Patents

Literature

48results about How to "Increased digging depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

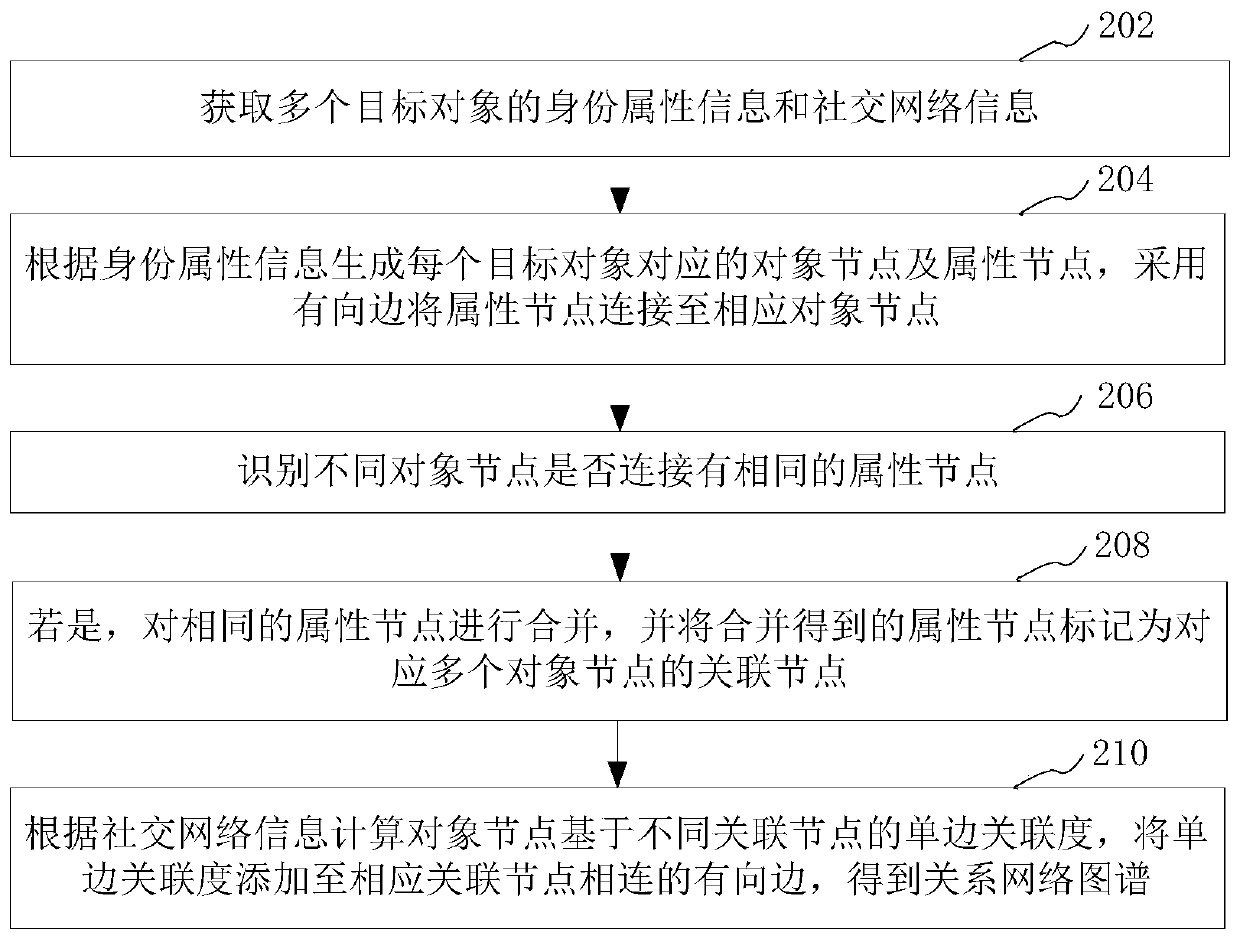

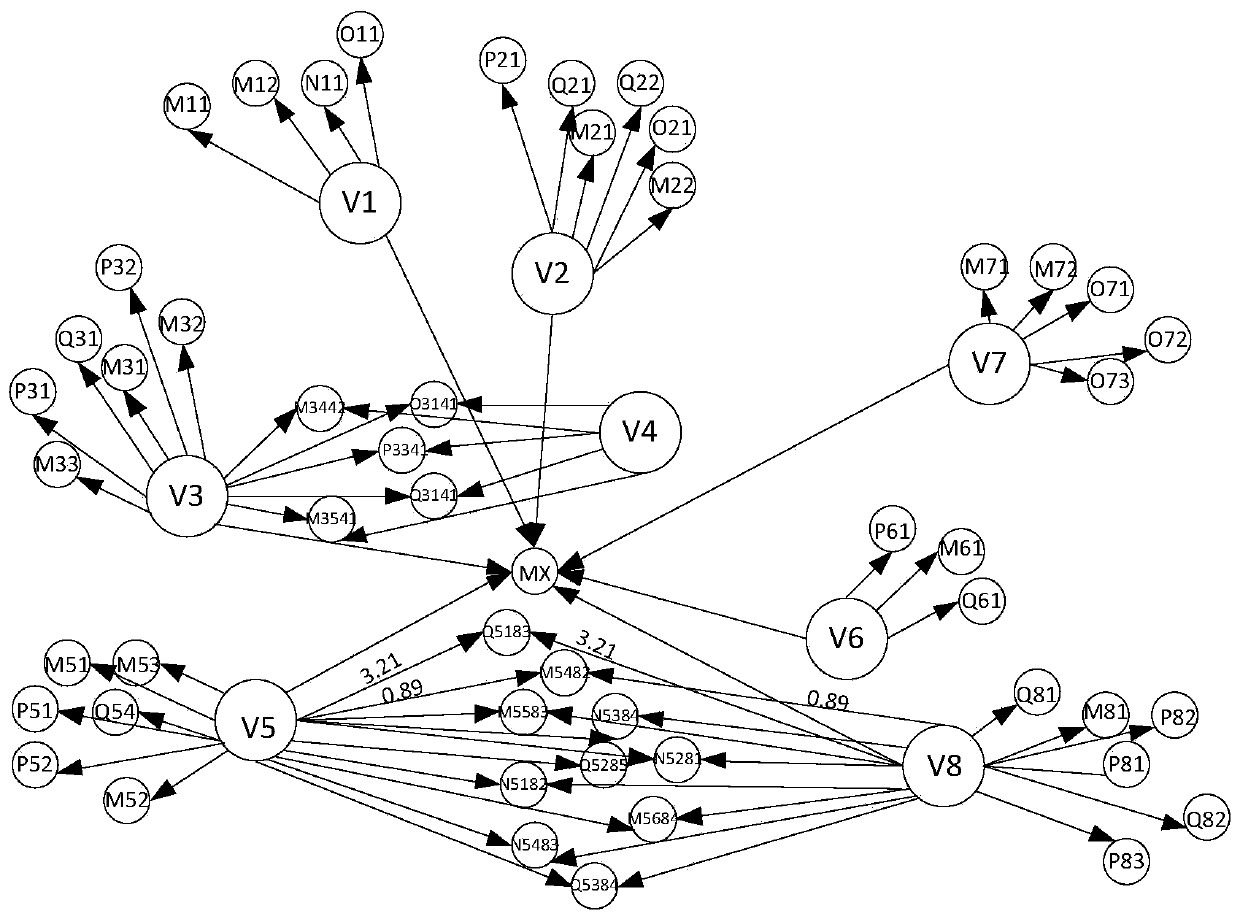

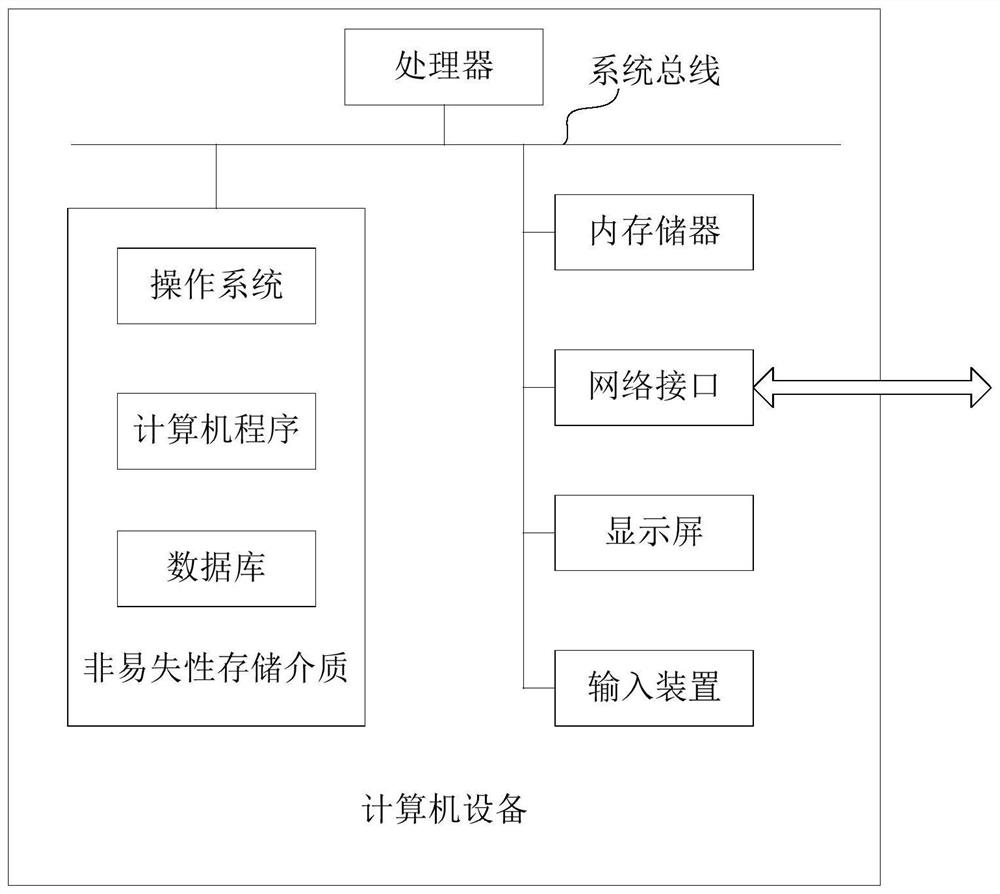

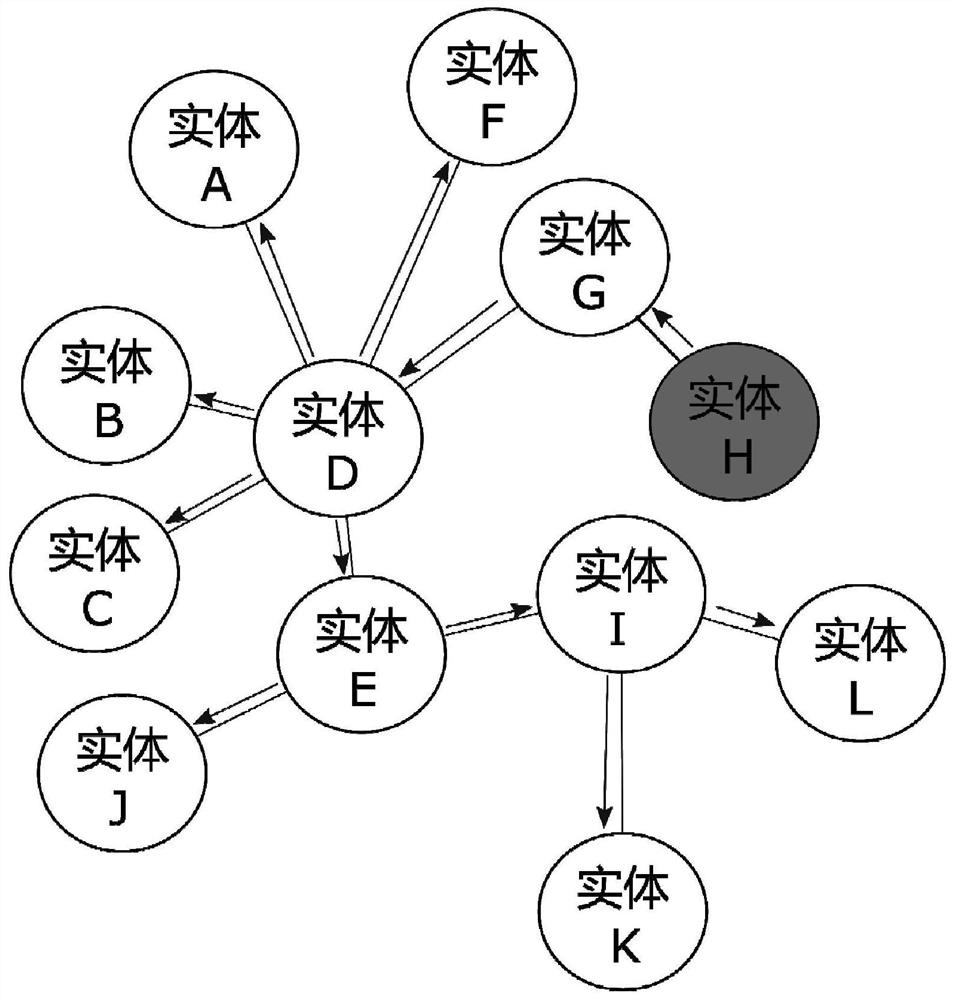

Relational network graph construction method and device, computer equipment and storage medium

ActiveCN110659395AImprove mining accuracyImprove scalabilityWeb data indexingOther databases indexingAlgorithmTheoretical computer science

The invention relates to a relational network graph construction method and device, computer equipment and a storage medium. The method comprises the following steps: acquiring identity attribute information and social network information of a plurality of target objects; generating an object node and an attribute node corresponding to each target object according to the identity attribute information, and connecting the attribute node to the corresponding object node by adopting a directed edge; identifying whether different object nodes are connected with the same attribute node or not; if yes, merging the same attribute nodes, and marking the attribute nodes obtained by merging as associated nodes corresponding to a plurality of object nodes; and calculating unilateral association degrees of the object node based on different associated nodes according to the social network information, and adding the unilateral association degrees to directed edges connected with the correspondingassociated nodes to obtain a relational network graph. By adopting the method, the association relationship acquisition efficiency can be improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

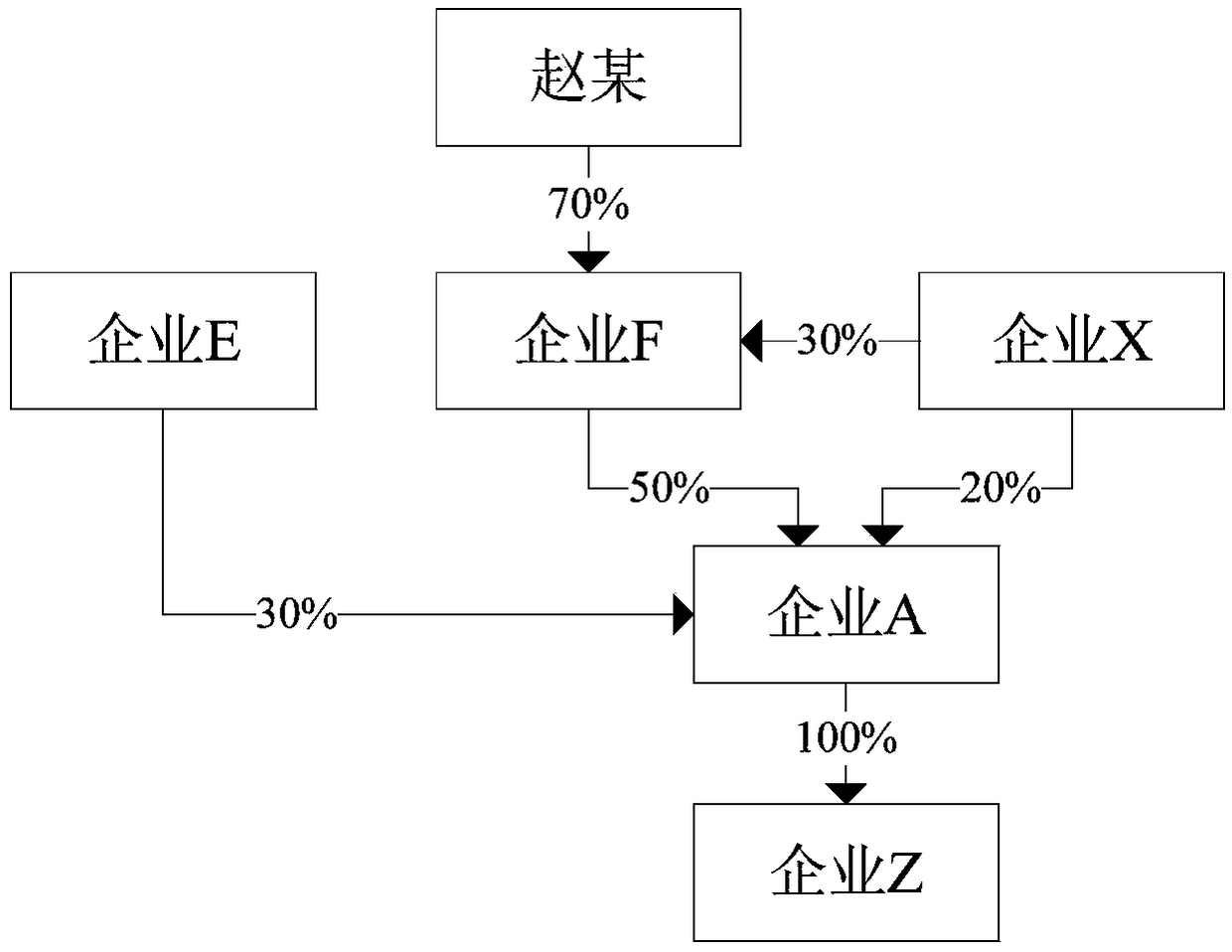

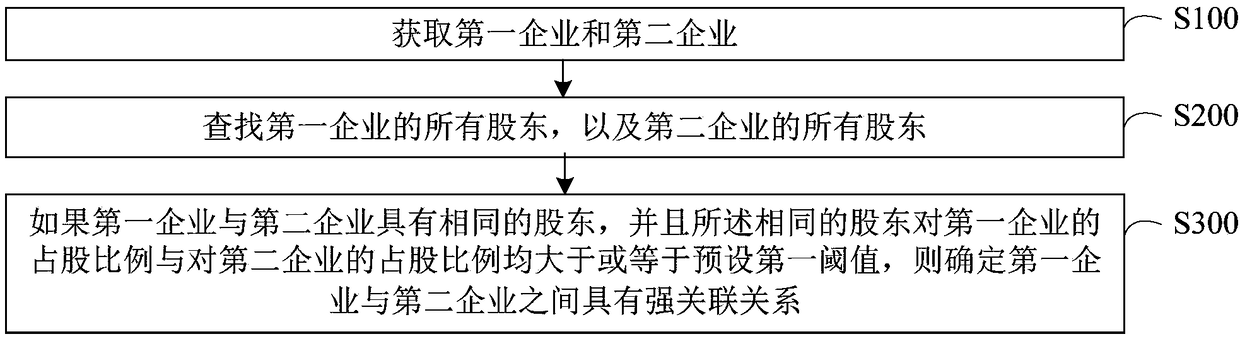

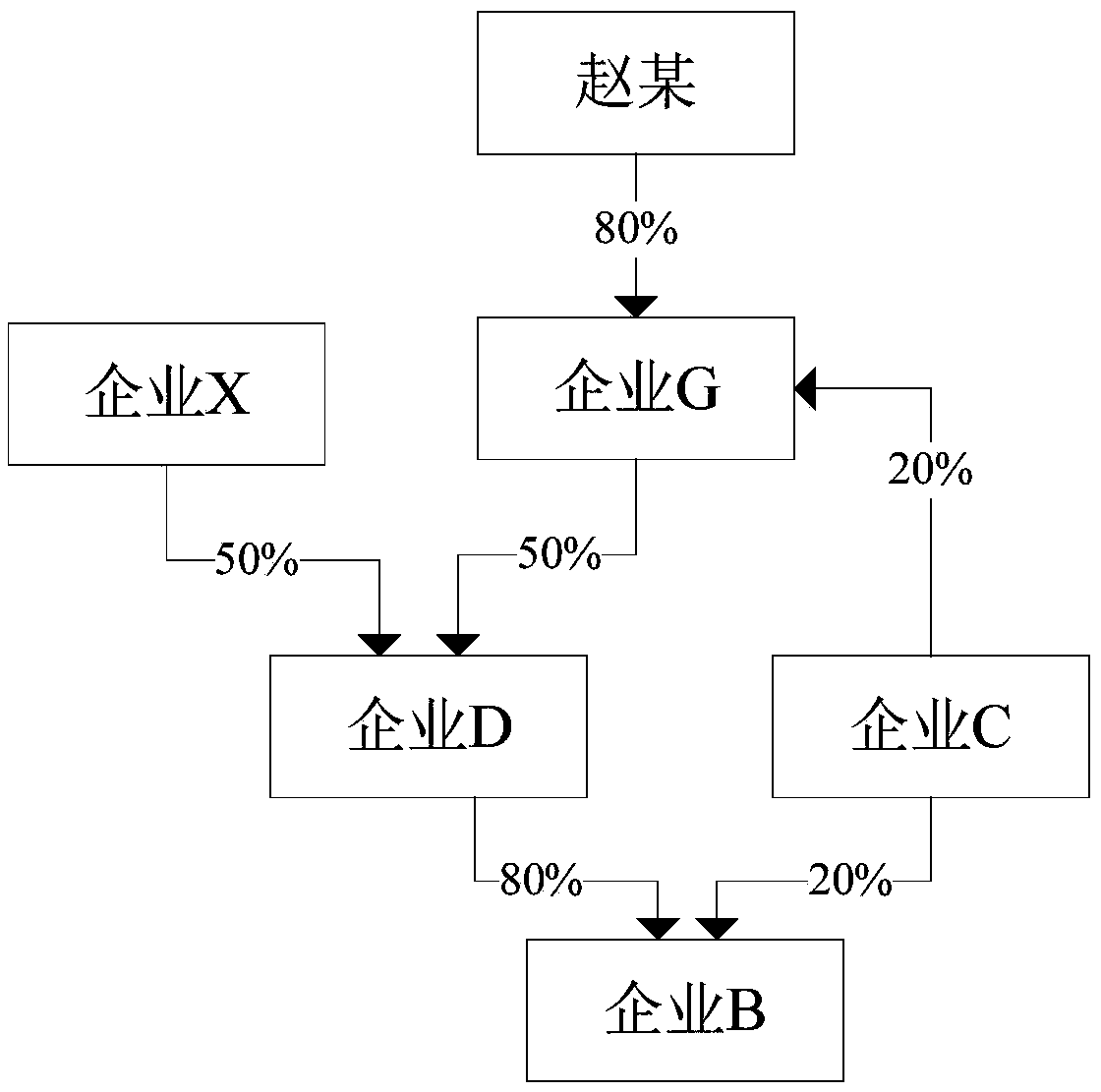

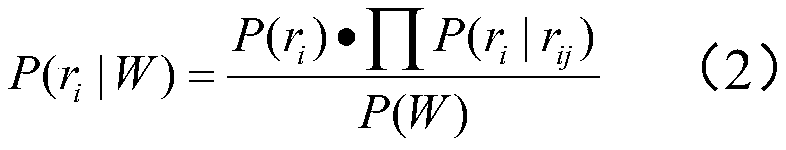

Enterprise association relationship analysis method and device and computer-readable storage medium

InactiveCN109271426AIncreased digging depthReduce riskData miningSpecial data processing applicationsKnowledge managementRelationship analysis

The embodiment of the invention discloses an enterprise association relationship analysis method and device and a computer-readable storage medium. The method comprises the following steps: acquiringa first enterprise and a second enterprise; searching for all shareholders in the first business and all shareholders in the second business; and if the first enterprise and the second enterprise havethe same shareholders, and both the share ratio of the same shareholders to the first enterprise and the share ratio to the second enterprise are greater than or equal to a preset first threshold value, determining that there is a strong association relationship between the first enterprise and the second enterprise. Through this method, we can dig out the strong relationship between two enterprises which have no direct or indirect investment relationship, but have common and influential investors, enhance the mining depth of the relationship between enterprises, and reduce the risk of missing the association relationship to the related enterprises.

