Patents

Literature

124results about How to "Improve mastery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for professional development training, assessment, and automated follow-up

InactiveUS20110070567A1Broaden their knowledgeImprove masteryElectrical appliancesTeaching apparatusThe InternetSkill sets

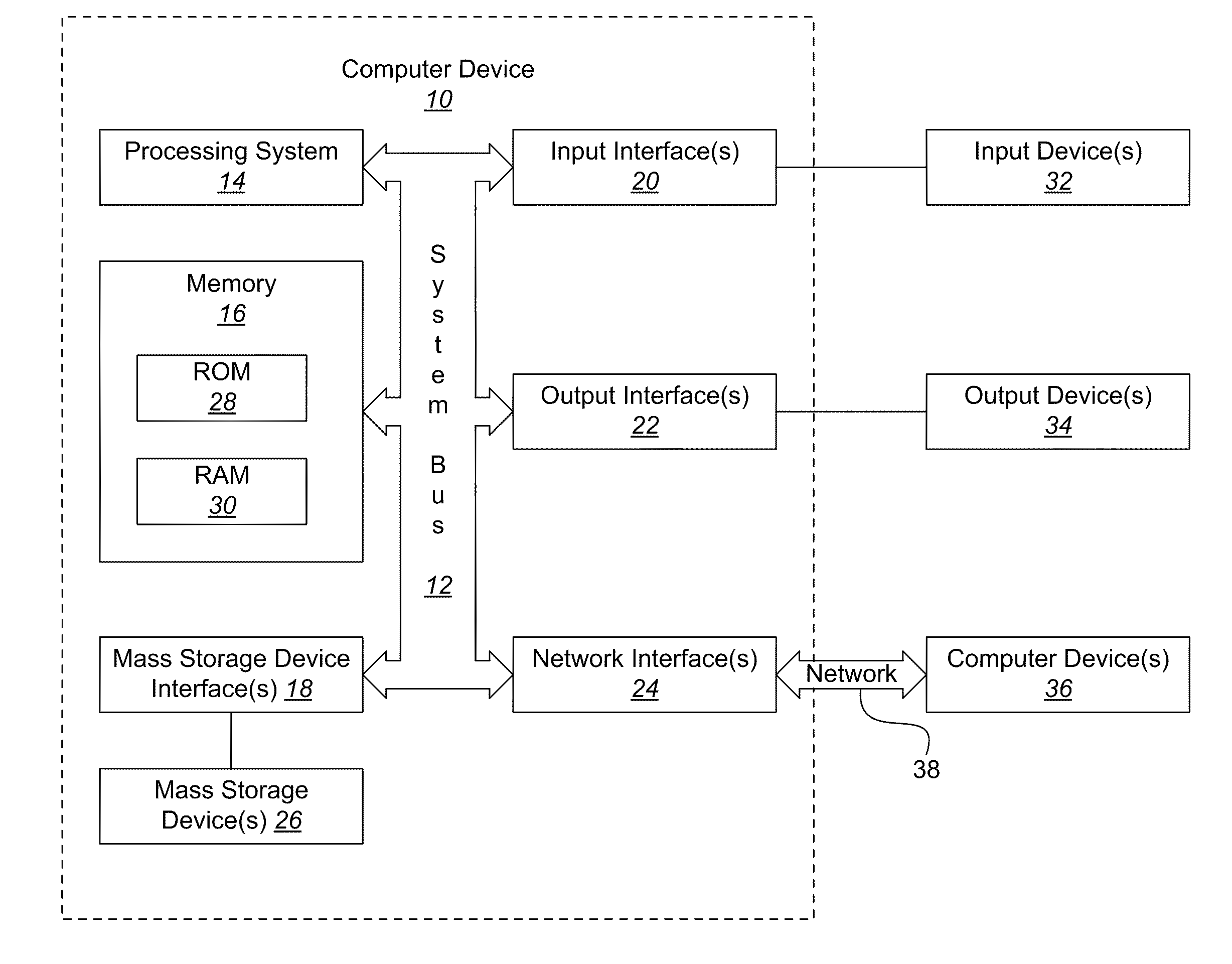

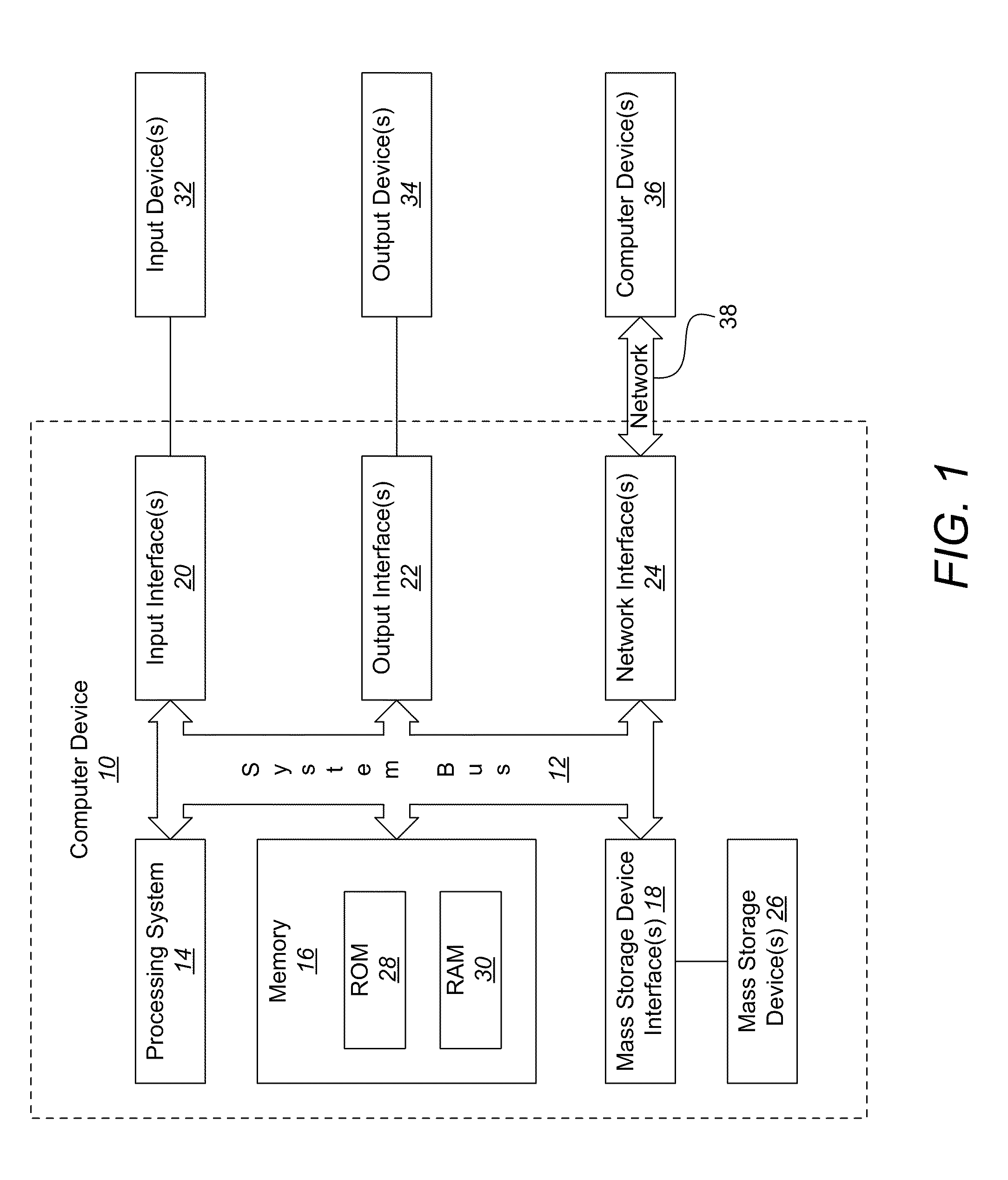

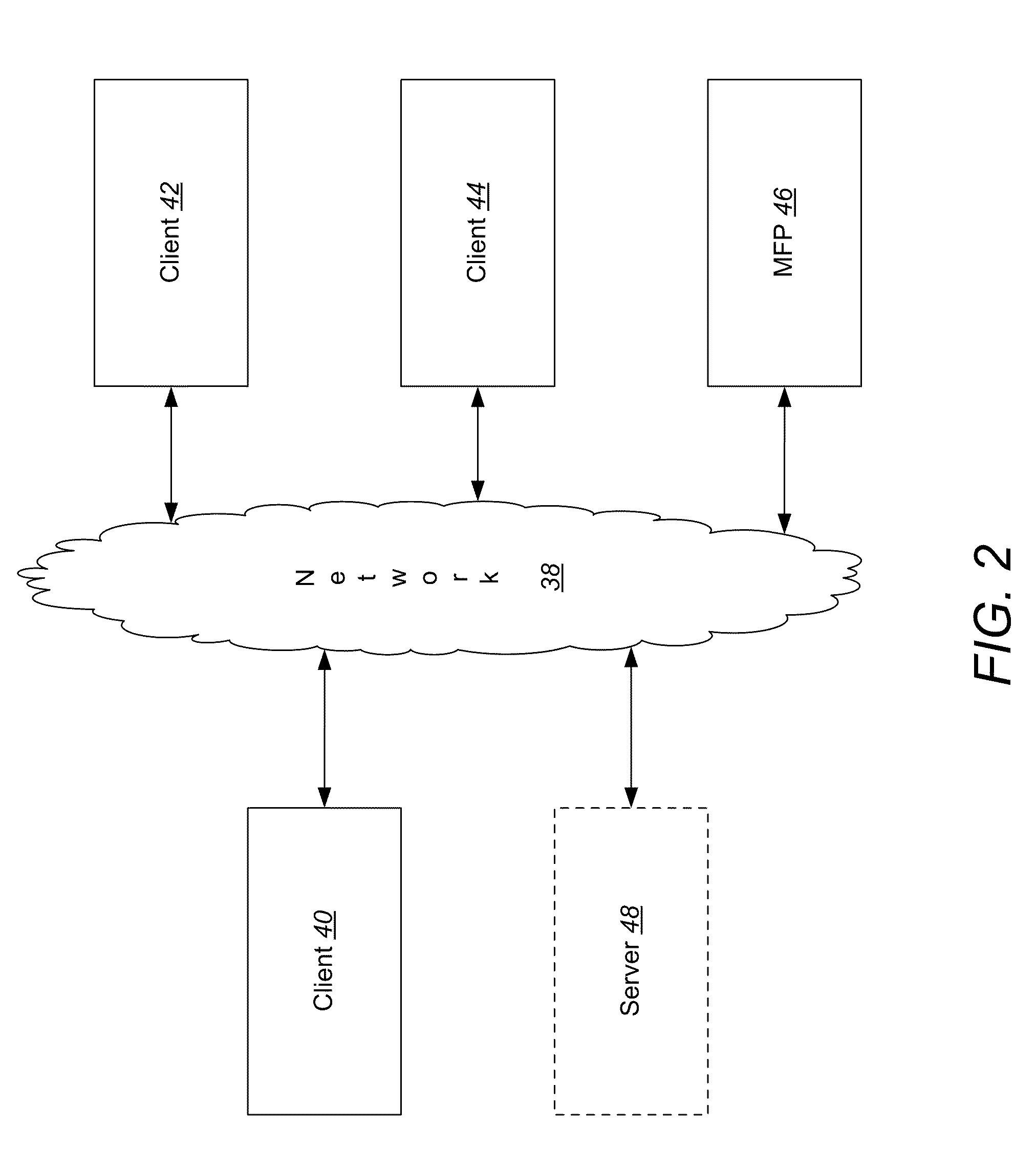

Systems and methods for providing web-enabled professional development training to participants in diverse industries to thereby improve the participant's knowledge, skills, and proficiency. Professional development training is provided over the Internet. Following the training, at least one participant is provided with a first question set regarding the training. The participant is then allowed to implement concepts and principles according to the training previously received. After a predetermined period of time elapses, additional follow-up questions are generated based on the participant's responses to the first question set and the participant's implementation of training principles and concepts. The follow-up questions may then be presented to the participant via the Internet. In a further implementation, the follow-up questions may be presented to a supervisor of the participant. In some implementations, the Internet may be utilized to assess the participants performance prior to and after receiving training.

Owner:FRONTLINE TECH GRP LLC

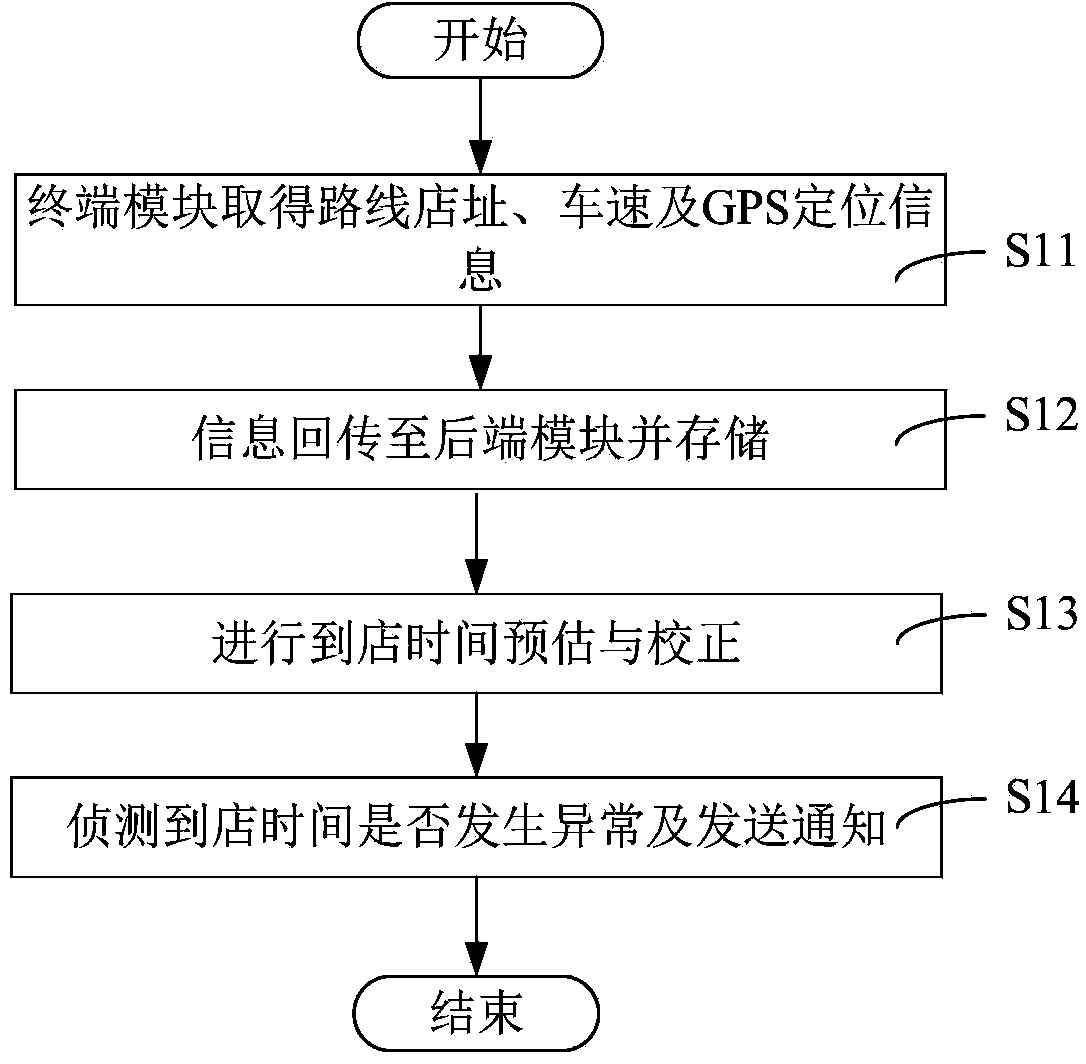

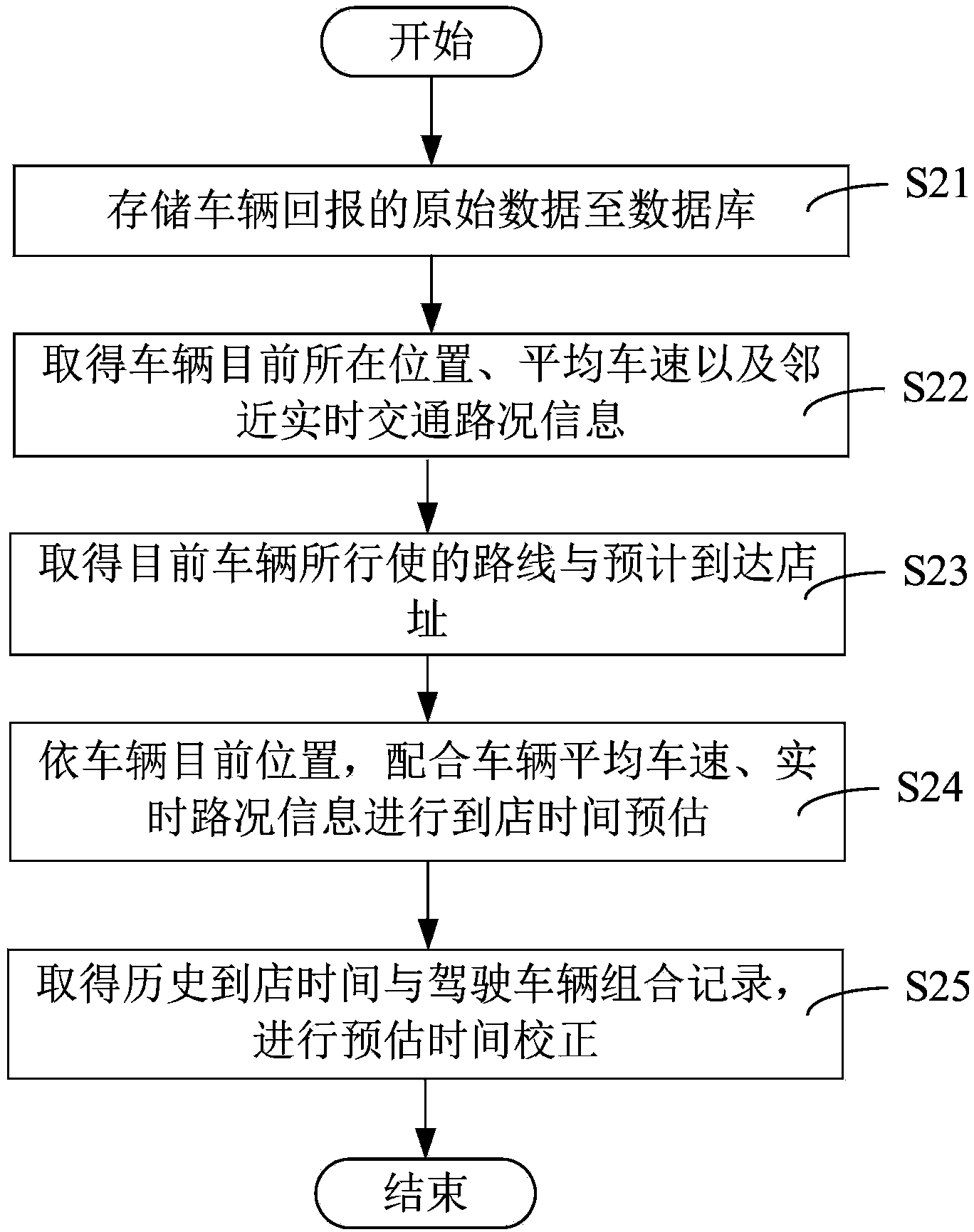

Logistic distribution arrival time predicting system with informing function and method

