Ultrasonic noiseless drill

An ultrasonic, silent drilling technology, applied in wall drilling device, ultrasonic silent drilling. It can solve problems such as low efficiency, difficult drilling, and reduction of drill bit speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

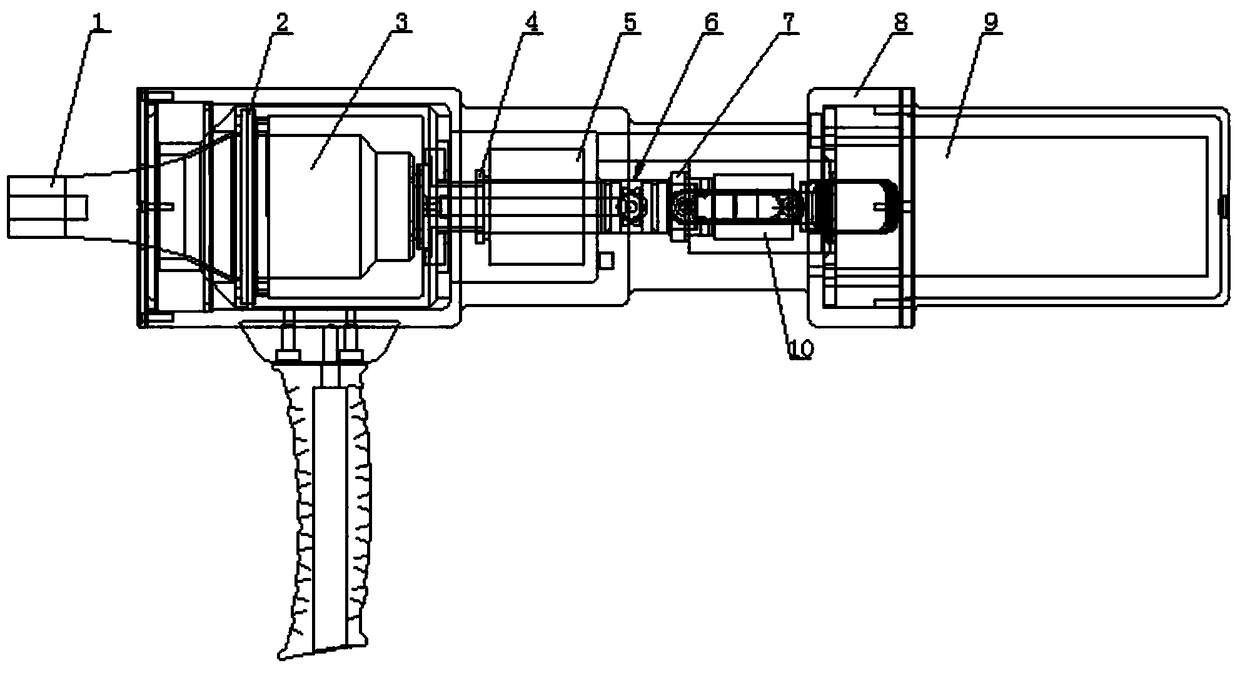

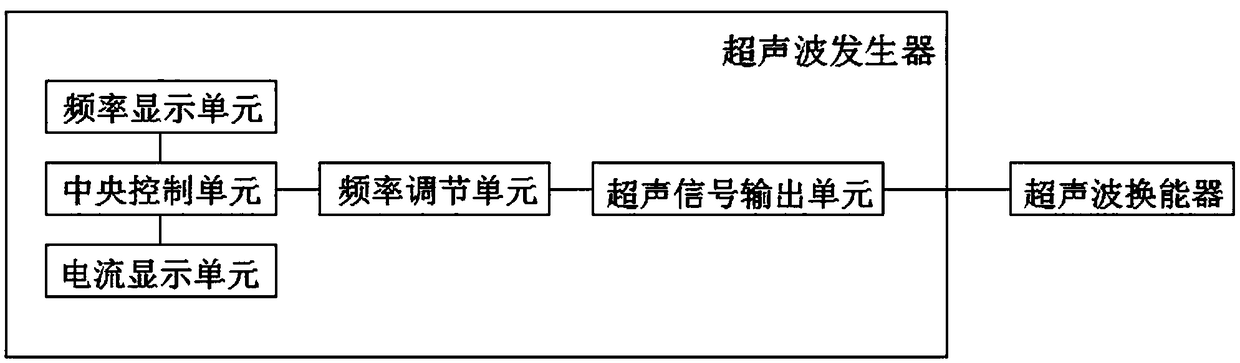

[0026] An ultrasonic silent drill, including a handheld frame, a motor is installed at the rear end of the handheld frame, and the output end of the motor is connected to the main shaft through a coupling. The innovation of the present invention is that the front end of the main shaft is the same as An ultrasonic transducer is installed on the shaft, and the front end of the ultrasonic transducer is protruded from the hand-held frame. The tool head is connected with the ultrasonic transducer and the ultrasonic generator.

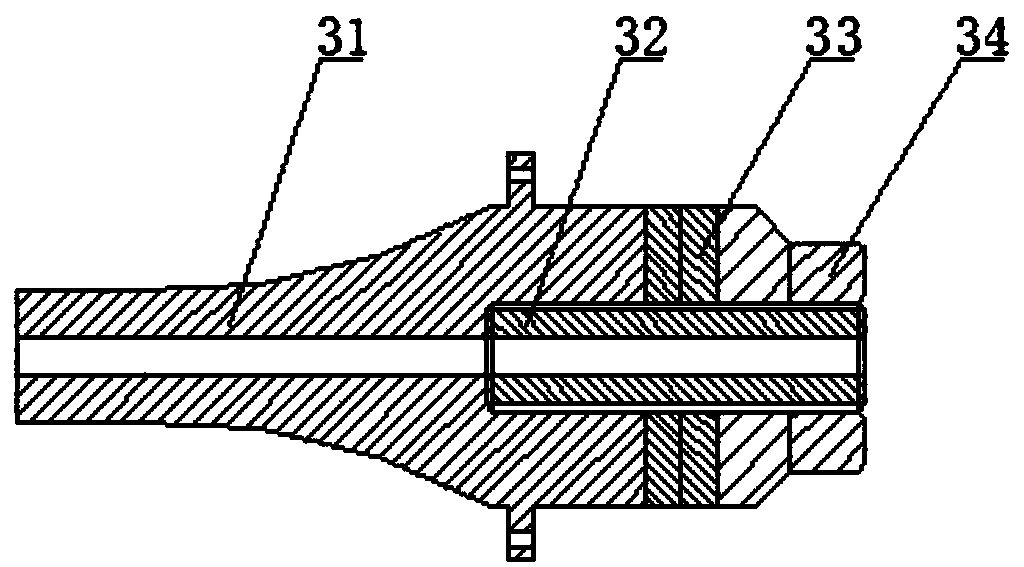

[0027] In this embodiment, an ultrasonic transducer fixing frame is installed on the front end of the handheld frame, the ultrasonic transducer is installed in the ultrasonic transducer fixing frame, and the rear end of the ultrasonic transducer fixing frame It is coaxially installed with the main shaft, and the ultrasonic transducer fixing frame drives the ultrasonic transducer to rotate synchronously under the action of the main shaft.

[0028] In this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com