Owner:ZHONGKE DINGFU BEIJING TECH DEV

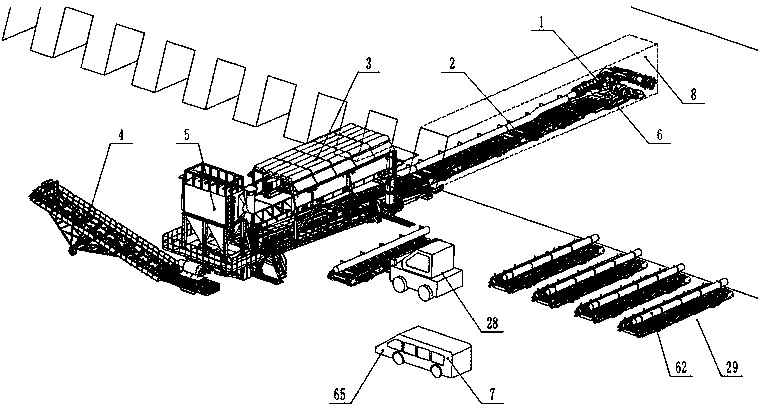

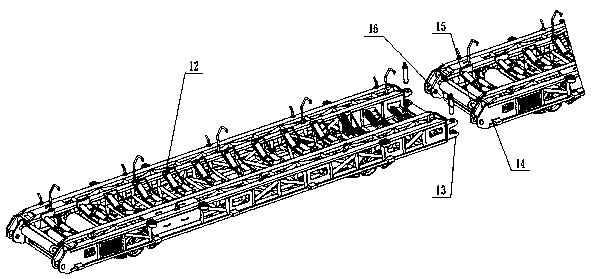

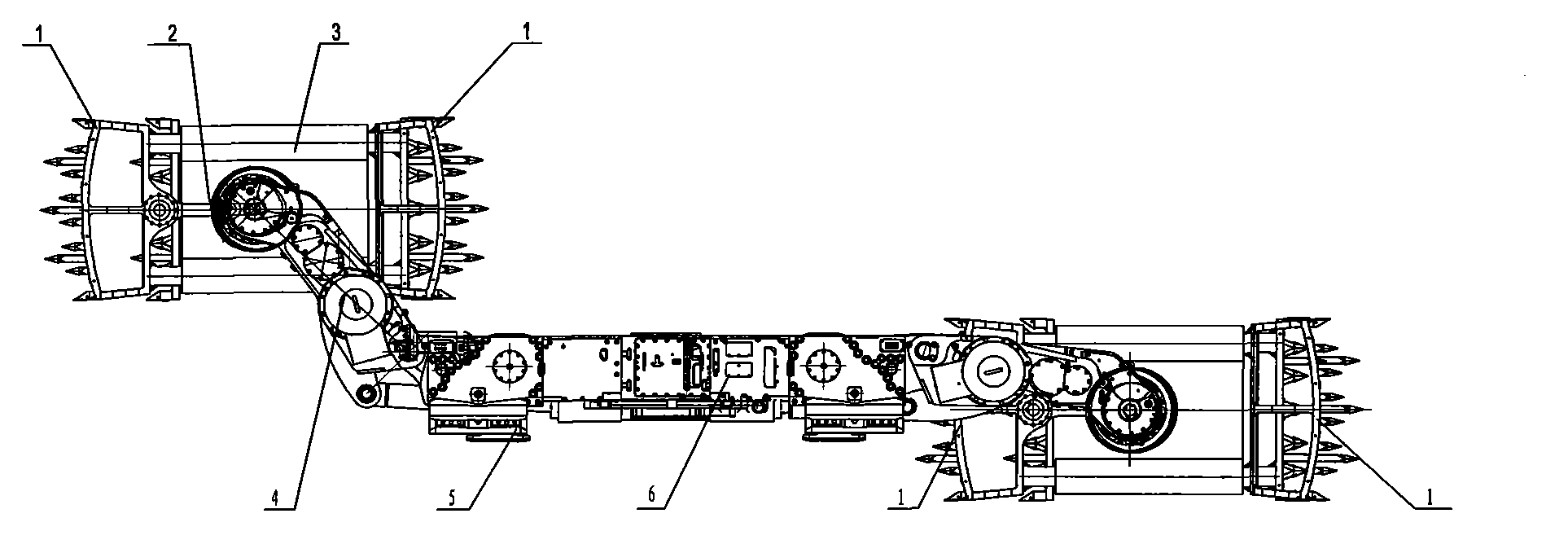

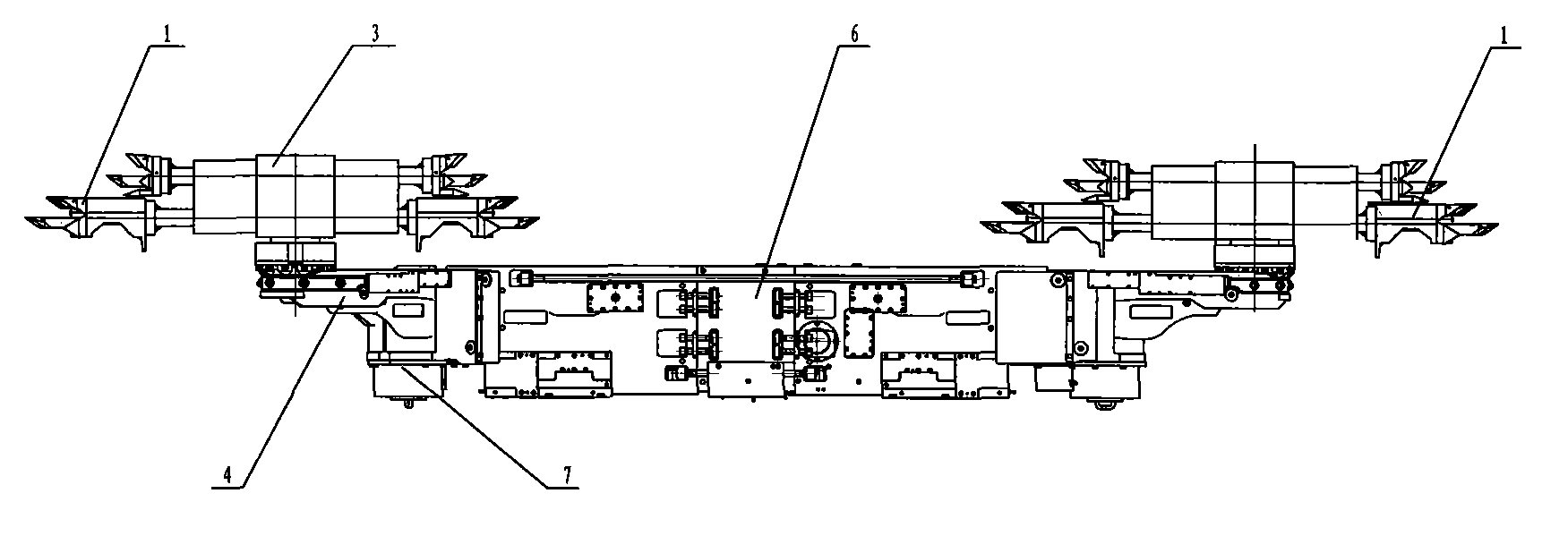

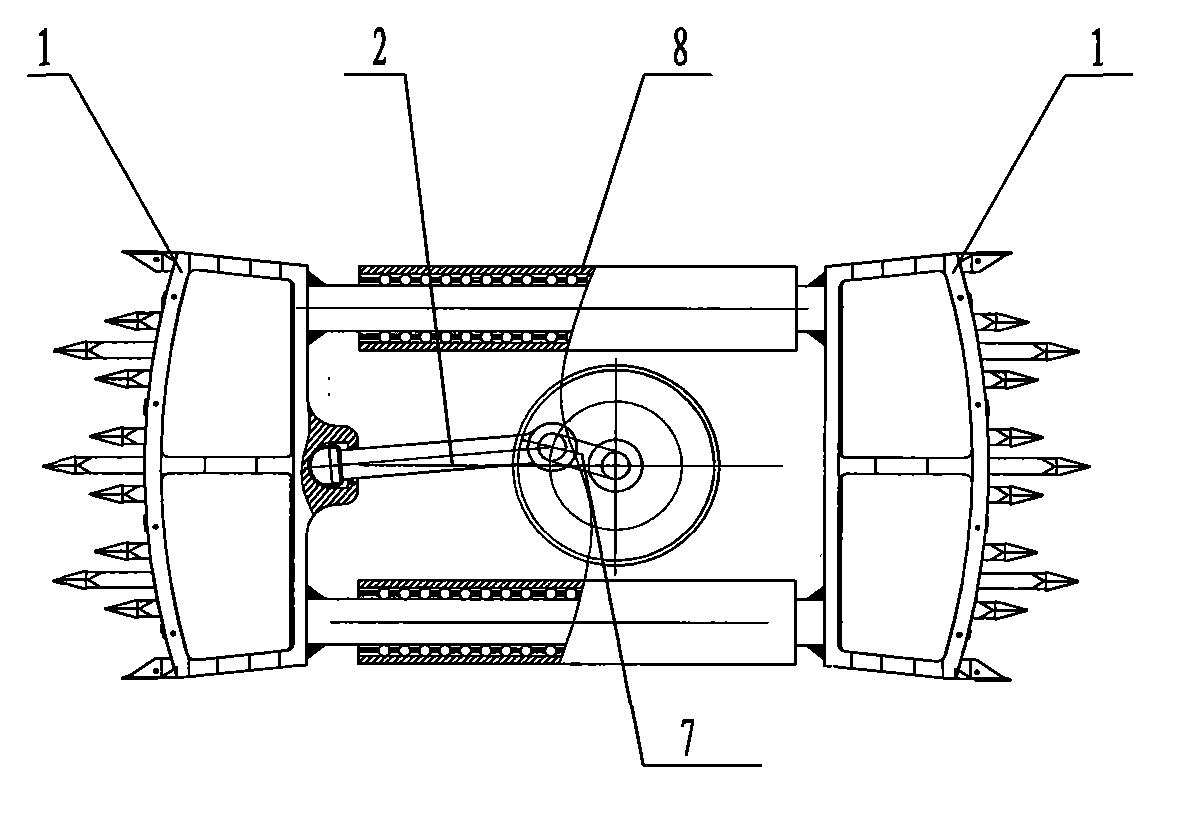

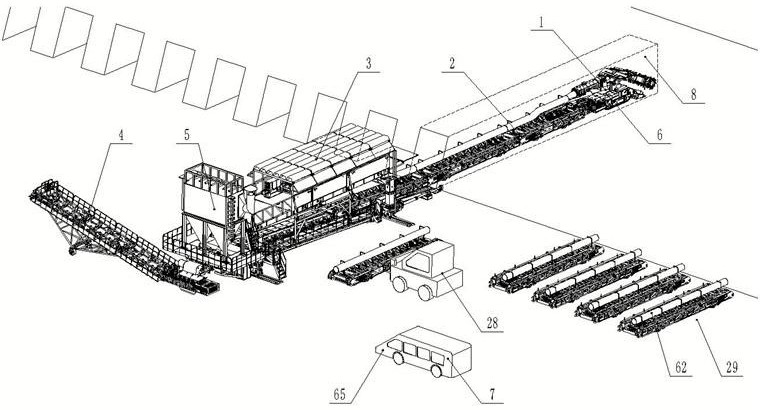

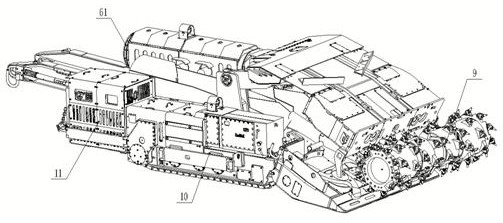

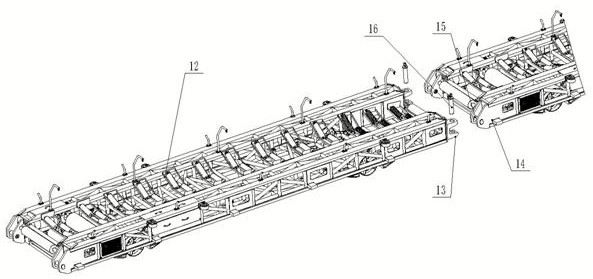

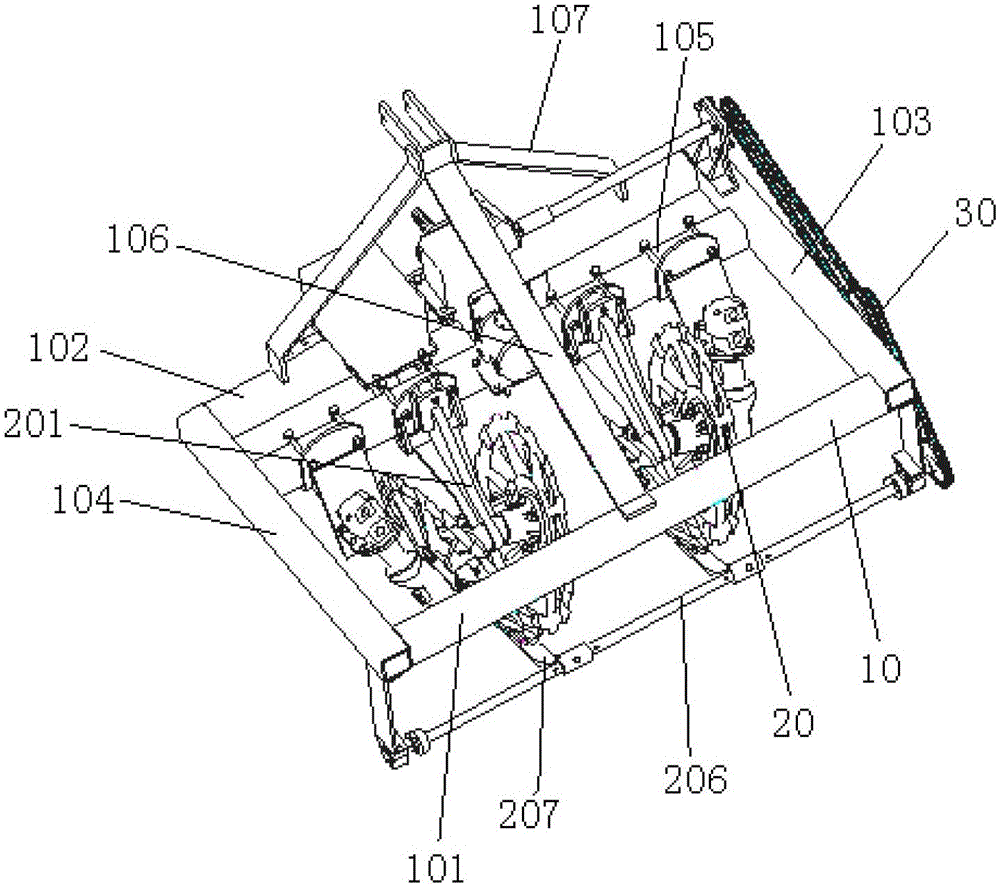

Slope mining system for open-pit mines

ActiveCN109931066AImproving the technical strength of side miningRealize intelligenceDust removalFire preventionAdhesiveEngineering

The invention relates to the technical field of slope mining of open-pit mines and particularly relates to a slope mining system for the open-pit mines, and realizes safe, efficient and green mining of slope briquettes of the open-pit mines. The slope mining system comprises a slope continuous coal mining machine for carrying out roadway type mining, a multi-unit rapid connection adhesive tape conveying system for carrying out rapid conveying, a stepping type walking platform for carrying out external propelling and whole movement, a movable type unloading part for carrying out external conveying, a pulling-out type ventilation and dust removal system for carrying out roadway ventilation and dust removal, a navigation and stability monitoring system for carrying out remote accurate controland slope stability monitoring, and a remote control platform for carrying out remote control. According to the slope mining system for the open-pit mines, provided by the invention, the safe, efficient and green mining of slope briquette resources can be realized, the strength of an slope mining technology of the open-pit mines in China can be remarkably improved, and remarkable economic benefits and social benefits can be brought for enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

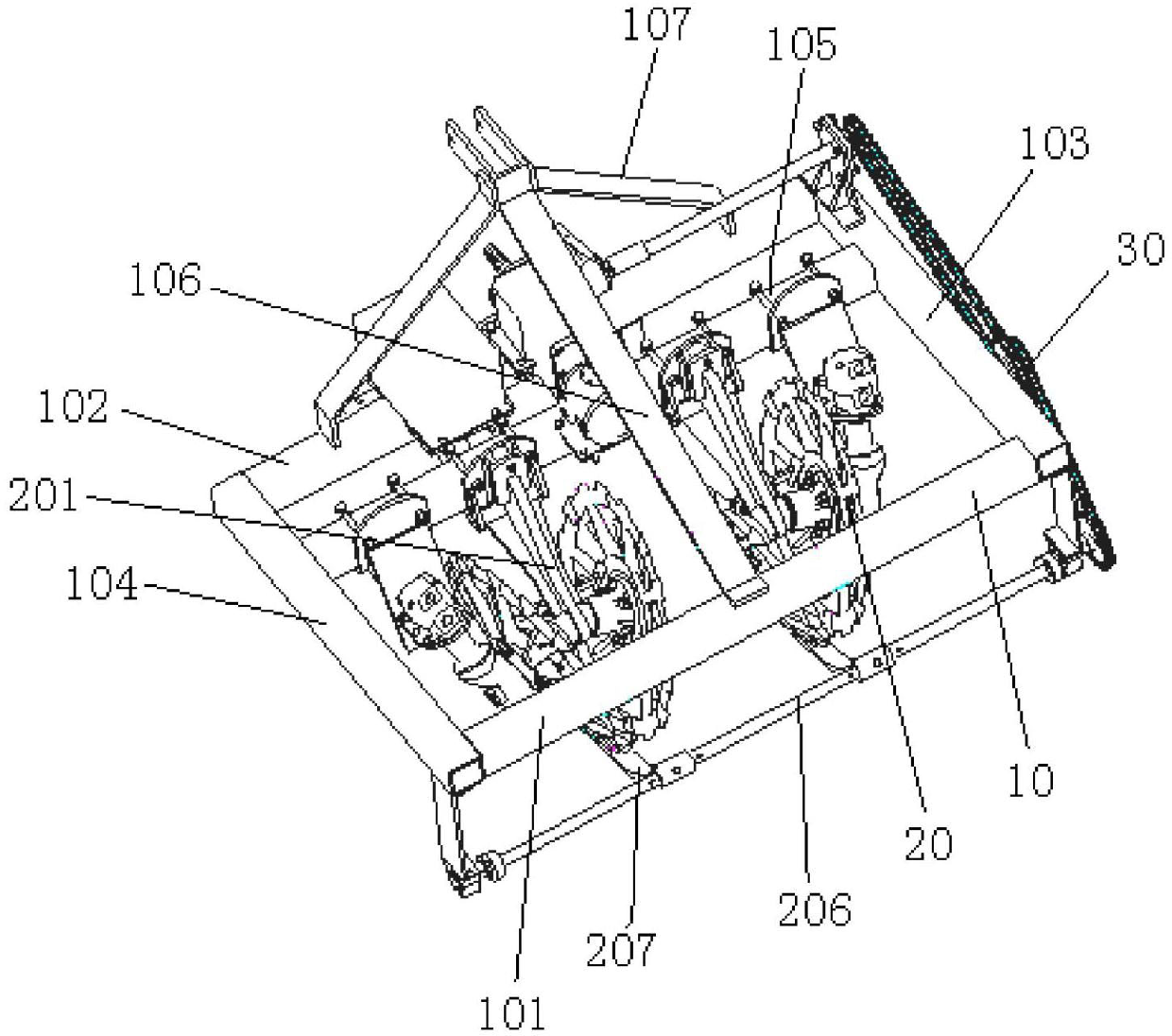

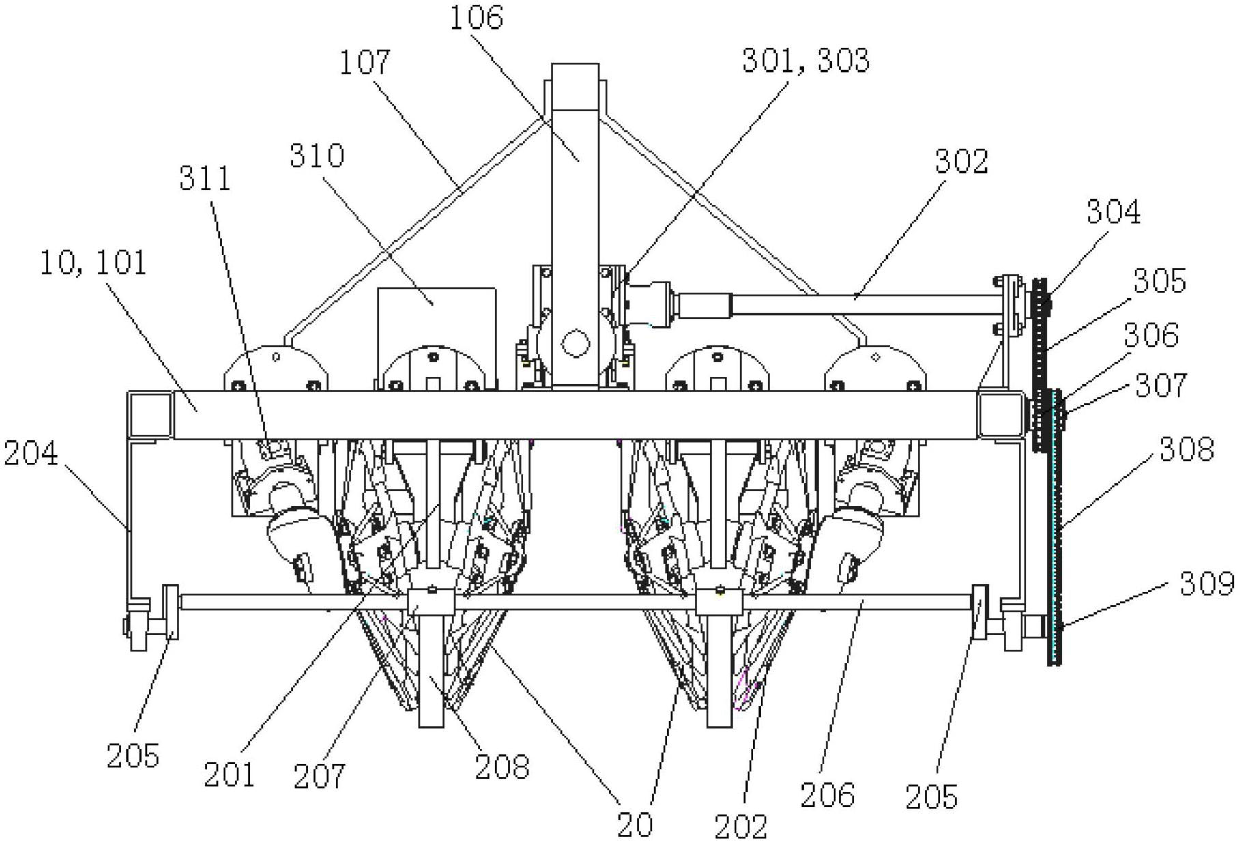

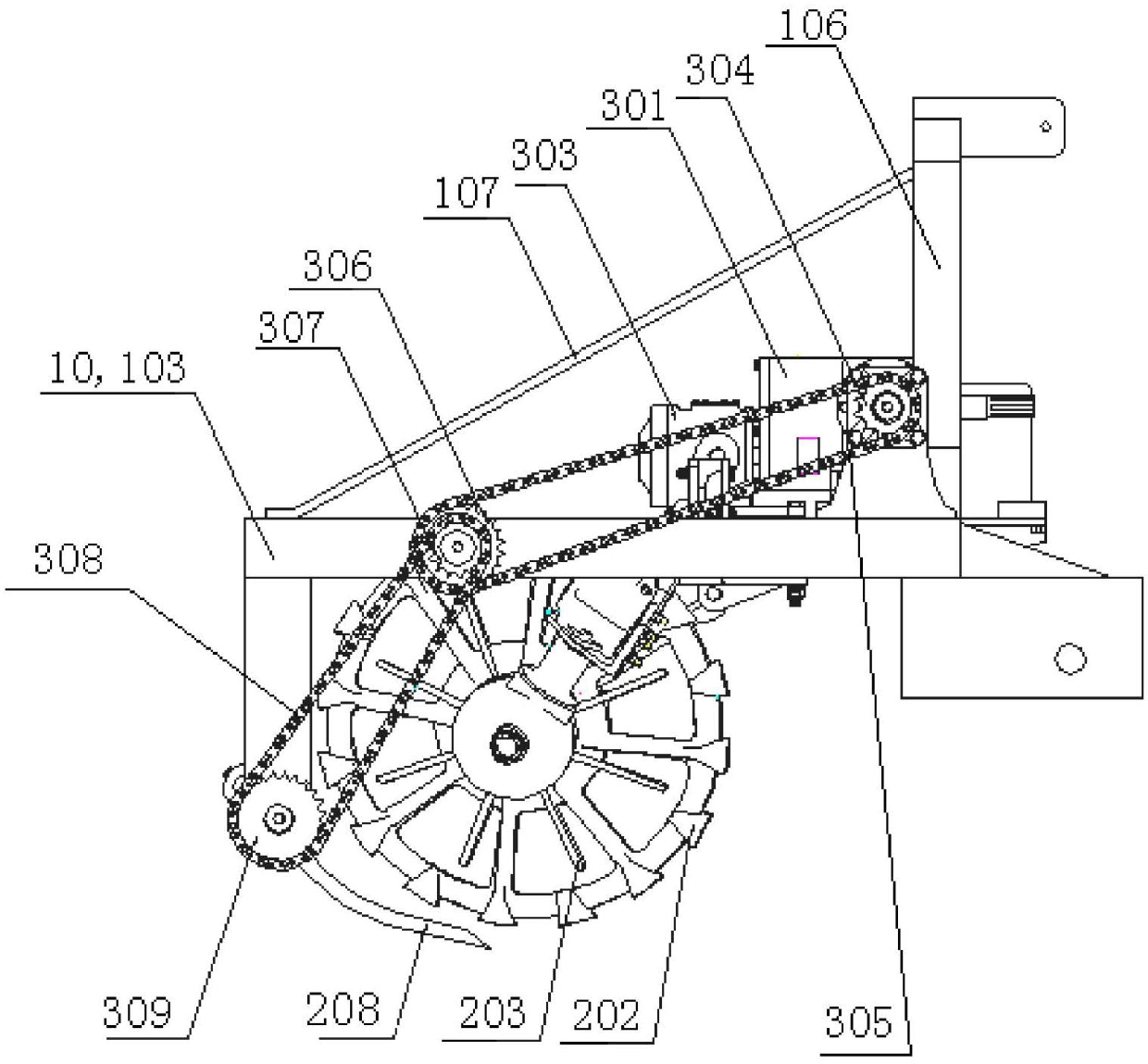

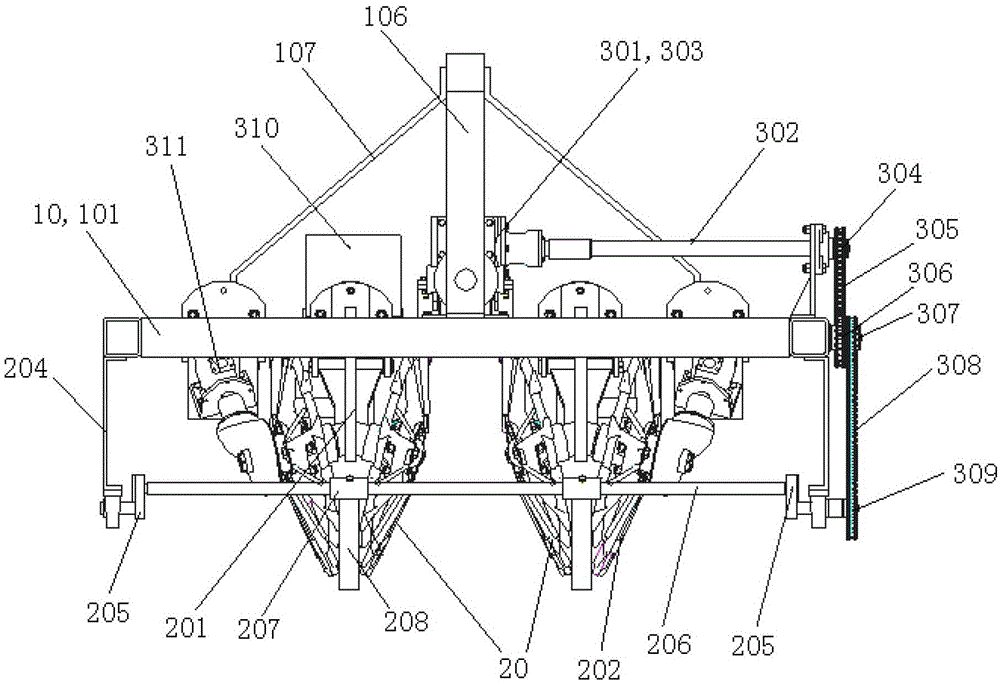

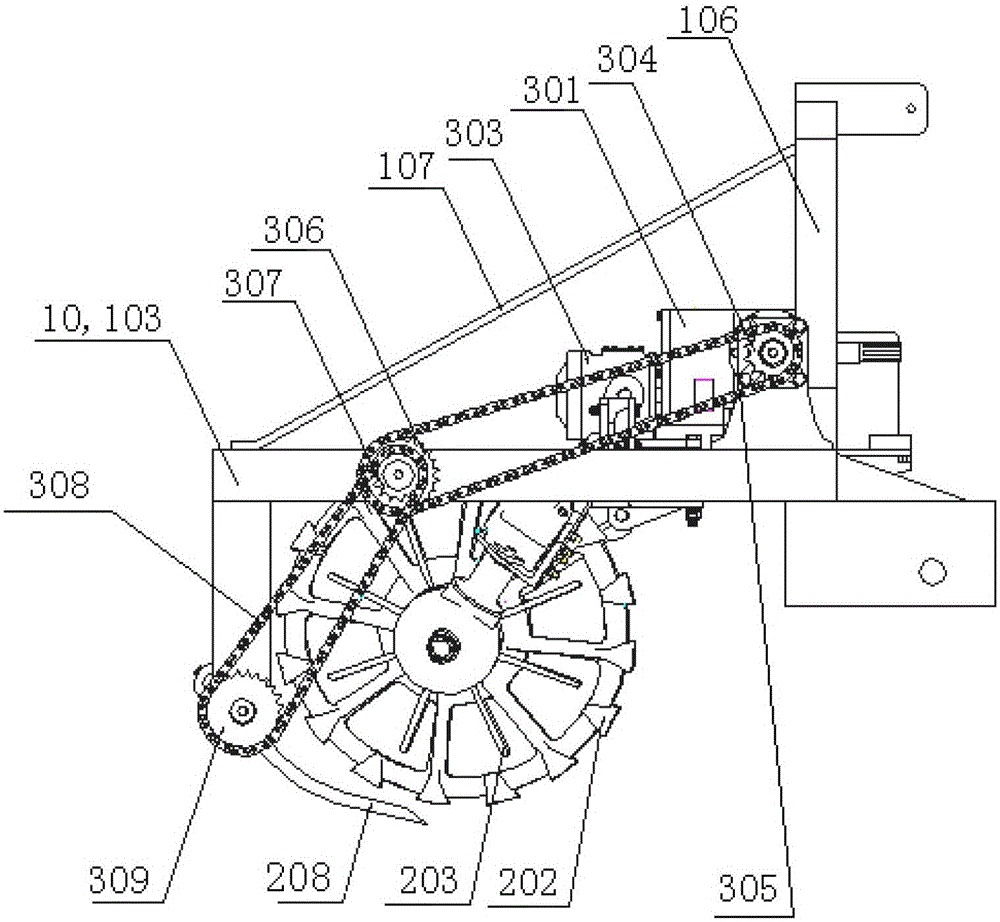

Beet digger

The invention relates to a beet digger, which is characterized by comprising a machine frame, a combined digging part and a driving system, wherein the machine frame comprises a first cross beam, a second cross beam, a third cross beam between the first and second cross beam, a first longitudinal beam and a second longitudinal beam; the combined digging part comprises a disc axle arm frame, one end of the disc axle arm frame is connected with the third cross beam, the other end of the disc axle arm frame is connected with two connecting shafts, and the other ends of the two connecting shafts are both connected with a disc; eccentric wheels are arranged below the longitudinal beams on the side of the first cross beam; the two eccentric wheels are connected by a first drive shaft which is provided with a digger blade positioned at a lower nonaligned place between the two discs; the driving system comprises a gear box arranged on the second cross beam, the input end of the gear box is connected with a power device, and the output end of the gear box is connected with a second drive shaft and a gear oil pump respectively; the second drive shaft drives the eccentric wheels to rotate through a chain wheel drive device; the input end of the gear oil pump is connected with an oil tank; the output end of the gear oil pump is connected with a hydraulic motor; and the power output end of the hydraulic motor is connected with one of the two discs.

Owner:CHINA AGRI UNIV

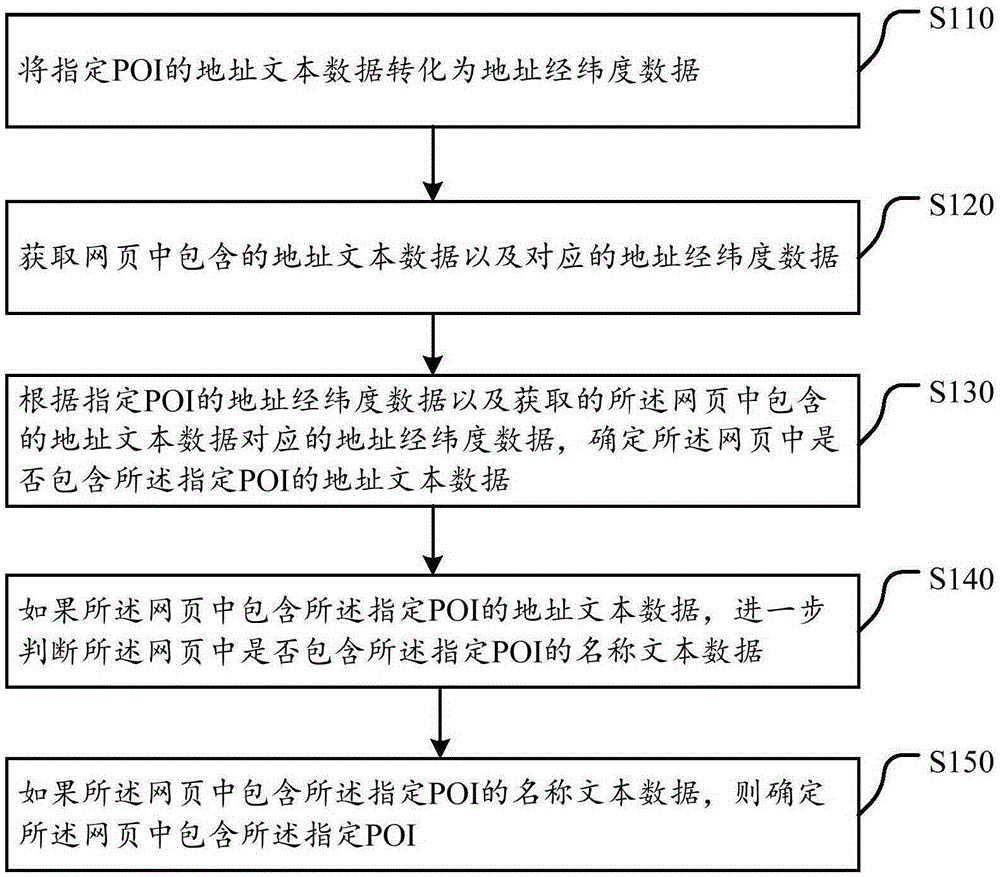

Method and device for judging whether webpage contains specified point of interest POI

InactiveCN105279246AIncreased digging depthIncrease the amount of dataGeographical information databasesSpecial data processing applicationsLongitudeText matching

The invention discloses a method and a device for judging whether a webpage contains a specified point of interest POI. The method comprises the following steps: converting address text data of the specified POI into address latitude and longitude data; obtaining address text data and corresponding address latitude and longitude data contained in the webpage; determining whether the webpage contains the address text data of the specified POI according to the address latitude and longitude data of the specified POI and the address latitude and longitude data corresponding to the obtained address text data contained in the webpage; if the webpage contains the address text data of the specified POI, further judging whether the webpage contains name text data of the specified POI; and if the webpage contains the name text data of the specified POI, determining that the webpage contains the specified POI. According to the method and the device disclosed in the technical scheme of the invention, by means of the property that the specified POI has unique latitude and longitude, a single text matching manner is avoided, the mining depth is large, the obtained data sizes are greatly increased, and meanwhile, the accuracy is guaranteed.

Owner:BEIJING QIHOO TECH CO LTD +1

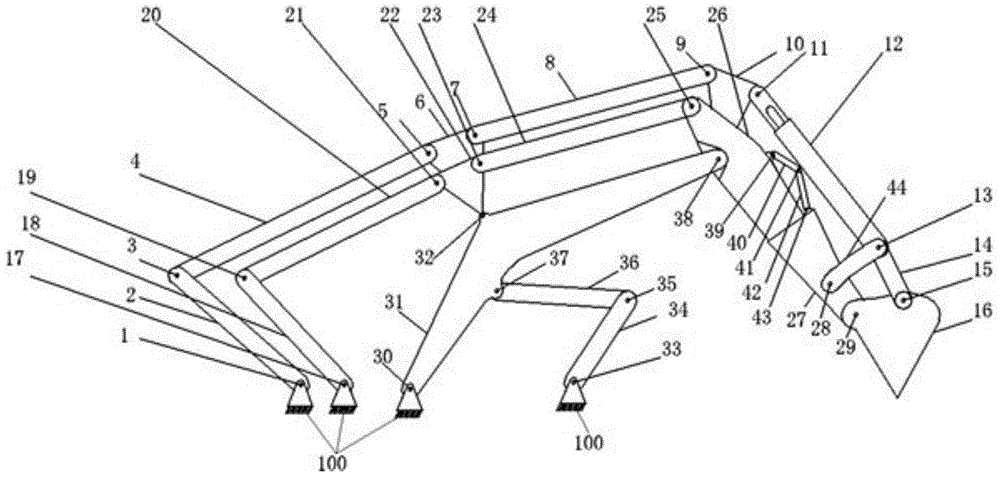

Bucket rod telescopic excavating mechanism capable of expanding excavation depth through control of crank sliding block

InactiveCN105133679AReasonable structureFunction increaseMechanical machines/dredgersSludgeBase function

The invention discloses a bucket rod telescopic excavating mechanism capable of expanding the excavation depth through control of a crank sliding block. The mechanism comprises a rack, a bucket, a bucket turnover assembly, a bucket lifting assembly, a movable arm swing assembly and a telescopic assembly. The excavating mechanism is reasonable in structure and multifunctional and has the turnover and lifting function of the bucket, the swing function of movable arms, and the function of adjusting the excavating depth; and particularly, for the excavating depth adjusting function, on the premise that an excavator body is not moved, the excavating depth can be increased, and the excavating mechanism can complete the basic function of an excavator and can better complete tasks under some conditions (such as sludge cleaning work and slope work of a river bed); and the aims that one machine has multiple functions, and time and labor are saved are achieved.

Owner:GUANGXI UNIV

Space meshing based government affair big data mining method

ActiveCN105279260AIncreased digging depthRelational databasesCharacter and pattern recognitionData setGranularity

The invention discloses a space meshing-based government affair big data mining method. The method comprises the following steps: determining the size of a space grid according to the space granularity of the data in government affair data sets; dividing the space grid and assigning the data in each data set to the grid as attribute values; and carrying out grid data storage and multi-dimensional data mining by taking a cell grid as a unit. According to the method, the data sets of different types are organized under a uniform time-space dimension, so that the mining of government affair big data in different types is effectively realized, and the depth of the information mining is greatly increased.

Owner:WUHAN UNIV

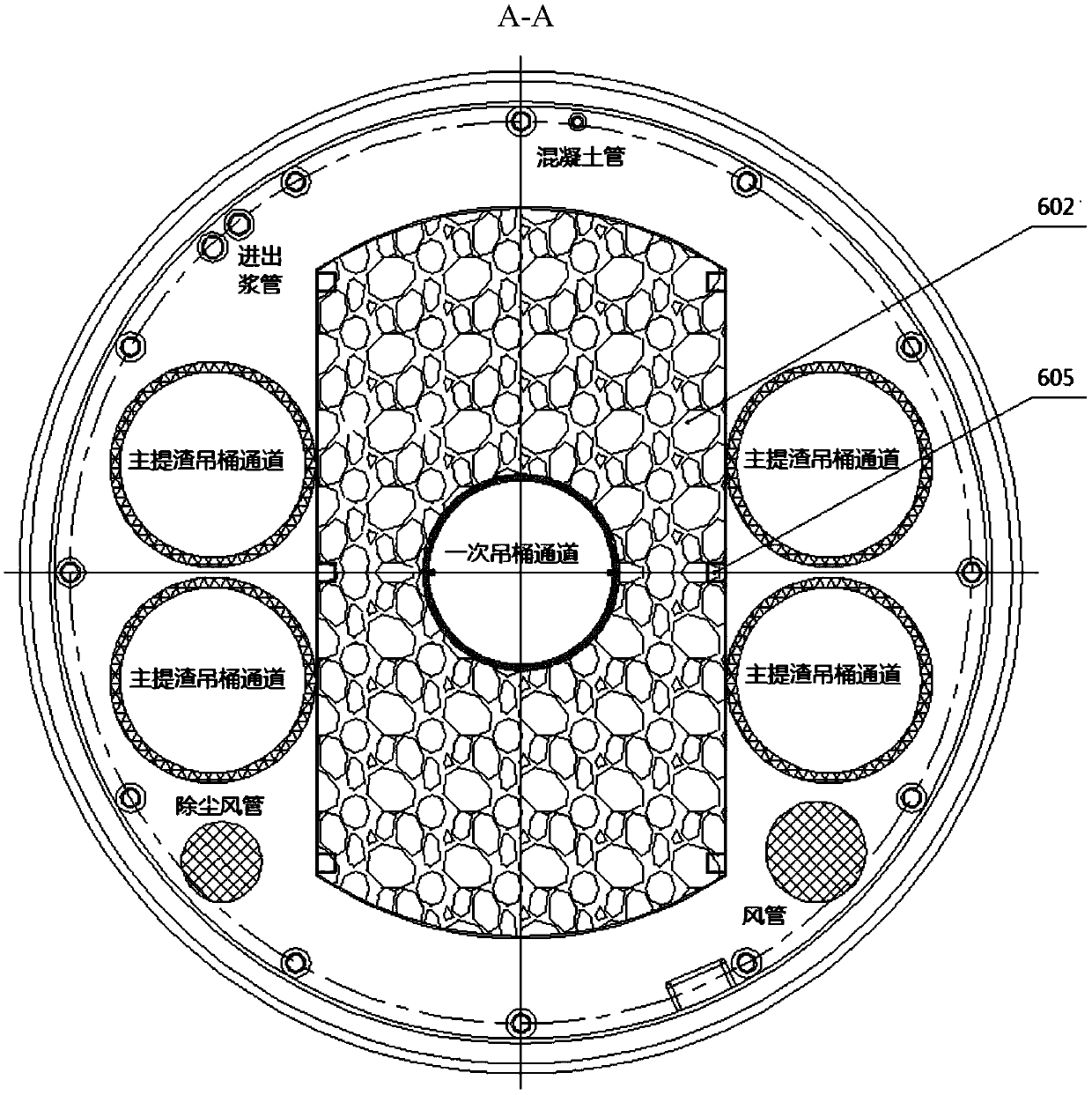

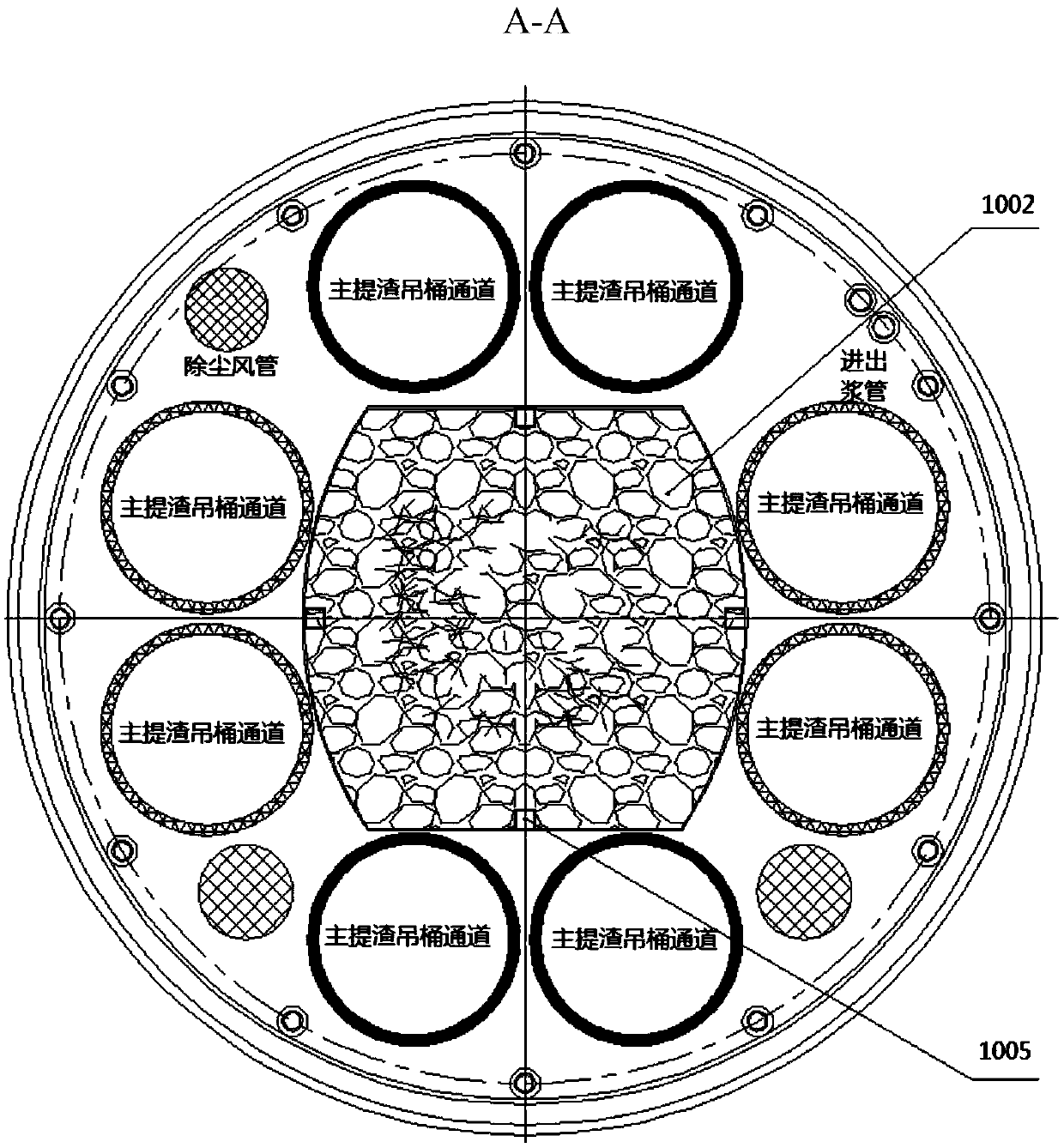

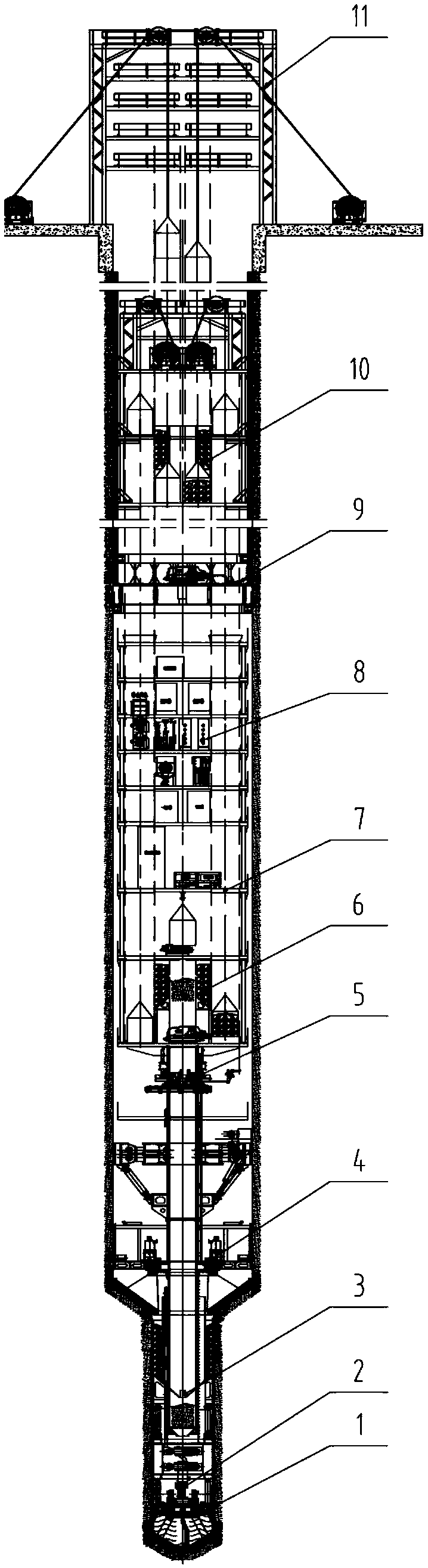

Deep shaft rock tunnel boring machine

The invention discloses a deep shaft rock tunnel boring machine. The machine comprises a derrick arranged on the ground and an underground device platform, wherein a first-stage slag transfer system,a second-stage tunnel boring system, a second-stage slag discharge system, a first-stage slag discharge system and a first-stage tunnel boring system are sequentially arranged below the device platform, the first-stage tunnel boring system is used for expanding the depth of the shaft, the second-stage tunnel boring system is used for expanding the width of the shaft, the first-stage slag dischargesystem conveys the rock slag generated by the excavation of the first-stage tunnel boring system to the first-stage slag transfer system, the second-stage slag discharge system conveys the rock slaggenerated by the excavation of the second-stage tunnel boring system to the first-stage slag transfer system, and the first-stage slag transfer system is used for discharging the rock slag. By arranging the synchronous work of the second-stage tunnel boring system, the depth and the width of the shaft are simultaneously expanded, the hierarchical excavation effectively increases the excavation depth; and by arranging the slag discharge system and the slag transfer system, the slag discharge operation can be completed in the excavation process, so that the automation degree and the working efficiency are further improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

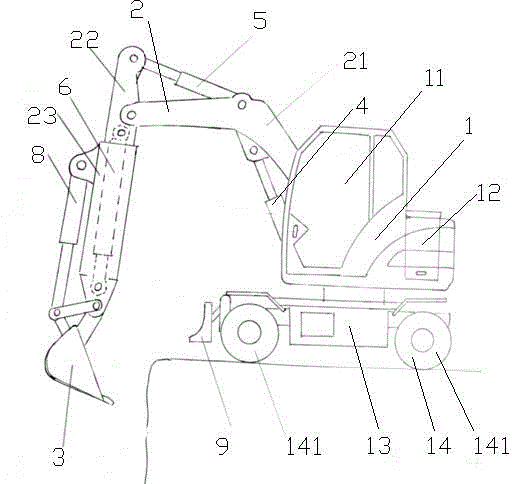

Wheel type excavator with telescopic arm

InactiveCN104404990ASolve the problem of digging depthExpand the scope of workMechanical machines/dredgersImpellerPressure difference

The invention provides a wheel type excavator with a telescopic arm. The wheel type excavator comprises a casing, end covers and a rotor, wherein a feeding opening is formed in the upper part of the casing, a discharging opening is formed in the lower part of the casing, the end covers are arranged at the two ends of the casing, and are fixedly arranged on the casing through screw bolts, the rotor is transversely arranged inside the casing, and comprises an impeller and a rotating shaft, the rotating shaft is arranged in the center position of the impeller, and one end of the rotating shaft extends out of the end covers. The wheel type excavator is characterized in that the discharging opening of the casing is in inclined arrangement, the discharging opening forms a certain included angle with the center axial line of the casing in the horizontal direction, the opening shape of the discharging opening is made into a triangular shape, a trapezoidal shape or a parallelogram shape. The wheel type excavator solves the problems that in the low-speed feeding process of the existing rotating material feeder, the intermittent material discharging is obvious, and the continuous feeding cannot be realized. The wheel type excavator has the advantages that the continuous and uniform feeding is realized, the pressure difference resistance performance is also realized, and the wide popularization and application values are realized.