InactiveCN104008473AImprove accuracyImprove masteryLogisticsTransmissionTime scheduleComputer module

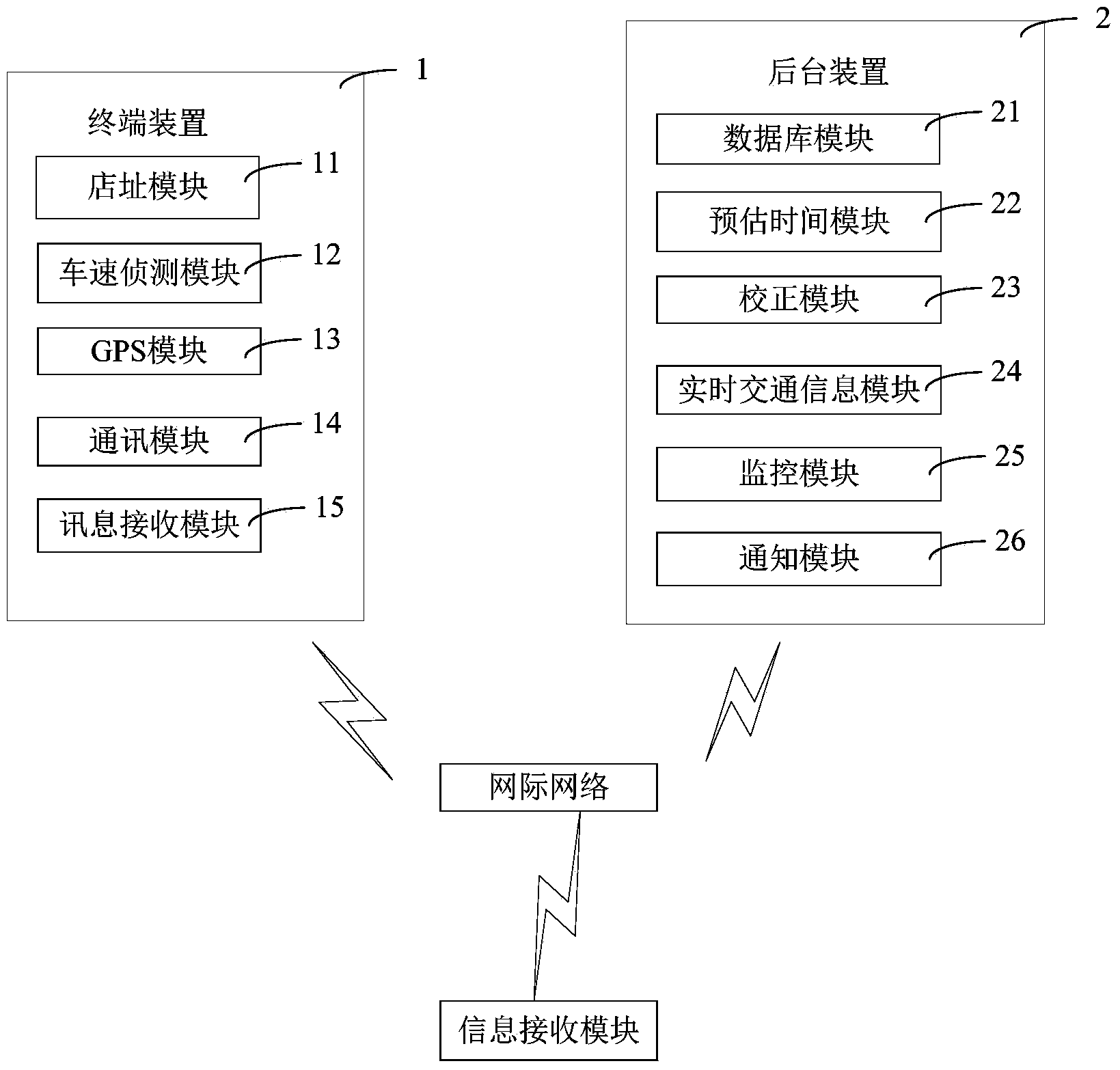

The invention provides a logistic distribution arrival time predicting system with an informing function and a related method. A vehicle machine terminal module arranged on a vehicle periodically collects information such as current position coordinates and vehicle states according to a distribution station schedule assigned in advance. The information is sent back to a background server in a real-time manner through wireless communication. The arrival time of each distribution station is estimated on the basis of real-time traffic information and cargo information. The estimated results are corrected in reference to history records, driver vehicle combinations, cargo volumes, etc. The estimated results which can be referred for logistic managers for decision-making can be automatically sent to related personnal through a system in certain conditions.

Owner:CHUNGHWA TELECOM CO LTD

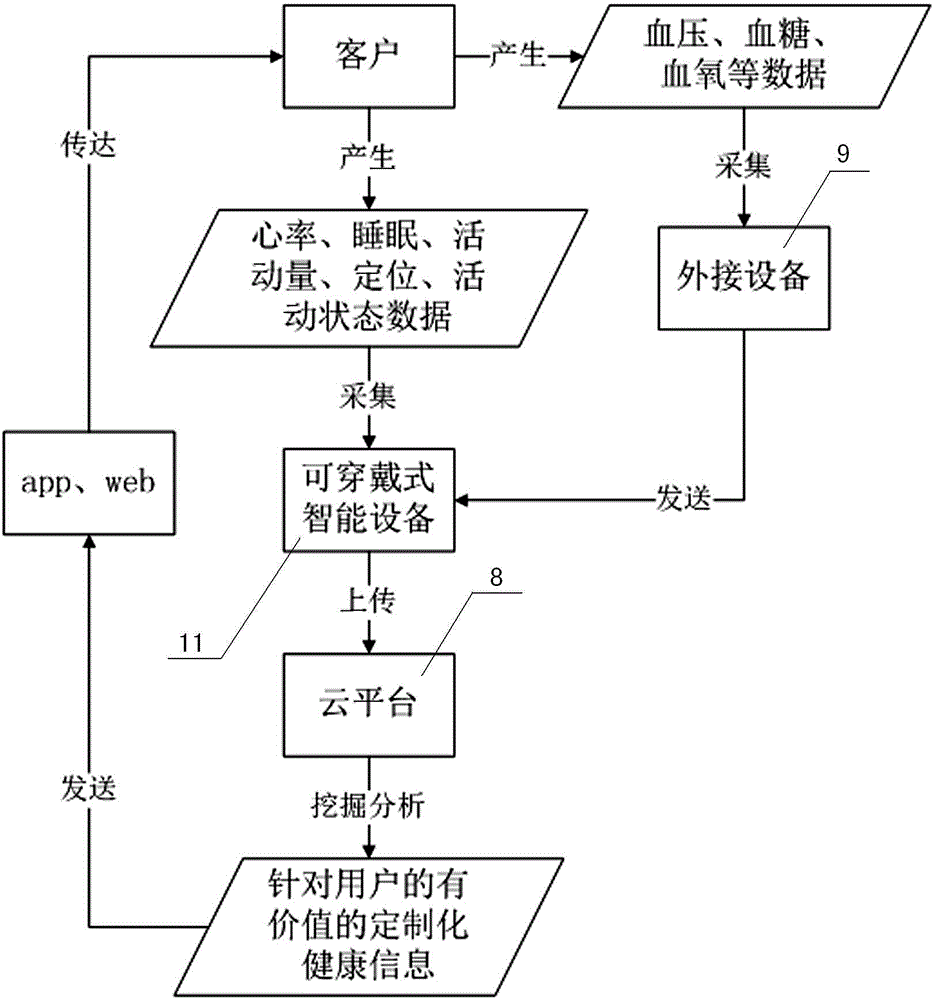

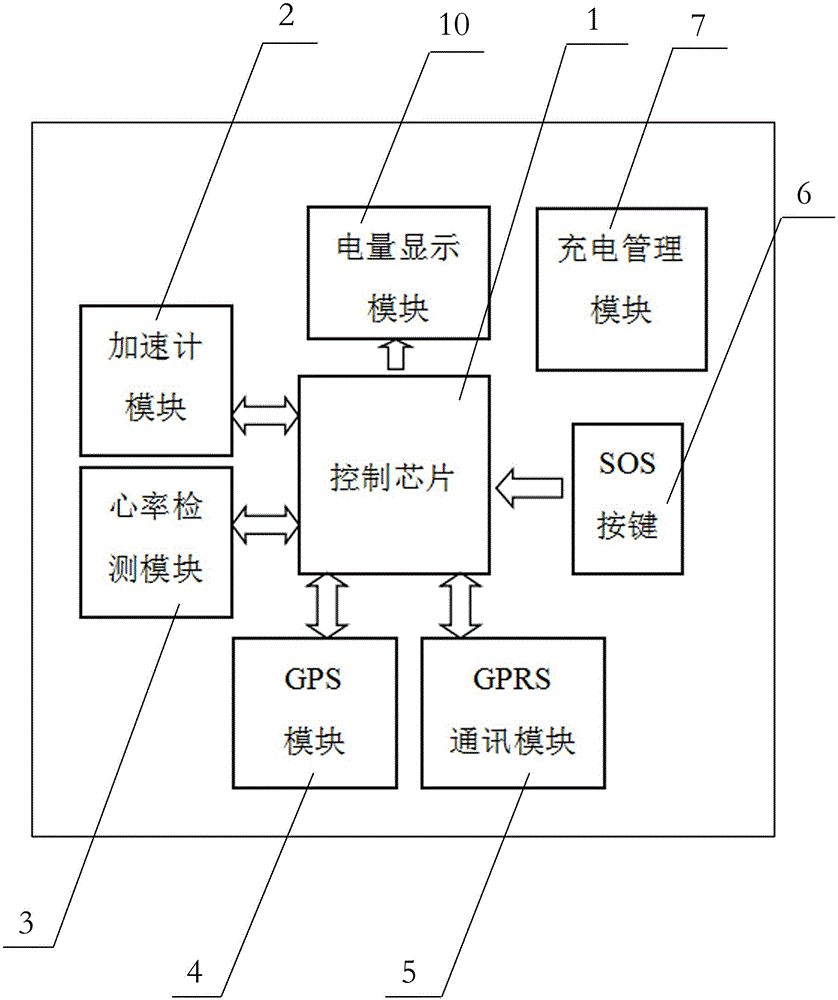

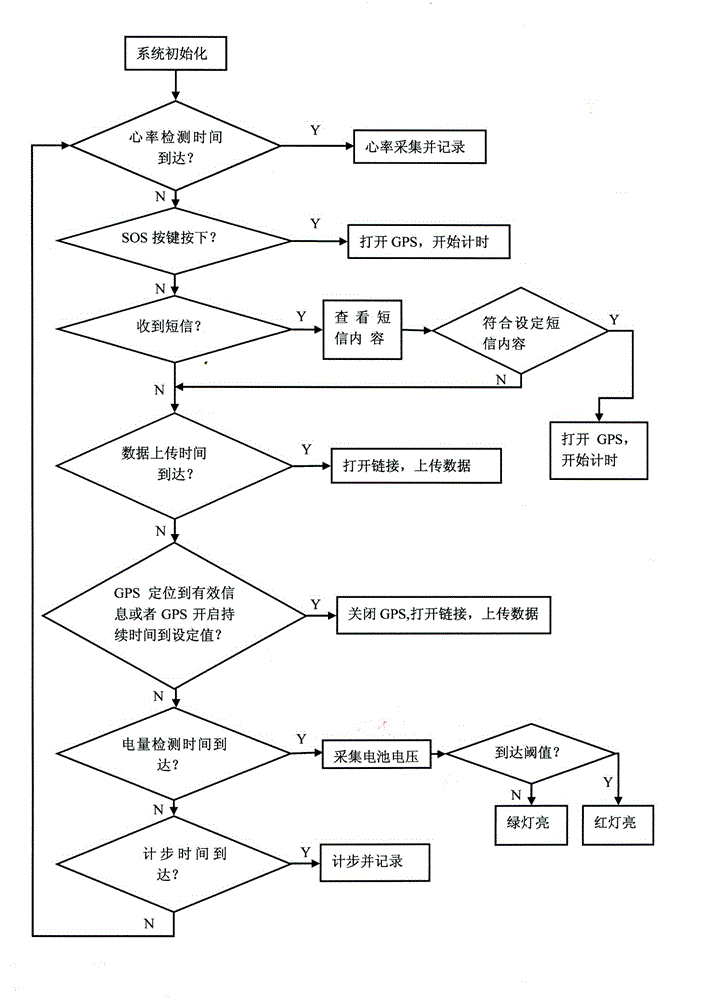

Wearable equipment analysis system on basis of big data platform and data analysis method thereof

The invention discloses a wearable equipment analysis system on the basis of a big data platform. A cloud data platform is connected with wearable equipment in a wireless transmission manner; the wearable equipment is also in data connection with external equipment in a wireless transmission manner; a control chip is arranged at the position of an integrated circuit board; the control chip is respectively and bidirectionally in data connection with an accelerometer module, a heart rate detection module, a GPS module and a GPRS module; one signal input end of the control chip is connected with the signal output end of an S0S key module. data, such as a heart rate, an activity level, an active state, and positioning information, of a human body is measured and acquired by an intelligent wearable bracelet, data, such as a blood pressure, blood oxygen and blood sugar of the human body, is acquired by the external equipment, and the data is uploaded to the cloud platform by the GPRS transmission module so as to form big data. The cloud platform can carry out analysis processing on the big data by an algorithm and obtains human body disease possibility prediction by combining factors such as climate, sleep quality, and the basic situation of the body.

Owner:SHANGHAI FULI INFORMATION TECH

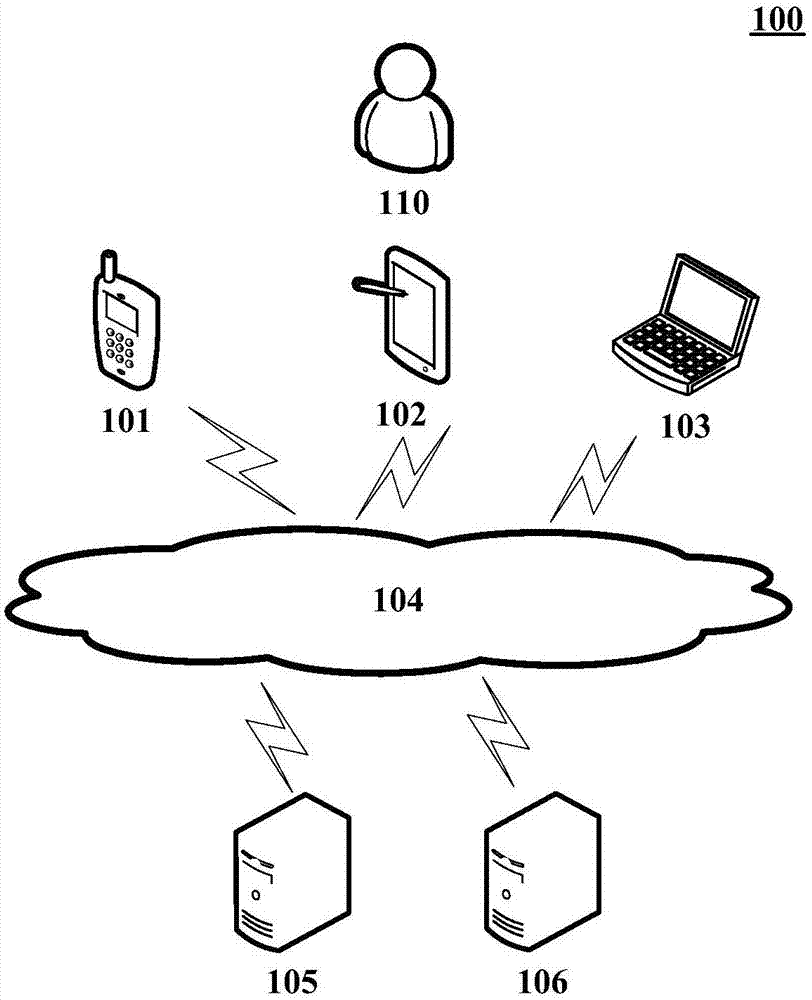

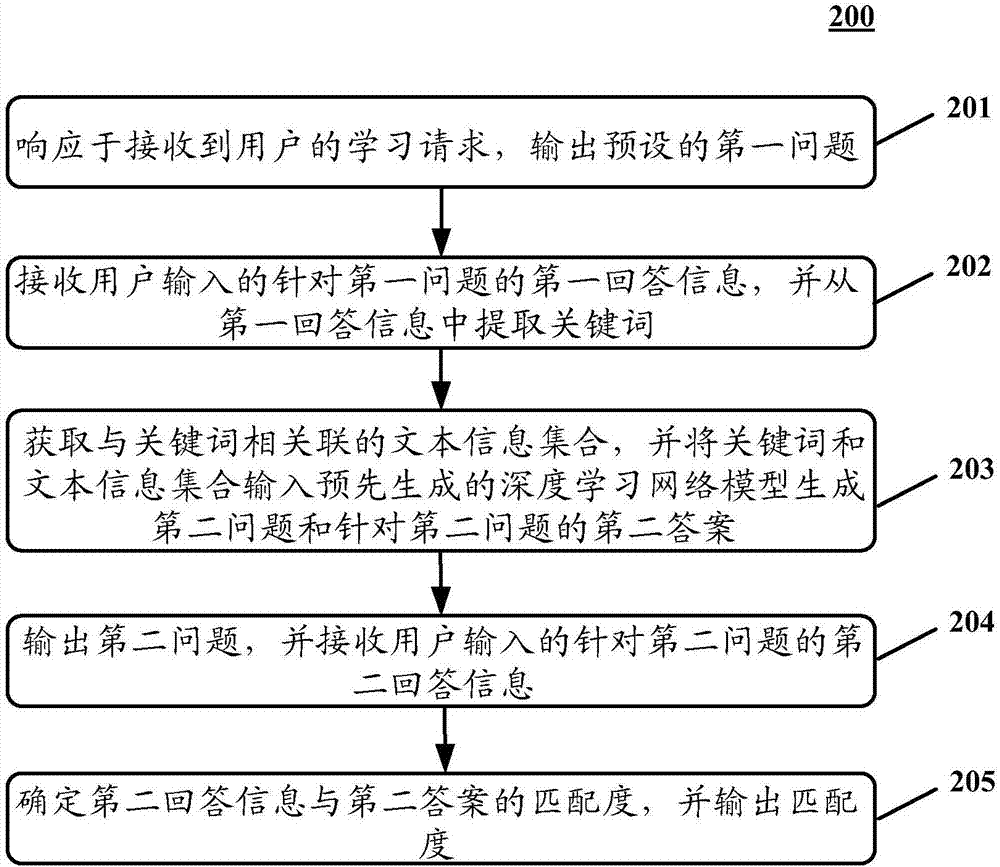

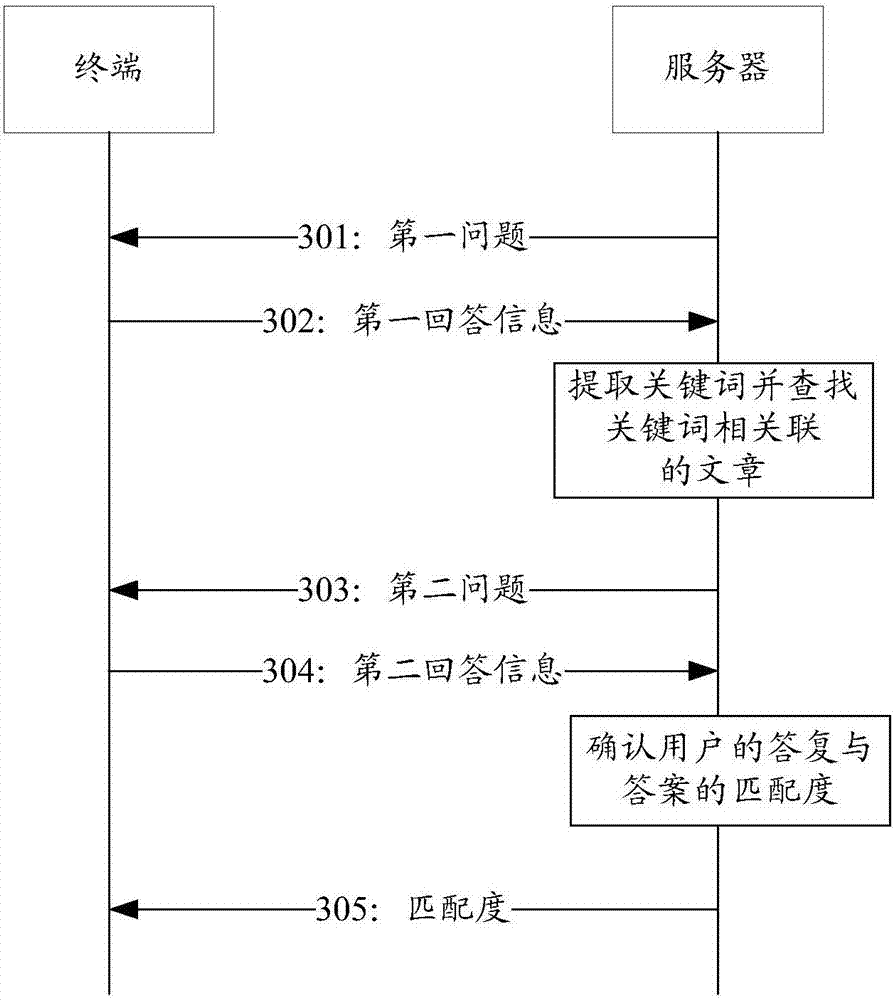

Information output method and information output device

InactiveCN107133303AImprove masteryData processing applicationsSpecial data processing applicationsUser inputOutput device

The invention discloses an information output method and an information output device. The information output method includes outputting a preset first problem by responding to that a learning request of a user is received; receiving first answering information of the first problem inputted by the user, and extracting keywords from the first answering information; acquiring a text information set related to the keywords, and inputting the keywords and the text information set into a pre-generated deep learning network model to generate a second problem and a second answer of the second problem, wherein the deep learning network model is used for representing the relations among the text information, the keywords, the problem and the answer; outputting the second problem, and receiving second answering information of the second problem inputted by the user; determining the matching degree of the second answering information and the second answer and outputting the matching degree. The information output method is capable of achieving targeted detection of learning conditions of the user and adjusting learning schemes according to detection results.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

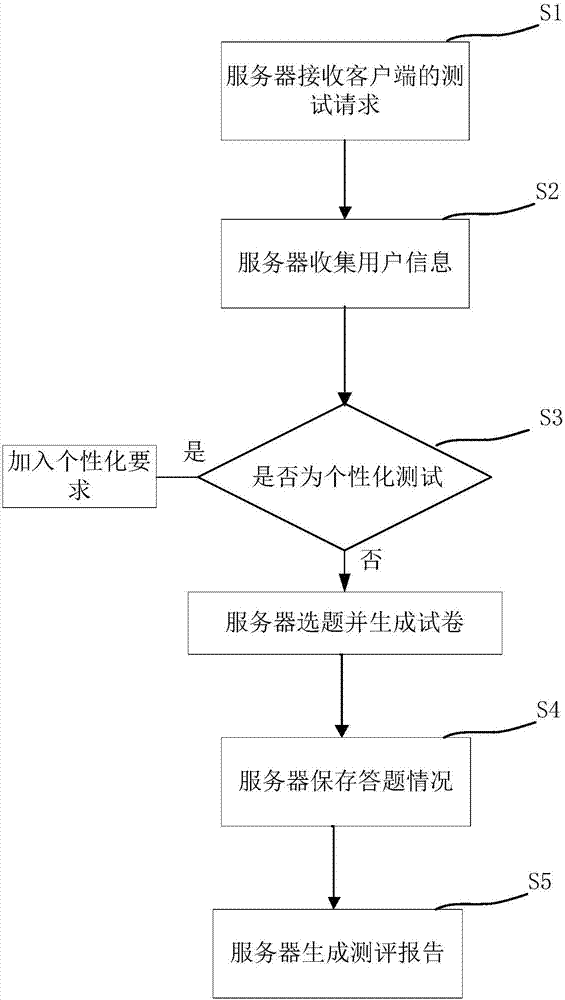

Examinee self-assessment method based on BS architecture

InactiveCN107483397ANot affected by the test environmentAdd funResourcesTransmissionPersonalizationSoftware engineering

The invention relates to an examinee self-assessment method based on BS architecture. The method comprises the following steps: S1, a server receives a testing request of a client, wherein the testing request includes user account information and a testing type; S2, the server collects the mistakes and marked topics in exercise and testing records of the user according to the user account information; S3, the server judges whether the testing type is the personalized testing, if the testing type is the personalized testing, a personalization requirement is added to a topic selection limiting condition, and the server enters the step S4; or, the server directly enters the step S4; S4, the server generates a test paper to send to a client; S5, the server receives a answer result sent by the client, and judges, records and saves the answer situation; and S6, the server generates an assessment result by synthesizing this testing result and the user historic answer record. Compared with the prior art, the user can perform intensive training, understand the knowledge mastering situation, perform the horizontal and vertical comparisons through the help of the self-assessment method disclosed by the invention.

Owner:上海高顿教育培训有限公司

Instruction follow up method

InactiveUS20060115801A1Increase information retentionImprove masteryElectrical appliancesTeaching apparatusObjective informationTraining program

The present invention provides a method of enhancing the retention of learning objective information imparted to a student during an event training program. The method includes performing assigned activities by the student following the event training, which activities include tasks putting into actual practice in the student's daily activities, objective information imparted to the student during the event training program, and participation by the student in one or more follow up conference sessions during which sessions the learning objective information imparted to the student during the event training is reinforced through predetermined discussion conducted by a follow up program facilitator. The preparation of content material for each follow up session is predicated upon and includes the original content of the event training, along with information gathered from each student prior to each follow up session, such information including the culmination of student experiences learning the content in performing the assigned activities. The discussion at the follow up conference includes comments from the student on experiences gained from actual practice of the tasks. The retention of learning objective information by a student after an event training program is evaluated, the evaluation including an assessment of assignments completed by the student and by the student's participation in the discussion.

Owner:GANLEY CHRISTINE +1

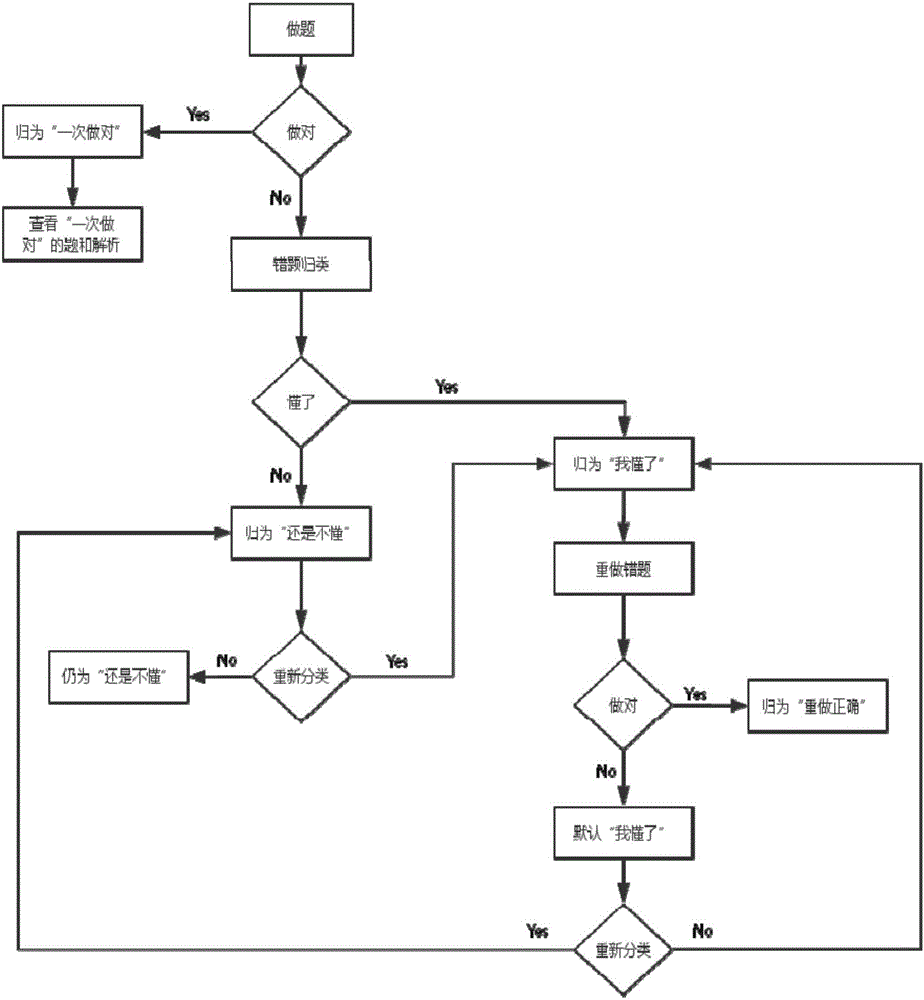

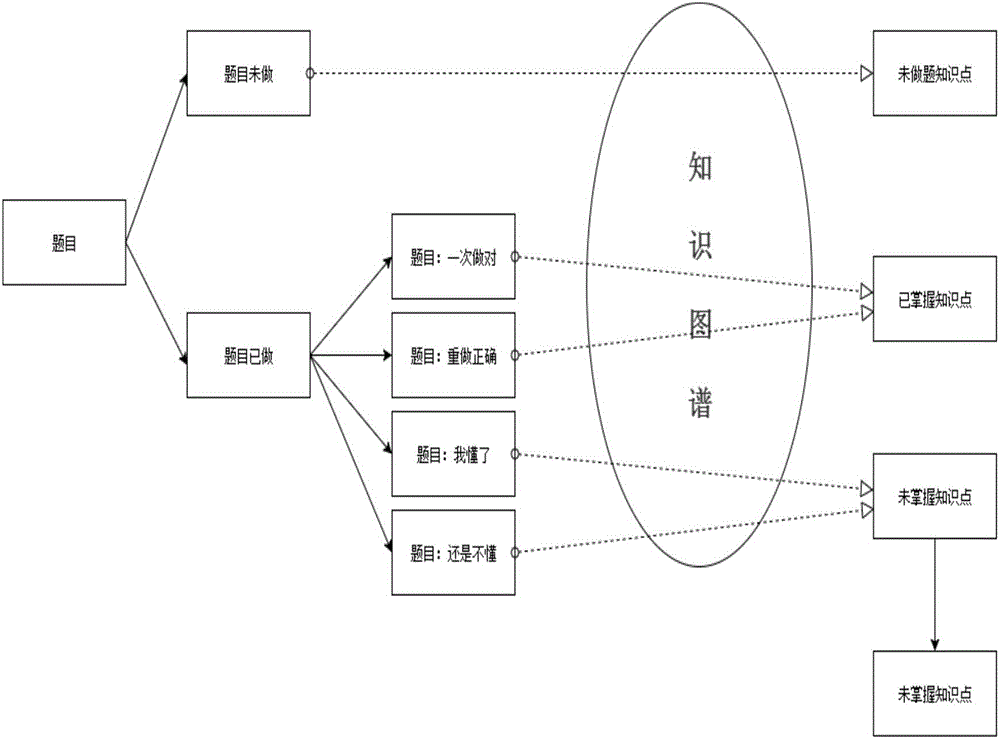

Question detailed classification method

ActiveCN106503074AAvoid multiple pointless redoesImprove real-time performanceRelational databasesSpecial data processing applicationsClassification methodsData mining

The invention relates to a question detailed classification method which is used for conducting detailed classification on questions according to answer and feedback results of users. The method comprises the steps of database building, wherein a database is built and comprises a question bank, a resource bank, a knowledge point bank, a user answer result bank and a knowledge point mastering result bank; question detailed classification, wherein detailed classification is conducted on questions in the question bank according to the answer and feedback results of the users, and classification results are stored in a user answer result bank; knowledge point mastering situation analysis, wherein the questions in the question bank and knowledge points in a knowledge point bank are related, the mastering situation of the users on the knowledge points is analyzed according to the answer and feedback results of the users, and analysis results are stored in the knowledge point mastering result bank. Compared with the prior art, the method has the advantages of being high in adaptability, high in individuation degree, capable of enabling the users to master the knowledge points conveniently and observing the mastering results easily and the like.

