cleaning component 5, a lower cleaning component 6, a hopper 7, a processing box component 8, Shake component 9, transmission component 10, plate 11 and clamping component 12 left and right, the two ends of the first fixed rod 1 connect the second fixed rod 2 by connecting the fixed rod 3, connect the lower cleaning component 6 under the connected fixed rod 3, the second A transmission assembly 10 is arranged between the first fixed rod 1 and the second fixed rod 2. The transmission assembly 10 is provided with a plate 11 and a protective cover 4. An upper cleaning assembly 5 is arranged inside the protective cover 4. A receiving hopper is arranged below the transmission assembly 10. 7. A processing box assembly 8 is connected under the receiving hopper 7, and the processing box assembly 8 is connected with a left and right shaking...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap