Excavator being large in excavation range and high in stability

An excavator and stability technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of unstable factors, limited excavation range, etc., to increase the excavation range , The effect of reducing material cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

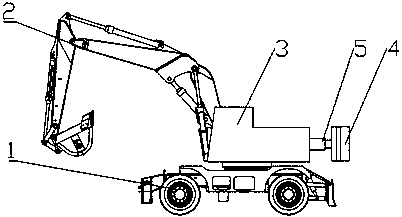

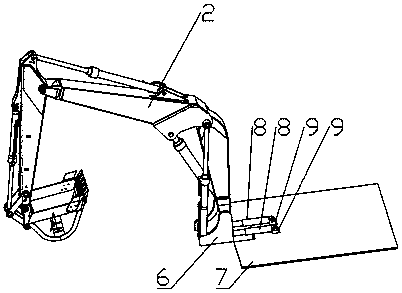

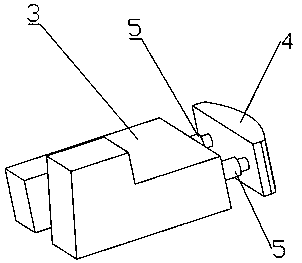

[0022] Embodiment 1, this embodiment provides the specific structure of the excavator. Such as Figures 1 to 3 As shown, the excavator in this embodiment includes a lower traveling mechanism 1, a fuselage 3, a working device 2, and a counterweight 4. The lower traveling mechanism 1 is connected to the fuselage 3 through a slewing bearing, and the connection between the working device 2 and the fuselage 3 The first hydraulic cylinder group 8 is arranged between them, the first hydraulic cylinder group 8 includes two hydraulic cylinders, the cylinder barrel of the hydraulic cylinder is hinged with the hinge seat 9 on the fuselage bottom plate 7, and the piston rod top of the hydraulic cylinder is connected with the working device base 6 rear fixedly connected to the upper part of the body, a second hydraulic cylinder group 5 is arranged between the counterweight 4 and the fuselage 3, and this group of hydraulic cylinders also includes two hydraulic cylinders, the cylinder barrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com