Owner:上海高顿教育科技有限公司

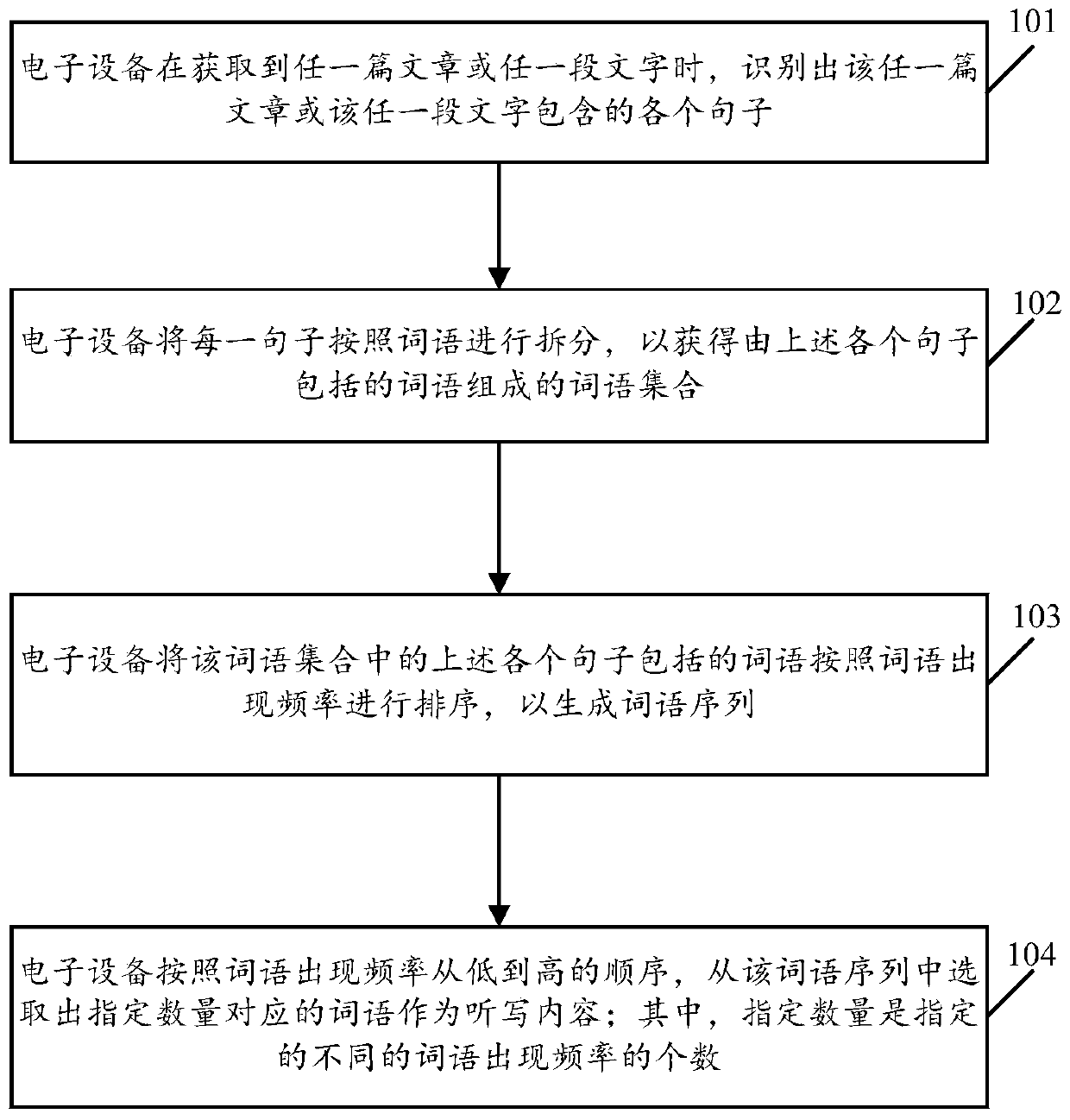

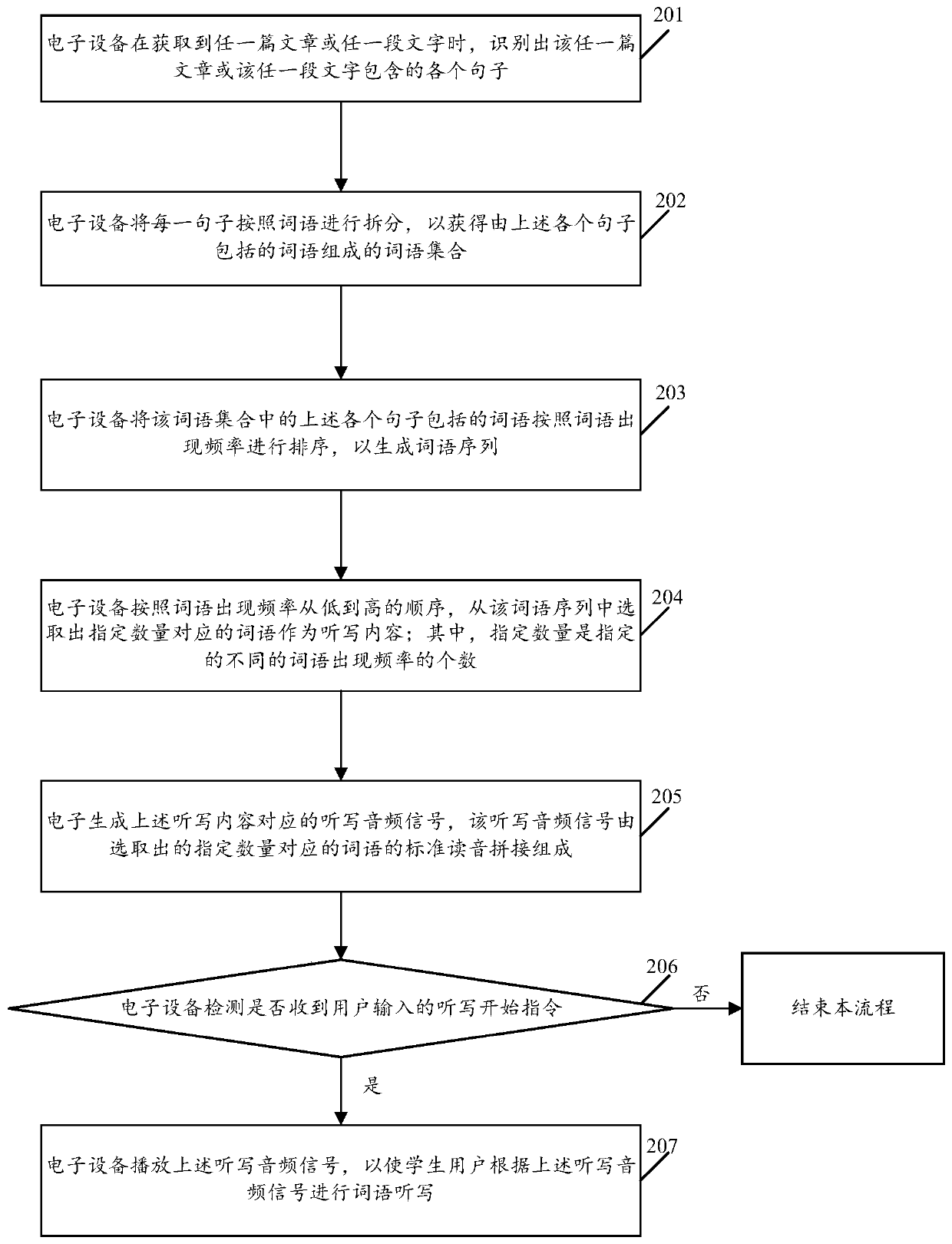

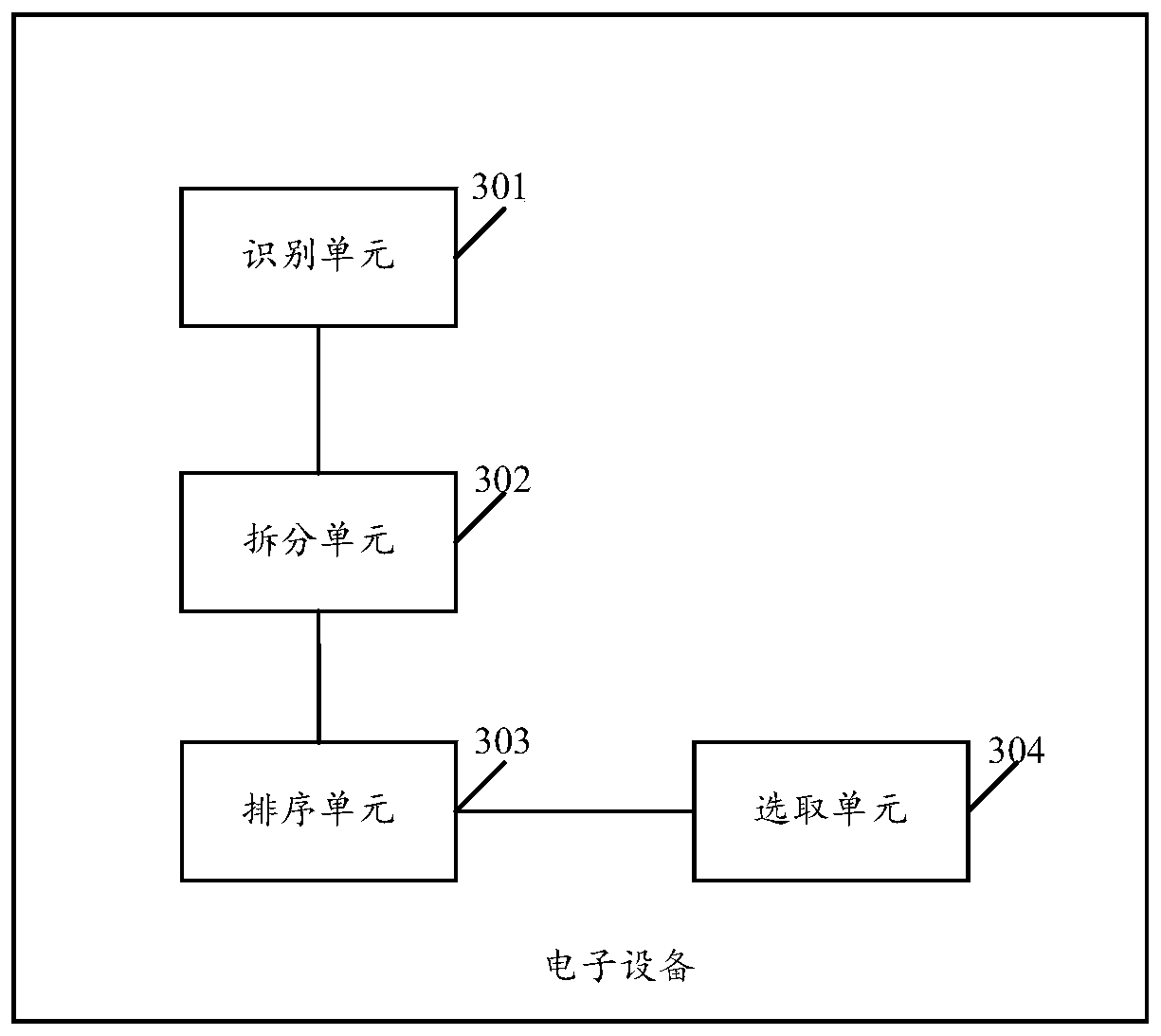

Dictation content generation method and electronic equipment

PendingCN109960809AImprove production efficiencyImprove masteryData processing applicationsCharacter and pattern recognitionContent generationSpeech recognition

The invention discloses a dictation content generation method and electronic equipment, and the method comprises the steps: when identifying any article or any text segment, identifying each sentencecontained in the article or the text segment; splitting each sentence according to words to obtain a word set composed of words included in each sentence; sorting words included in each sentence in the word set according to word occurrence frequency to generate a word sequence; according to the sequence of the word occurrence frequencies from low to high, selecting the words corresponding to the specified number from the word sequence as dictation contents; wherein the specified number is the number of specified different word occurrence frequencies. By implementing the embodiment of the invention, not only can the generation efficiency of the dictation content be improved, but also the mastery degree of students on the dictation content (such as words) with lower occurrence frequency canbe improved.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

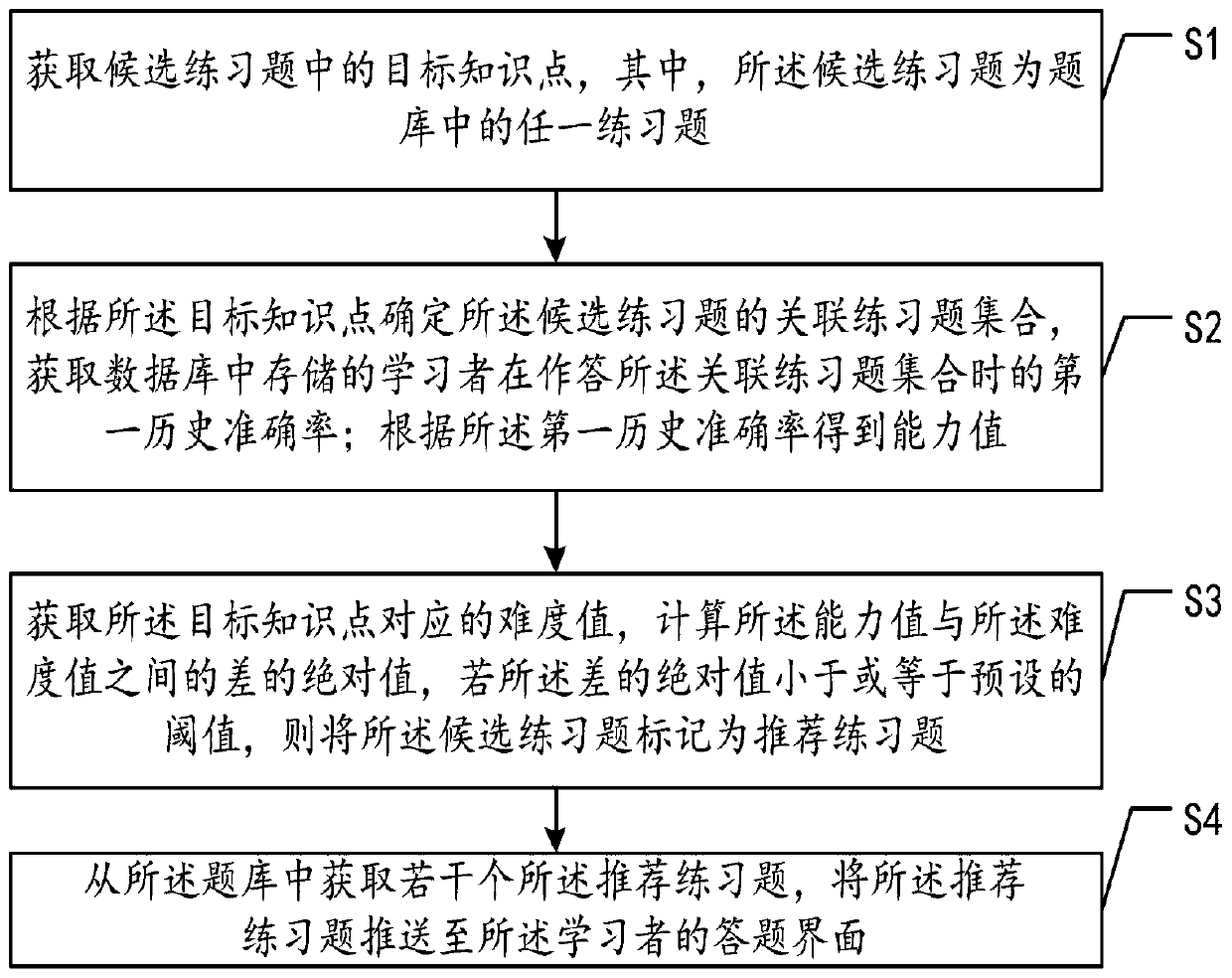

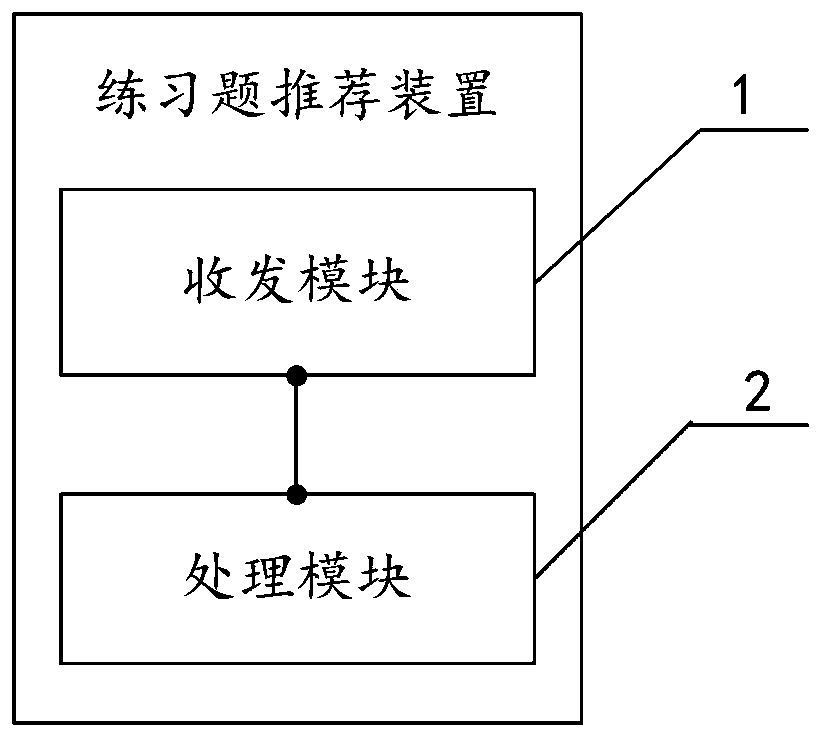

Exercise question recommendation method and device, equipment and storage medium

ActiveCN110413728AImprove masteryData processing applicationsText database queryingComputer scienceBig data

The invention relates to the field of big data, and provides an exercise recommendation method, a device, equipment and a storage medium, and the method comprises the steps: obtaining target knowledgepoints of candidate exercises; determining an associated exercise set of the candidate exercises according to the target knowledge point to obtain a first historical accuracy rate of a learner when answering the associated exercise set stored in a database; obtaining a difficulty value corresponding to the target knowledge point, and calculating an absolute value of a difference between the capability value and the difficulty value; if the absolute value of the difference is smaller than or equal to a preset threshold value, marking the candidate exercises as recommended exercises; and obtaining a plurality of recommended exercises from the question bank, and pushing the recommended exercises to an answering interface of the learner. A plurality of recommended exercises are obtained by comparing the ability value with the difficulty value, and the recommended exercises are recommended to the learner; according to the answer accuracy of the learner, the ability value of the learner relative to the knowledge points is continuously updated, the suitable exercises are recommended to the learner, and the learning efficiency of the learner is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Information processing method and electronic device