Owner:山东冠县鲁牛工程机械有限公司

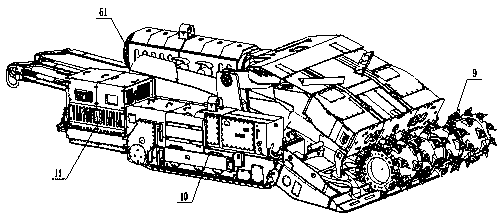

Punch-cutting mining method and punch-cutting mining machine implementing method

The invention belongs to the machinery field and especially relates to a punch-cutting mining method suitable for the mining field and a punch-cutting mining machine implementing the method. According to the method, a machine body, a walking part, a reciprocating impact part and the like are arranged; a lifting device is arranged or not arranged on the machine body; a dynamic impacting member is disposed on an impact driving device; a guiding device is provided with an impact guiding element; two ends of the impact guiding element are both equipped with an impactor or one end is provided with an impactor and the other end is provided with a counterweight; and the machine body supports the impactor to shock dropping materials back and forth. The equipment comprises the machine body, the walking part, the reciprocating impact part and the like. The reciprocating impact part comprises the dynamic impacting member, the impact driving device, the impactor and the like. The impact driving device comprises the dynamic impacting member. The guiding device comprises the impact guiding element; the dynamic impacting member drives the impactor to shock the coal wall or rock faces for blanking materials; the lifting device is arranged or not arranged on the machine body; the walking part is disposed on the lower part of the machine body and drives the machine body to walk so as to blank materials during walking and walk back to blank materials without turning the machine body.

Owner:刘素华

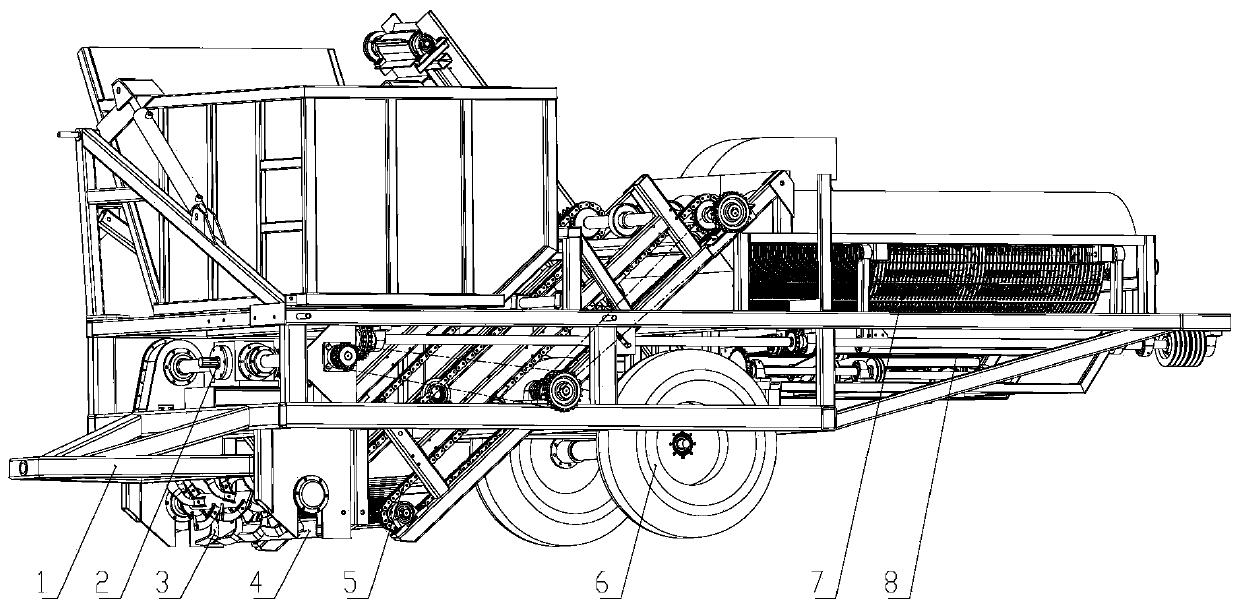

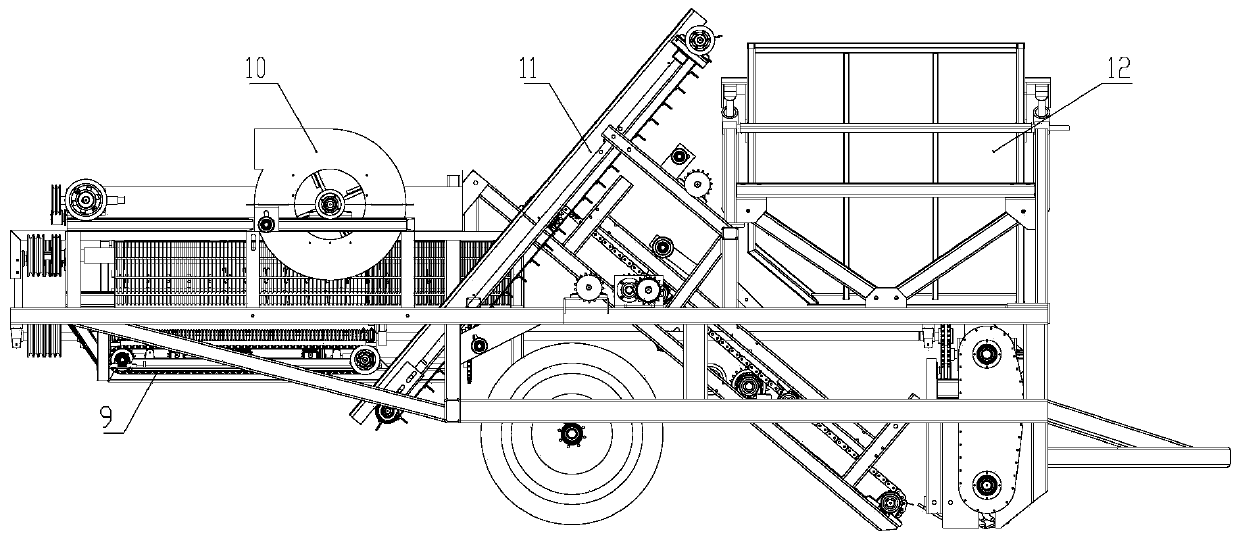

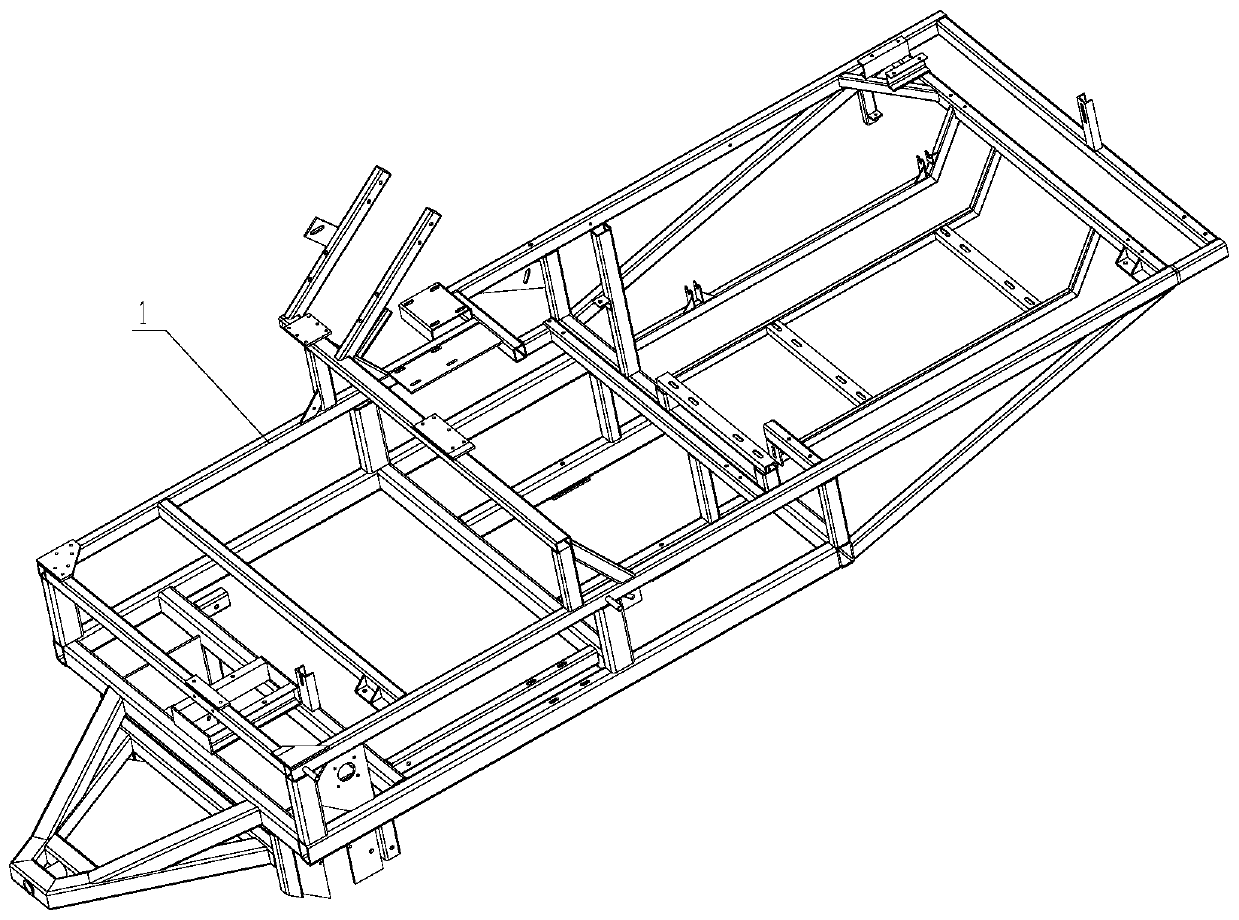

Traction type cyperus esculentus harvester

InactiveCN111133877AImprove harvesting efficiencyReduce machine lossThreshersDiggersAgricultural scienceAgricultural engineering

The invention provides a traction type cyperus esculentus harvester, belongs to the technical field of agricultural machinery, and particularly relates to a cyperus esculentus harvester. The tractiontype cyperus esculentus harvester comprises a main machine frame, wherein a transmission system, a rotary digging device, a digging shovel, an elevating net chain assembly, a travelling wheel combination, a dual-drum threshing device, a vibrating screen assembly, a horizontal conveying device, an impurity sucking fan, a belt elevator and a grain tank are arranged on the main machine frame; the digging shovel is mounted at the rear part of the rotary digging device; the elevating net chain assembly is obliquely arranged on the main machine frame, and two ends of the elevating net chain assemblyare adjacent to the digging shovel and the dual-drum threshing device; the vibrating screen assembly is arranged below the dual-drum threshing device; the horizontal conveying device is located outside an outlet of the vibrating screen assembly; the impurity sucking fan is arranged above the horizontal conveying device; and the lower end of the belt elevator is located below the front part of thehorizontal conveying device, and the upper end of the belt elevator extends to the edge of a grain tank. Through the adoption of the traction type cyperus esculentus harvester disclosed by the invention, the harvesting efficiency is notably improved, the machine harvesting loss is reduced, and operating cost is saved.

Owner:JILIN ACAD OF AGRI MACHINERY

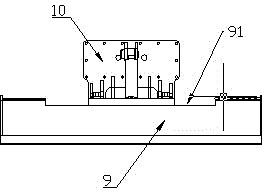

Mechanical excavating machine with telescopically controlled movable arm and bucket rod

InactiveCN104912135AReasonable structureFunction increaseMechanical machines/dredgersEngineeringFuselage

The invention discloses a mechanical excavating machine with a telescopically controlled movable arm and a telescopically controlled bucket rod. The mechanical excavating machine comprises a machine frame, a bucket, a bucket turning component, a bucket lifting component, a movable arm swinging component, a movable arm telescopic component and a bucket rod telescopic component. The excavating machine provided by the invention has the functions of adjusting excavating radius and excavating depth, the excavating radius and / or excavating depth can be increased on the premise that an excavating machine body is not moved, the excavating machine provided by the invention can better finish tasks under some conditions, such as high-altitude rescue, building detachment, silt-clearing work of a riverbed and slope work, one machine has multiple purposes, and more time and more labor are saved.

Owner:GUANGXI UNIV

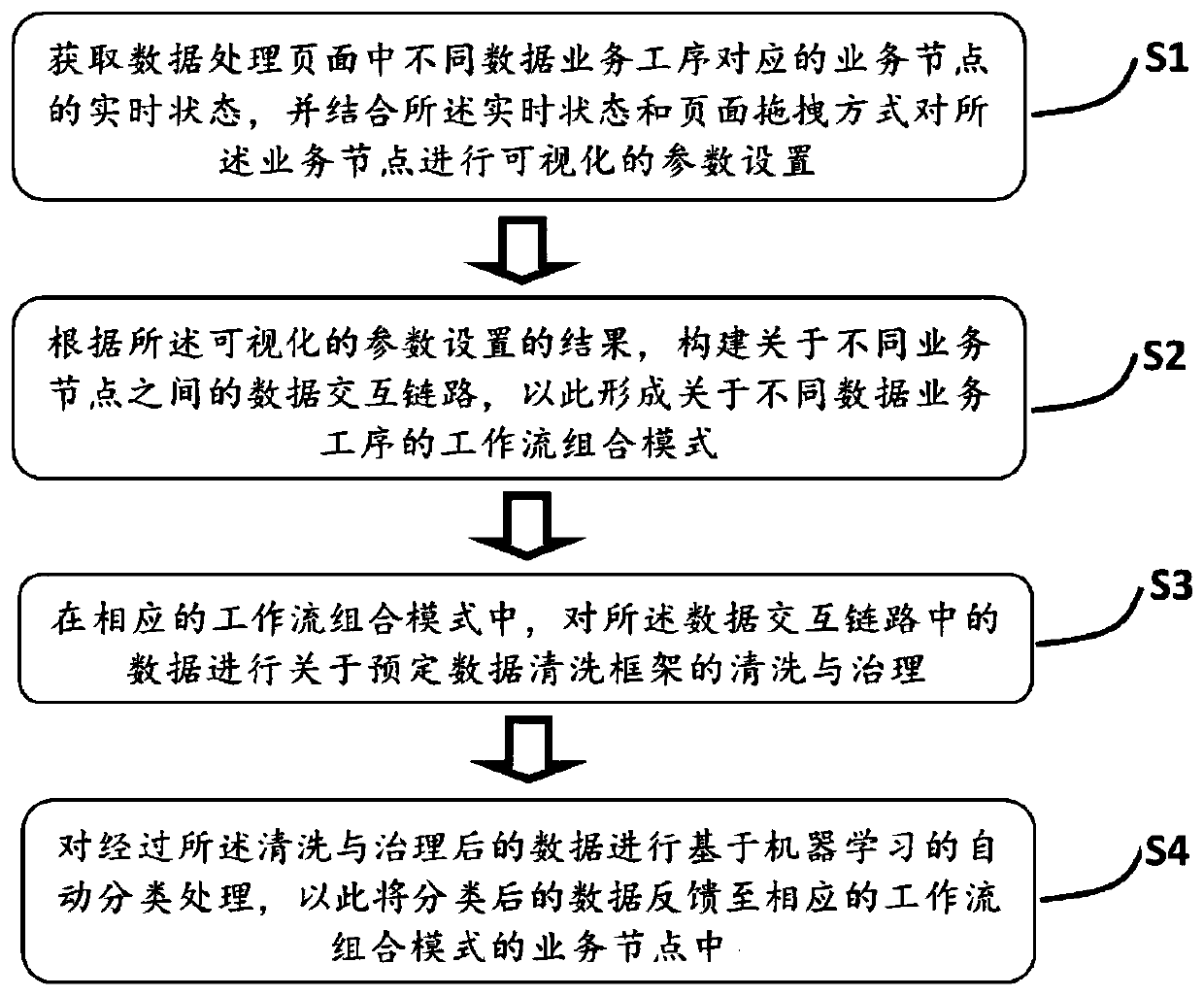

Data mining method and system

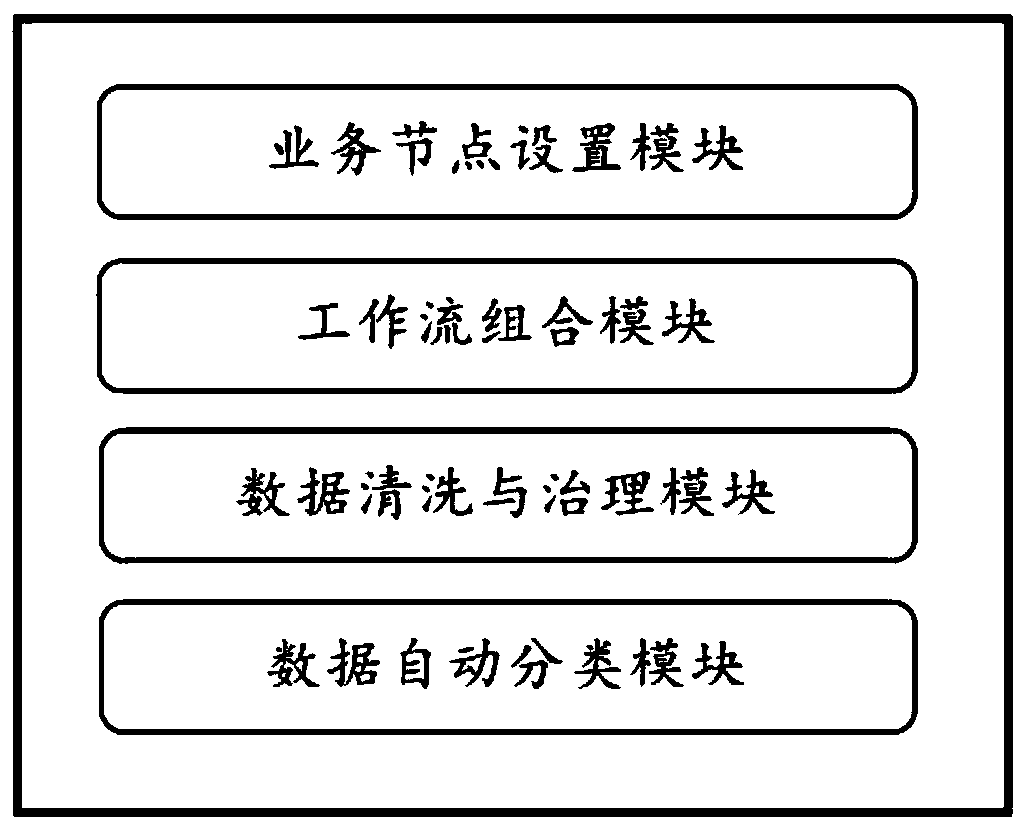

ActiveCN111367969AGuaranteed validityGuaranteed accuracyDigital data information retrievalCharacter and pattern recognitionEngineeringData science

The invention provides a data mining method and system. According to the data mining method and system, visual parameter setting is carried out on the service node based on a page dragging mode; a user can directly participate in the related workflow automatic configuration of the big data service; besides, different cleaning procedures of detection, positioning, correction and verification are sequentially carried out on the big data through the corresponding data cleaning frameworks, so that non-clean data existing in the big data is effectively cleaned, the effectiveness and the accuracy ofthe data are guaranteed, and the mining depth, the mining efficiency and the mining accuracy of the big data can be effectively improved.

Owner:北京三维天地科技股份有限公司

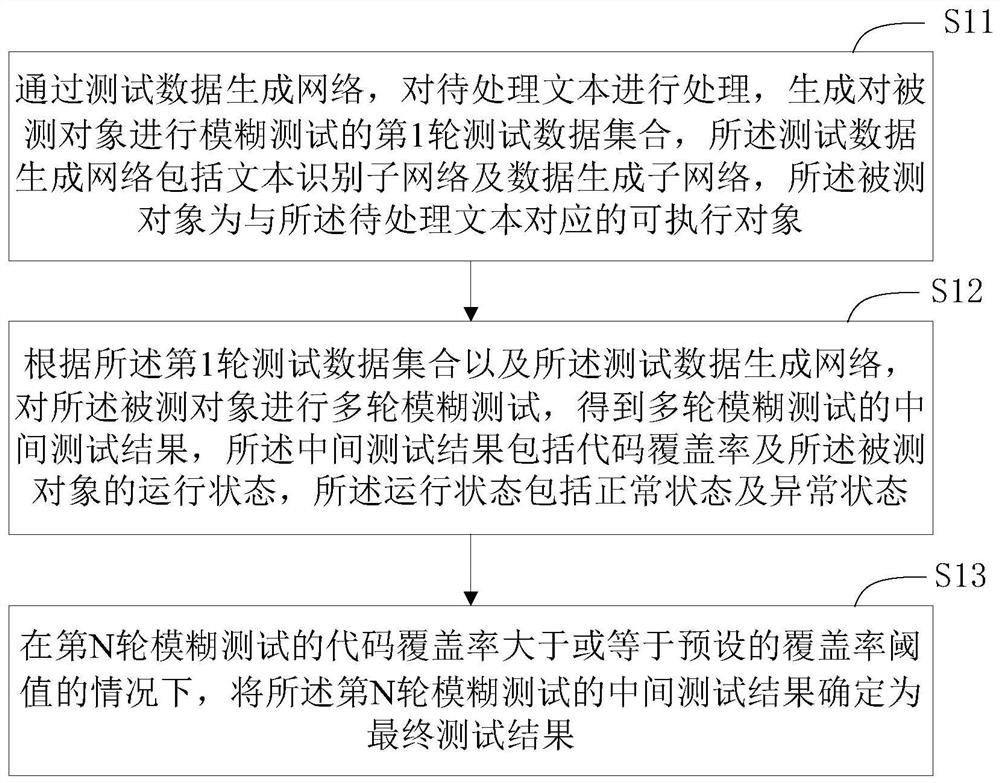

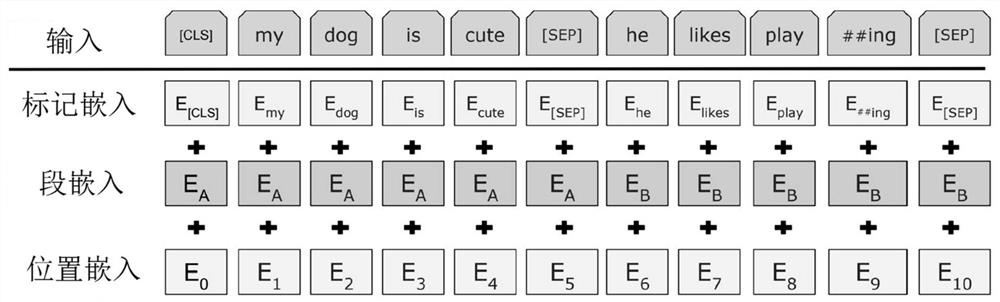

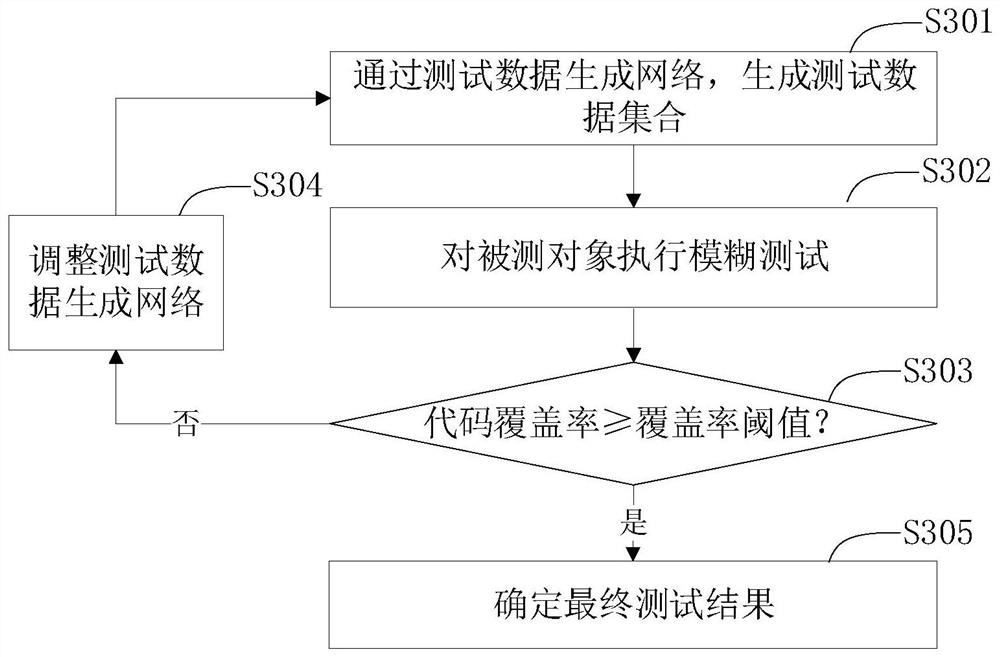

Fuzzy test method and device based on text recognition

PendingCN111858334AExpand coverageImprove effectivenessNatural language data processingSoftware testing/debuggingText recognitionData set

The invention relates to a fuzzy test method and device based on text recognition. The method comprises the steps that a to-be-processed text is processed through a test data generation network, a first round of test data set for conducting a fuzzy test on a tested object is generated, the test data generation network comprises a text recognition sub-network and a data generation sub-network, andthe tested object is an executable object corresponding to the to-be-processed text; according to the first round of test data set and the test data generation network, multiple rounds of fuzzy test is performed on the tested object to obtain an intermediate test result of the multiple rounds of fuzzy test, the intermediate test result comprising a code coverage rate and an operation state of thetested object; and when the code coverage rate of the Nth round of fuzzy test is greater than or equal to a preset coverage rate threshold, an intermediate test result of the Nth round of fuzzy test is determined as a final test result. According to the embodiment of the invention, the code coverage rate and mining depth of the fuzzy test can be improved, and the effectiveness of the fuzzy test isenhanced.

