A lighting box for a circuit board sub-assembly

A sub-assembly and circuit board technology, applied in the field of lighting boxes, can solve problems such as reduced work efficiency and inability to meet the needs of the project, and achieve the effects of speeding up production efficiency, preventing fluctuations in the current value range, and avoiding repeated picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment one step is described.

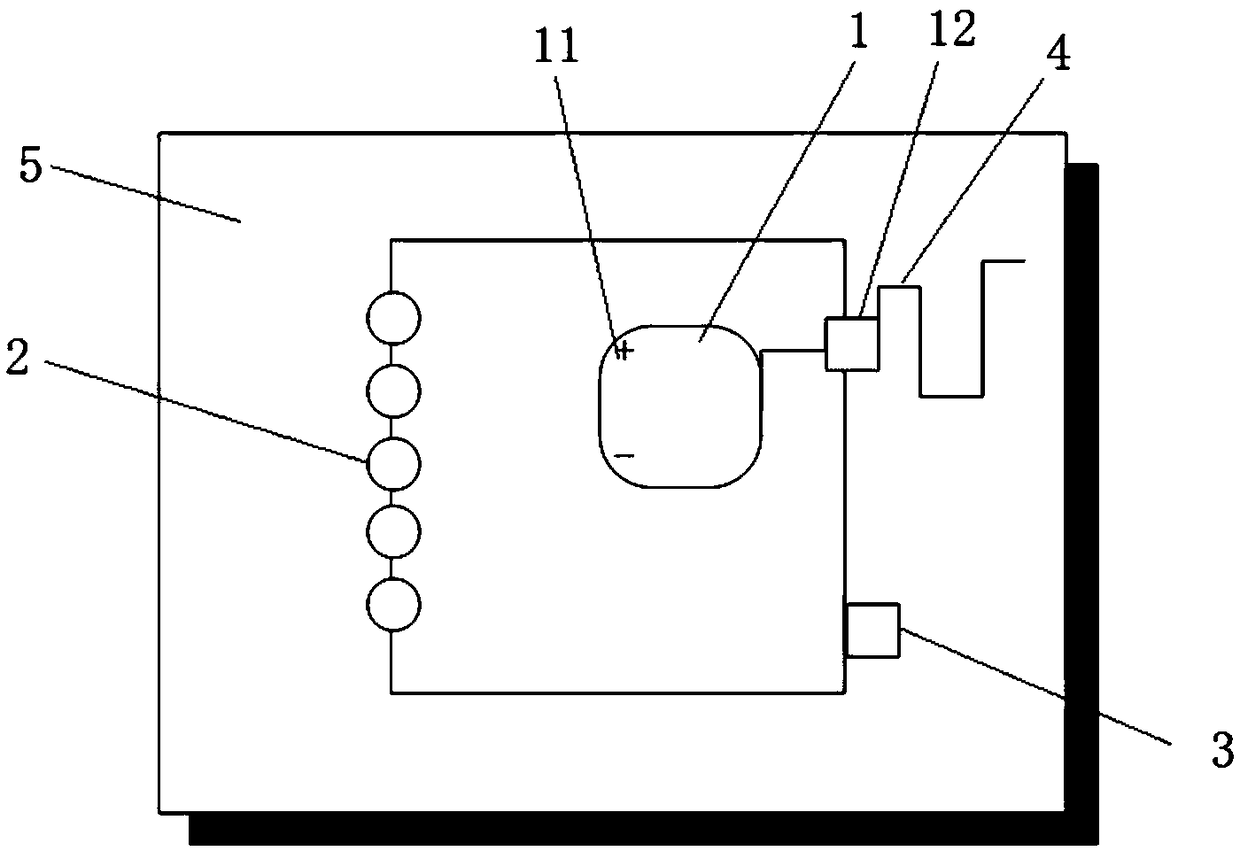

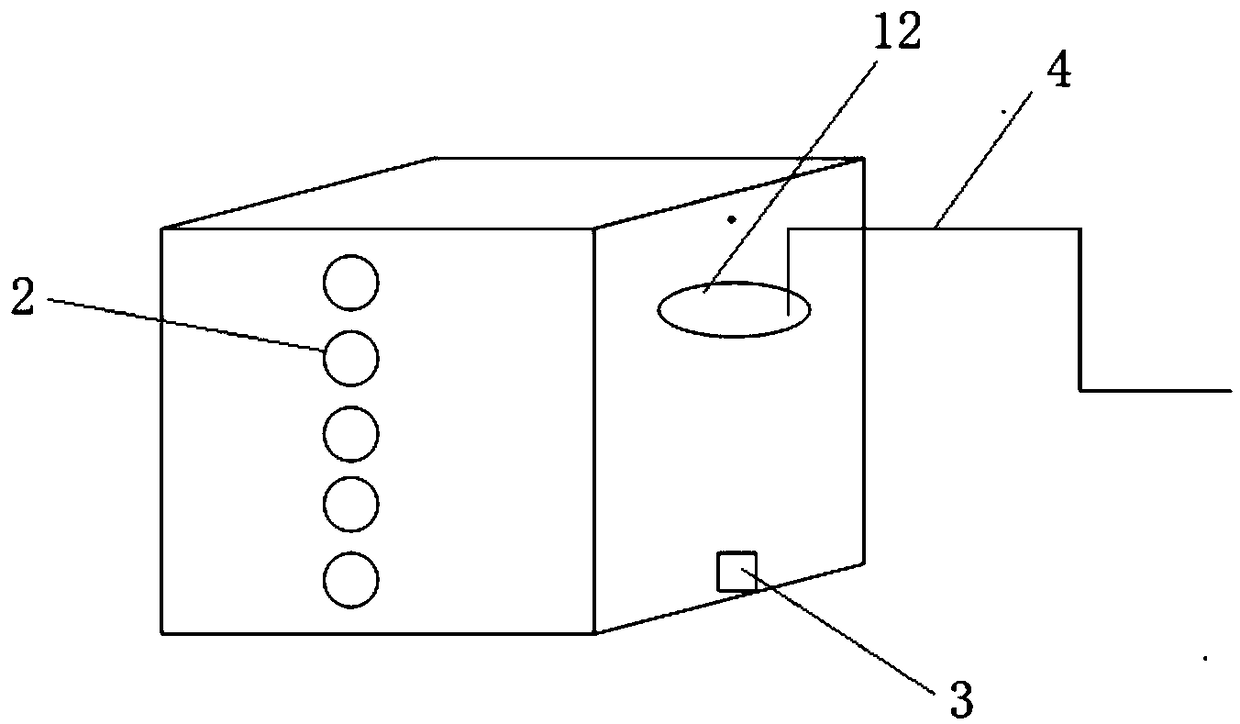

[0015] The invention provides a circuit board sub-assembly lighting tool, such as figure 1 As shown, it includes a lighting box, a workbench 5 for placing circuit board sub-assemblies, and a power button 3. The circuit board sub-assembly is placed on the workbench 5 for placing circuit board sub-assemblies, and the power button 3 controls the opening or closing of the lighting box. .

[0016] Such as figure 2 As shown, the lighting box includes a power supply box 1 and several kinds of universal lighting connectors 2. The power supply box 1 has a built-in 13.5V constant power supply, and the lighting connector 2 includes plug terminals and wires for the corresponding circuit board sub-assembly to be inserted into. And the sheath, connected to the positive and negative two-hole output interface 11 of the corresponding power supply box 1 by wires, the plug terminal is drawn out, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com