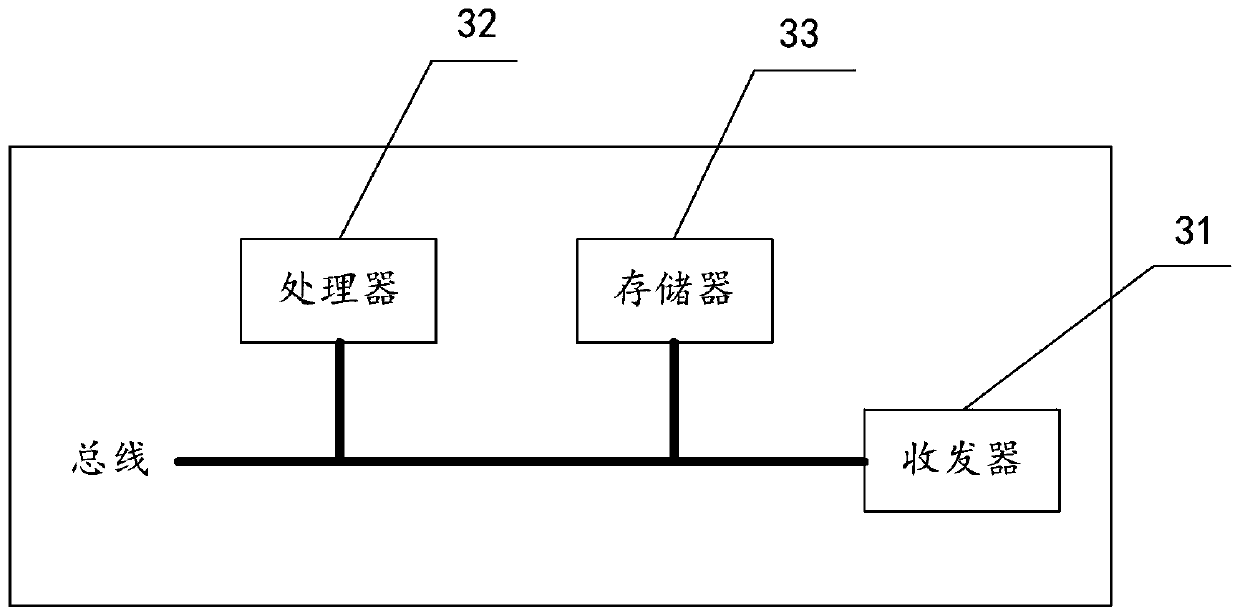

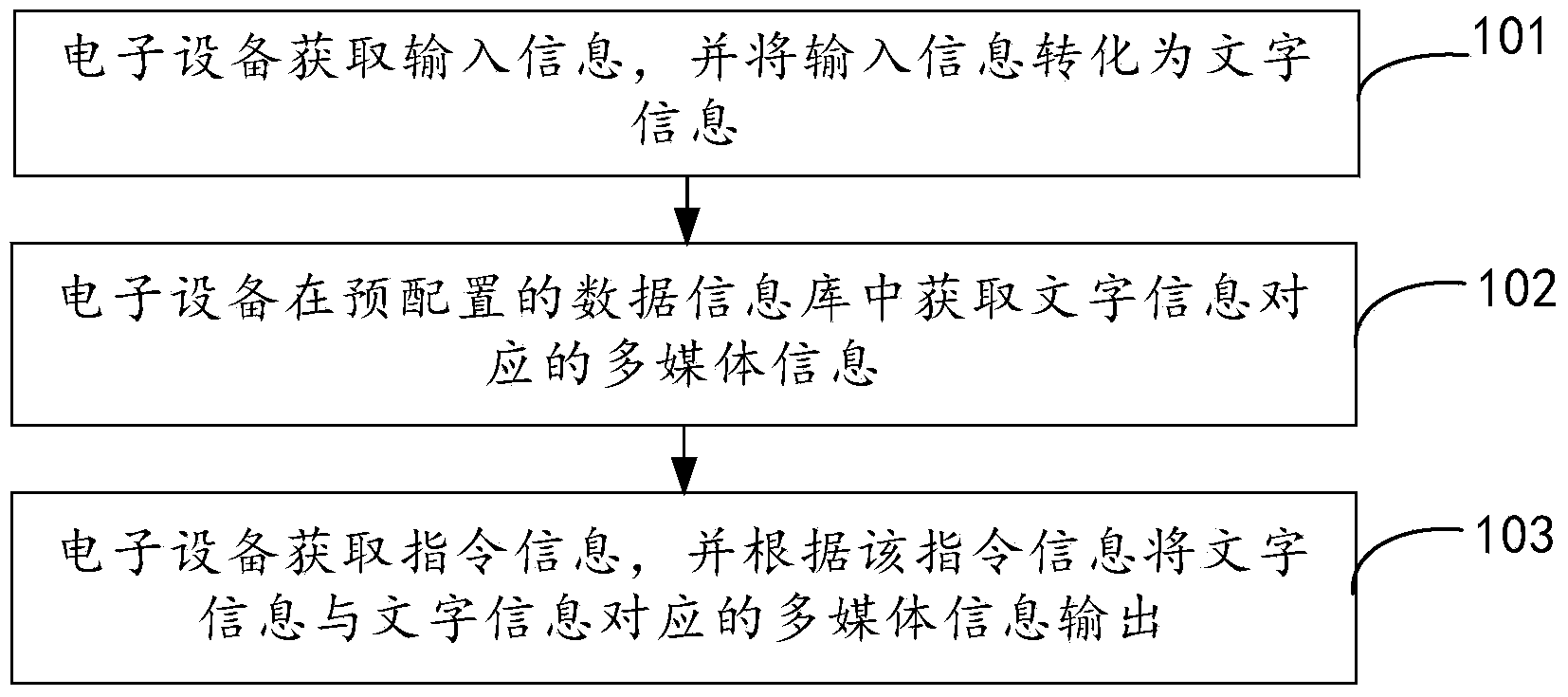

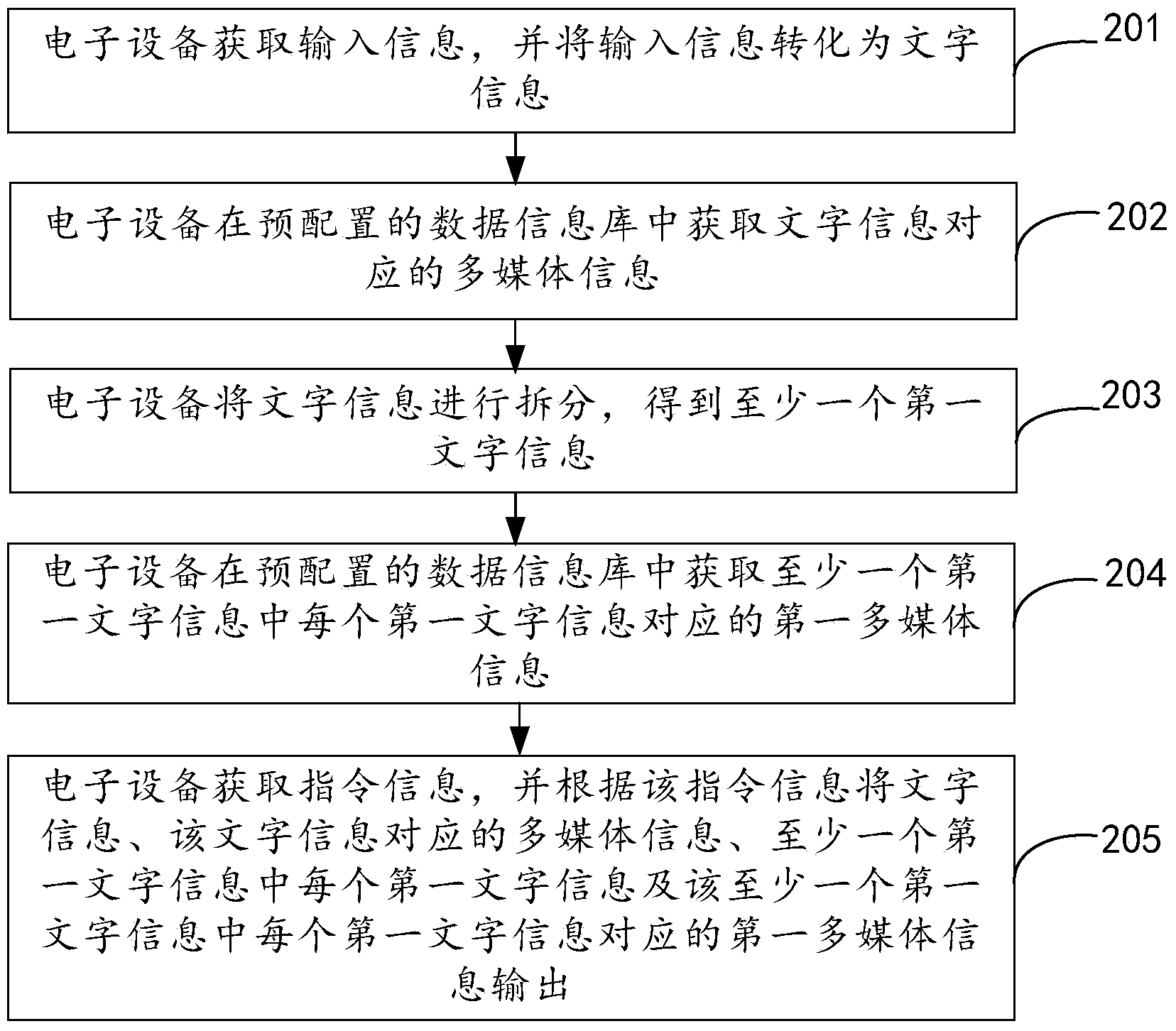

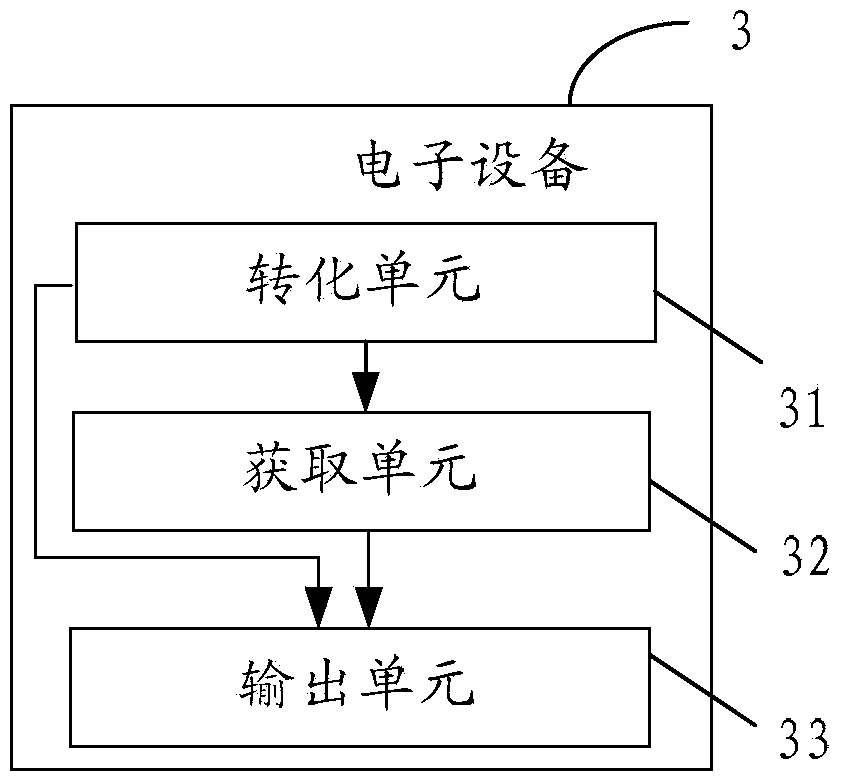

ActiveCN103714724AImprove interactivityImprove masteryElectrical appliancesSpecial data processing applicationsData informationMultimedia information

The embodiment of the invention relates to the technical field of electronic technology and the field of education and provides an information processing method and an electronic device. Interaction capacity between a user and the electronic device can be improved. The method particularly comprises the following steps that input information is acquired, the input information is converted into text information; multi-medium information corresponding to the text information is acquired in a pre-configured data information base; the data information base comprises a mapping relation table of the text information and the multi-medium information; instruction information is acquired, and the text information and the multi-medium information corresponding to the text information are output according to the instruction information. The information processing method and the electronic device are applied to the text teaching process.

Owner:JIANGXI MIISI TECH

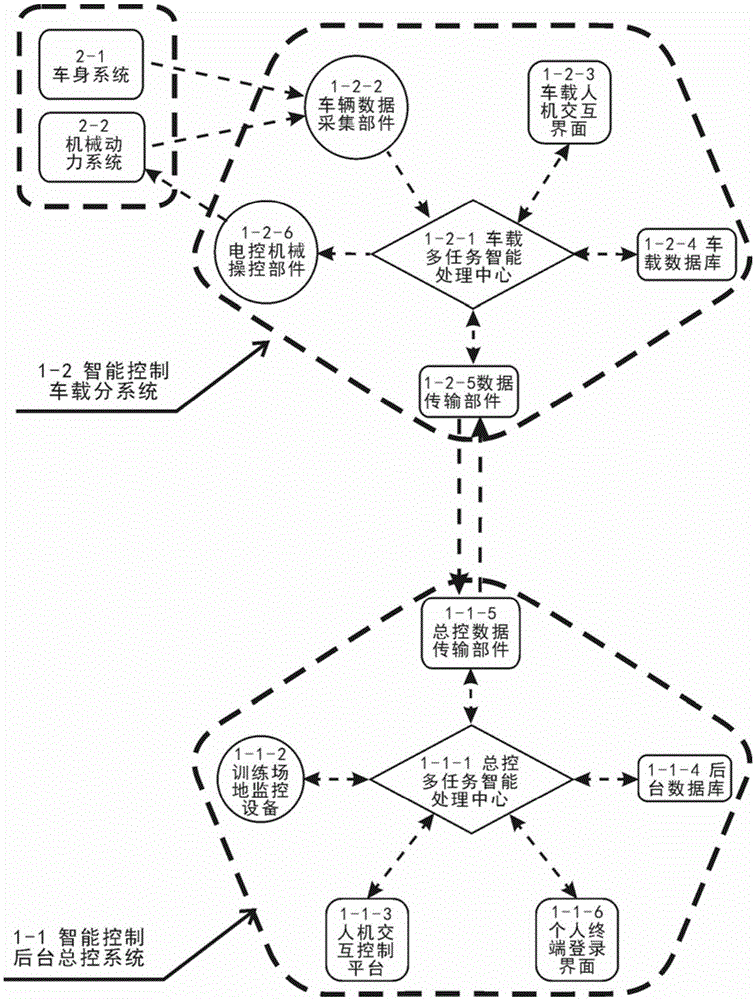

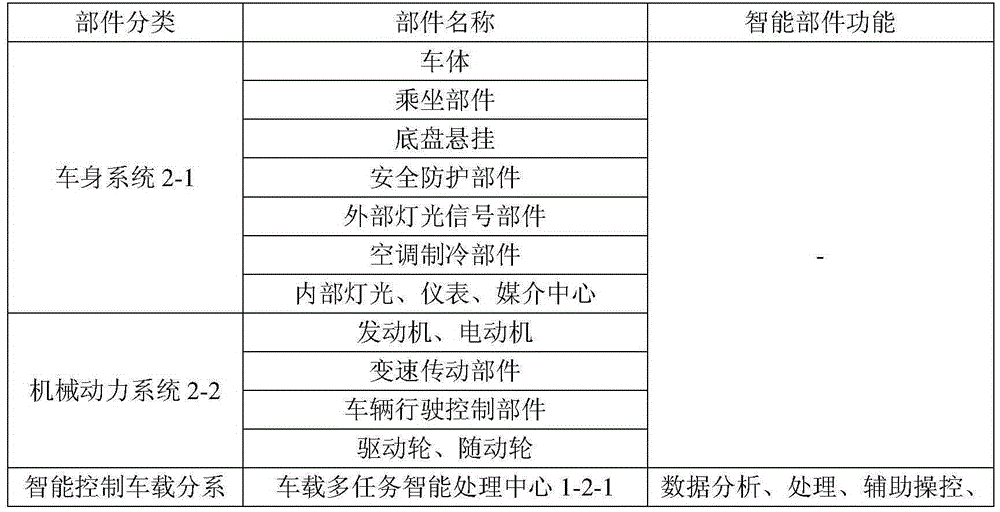

Intelligent vehicle driving training system

ActiveCN105261259AGet hands-onAchieving Integrated LearningTeaching apparatusData connectionDriver/operator

The invention discloses an intelligent vehicle driving training system, which is composed of an intelligent control system and an intelligent control driving coach vehicle in cooperative and matched work. The intelligent control system comprises an intelligent control backstage general control system and an intelligent control vehicle-mounted subsystem, and the intelligent control backstage general control system and the intelligent control vehicle-mounted subsystem are in data connection via an information network. The intelligent vehicle driving training system has the beneficial and technical effects that the existing driver training mode is changed, the existing driving training vehicle is updated to an intelligent tool, and during the driving process, voice and dynamic image assistant help is provided for a driving learner and the coach via a man-machine interactive system; high-tech equipment and internet information sharing technology are used massively, a vehicle driving learning interconnection scheme is creatively provided, intelligent assistant control and data storage functions of a remote server are enhanced, and driving data of the learner are comprehensively judged via the intelligent system in combination with examination of the backstage operator.

Owner:杜霄鹤

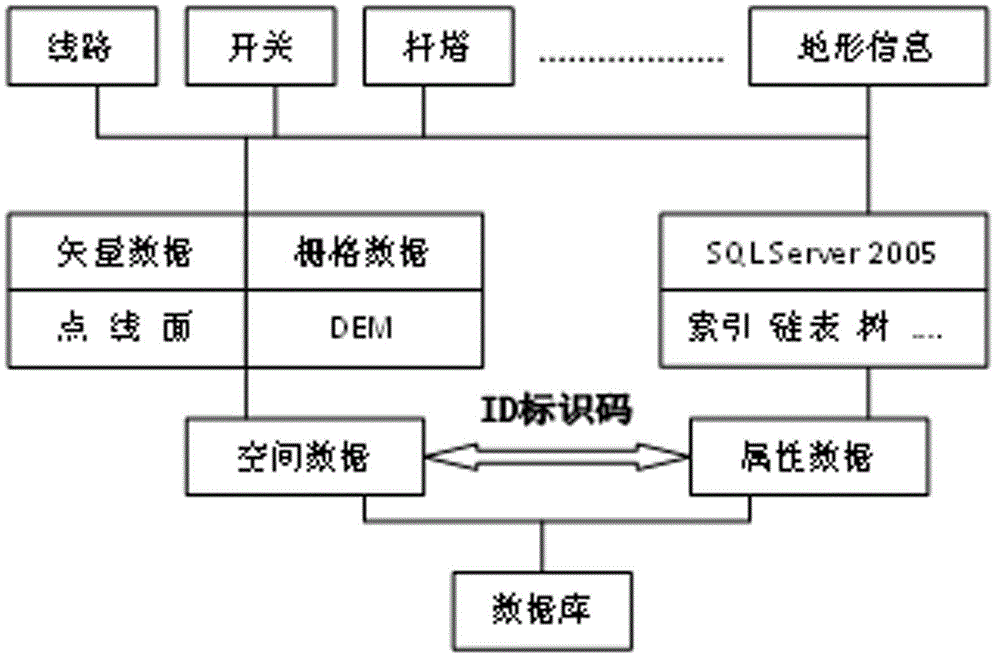

Three-dimensional geographic information management system

The invention discloses a three-dimensional geographic information management system. The three-dimensional geographic information management system is characterized by comprising a geographic information query and management system, a three-dimensional infrastructure and equipment scene query and management system and a three-dimensional pipeline facility scene query and management system. The geographic information query and management system is capable of establishing and showing real morphosequent and integrating vector line information of traffic roads, rivers, vegetations and settlement places to provide basic geographic data for subsequent planning, designing and maintaining. After a user loads station and pipeline models, the three-dimensional infrastructure and equipment scene query and management system is capable of browsing infrastructures from different angles. The three-dimensional pipeline facility scene query and management system is capable of directly displaying numbers, materials, specification information and conveying medium names of pipelines inside and outside a station to realize pipeline query according to different media, models, types and affiliated regions, and query results are displayed in a table or graphic mode and supportive to printing or exporting and can be dynamically displayed in highlighted and blinking manners to enable clearness of all of the pipelines different in specification and medium.

