Holder Conductor

A technology of electrical conductors and handles, applied in circuits, electrical components, coupling devices, etc., can solve problems such as poor contact of wires, poor balance of handles, and inability to control the accuracy and quality of assembly balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

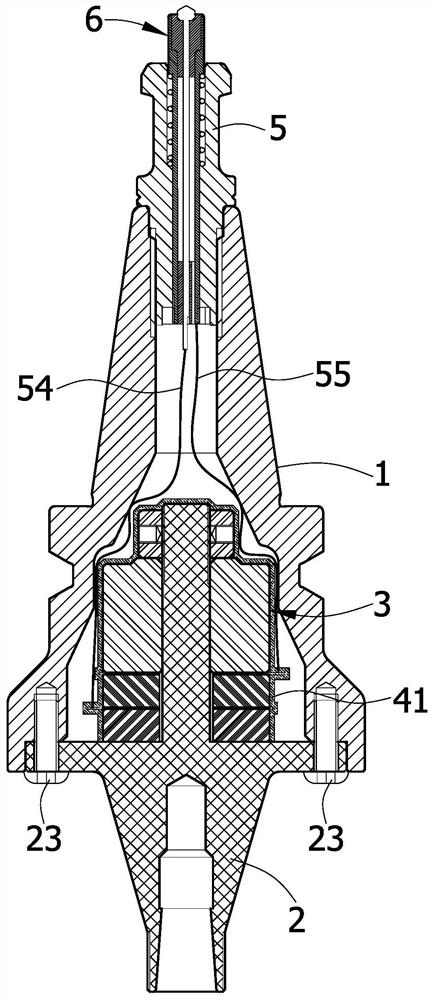

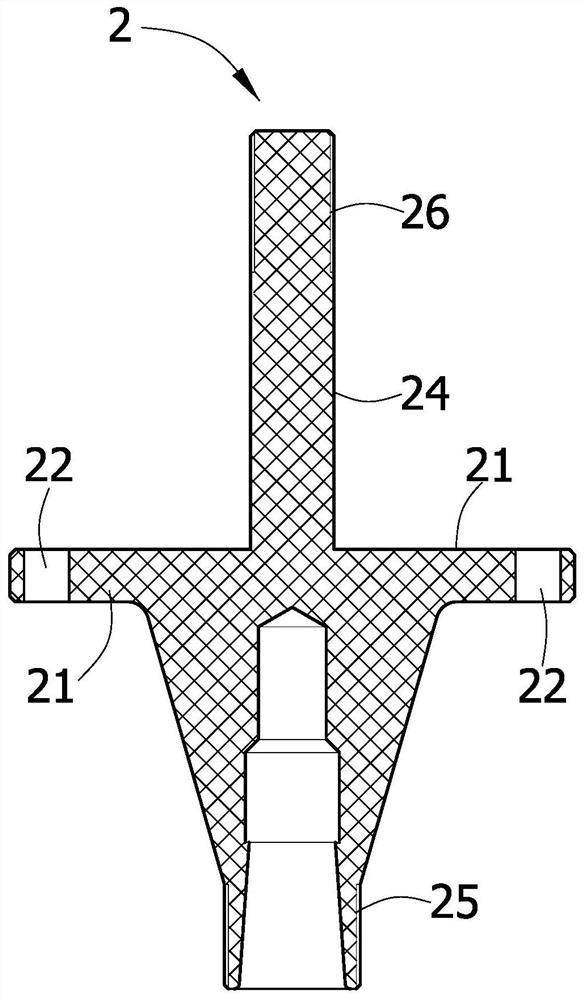

[0033] see figure 1 , The first embodiment of the ultrasonic tool holder provided by the present invention mainly includes: a tool holder 1, a horn 2, a coating 41, a contact electrode pull bolt 5 and a contact electrode 6. Wherein, the contact electrode 6 is composed of a contact negative electrode 63 , two insulating sleeves 62 , a contact positive electrode 61 and a nut 65 .

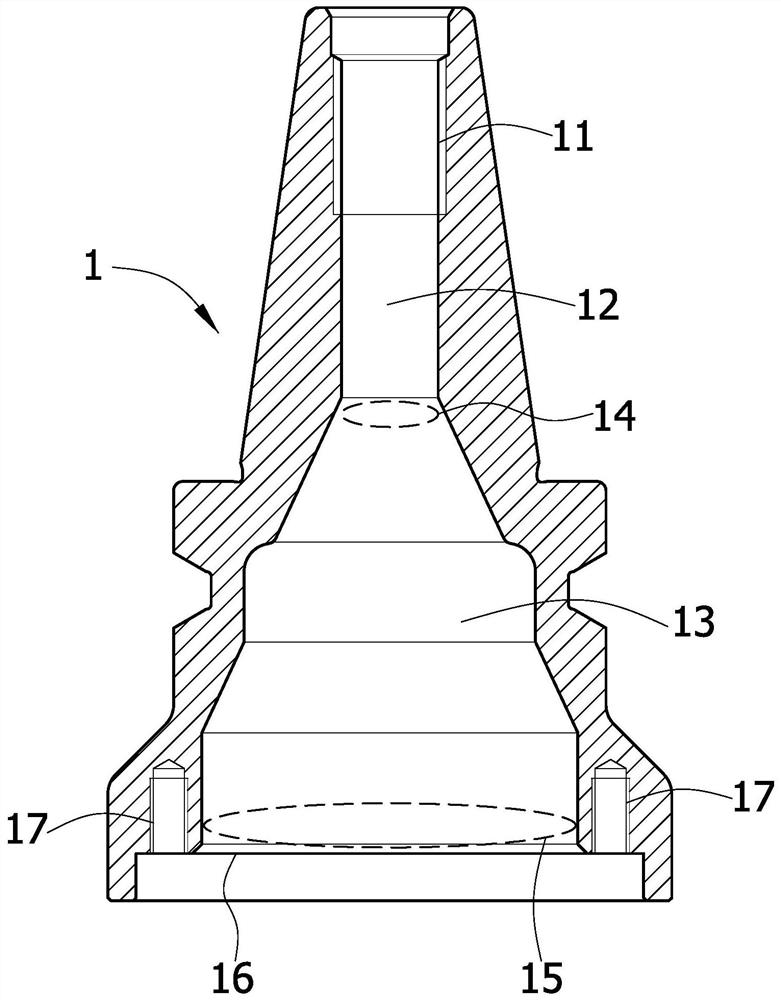

[0034] see figure 2 The knife cover 1 (knife cover) is made of stainless steel alloy steel with a chromium content of 10% by mass or more. Examples of the alloy steel include Asada loose iron ( Martensite) and other stainless steel types, in which a passage 12 (flow passage) including a threaded portion 11 (threaded portion) and a thread height (height of thread) communicates with a resonant cavity 13 (resonantcavity), the resonant cavity 13 It has a first side 14 facing the passage 12 and a second side 15 facing an opening bottom 16 (opening bottom), and the opening bottom 16 is surrounded by a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com