Stirring device for compound cement-based permeable crystallization type waterproof material

A technology of infiltration crystallization and waterproof materials, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of low mixing efficiency, high labor intensity, poor mixing effect, etc., and achieve improved mixing effect and automation High, improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

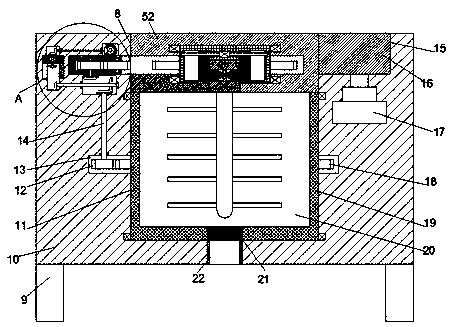

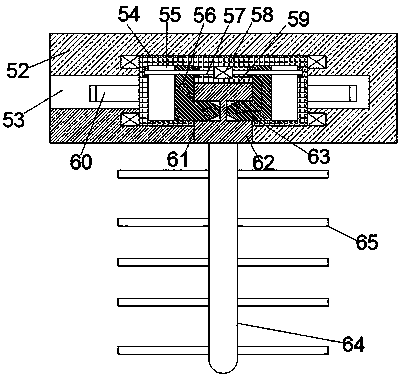

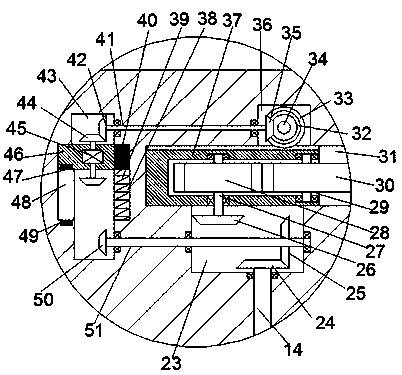

[0022] Such as Figure 1-3As shown, a stirring device for a composite cement-based permeable crystalline waterproof material of the present invention includes a cabinet 10 fixedly arranged on a support frame 9 and a stirring structure arranged in the cabinet 10, and the cabinet 10 A first rotary slot 11 is provided, and the inner top wall of the first rotary slot 11 is provided with a first communication slot 8 for communicating with the outside. Groove 13, a stirring box 19 is rotatably installed in the first rotating groove 11 through a bearing, and an outer ring gear 18 extending into the second rotating groove 13 is fixedly arranged on the outer surface of the stirring box 19 in the circumferential direction, In the left end wall of the first communication groove 8, a first sliding groove 31 is extended to the left, and a sliding block 37 is installed in the first sliding groove 31, and a sliding block 37 is installed in the sliding block 37. There is a third turn slot 29...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com