Owner:DALIAN LINGDONG TECH DEV

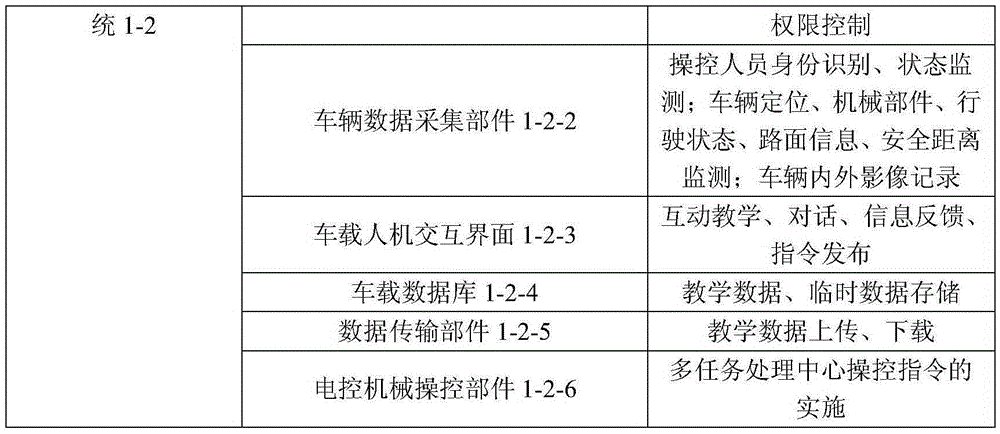

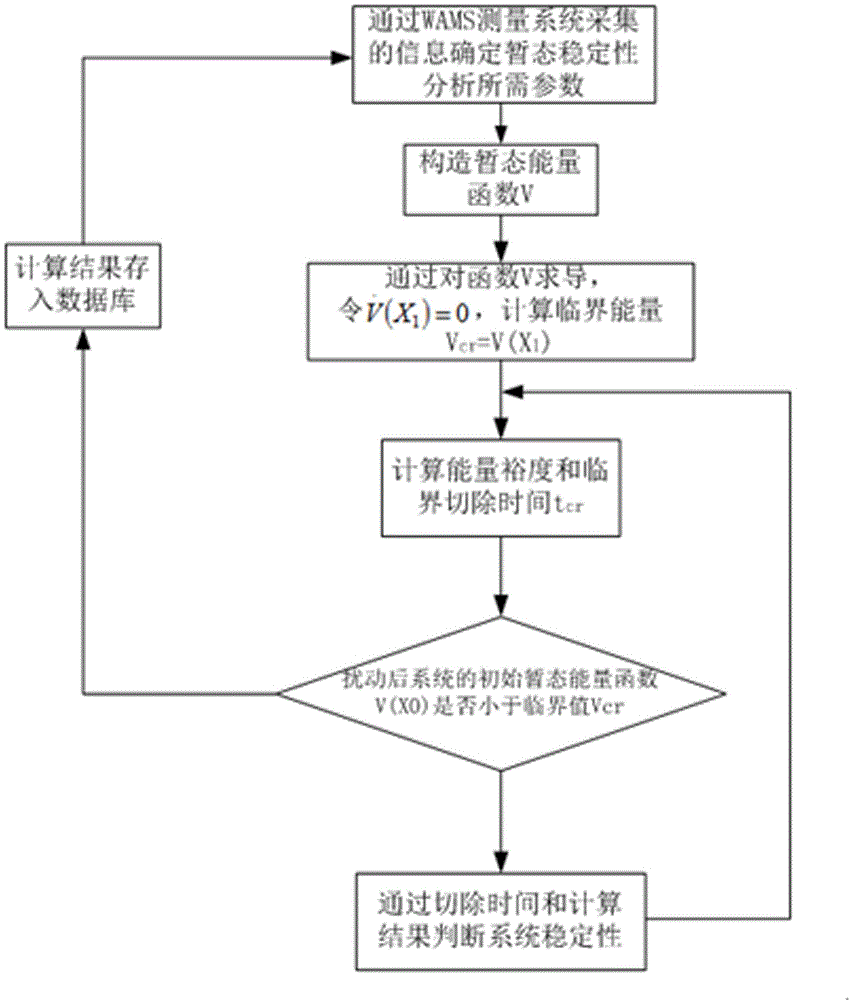

Power grid stability margin visualized display method based GIS

ActiveCN105656028AEasy to learnReduce misjudgmentSpecial data processing applicationsInformation technology support systemElectric power systemEconomic benefits

The invention discloses a power grid stability margin visualized display method based a GIS. The method comprises the following steps of: obtaining measurement data of an electric power system wide area measurement system; carrying out state estimation on the measurement data of the electric power system wide area measurement system; directly reading data after state estimation correction; carrying out dynamic modeling according the data after the state estimation correction; and carrying out visualized display on a critical stable value and a stability margin of an equivalent electric power system. The power grid stability margin visualized display method has the advantages that equivalence processing on whole network data or on data outside the research range in the stability margin calculating process is omitted, the calculating time and resources are saved, and a huge economic benefit is generated. The regional stability margin is displayed in a geographical information map mode, the angle of stability condition display and judging is expanded from point and line to plane, so that people can globally grasp the stability condition of the electric power system more visually and effectively, better learning and application of control personnel are facilitated, and the stable operation of the electric power system is ensured.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

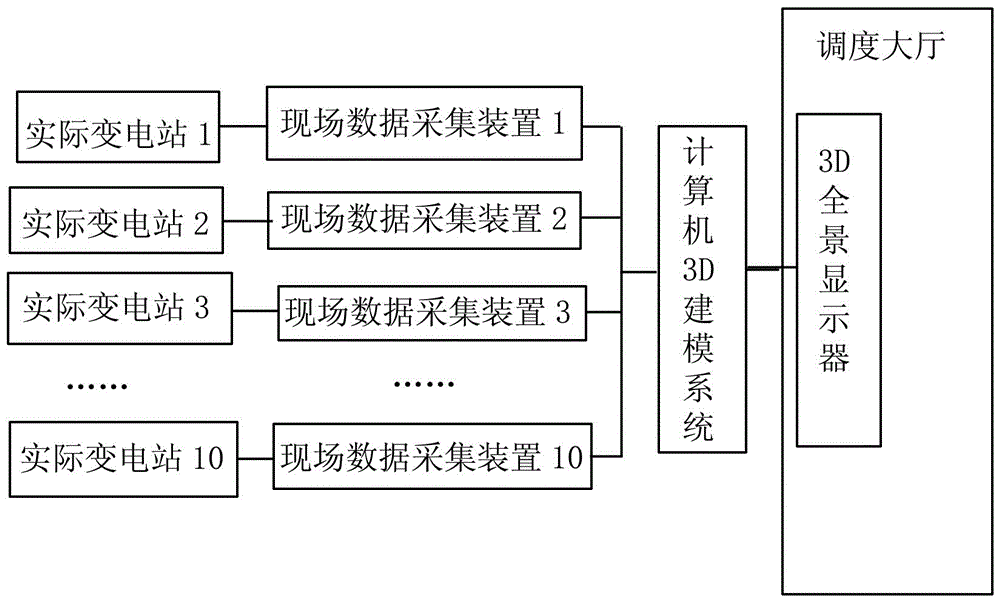

3D substation panoramic real-time control system based on virtual simulation technology

PendingCN105894576AImprove masteryImprove understandingData processing applications3D modellingReal-time Control SystemReal-time data

The invention discloses a 3D substation panoramic real-time control system based on a virtual simulation technology. A plurality of field data acquisition devices are respectively mounted on a plurality of actual substations. The output ends of the field data acquisition devices are connected with the input end of a control system. The output end of the control system is connected with the input end of a computer 3D modeling system. The output end of the computer 3D modeling system is connected with a 3D panoramic display in a dispatching hall. The field data acquisition devices are used for surveying and mapping the substation sites and collecting the relative positions, deviation angles and actual sizes of all equipment in the substations. The control system is used for adjusting the parameters of the relative positions, deviation angles and actual sizes and transmitting the adjusted real-time data to the computer 3D modeling system. The computer 3D modeling system carries out 3D modeling of the original equipment according to the collected and processed data and carrying out 360-degree panoramic display of the modeled equipment models.

Owner:STATE GRID CORP OF CHINA +2

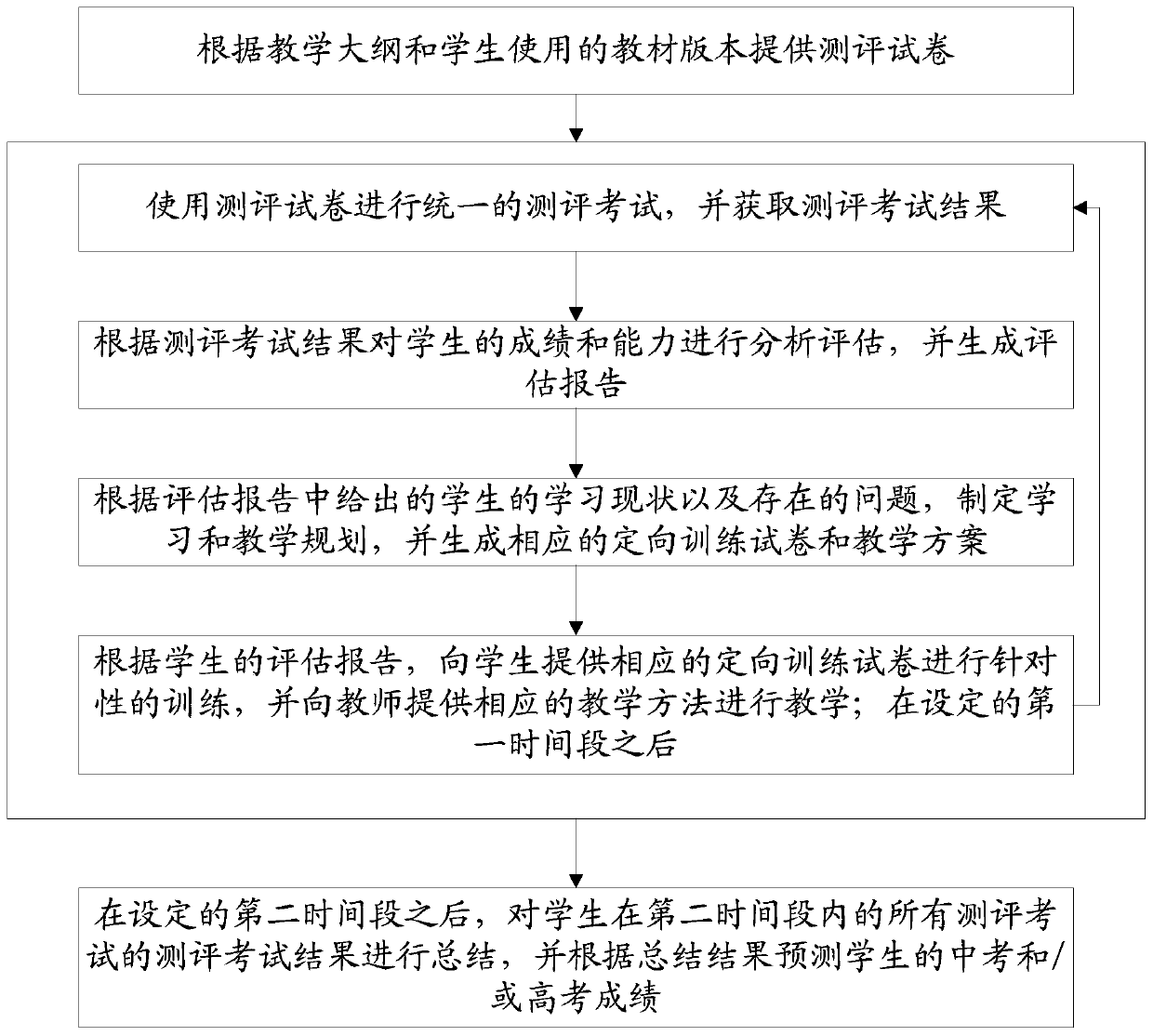

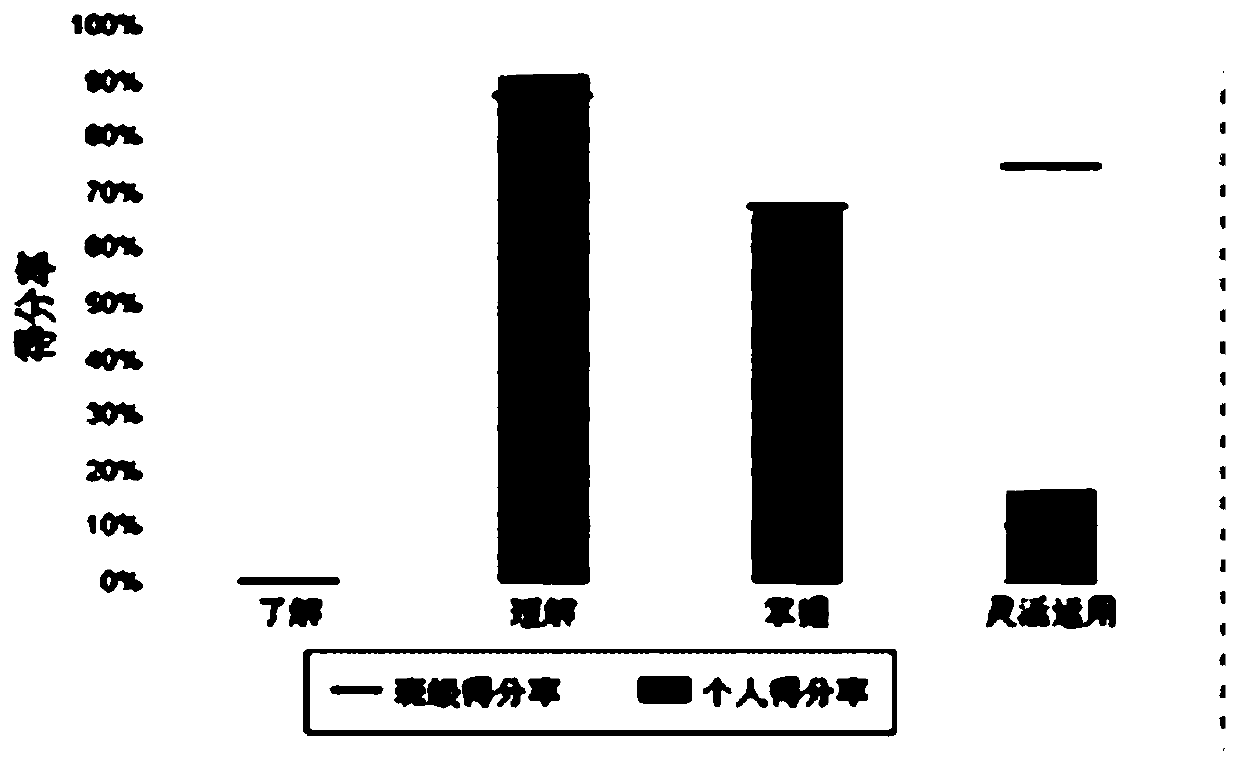

Primary and secondary school student academic ability evaluation method and system

PendingCN110490467AImprove masteryImprove the level of teaching and researchResourcesStudy planningComputer science

The invention discloses a primary and secondary school student academic ability evaluation method and system. The method comprises: providing an evaluation test paper; performing an evaluation test byusing the evaluation test paper to obtain an evaluation test result; formulating learning and teaching plans according to an evaluation report generated according to the evaluation examination result, and generating directional training examination paper and a teaching scheme; according to the evaluation report, providing corresponding directional training test paper for targeted training, and providing a teaching method for teaching; after the first time period, executing the evaluation again; and after the second time period, summarizing the evaluation examination results of all the evaluation examinations of the students, and predicting the scores of the middle school examinations and / or college entrance examinations of the students. The method and system has the advantages that the scores of students can be accurately evaluated, the defects can be found, targeted learning plans can be executed for the defects, and missing inspection and vacancy filling are carried out; and the middle school or college entrance examination scores of the students are scientifically predicted according to the test scores, so that the students can know their own defects in advance and prepare formiddle school examination and college entrance examination.