Owner:北京丁牛科技有限公司

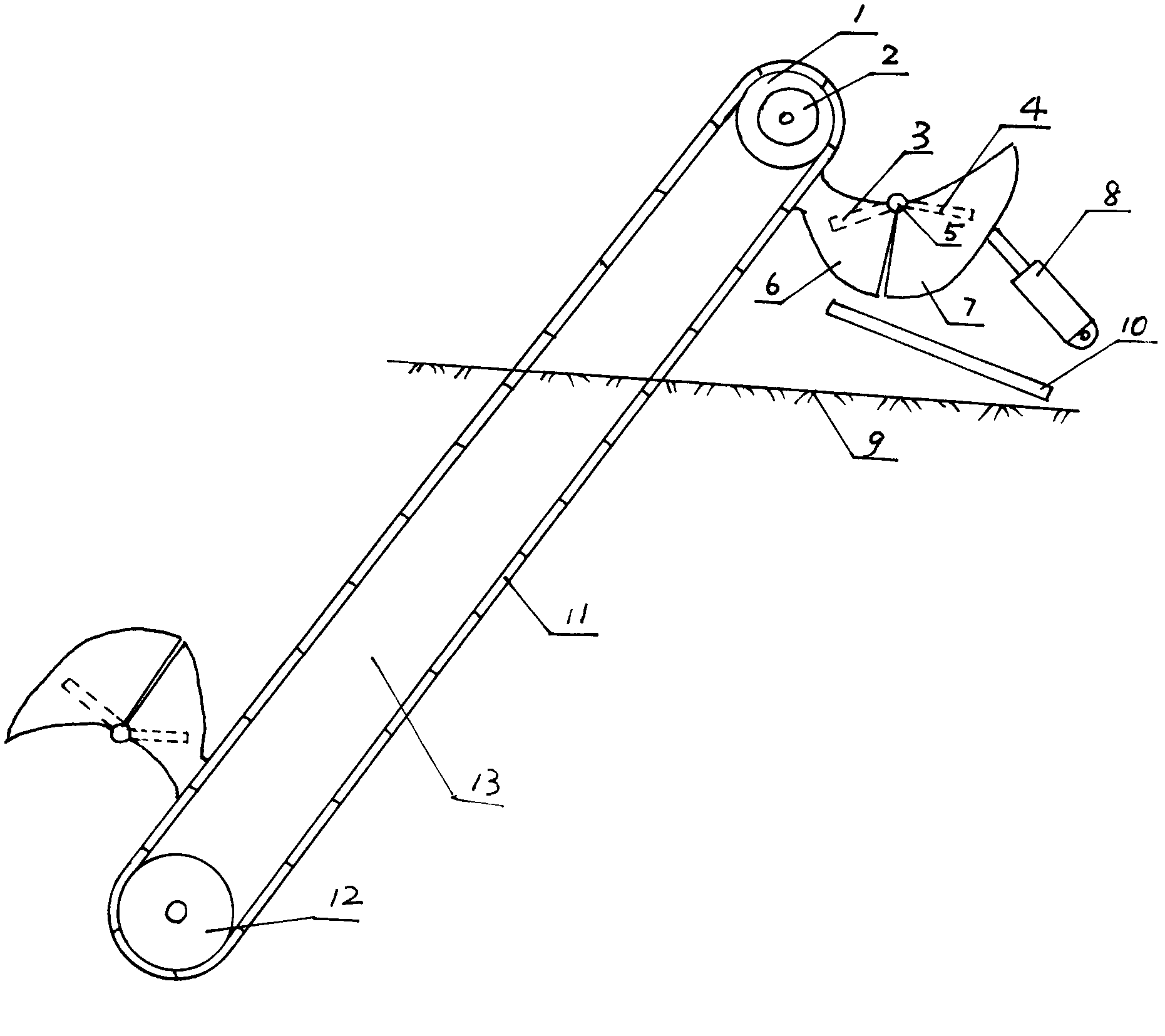

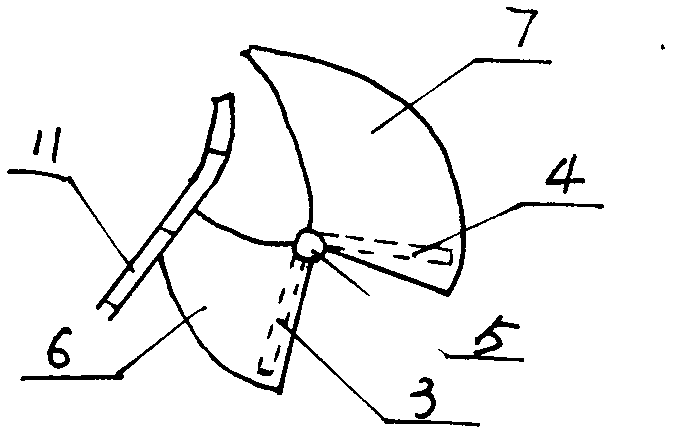

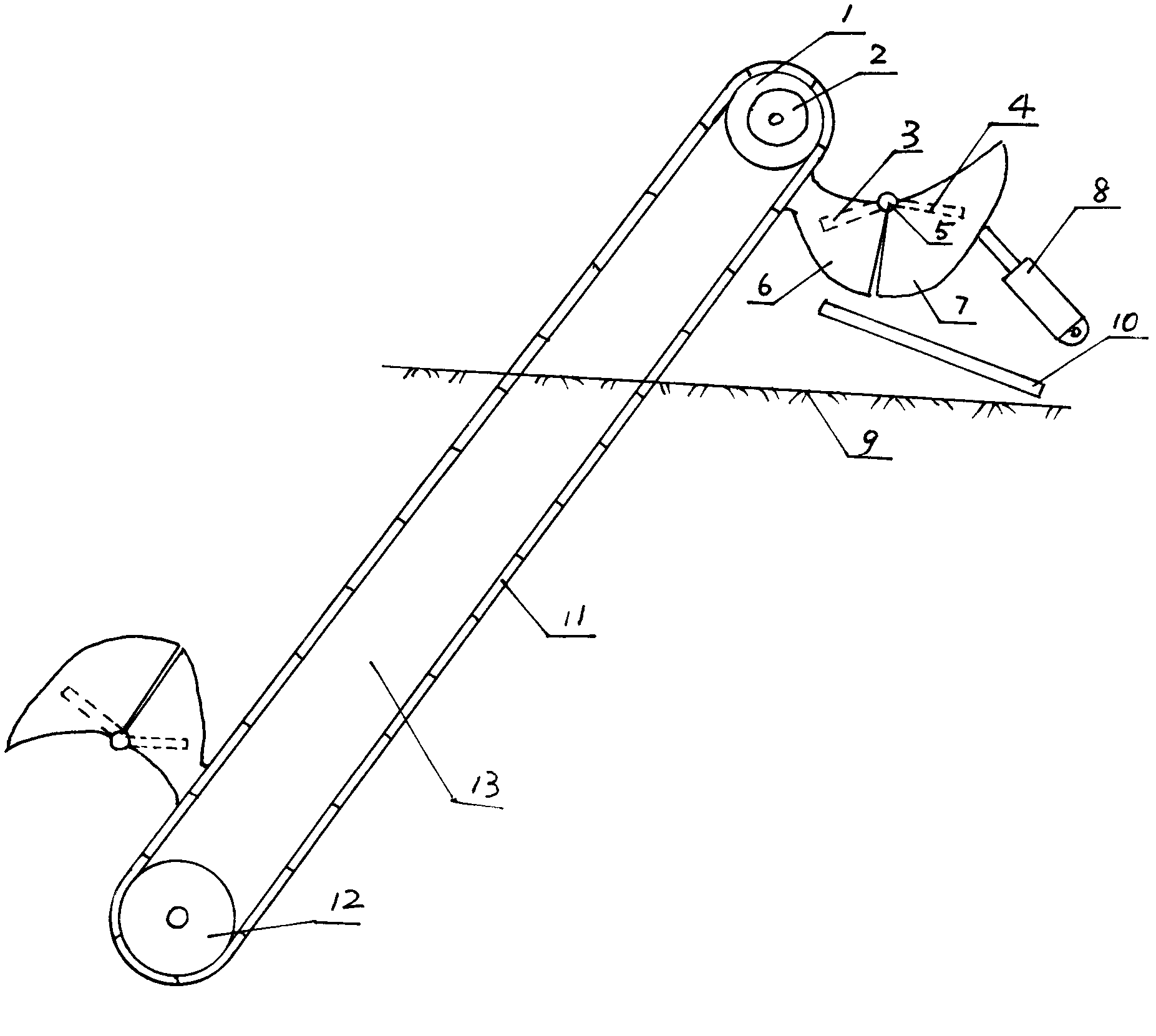

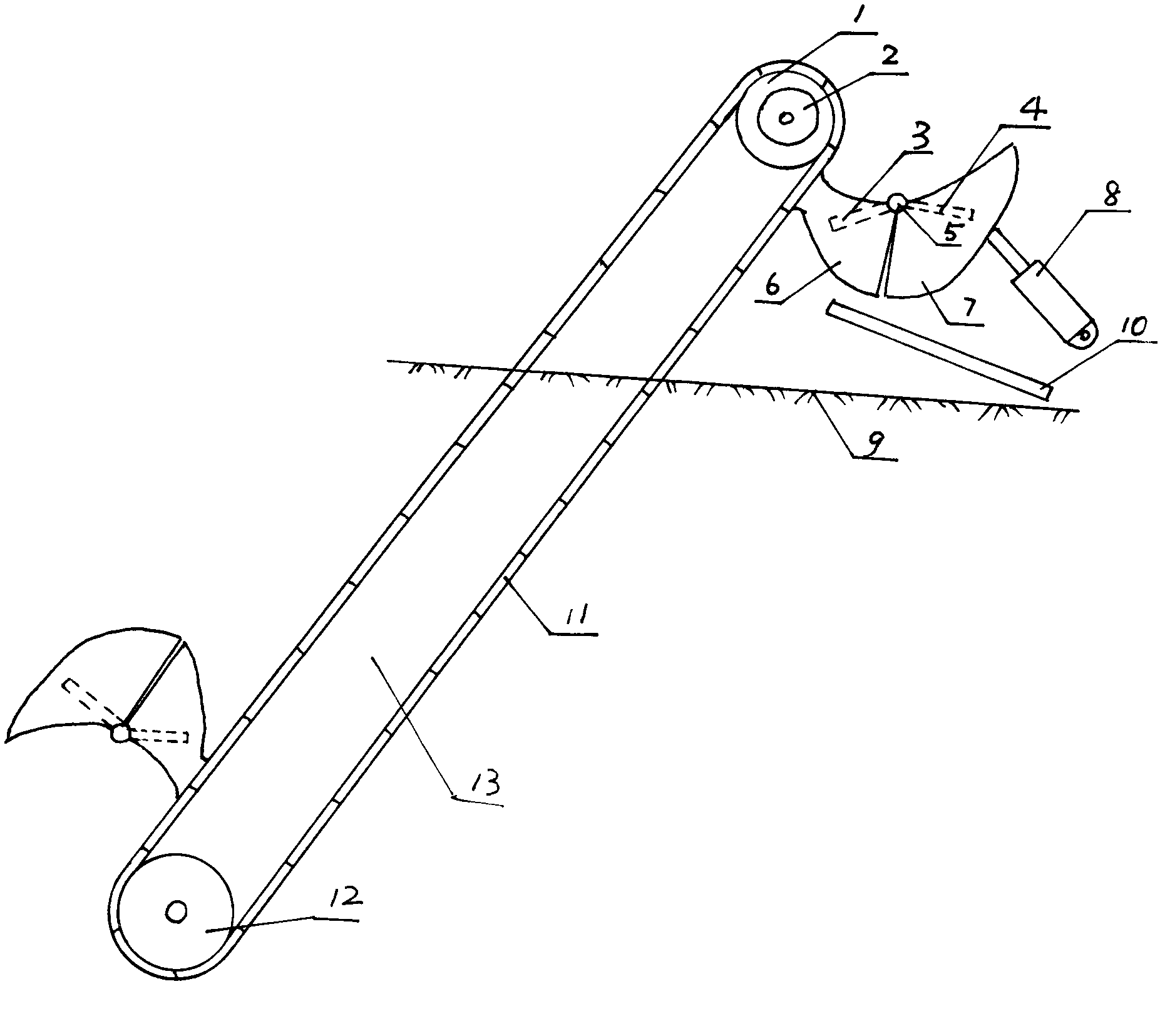

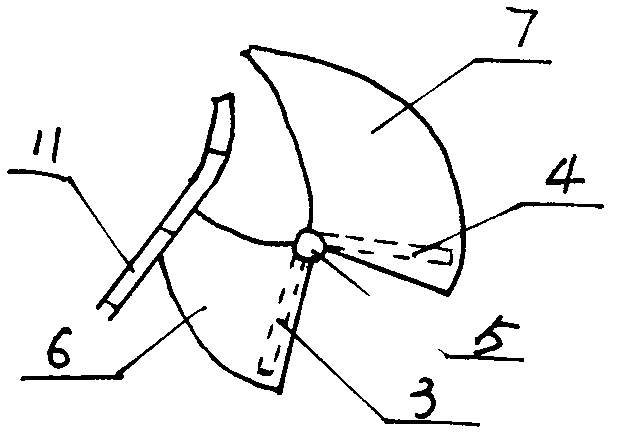

Chain excavator

InactiveCN102561437AIncrease the lengthIncreased digging depthSoil-shifting machines/dredgersHydraulic motorLeft half

The invention relates to a chain excavator for excavating a deep ditch, comprising an arm lever, a driving wheel, a driven wheel, chains and buckets. The driving wheel is arranged on the upper end of the arm lever and driven by a hydraulic motor; the driven wheel is arranged on the lower end of the arm lever; the chains surround the arm lever; the buckets are fixed on the chain; the chain excavator is provided with only two buckets, and the two sections of chains arranged between the two buckets have the same length; the buckets comprise a left half bucket and a right half bucket which are connected by a pin shaft; two left mud scraping plates are arranged in the left half bucket and clung to the front side wall and the rear side wall of the left half bucket respectively; the right ends of the two left mud scraping plates are fixed on the upper opening end of the right half bucket; the two left mud scraping plates are located on the extended line of the upper opening edge of the right half bucket; two right mud scraping plates are arranged in the right half bucket and clung to the front side wall and the rear side wall of the right half bucket respectively; the left ends of the two right mud scraping plates are fixed on the upper opening end of the left half bucket; the two right mud scraping plates are located on the extended line of the upper opening edge of the left half bucket; a hydraulic oil cylinder is arranged on the right of the buckets; and a sliding chute is arranged below the buckets.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

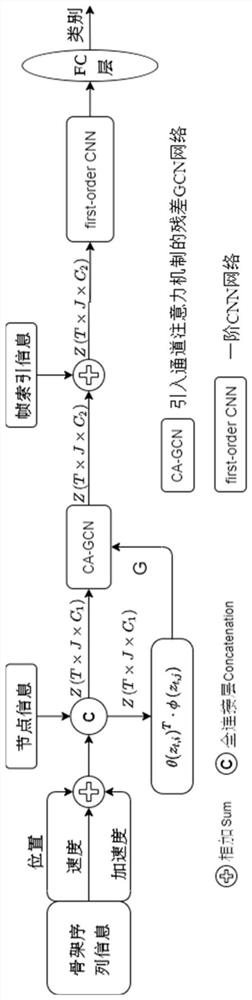

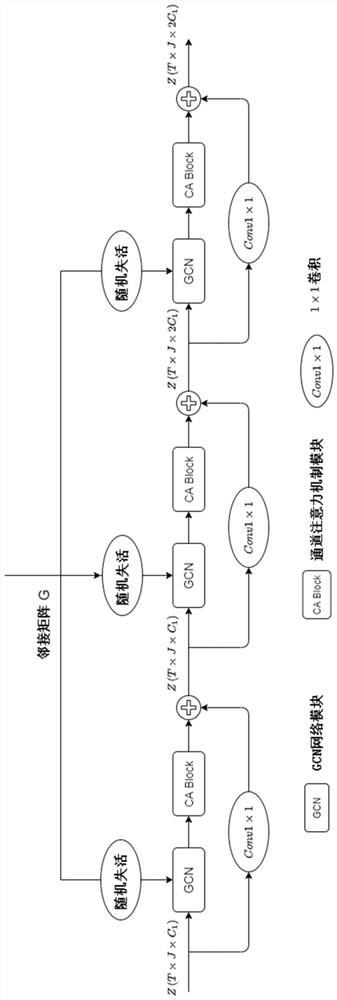

Lightweight graph convolution human skeleton action recognition method based on channel attention

ActiveCN113111760AIncreased digging depthEasy to identifyCharacter and pattern recognitionNeural architecturesEngineeringHuman skeleton

The invention relates to a lightweight graph convolution human skeleton action recognition method based on channel attention. The method comprises the following steps: S1, skeleton sequence information of a human skeleton in a video image is acquired; S2, joint point index information is added, and an adjacent matrix of skeleton joint points is calculated; s3, spatial features of the skeleton sequence are extracted by using an adjacent matrix and a residual GCN network introducing a channel attention mechanism, wherein the adjacent matrix is subjected to random inactivation processing during use; S4, frame index information is added, and maximum pooling processing is carried out; s5, time features of the skeleton sequence are extracted by using a first-order CNN network; s6, a final feature sequence is generated through maximum pooling, and an identification classification result is obtained. Compared with the prior art, the method has the advantages of being high in robustness, real-time performance and accuracy and the like.

Owner:TONGJI UNIV

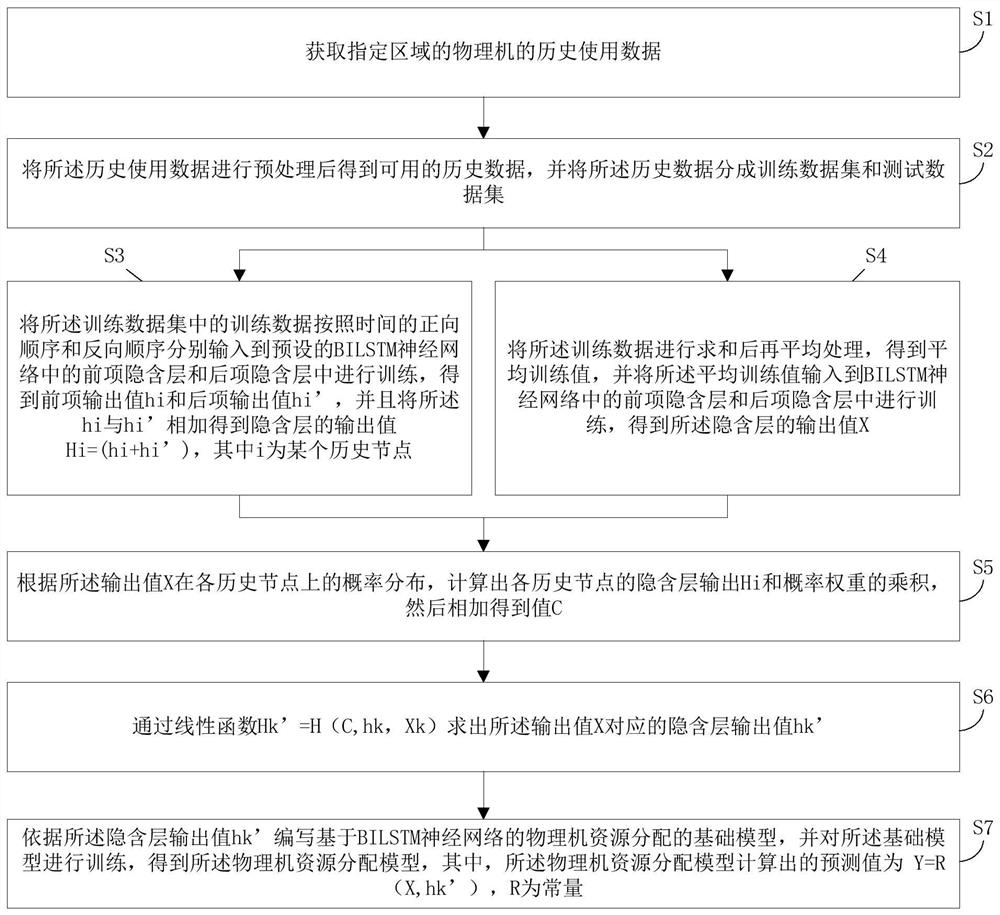

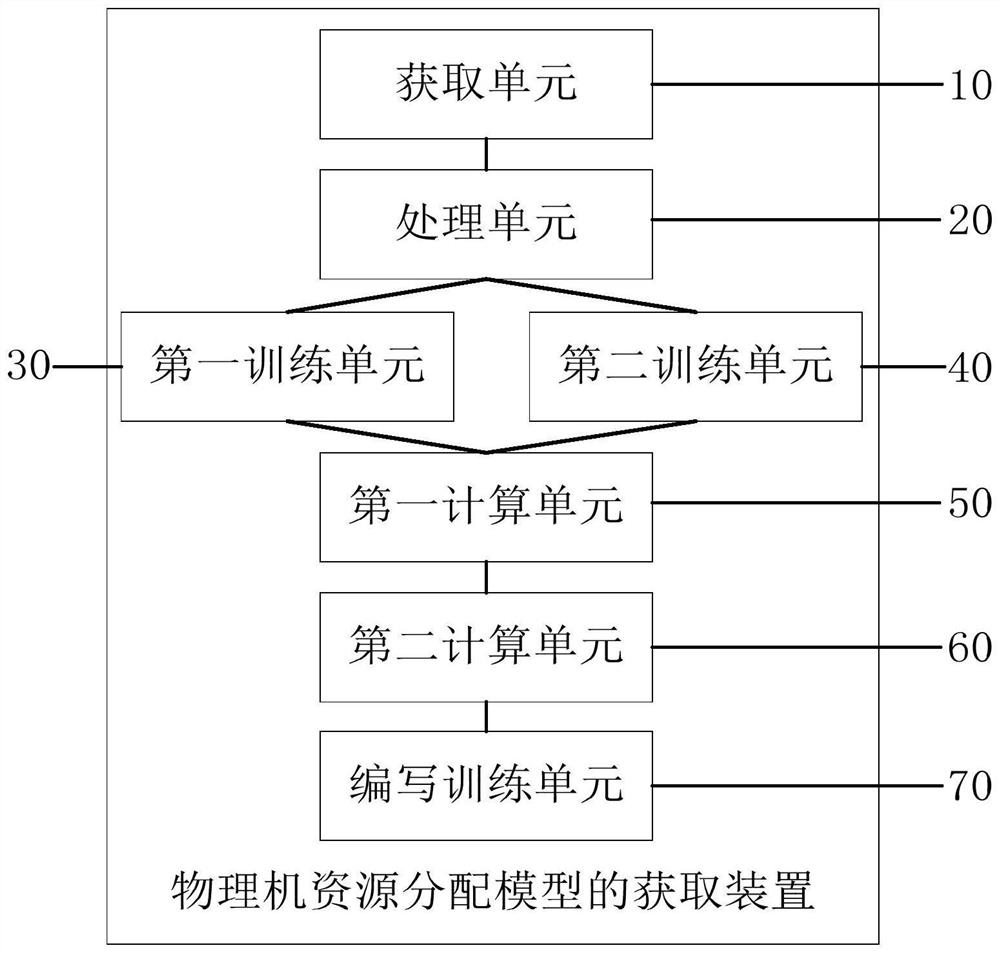

Physical machine resource allocation model obtaining method and device and computer equipment

