A screw plate system for posterior fixation of the axis

A screw and steel plate technology, which is applied in the field of medical devices, can solve problems such as screw entry and spinal canal invasion, and achieve the effects of reducing the possibility, avoiding infringement, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

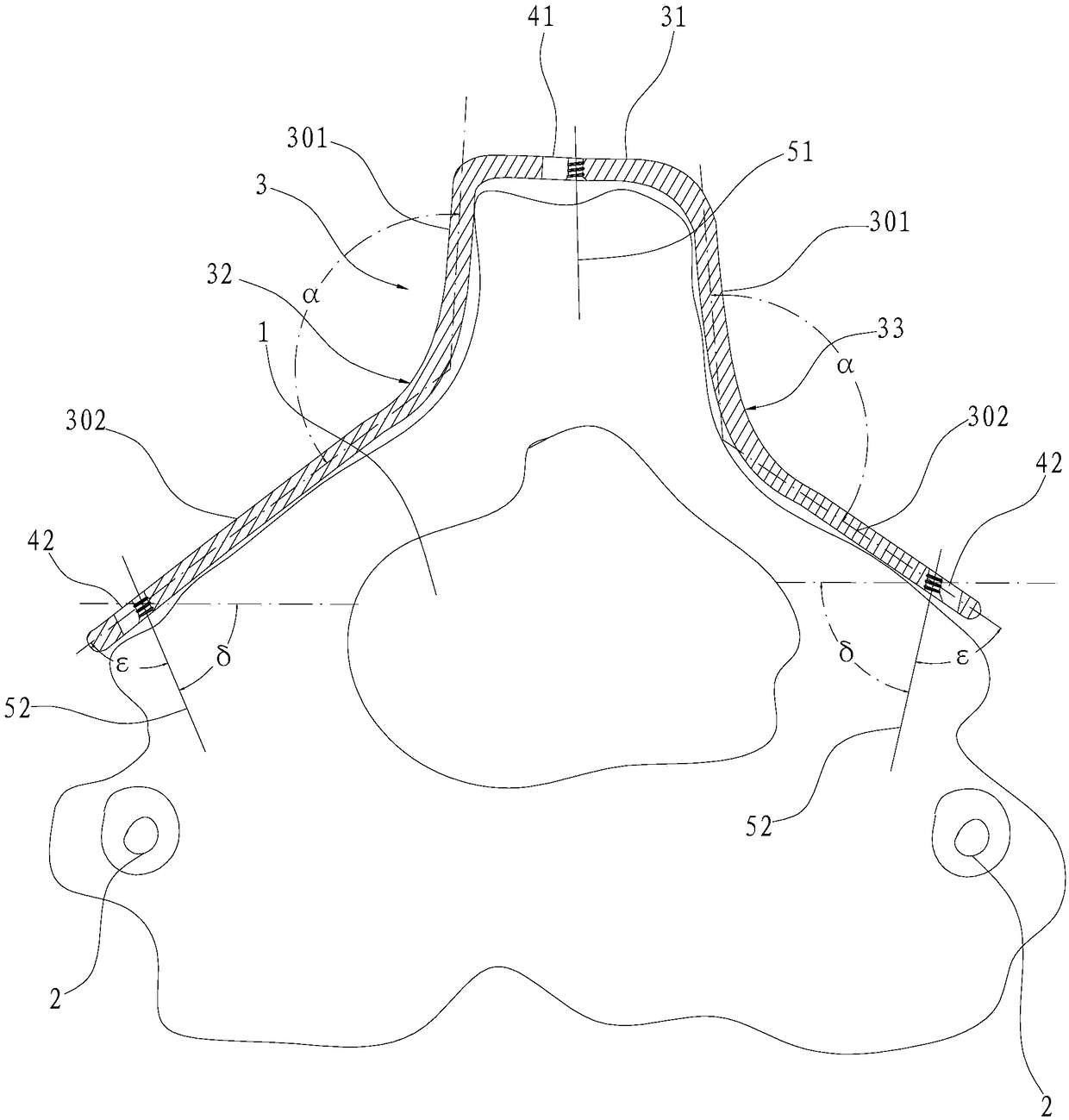

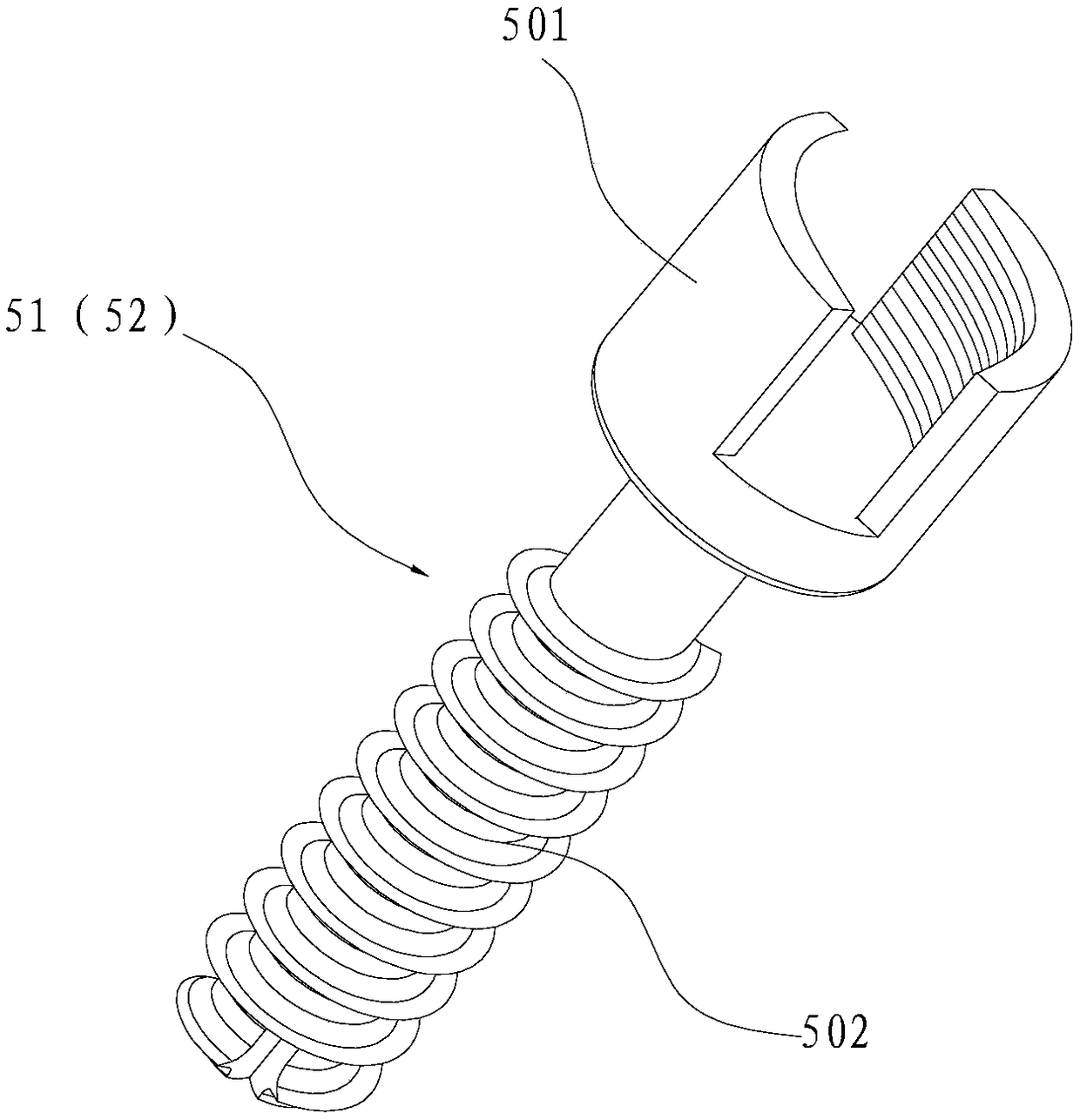

[0019] Such as figure 1 with 2 As shown, a screw plate system for posterior axial fixation includes a spinous process screw 51, an isthmic screw 52, and a spinous process plate 3. figure 1 The central axis of the spinous process screw 51 and each isthmus screw 52 are used to indicate the positions of the two. The above-mentioned spinous process steel plate 3 includes a head end 31 and a first shoulder 32 and a second shoulder 33 respectively arranged on both sides of the head end 31, and the head end 31 matches the anatomical structure of the tip of the spinous process , The first shoulder 32 is matched with the side of the spinous process and the lamina on the side of the tip of the spinous process respectively. In order to enable the spinous process plate 3 of the present invention to be more accurately attached to the fractured surface of the axis, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com