Thermal environment two-way loading test equipment and test method

A technology of two-way loading and testing equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials to achieve effective mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

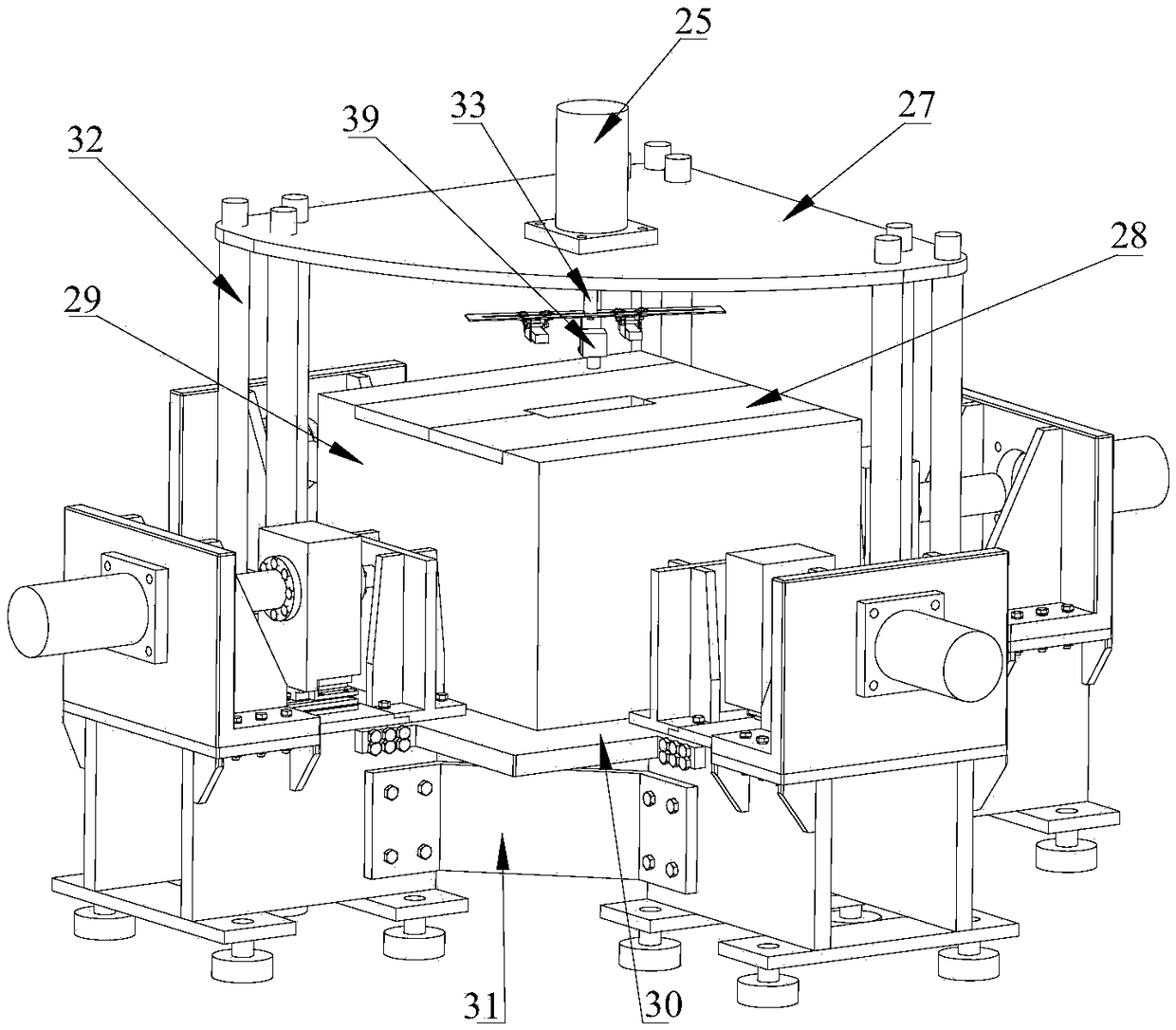

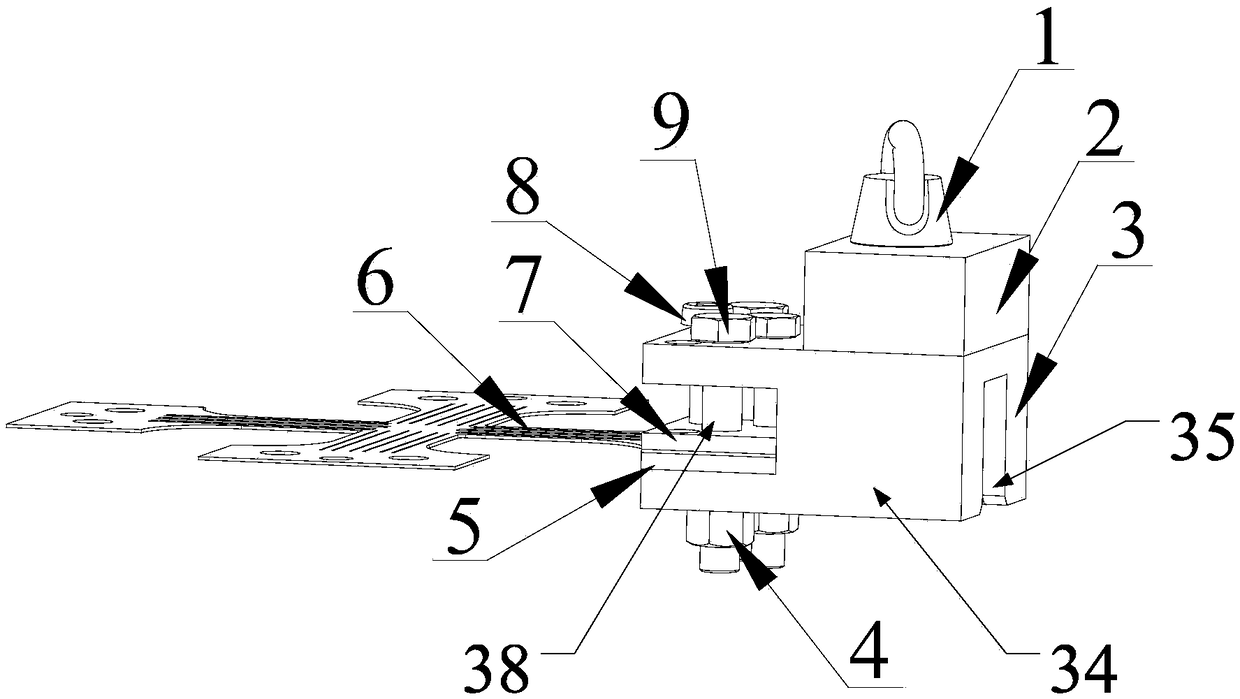

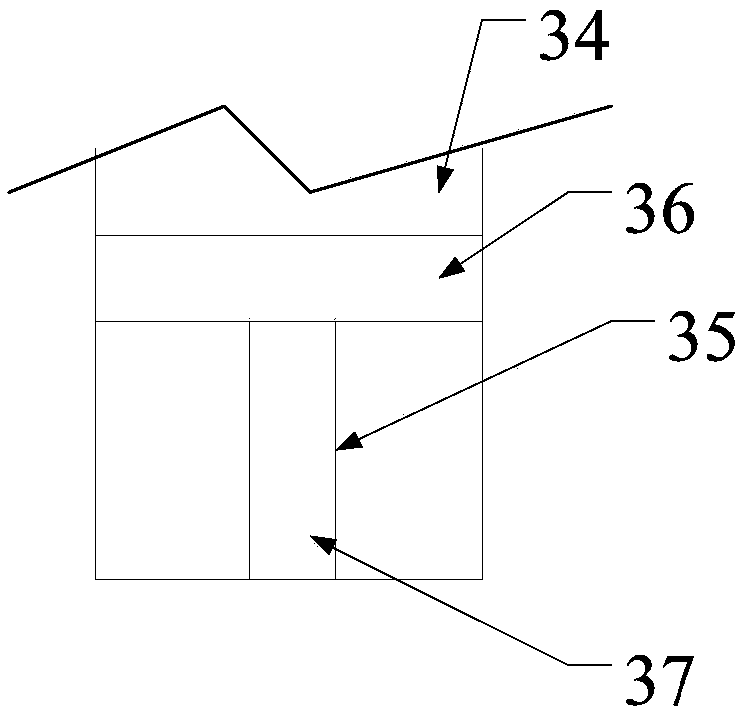

[0044] Such as Figure 1 to Figure 5 As shown, the present invention provides a thermal environment bidirectional loading test equipment for performing optical speckle strain measurement on a cross-shaped test piece, including: a frame, which includes a workbench 30, centered on the workbench 30, Four side supports and optical measurement support that are distributed in a cross shape; a heating furnace 29, which is arranged on the workbench 30, and the circumferential side wall of the heating furnace 29 is formed with four wall holes, and the heating furnace The top wall is provided with an observation window; four stretching devices are respectively arranged on the four side supports, and the stretching devices include a stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com