PendingCN111651264AIncreased digging depthImprove forecast accuracyResource allocationNeural architecturesHidden layerData set

The invention discloses a physical machine resource allocation model obtaining method and device and computer equipment, and the method comprises the steps: inputting data in a training data set intoa preset BILSTM neural network for training, and obtaining an output value Hi = (hi + hi ') of a hidden layer; summing and averaging the training data to obtain an average training value, and inputting the average training value into a BILSTM neural network for training to obtain an output value X of the corresponding hidden layer; calculating the product of the hidden layer output Hi of each historical node and the probability weight according to the probability distribution of the output value X on each historical node, and performing adding to obtain a value C; solving a hidden layer outputvalue hk' corresponding to the output value X through a linear function Hk '= H (C, hk, Xk); and writing a physical machine resource allocation basic model based on the BILSTM neural network according to the hidden layer output value hk ', and training the basic model to obtain a physical machine resource allocation model. The prediction precision is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

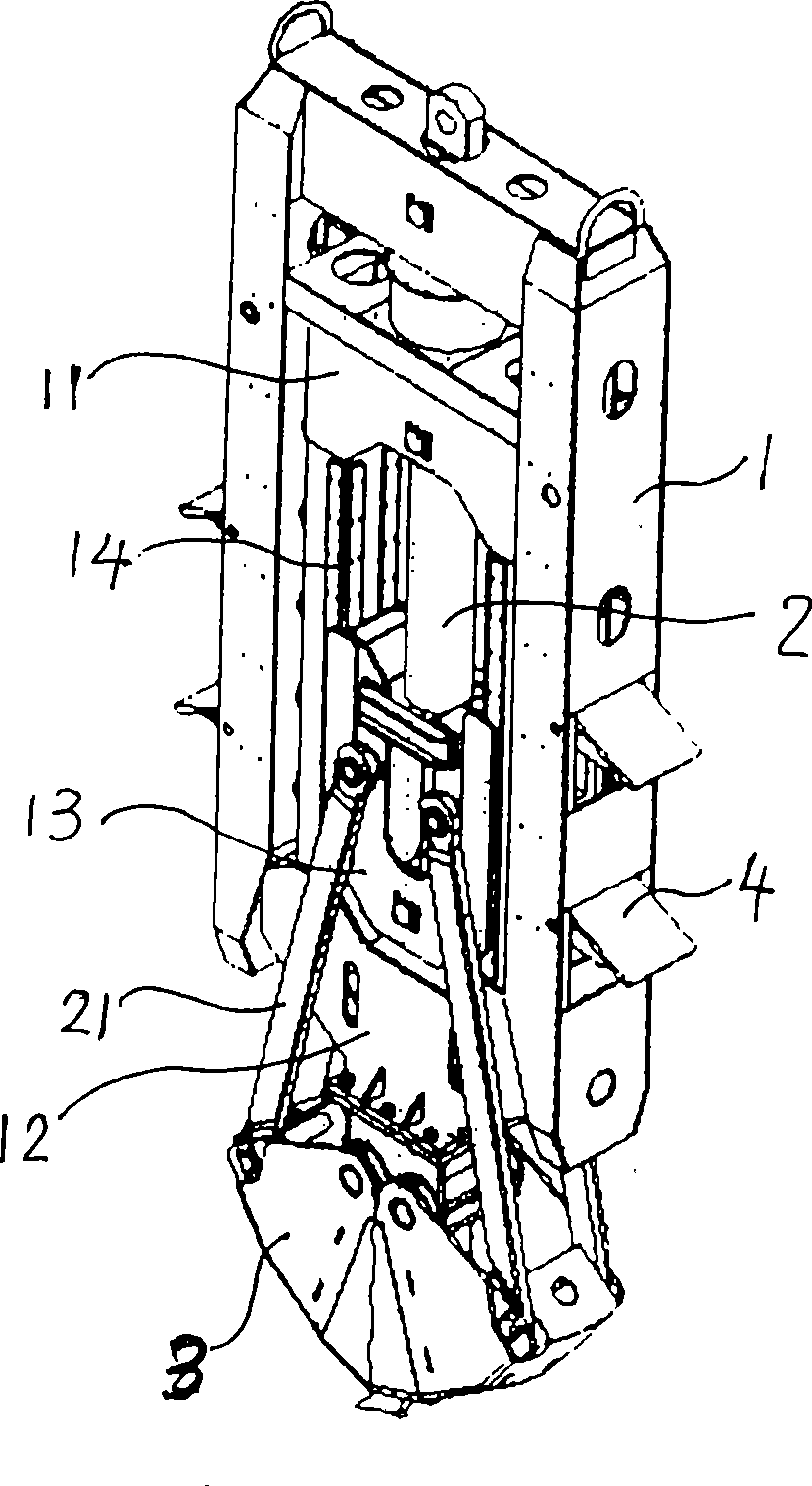

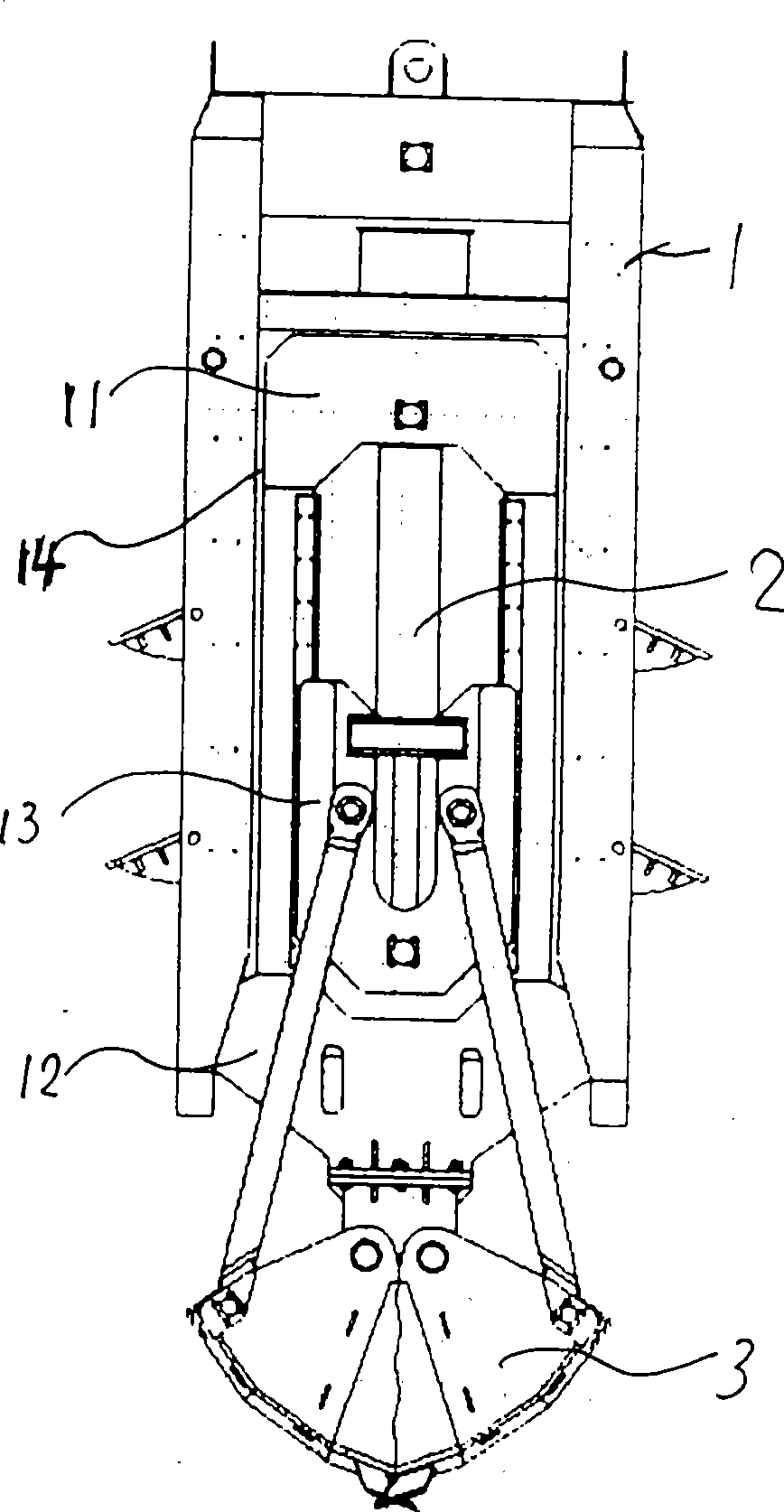

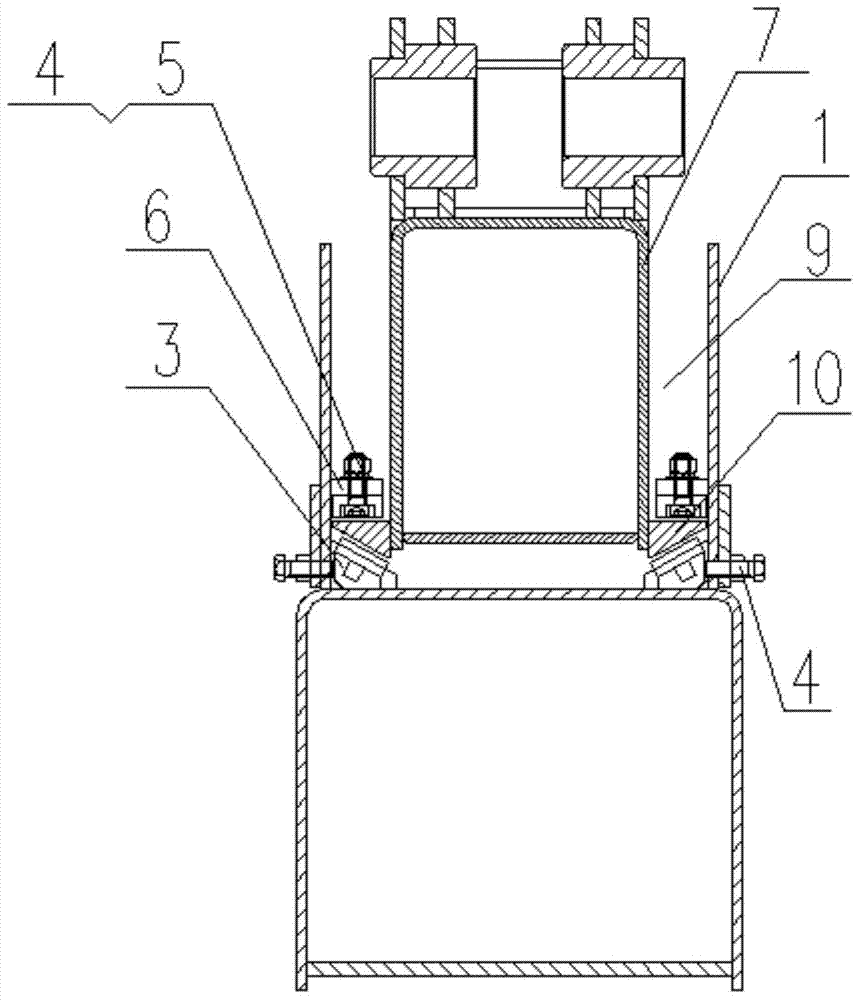

Hydraulic claw bucket of slotting machine

InactiveCN101413282APrevent floatingNo need to increase load capacitySoil-shifting machines/dredgersSlurry wallEngineering

The invention relates to an underground continuous wall grooving machine, in particular to a hydraulic crab bucket of the grooving machine. The aim of the invention is to solve a problem of generating a hollow cutting phenomenon due to the upward floating of a machine body when the hydraulic crab bucket grabs and closes, and provide the hydraulic crab bucket provided with power assisting devices. The structure of the grooving machine consists of the machine body, a hydraulic device and a crab bucket, wherein two sides of the machine body are at least provided with a power assisting device respectively. The grooving machine has the advantages that when an excavation project is in an underground deep trench and comes across an underground hard soil layer, the power assisting devices of the grooving machine can be started. When the power assisting devices at the two sides of the machine body of the hydraulic crab bucket are opened, the whole machine body can be blocked in the trench, and then, when the crab bucket downwards excavates a hard soil layer, under the action of the power assisting devices, the upward floating of the machine body can be avoided. The key points are that the grooving machine has low cost and light weight, is arranged on the hydraulic crab bucket, and can achieve the effect of increasing the weight without increasing the load capacity of a hoister. At the same time, the excavating depth can be increased.

Owner:丁明明

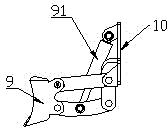

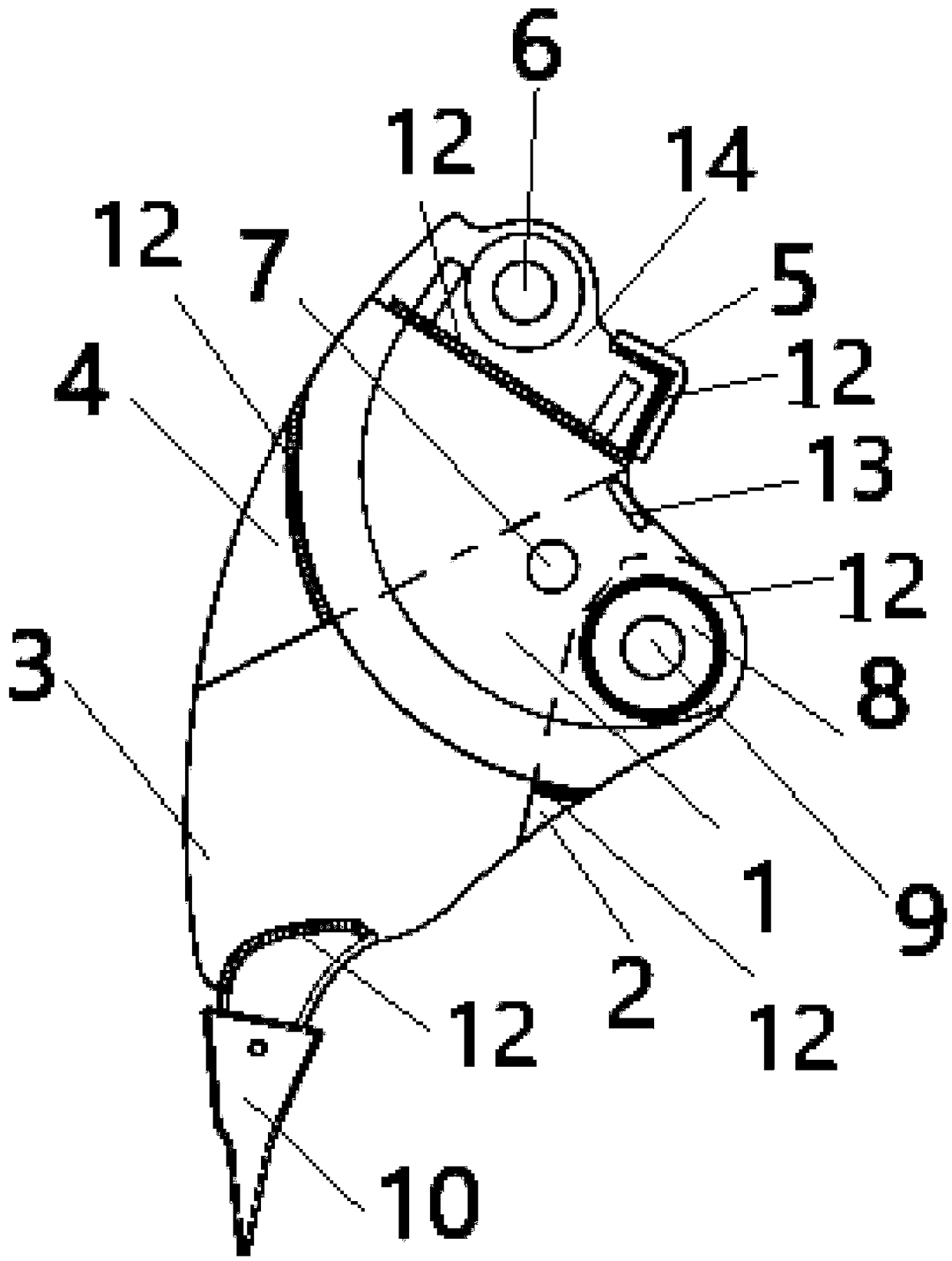

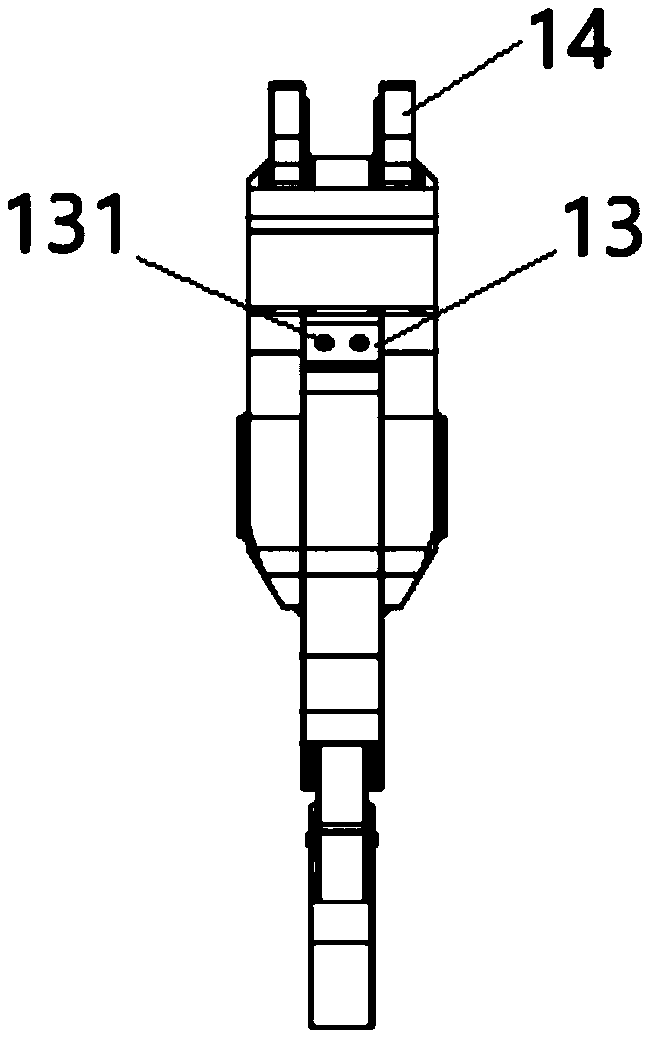

Split crusher and breaking device thereof

The invention discloses a split crusher and a breaking device thereof. The crusher comprises clamping plates, a positioning part and a crushing head, wherein the two clamping plates are arranged oppositely for clamping and fixing the positioning part; the crushing head comprises a crushing part, a middle part and a fixing part; the fixing part is contacted with the positioning part; the space formed by the positioning part and the clamping plates in a surrounding mode is used for accommodating and fixing the fixing part; and the fixing part and the clamping plates are detachably connected through fixing pieces. The crusher is split and is formed by three parts of the clamping plates, the positioning part and the crushing head; the crushing head is a vulnerable component which directly contacts an excavation surface; the clamping plates and the positioning part are arranged for clamping the crushing head and surrounding and fixing the crushing head through the corresponding space, the crushing head can be replaced or maintained quickly in a condition of ensuring the overall working strength to be unchanged, different types of crushing heads can be replaced conveniently, and the adaptability is improved; and thus, the material cost and the time cost are saved, the labor intensity of manual replacement is reduced, and the efficiency is improved.