Owner:常州易学网络科技有限公司

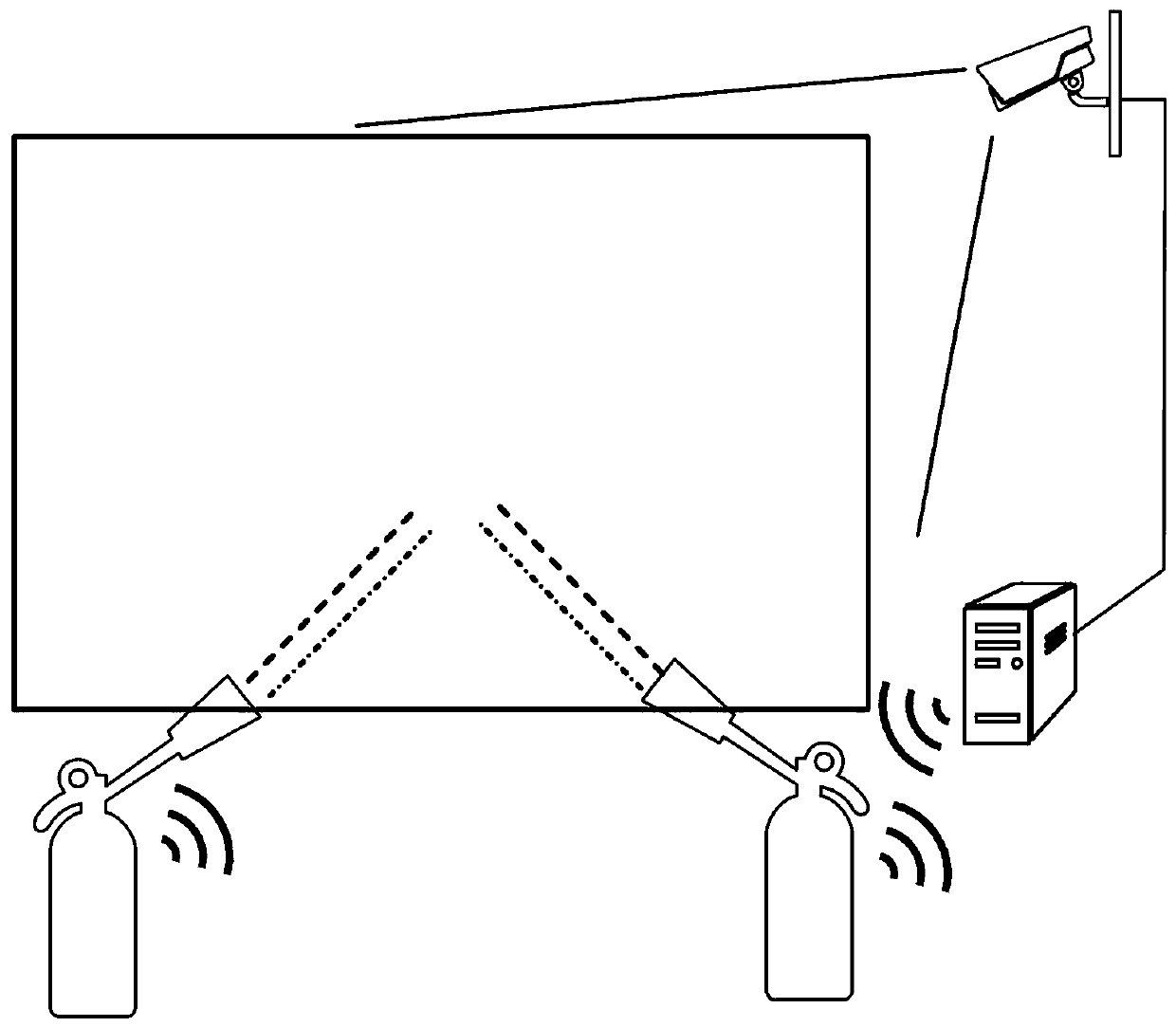

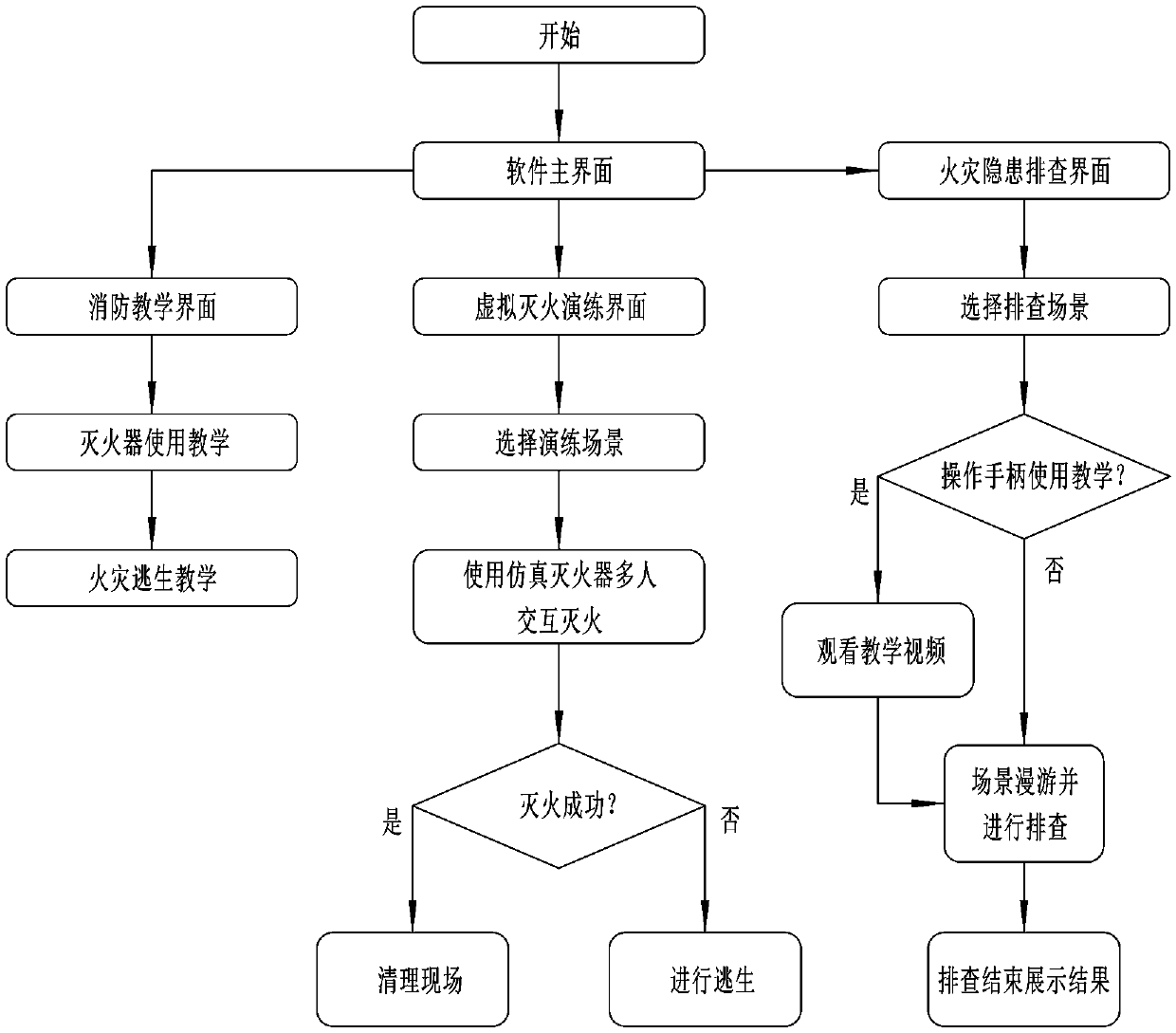

Virtual firefighting training device based on Unity3D

ActiveCN109767668AImprove masteryHighlight substantive featuresCosmonautic condition simulationsSimulatorsSurveillance cameraFirefighting

The invention provides a virtual firefighting training device based on Unity3D, which comprises a simulated fire extinguisher, a screen, a monitoring camera, a projector, VR equipment, an operating handle and a monitoring terminal. Fire extinguishing practical training software is installed on the monitoring terminal; and the fire extinguishing practical training software comprises a firefightingteaching unit, a fire extinguishing virtual drill unit and a fire potential risk identification unit. The invention provides the virtual firefighting training device based on Unity3D; the problem thatan existing virtual fire extinguishing system cannot effectively distinguish a type of a fire extinguisher used by a tester is solved; whether the tester masters a correct fire extinguishing mode canbe judged; the virtual firefighting training device is beneficial for greatly improving the mastering degree of the tester for fire extinguishing of the fire extinguisher; and in addition, the dangerin fire extinguishing practical training in reality also can be effectively avoided.

Owner:ZHENGZHOU WONDER ELECTRICAL POWER

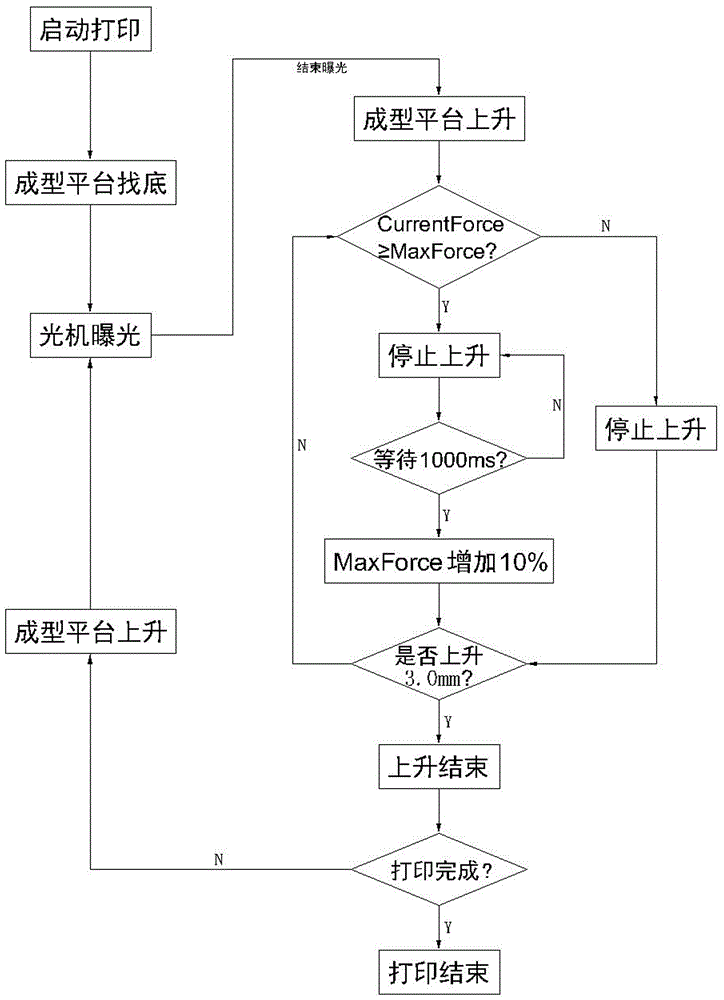

3D printing method based on force feedback system

ActiveCN106273513AGuaranteed print qualityIncrease success rateAdditive manufacturing apparatusEngineeringMotor drive

The invention discloses a 3D printing method based on a force feedback system. The method includes the following steps that firstly, when printing is started, a motor drives a forming platform to begin to move downwards, and the force feedback system controls the forming platform to successfully find the bottom; secondly, exposure printing of a first layer is carried out; thirdly, after exposure is finished, the forming platform moves upwards for stripping, and meanwhile the current stripping force CurrentForce is compared with a threshold value MaxForce set in the current state of the force feedback system; fourthly, if CurrentForce>=MaxForce, the forming platform stops moving upwards or moves upwards in a decelerating mode, and the fifth step is executed, and if CurrentForce<MaxForce, the forming platform continues moving upwards, and the sixth step is executed; fifthly, MaxForce is automatically increased by a scale value, and the fourth step is executed again; sixthly, the forming platform stops when moving upwards to a set height distance, and stripping is completed; seventhly, the motor drives the forming platform to move downwards again for exposure printing of a next layer; eighthly, the third step to the seventh step are repeated till printing of a printout is completed. By means of the force feedback system, the printing process is more intelligent, and the printing success rate and the printout quality are greatly improved.

Owner:GUANGZHOU HEYGEARS INTELLIGENT TECH CO LTD

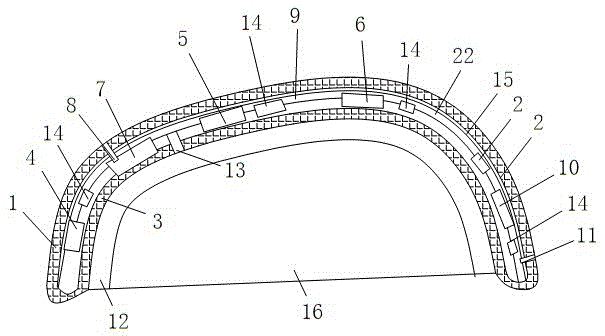

Biochemical sensing helmet for field individual combat based on Beidou navigation satellite system

InactiveCN105520254AImprove masteryFacilitate real-time communicationSatellite radio beaconingHelmetsNatural satelliteBeiDou Navigation Satellite System

The invention discloses a biochemical sensing helmet for field individual combat based on a Beidou navigation satellite system. The biochemical sensing helmet comprises an outer cover and a liner which are connected in sequence, as well as at least one flat interlayer arranged between the outer cover and the liner, wherein each flat interlayer comprises a bag-type main body and an inner cavity, and the inner cavity is internally provided with a Beidou receiving antenna, a storage unit, a miniature locator, an arithmetic unit, a voice module, a biochemical sensor and an alarm which are connected in sequence; and the biochemical sensor senses biochemical signals of human beings except the combating person or animals. With the biochemical sensing helmet, an individual soldier or a logistic system can find the lost protective clothing after a field combat or during the field combat through the terminals on the biochemical sensing helmet, so that the important combat intelligence information can be obtained, the combat data can be analyzed and reserved conveniently, and the necessary intelligence information can be found with the command system or the logistic system; and the individual combat effectiveness index is increased.