Owner:刘裕志

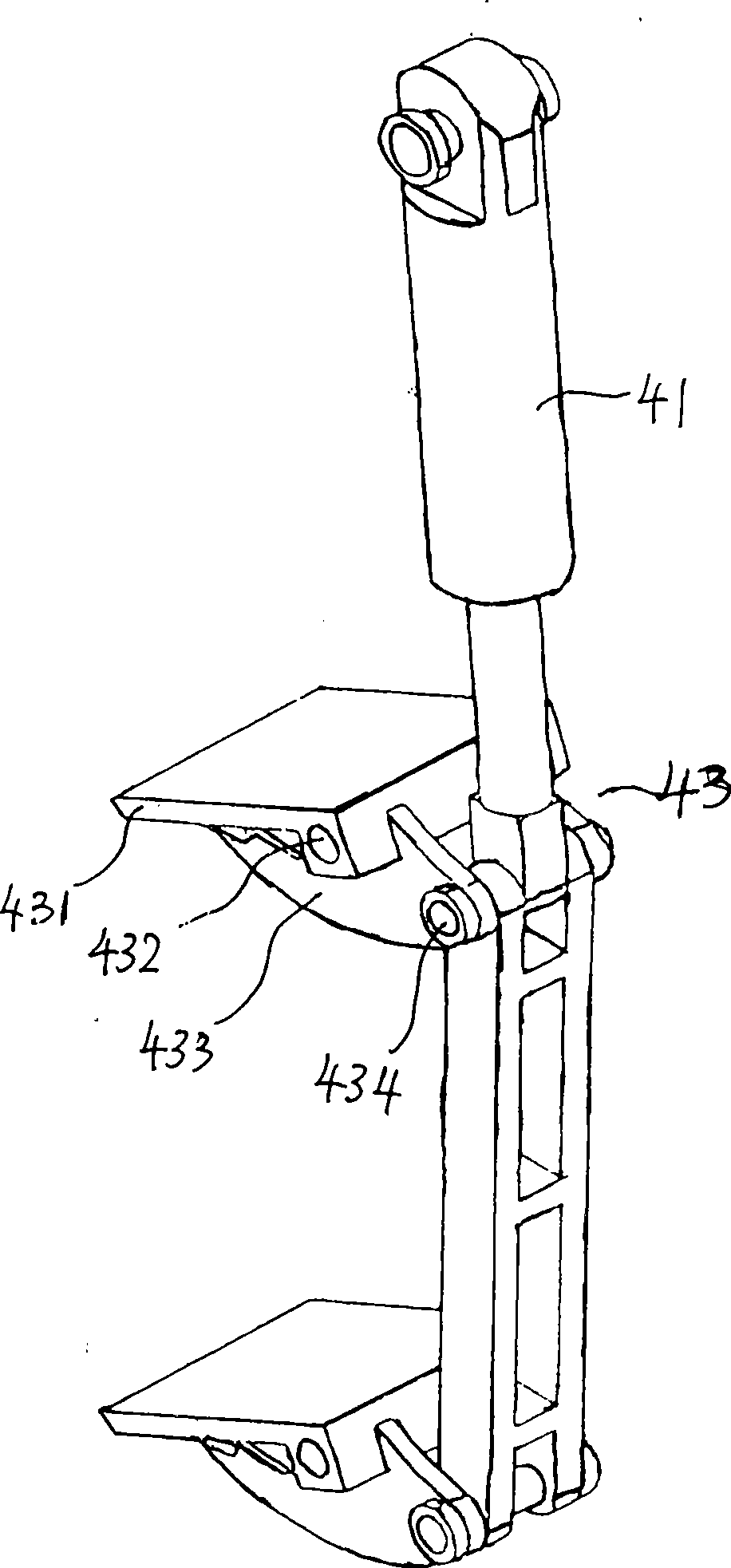

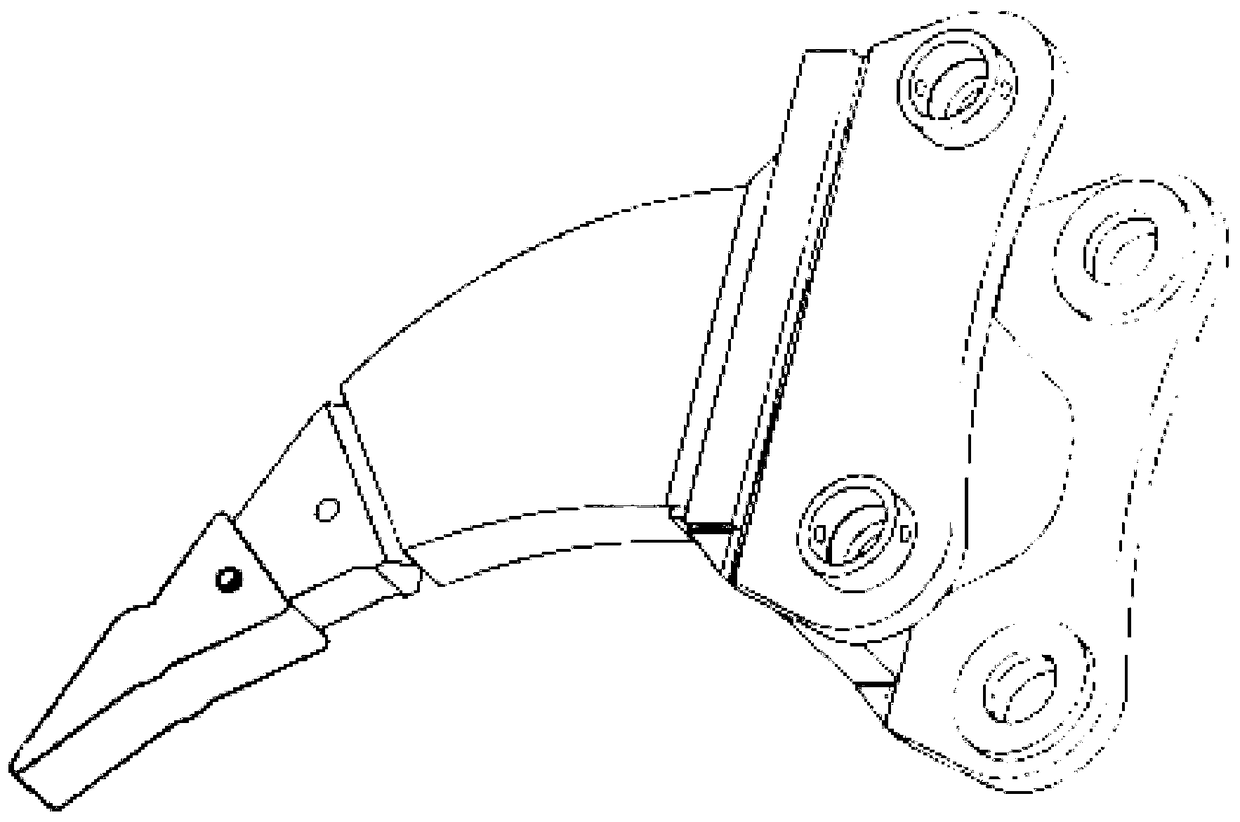

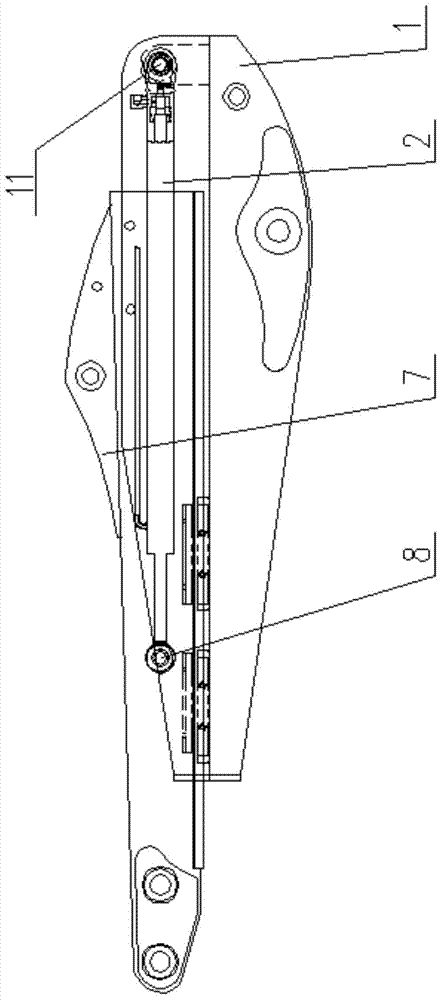

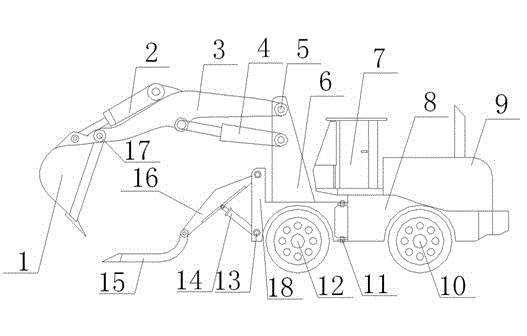

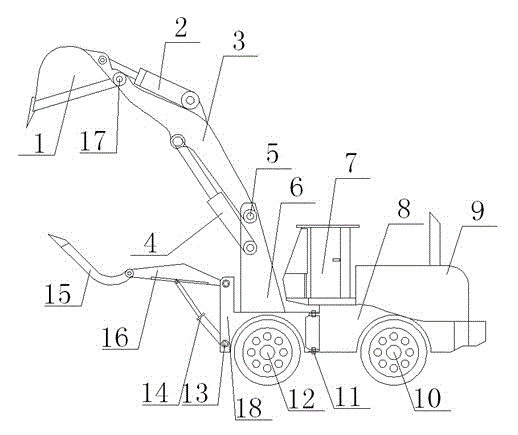

Novel telescopic bucket rod structure of loader-digger

InactiveCN103541383AIncreased digging depthIncrease heightMechanical machines/dredgersArchitectural engineeringHinge point

The invention discloses a novel telescopic bucket rod structure of a loader-digger. The novel telescopic bucket rod structure comprises an outer bucket rod, an inner bucket rod and a telescopic oil cylinder. The inner bucket rod is arranged inside the outer bucket rod in a hinged mode through the telescopic oil cylinder, and the two ends of the telescopic oil cylinder are connected with the rear hinged point of the outer bucket rod and the rear hinged point of the inner bucket rod respectively through a second hinge pin and a first hinge pin. Guide grooves are formed in the two sides inside the outer bucket rod respectively, and an inclined sliding block is arranged in each guide groove. Upper sliding blocks are arranged on the upper portions of the inclined sliding blocks respectively and movably installed on the two sides inside the outer bucket rod through fixed bolts and spring washers, sliding rail inclined blocks are welded on the two sides of the inner bucket rod respectively and installed between the inclined sliding blocks and the upper sliding blocks, the inclined surfaces of the sliding rail inclined blocks are in sliding fit with the inclined surfaces of the inclined sliding blocks, and the upper end faces of the sliding rail inclined blocks make contact with the upper sliding blocks. According to the novel telescopic bucket rod structure, the bucket rods of the loader-digger does not need to be frequently replaced, a large amount of working time is saved, working efficiency is improved, and the application range of the whole loader-digger is also greatly widened.

Owner:XUZHOU XUGONG SPECIAL CONSTR MASCH CO LTD

Loader with backhoe

InactiveCN103603401ASimple structureEasy to useMechanical machines/dredgersSteering wheelControl engineering

The invention discloses a loader with a backhoe. The loader comprises a front body, power wheels, a rear body, steering wheels, a driving console, a lower fork arm, a lower fork rotating shaft, a backhoe arm rotating shaft and a lower fork, the lower fork rotating shaft is arranged at the lower end of the front of the front body, the lower fork arm is arranged on the upper portion of the front end of the front body, the lower fork is arranged at the tip of the other end of the lower fork arm, a lower fork hydraulic rod is arranged on the outer side of the lower portion of the lower fork arm, a backhoe frame is arranged on the upper portion of the front body, the backhoe arm rotating shaft is arranged on the upper portion of the backhoe frame, a backhoe arm is arranged on the backhoe arm rotating shaft, the backhoe is arranged at the front end of the backhoe arm, a backhoe hydraulic rod is fixedly welded on the outer side of the upper portion of the backhoe arm, a backhoe arm hydraulic rod is arranged on the outer side of the lower portion of the backhoe arm, the steering wheels are arranged on the lower portion of the front body, the rear body is arranged at the rear end of the front body, the power wheels are arranged on the lower portion of the rear body, the driving console is arranged at one end of the upper portion of the rear body, and an engine is arranged at the other end of the upper portion of the rear body. The loader has the advantages that the loader is simple in structure, convenient to use, high in strength, large in force and high in loading efficiency, and materials are not easily scattered or leaked when the materials are raked at a closed position.

Owner:QINGDAO MODERN HAILIN PREVIOUS LAIZHOU HAILIN HEAVY IND

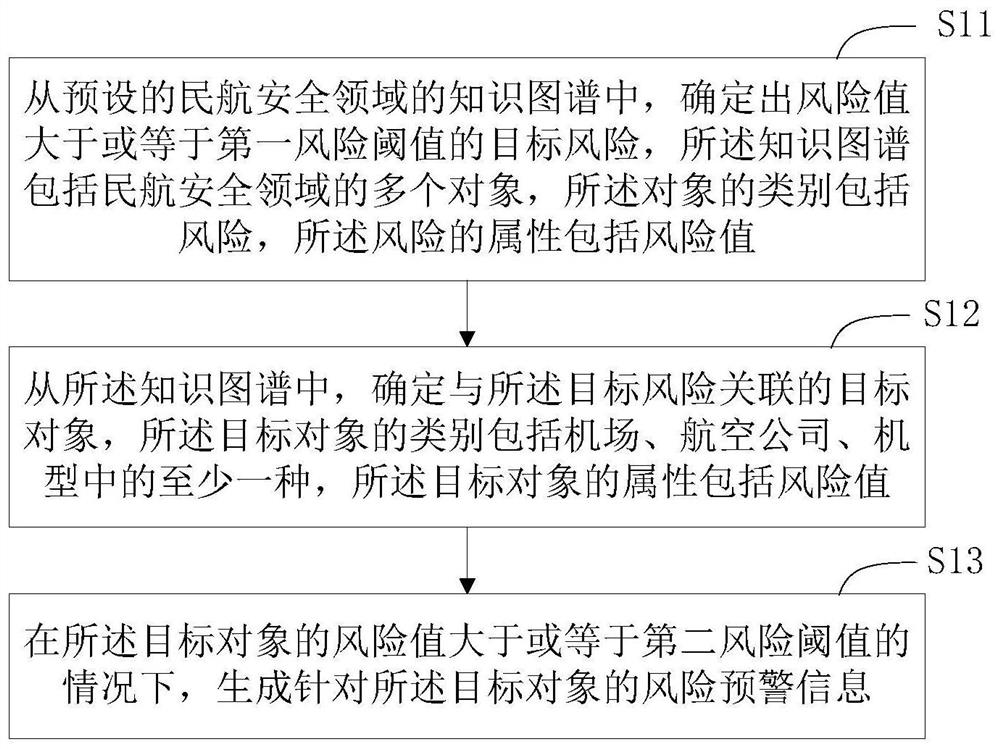

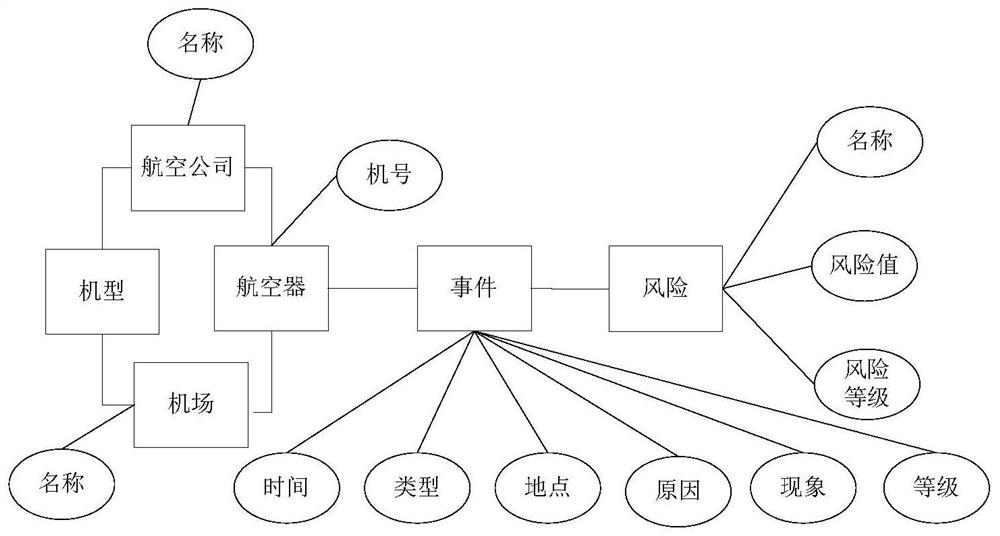

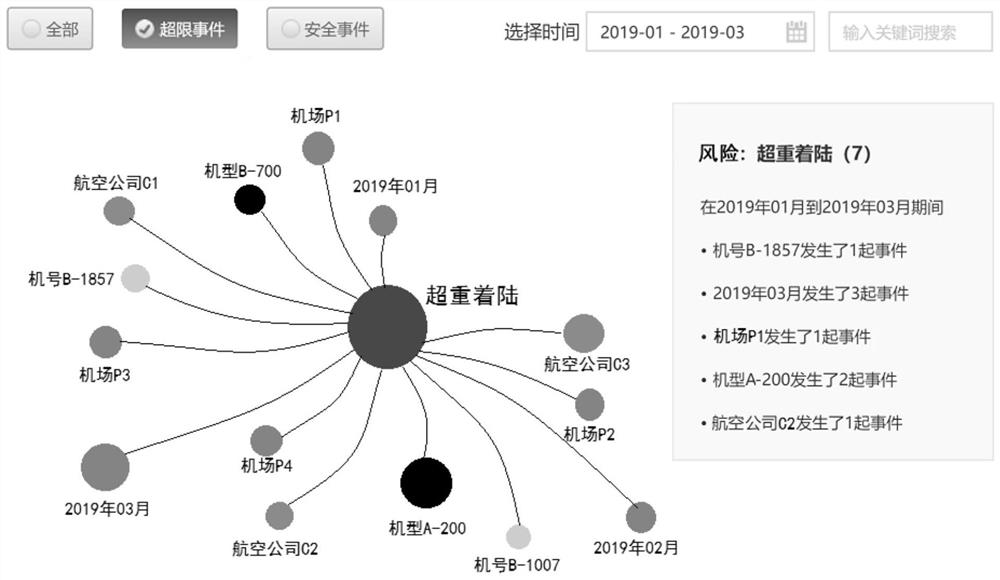

Civil aviation safety risk analysis method and device based on knowledge graph

ActiveCN111915207AIncreased digging depthImprove accuracyAlarmsResourcesCivil aviationKnowledge graph

The invention relates to a civil aviation safety risk analysis method and device based on a knowledge graph, and the method comprises the steps: determining a target risk with a risk value greater than or equal to a first risk threshold from the knowledge graph of a preset civil aviation safety field, wherein the knowledge graph comprises a plurality of objects of the civil aviation safety field,wherein the category of an object comprises a risk, and the attribute of the risk comprises a risk value; determining a target object associated with the target risk from the knowledge graph, whereinthe category of the target object comprises at least one of an airport, an airline company and a model, and the attribute of the target object comprises a risk value; and under the condition that therisk value of the target object is greater than or equal to a second risk threshold, generating risk early warning information for the target object. According to the embodiment of the invention, themining depth and accuracy of civil aviation safety risk analysis can be improved.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

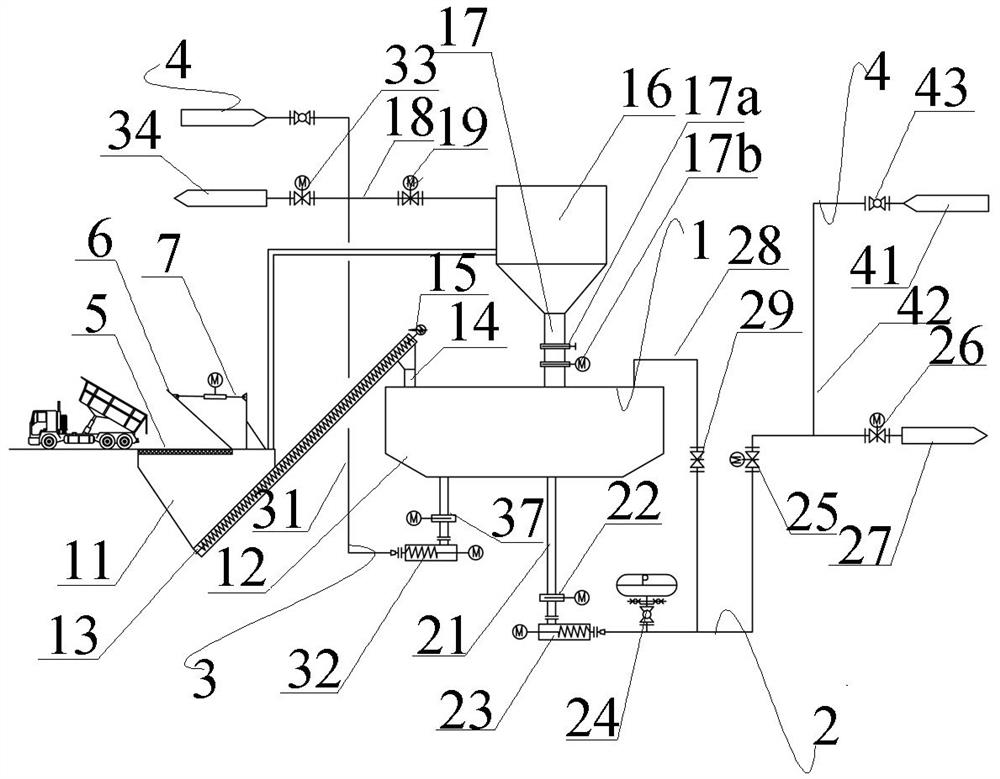

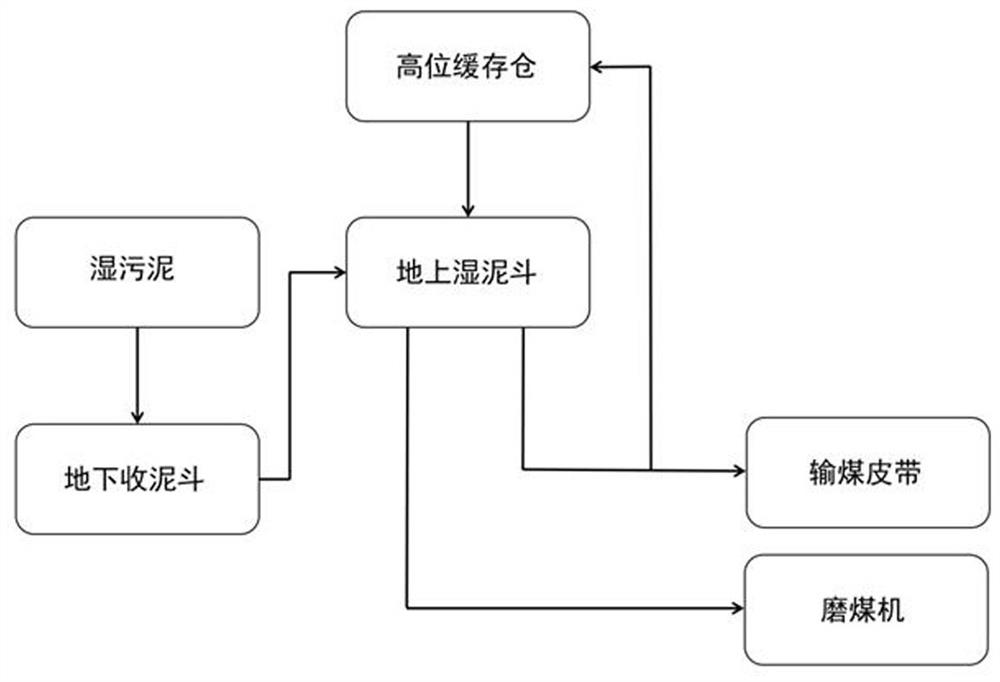

Coal-fired boiler synergistic solid waste resource utilization direct mixing system and working method thereof

ActiveCN114505160ASmall sizeIncreased digging depthCombined combustion mitigationGrain treatmentsProcess engineeringEnvironmental engineering

The invention discloses a coal-fired boiler collaborative solid waste resource utilization direct mixing system and a working method thereof. The coal-fired boiler collaborative solid waste resource utilization direct mixing system comprises a solid waste conveying system, a coal mill feeding system and a coal conveying belt feeding system, the solid waste conveying system comprises an underground receiving hopper, an overground receiving hopper and a shaftless screw conveyor for conveying solid waste from the underground receiving hopper to the overground receiving hopper, a high-position buffer bin is arranged over the overground receiving hopper, the bottom of the high-position buffer bin is communicated with the overground receiving hopper through a vertical pipeline, and the top of the high-position buffer bin is communicated with the bottom of the overground receiving hopper through a second backflow pipeline. Two feeding systems are arranged, one or both of two modes are selected, the feeding modes are flexible and high in practicability, meanwhile, the size of the underground receiving hopper is greatly reduced, consideration in the aspects of drainage, geological conditions and the like is reduced, a special evaluation process is not needed, the construction period is shortened, pit surface materials and corrosion-resistant and water-resistant materials are saved, and the construction cost is reduced. And the construction cost is greatly reduced.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

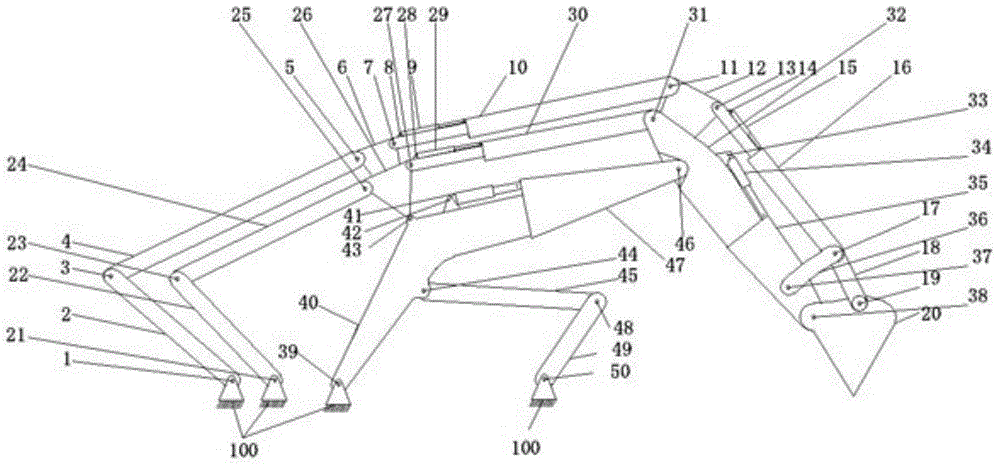

A side mining system for an open-pit mine

ActiveCN109931066BImproving the technical strength of side miningRealize intelligenceDust removalFire preventionSocial benefitsAdhesive belt

The invention relates to the technical field of slope mining of open-pit mines and particularly relates to a slope mining system for the open-pit mines, and realizes safe, efficient and green mining of slope briquettes of the open-pit mines. The slope mining system comprises a slope continuous coal mining machine for carrying out roadway type mining, a multi-unit rapid connection adhesive tape conveying system for carrying out rapid conveying, a stepping type walking platform for carrying out external propelling and whole movement, a movable type unloading part for carrying out external conveying, a pulling-out type ventilation and dust removal system for carrying out roadway ventilation and dust removal, a navigation and stability monitoring system for carrying out remote accurate controland slope stability monitoring, and a remote control platform for carrying out remote control. According to the slope mining system for the open-pit mines, provided by the invention, the safe, efficient and green mining of slope briquette resources can be realized, the strength of an slope mining technology of the open-pit mines in China can be remarkably improved, and remarkable economic benefits and social benefits can be brought for enterprises.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

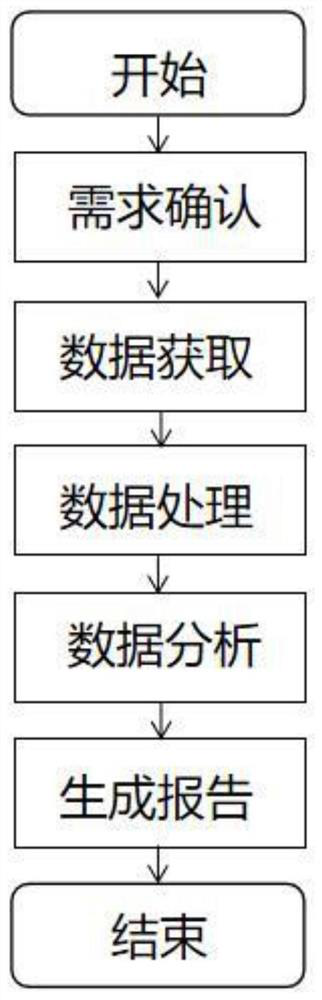

Power supply company power data mining method and system

InactiveCN112328582AImprove masteryIncreased digging depthRelational databasesResourcesData acquisitionData profiling

The invention discloses a power supply company electric power data mining method and system. The power supply company electric power data mining method sequentially comprises the following steps: demand confirmation, data acquisition, data processing, data analysis and report generation. The mining system for the power data of the power supply company comprises a demand confirmation module, a dataacquisition module, a data processing module, a data analysis module and a report generation module. According to the invention, the defect that the data value utilization degree in the production and operation monthly report is not high enough in the prior art is solved.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

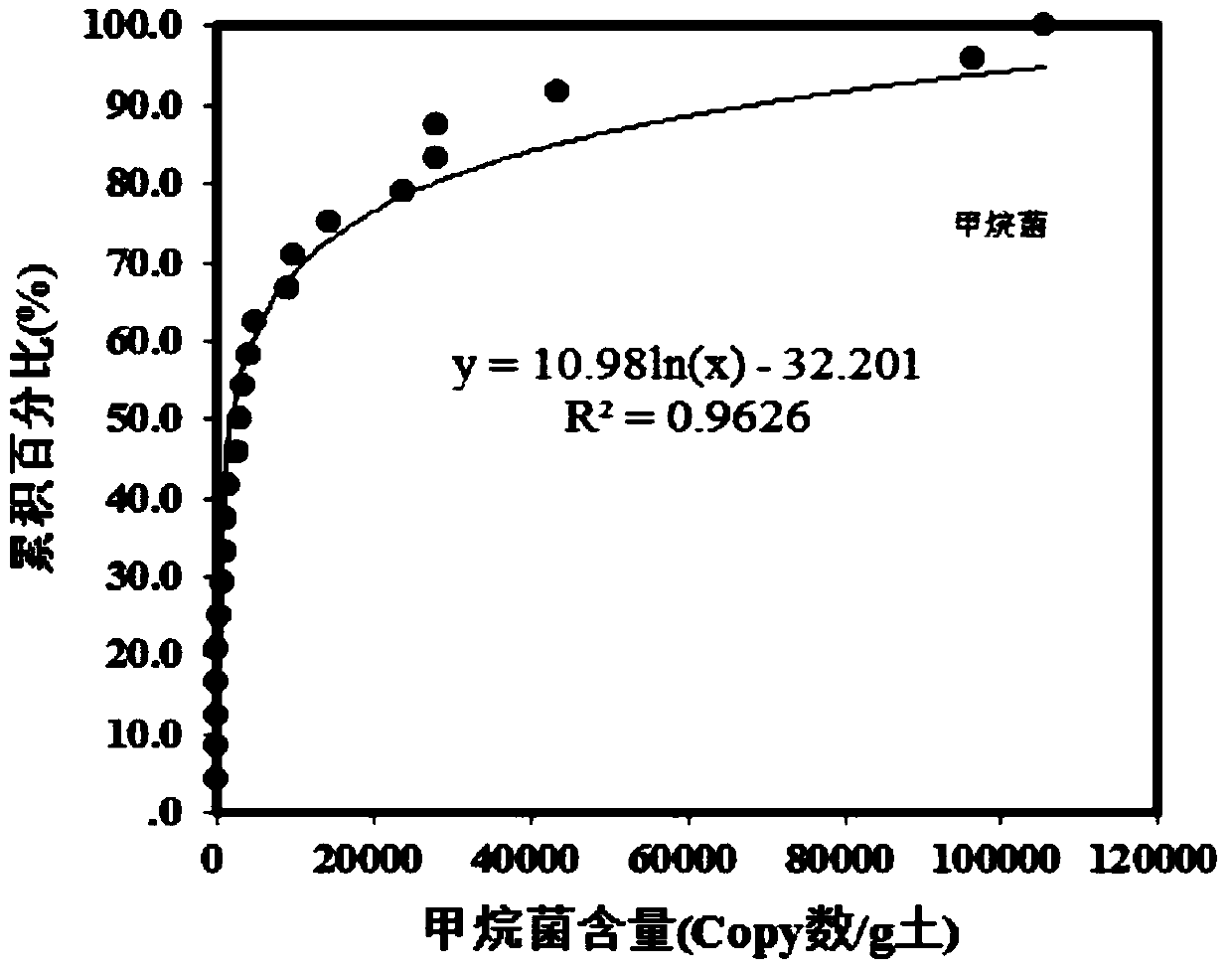

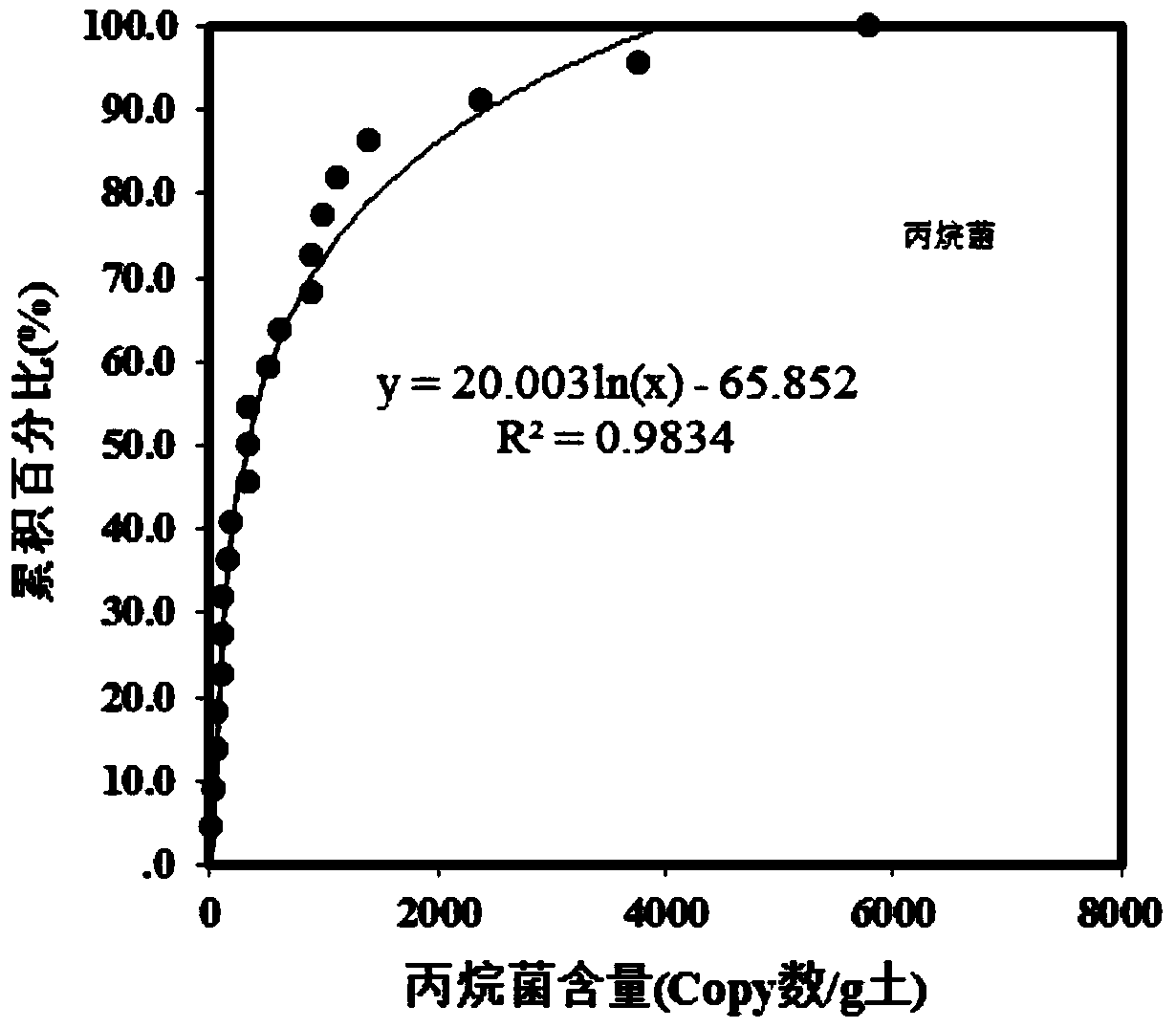

Gene Quantitative Microbial Oil and Gas Exploration Method Based on Mathematical Statistics

ActiveCN106126975BIncreased digging depthHigh precisionData processing applicationsMicrobiological testing/measurementMicroorganismMicrobial oil

The invention discloses a gene quantification microbial prospection method for oil and gas based on mathematical statistics, and relates to the technical field of microbial prospection for oil and gas. The method comprises the following seven steps: arranging and acquiring sample points, performing sample oil and gas microbial gene quantitative tests, drawing a data accumulation frequency curve, performing subsection optimal linear-regression analysis, determining oil and gas microorganism abnormal grade, describing oil and gas plane distribution characteristics, and locating an oil and gas reservoir target region. Based on a mathematical statistics method, the method improves excavation depth of gene quantitative data, and a set of gene quantitative oil and gas exploration technology method system which is complete in principle is formed. The method breaks through dependency of the prior art on borehole data, broadens application range of a gene quantitative technology, and is characterized by good operability, and greatly improves accuracy of determination of a oil and gas reservoir target region range.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

A sugar beet digging device

The invention relates to a beet digger, which is characterized by comprising a machine frame, a combined digging part and a driving system, wherein the machine frame comprises a first cross beam, a second cross beam, a third cross beam between the first and second cross beam, a first longitudinal beam and a second longitudinal beam; the combined digging part comprises a disc axle arm frame, one end of the disc axle arm frame is connected with the third cross beam, the other end of the disc axle arm frame is connected with two connecting shafts, and the other ends of the two connecting shafts are both connected with a disc; eccentric wheels are arranged below the longitudinal beams on the side of the first cross beam; the two eccentric wheels are connected by a first drive shaft which is provided with a digger blade positioned at a lower nonaligned place between the two discs; the driving system comprises a gear box arranged on the second cross beam, the input end of the gear box is connected with a power device, and the output end of the gear box is connected with a second drive shaft and a gear oil pump respectively; the second drive shaft drives the eccentric wheels to rotate through a chain wheel drive device; the input end of the gear oil pump is connected with an oil tank; the output end of the gear oil pump is connected with a hydraulic motor; and the power output end of the hydraulic motor is connected with one of the two discs.

Owner:CHINA AGRI UNIV

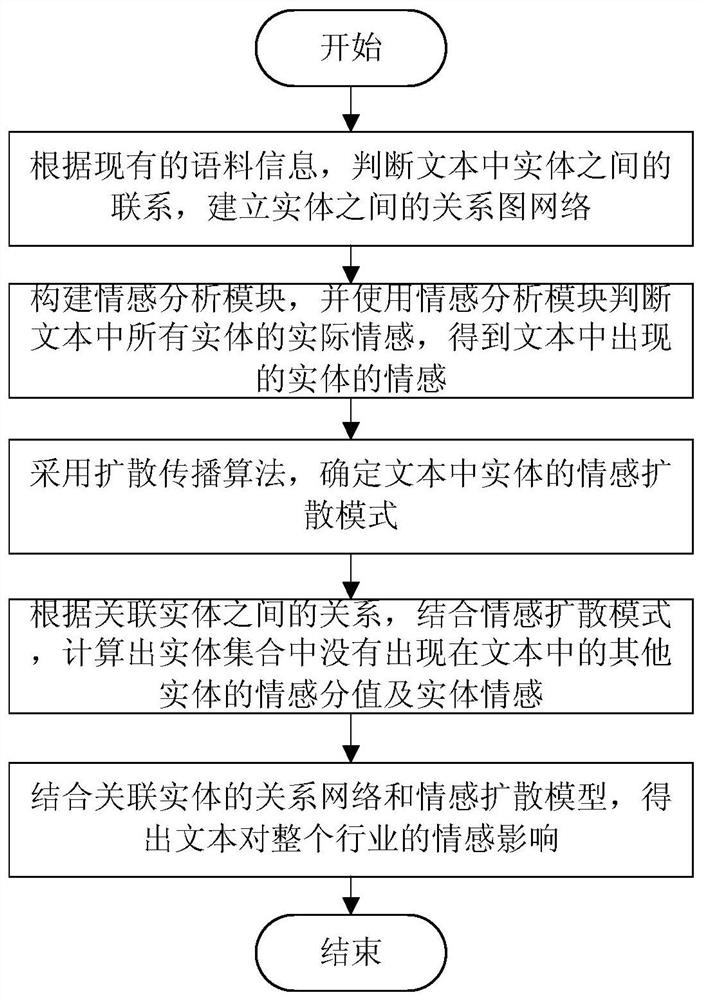

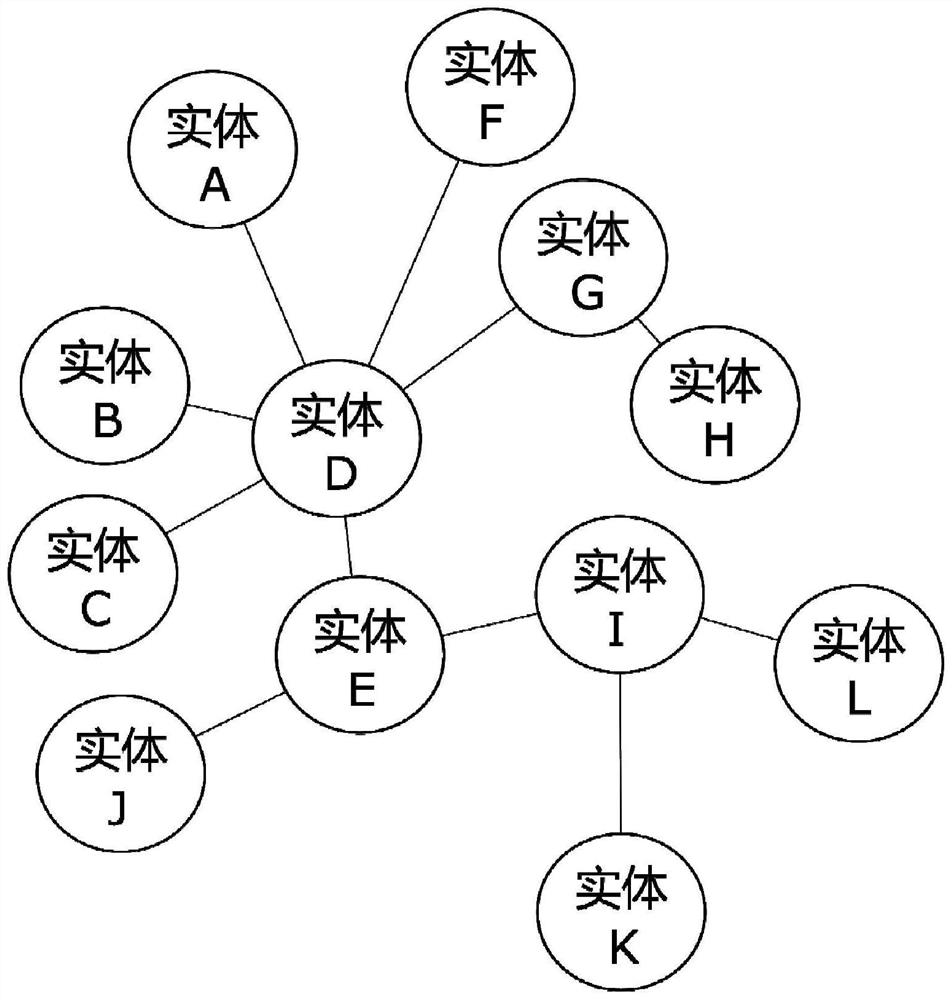

A Method of Sentiment Judgment for Related Entities Based on Diffusion Model

ActiveCN109471928BIncrease profitIncreased digging depthSpecial data processing applicationsText database clustering/classificationData miningEmotionality

The invention provides a method for judging the emotion of an associated entity based on a diffusion model, and relates to the field of information technology. This method first judges the connection between entities in the text based on the existing corpus information, establishes a relationship graph between entities, and builds a sentiment analysis module to judge the actual emotions of all entities in the text; then uses the diffusion propagation algorithm to target different Emotion determines different emotion diffusion patterns; according to the relationship between associated entities, combined with the emotion diffusion pattern, calculates the emotion scores of other entities; then determines the emotions of other entities according to the preset threshold; finally combines the relationship of associated entities The network and emotional diffusion model can be used to obtain the emotional impact of the text on the entire industry; the method for judging the emotion of related entities based on the diffusion model provided by the present invention can analyze the entities in the text and then extend it to other related entities , to improve the utilization of text and increase the depth of data mining.

Owner:北京国信云服科技有限公司 +1

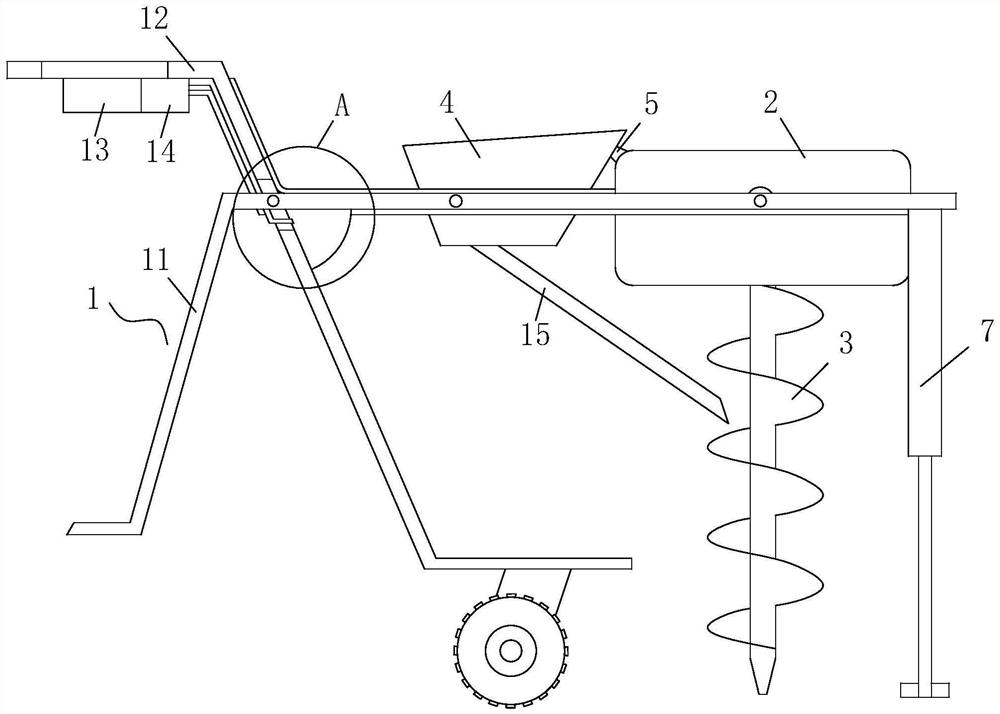

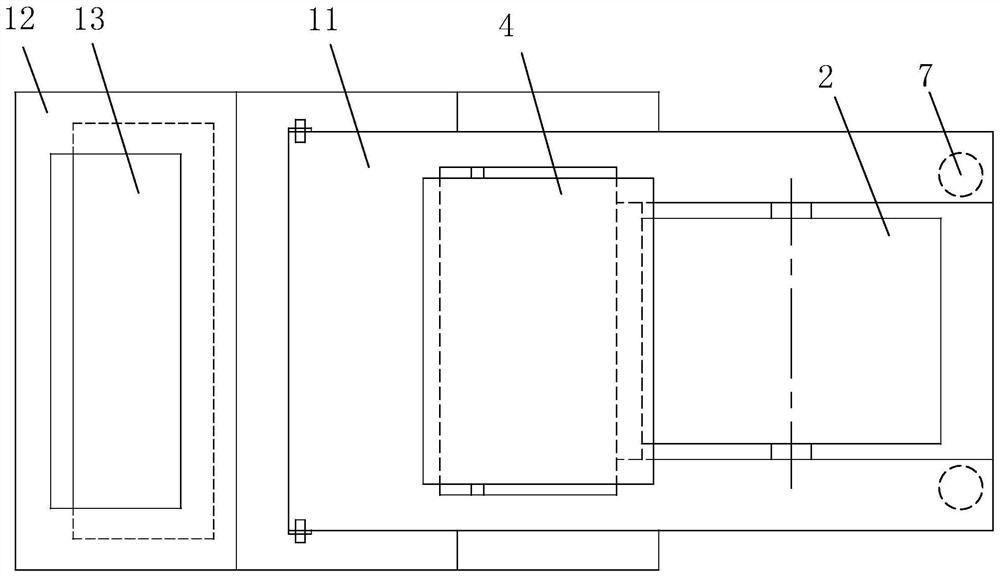

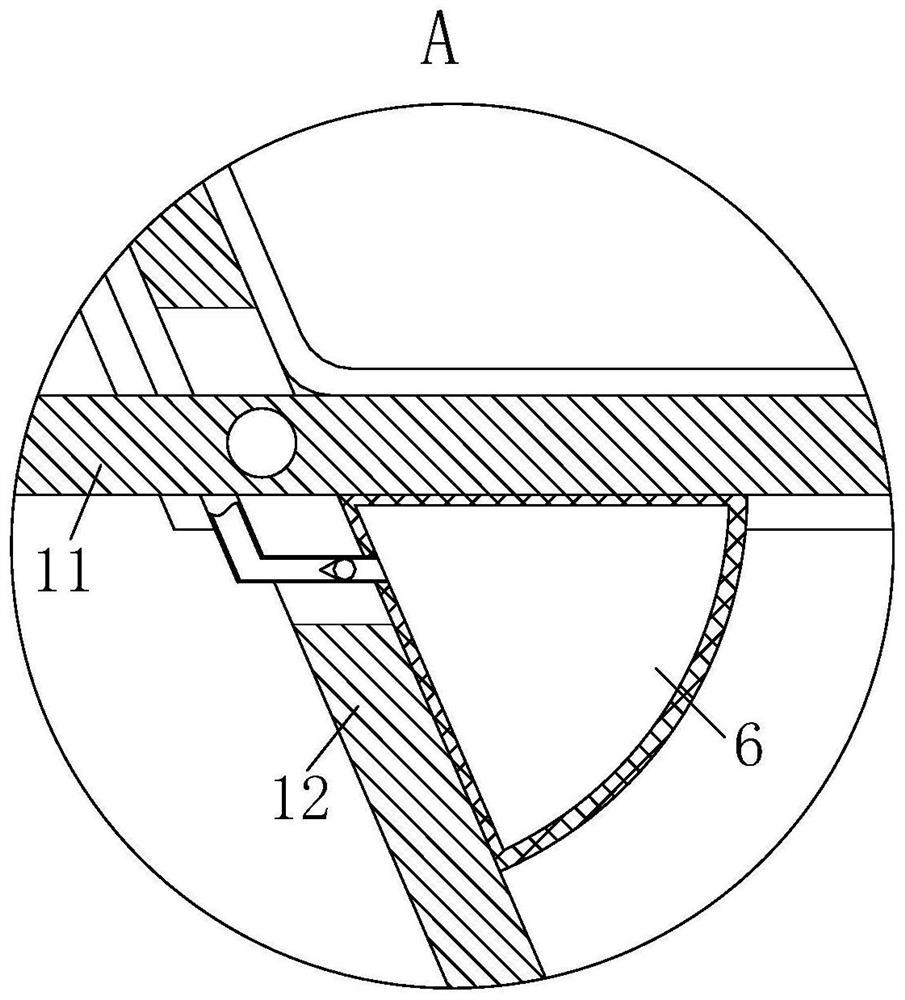

Device for automatically digging holes and synchronously applying base fertilizer based on dendrobium planting

ActiveCN114793549AIncreased digging depthExtended reaction timePlantingFertiliser distributersAgricultural scienceVehicle frame

The invention belongs to the technical field of agricultural machinery, and particularly relates to a dendrobium planting-based device for automatically digging pits and synchronously applying base fertilizer, which comprises a movable frame formed by hinging a motor bracket and a movable bracket; universal wheels are installed at the opposite bottom of the movable support, and a control box and an air pump are installed at the opposite top of the movable support. The drill bit deflects and moves downwards relative to the moving support along with the motor support to increase the pit digging depth, manpower applied by the pedal part is matched, the pit digging depth can be manually controlled while stability is guaranteed, emergencies caused by undefined soil conditions are stopped in time, and the pit digging efficiency is improved. And the time for manually controlling and switching an air pump control button on the control box to increase the inflation rate reaction of the inflatable cushion is provided, so that the operation controllability is improved.

Owner:霍山金斛宝农业发展有限公司

Chain excavator

InactiveCN102561437BIncrease the lengthIncreased digging depthSoil-shifting machines/dredgersHydraulic motorLeft half

The invention relates to a chain excavator for excavating a deep ditch, comprising an arm lever, a driving wheel, a driven wheel, chains and buckets. The driving wheel is arranged on the upper end of the arm lever and driven by a hydraulic motor; the driven wheel is arranged on the lower end of the arm lever; the chains surround the arm lever; the buckets are fixed on the chain; the chain excavator is provided with only two buckets, and the two sections of chains arranged between the two buckets have the same length; the buckets comprise a left half bucket and a right half bucket which are connected by a pin shaft; two left mud scraping plates are arranged in the left half bucket and clung to the front side wall and the rear side wall of the left half bucket respectively; the right ends of the two left mud scraping plates are fixed on the upper opening end of the right half bucket; the two left mud scraping plates are located on the extended line of the upper opening edge of the right half bucket; two right mud scraping plates are arranged in the right half bucket and clung to the front side wall and the rear side wall of the right half bucket respectively; the left ends of the two right mud scraping plates are fixed on the upper opening end of the left half bucket; the two right mud scraping plates are located on the extended line of the upper opening edge of the left half bucket; a hydraulic oil cylinder is arranged on the right of the buckets; and a sliding chute is arranged below the buckets.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com