Owner:WUHU ZHENHUA RONGKE INTELLIGENT TECH

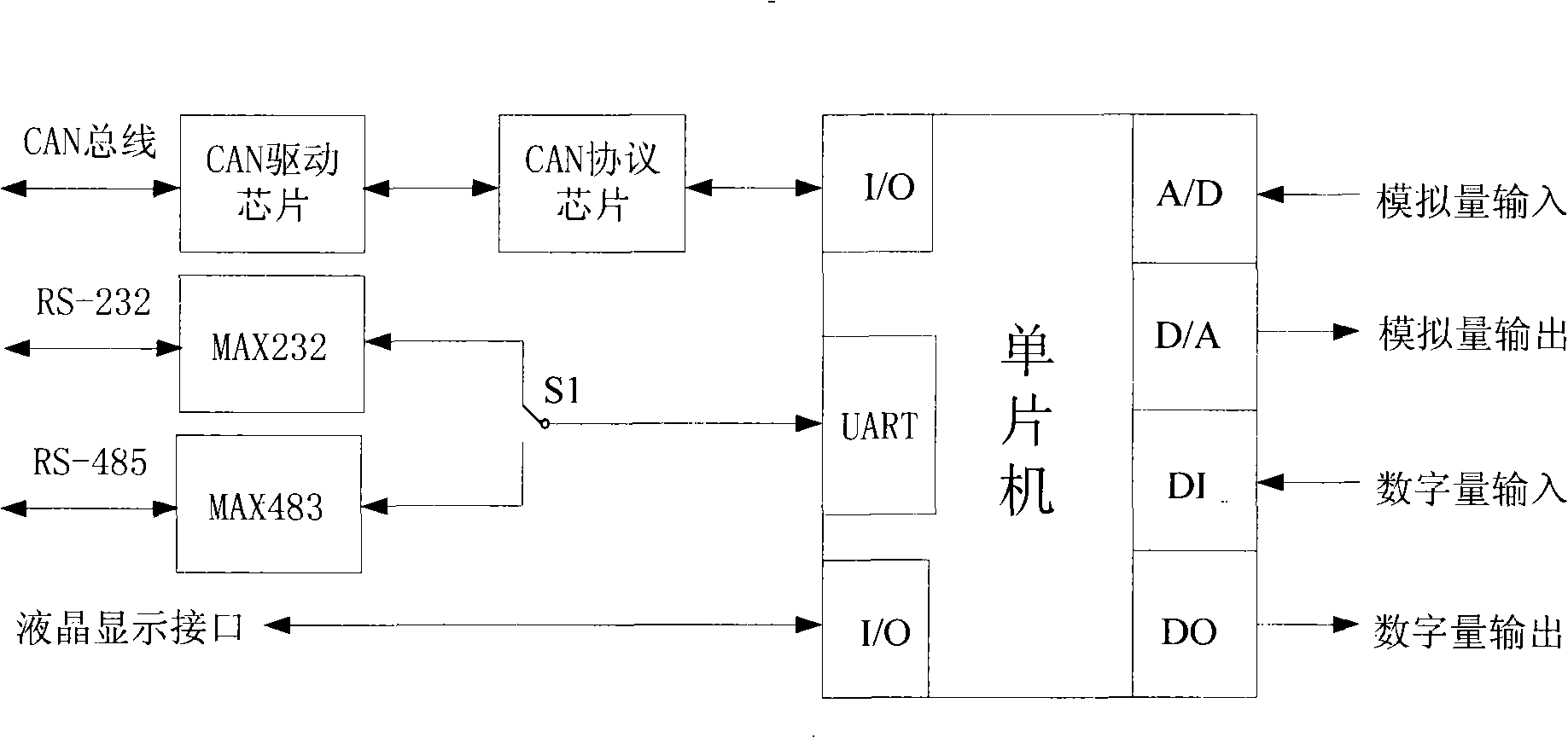

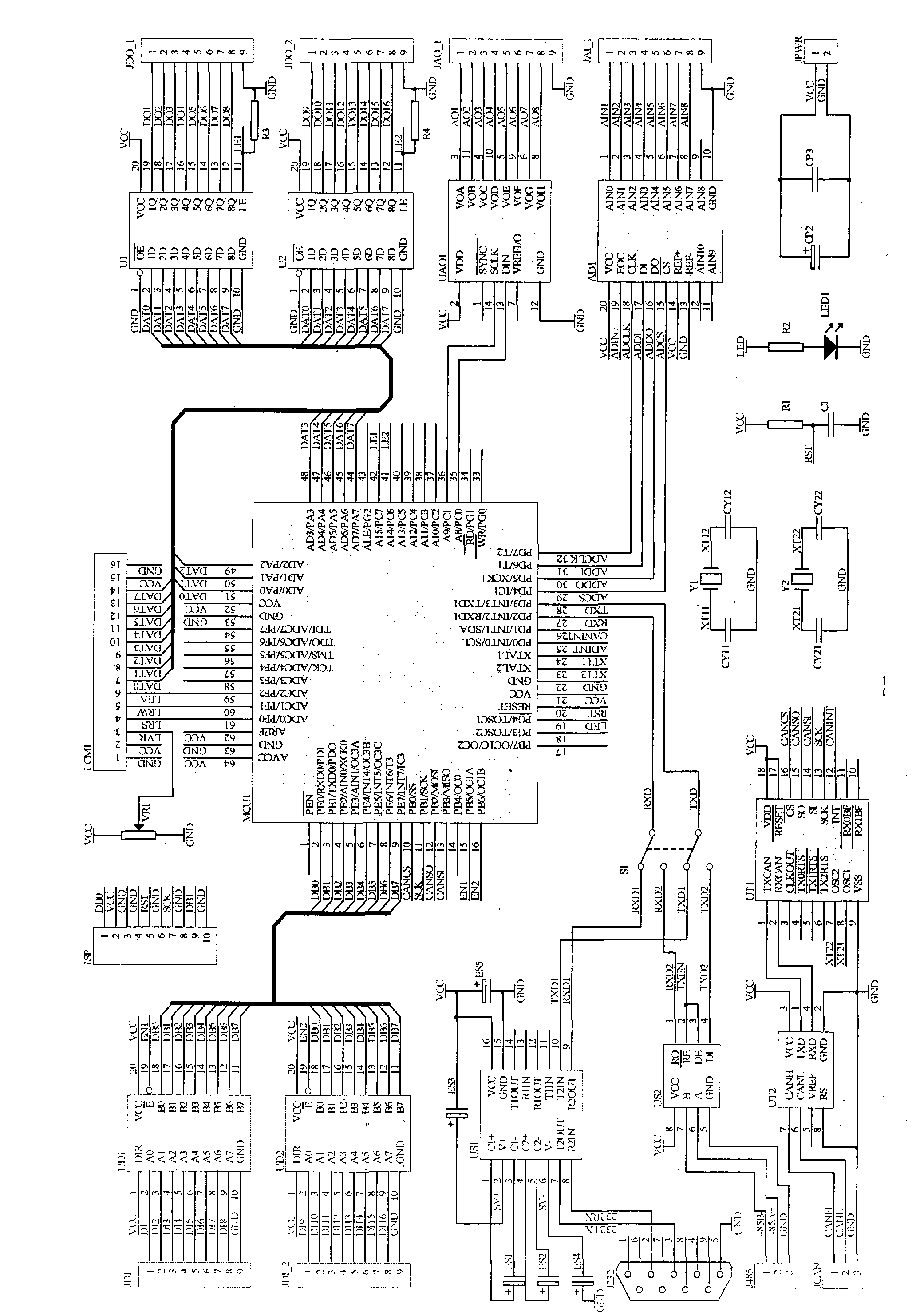

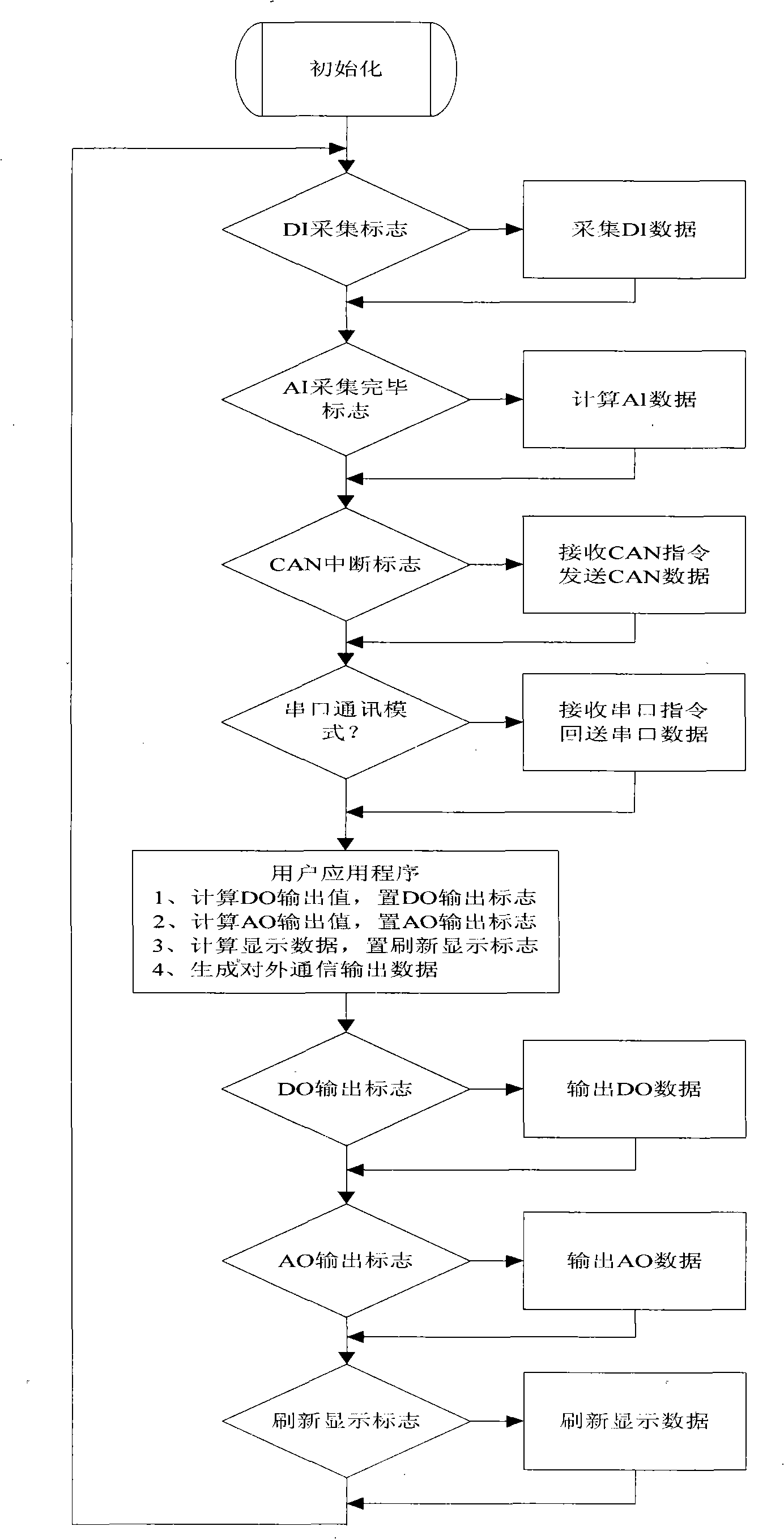

Multifunctional data acquiring-outputting teaching experimental device and control method thereof

InactiveCN101526806AMulti-purposeStrong flexibilityProgramme controlComputer controlMultiple functionMicrocomputer

The invention relates to a multifunctional data acquiring-outputting teaching experimental device and a control method thereof. The device comprises a single chip microcomputer, a digital-quantity input interface, a digital-quantity output interface, an analog-quantity input interface, an analog-quantity output interface and a display interface, wherein the single chip microcomputer stores a control program, is a control core of the whole device, and can acquire or output digital / analog signals; the digital-quantity input interface is formed by connecting the single chip microcomputer to a digital-quantity input terminal through an I / O extension module; the digital-quantity output interface is formed by connecting the single chip microcomputer to a digital-quantity output terminal through a latch; the analog-quantity input interface is formed by connecting the single chip microcomputer to an analog-quantity input terminal through an analog-quantity acquiring module; the analog-quantity output interface is formed by connecting the single chip microcomputer to an analog-quantity output terminal through an analog-quantity output module; the display interface is formed by connecting a display terminal with an I / O pin of the single chip microcomputer; and the control program comprises a main program and an interrupt service processing program. The device has the advantages of numerous functions, strong flexibility, great applicability to teaching, graduation design and extracurricular practice of students, reuse capability, plentiful interfaces, good software generality and good extensibility.

Owner:SHENYANG JIANZHU UNIVERSITY

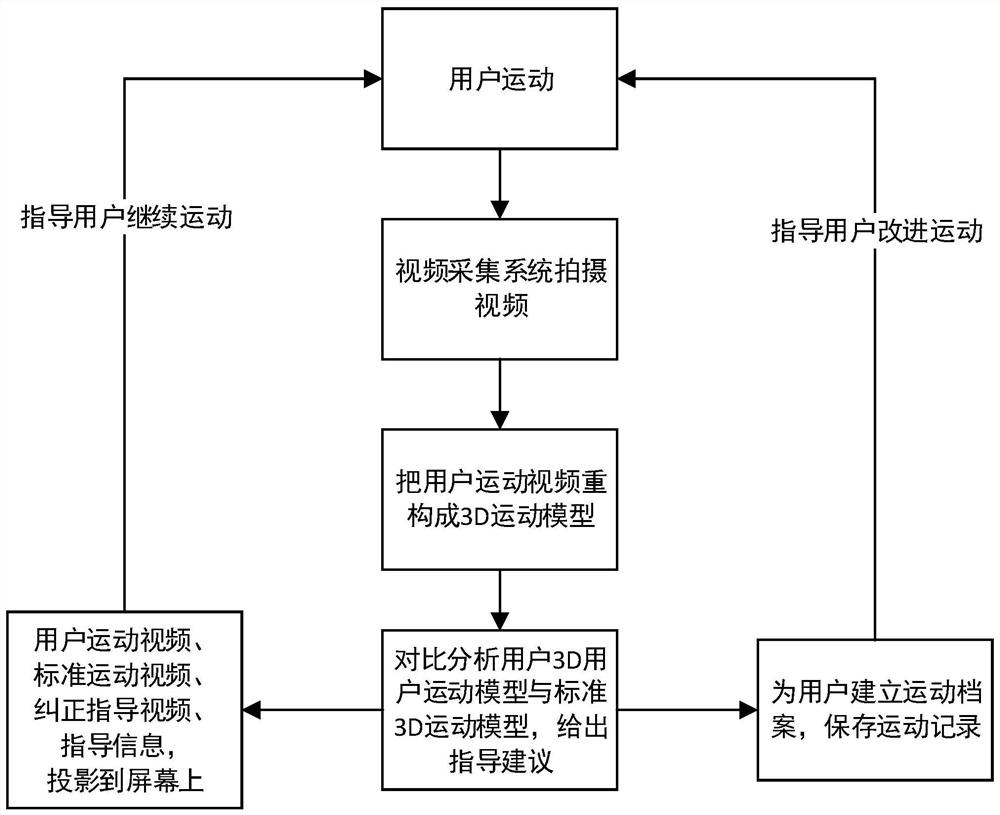

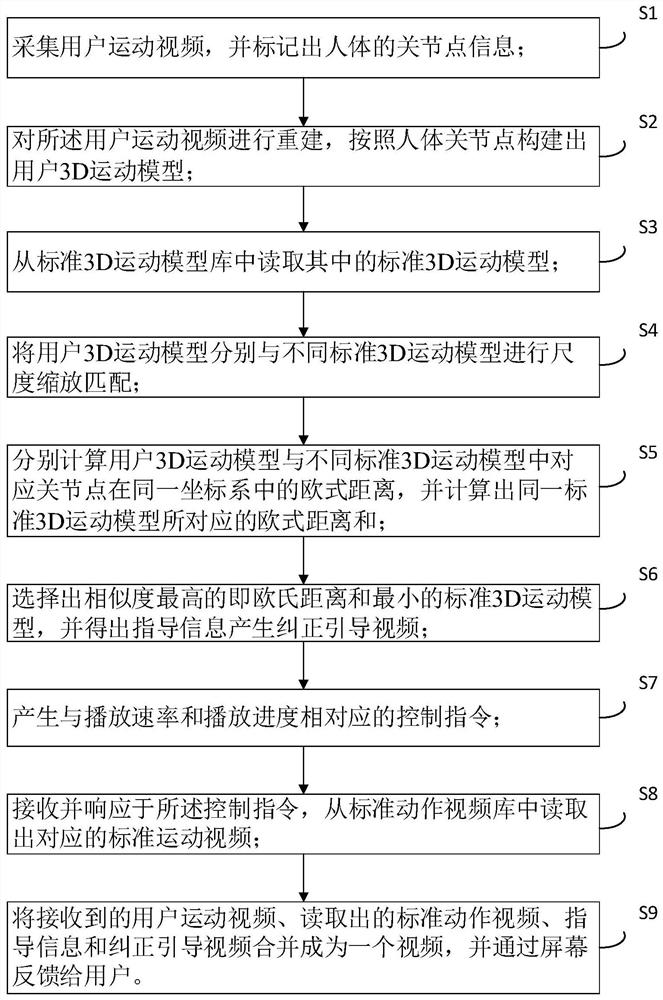

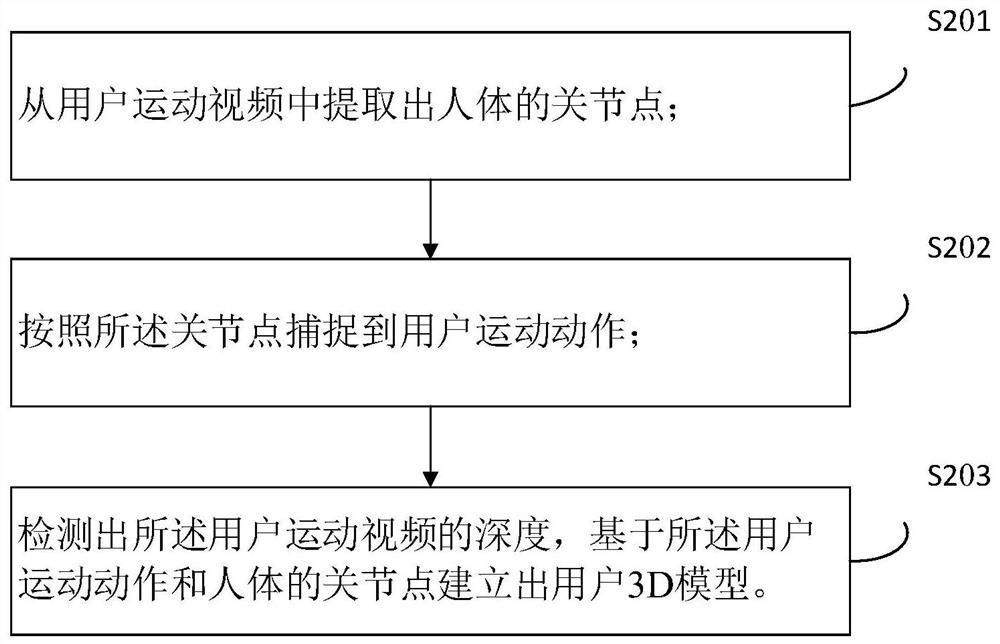

Intelligent fitness action guiding method based on 3D reconstruction

ActiveCN112487965AImprove masteryEasy to learnCharacter and pattern recognitionCarrier indexing/addressing/timing/synchronisingEngineeringHuman body

The invention relates to the technical field of intelligent equipment, in particular to an intelligent fitness action guiding method based on 3D reconstruction. The method comprises the steps of collecting a user motion video, and marking articulation point information of a human body; reconstructing a user 3D motion model for the user motion video; reading a standard 3D motion model; carrying outscale zooming matching on the user 3D motion model and different standard 3D motion models; selecting a standard 3D motion model with the highest similarity, and obtaining guide information to generate a correction guide video; the user sending out a gesture and generating a control instruction corresponding to the playing rate and the playing progress; and combining the received user motion video, the read standard action video, the guide information and the correction guide video into one video, and feeding back the video to the user through a screen. According to the invention, the 3D model is established for the collected motion video, the comparison and analysis result is provided for the user, and the playing progress is controlled through the gesture, so that the user can learn anduse conveniently.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

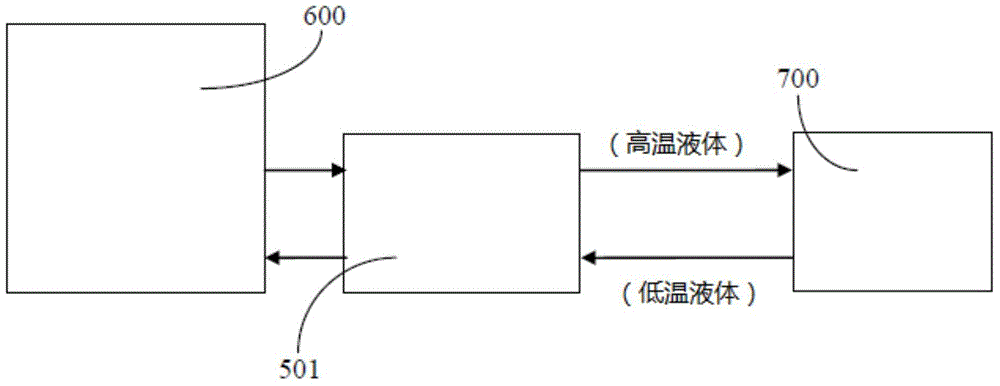

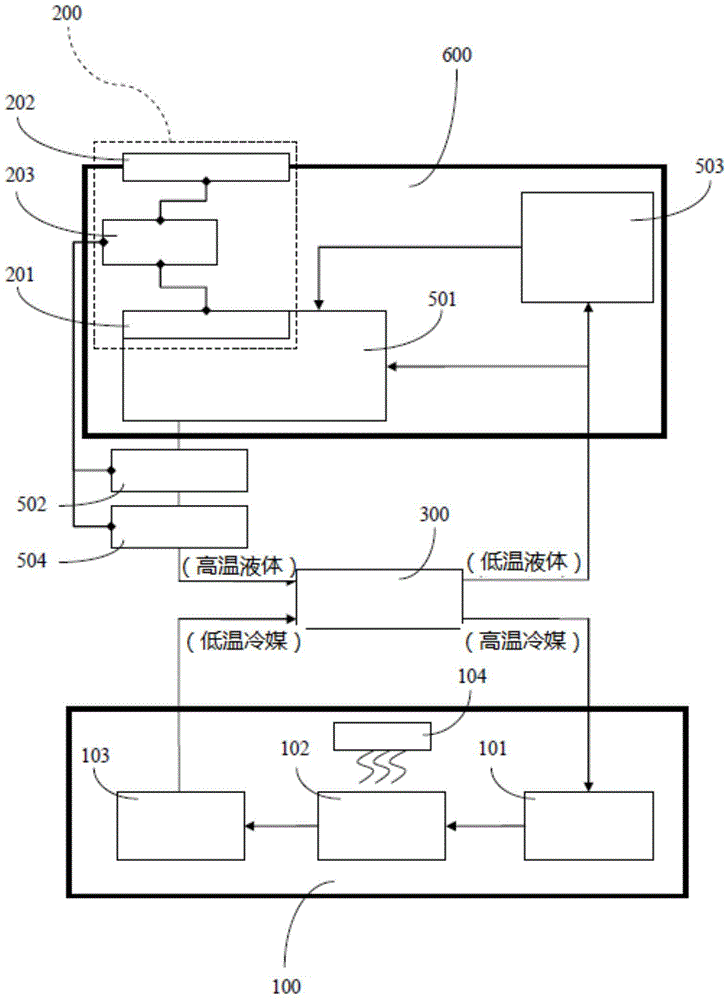

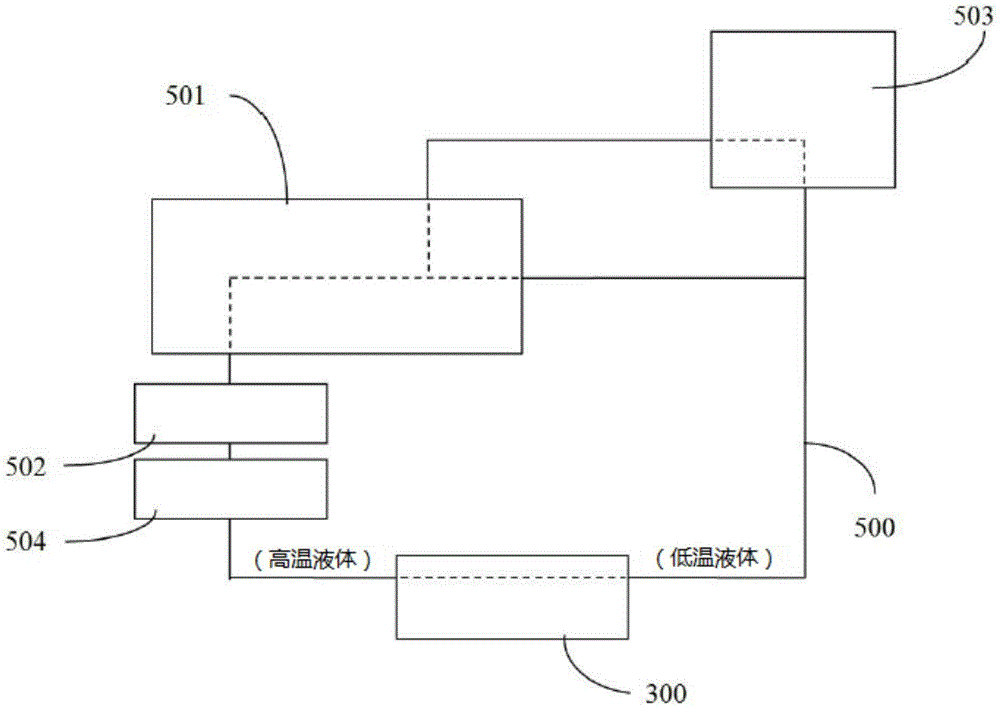

Cooling system for working fluid of machine tool and method for using thereof

InactiveCN105042914AImprove masteryEasy to assembleCompression machines with non-reversible cycleRefrigeration safety arrangementWorking fluidOperation mode

A cooling system for working fluid of machine tool is assembled with a temperature sensing and controlling device for controlling the operation modes of a cooling host thereof. The cooling host is a commercial available cooling host. The cooling host delivers refrigerants to a heat exchanger via a refrigerant circulation pipeline so at to cool down the working fluid, and the cooling host can be freely replaced by any commercial available cooling host based on the damage condition thereof. Based on this, the cooling system according to the present invention is capable of being assembled to various machine tools and capable of using various commercial available cooling hosts for the operation of the system.

Owner:ACCUTEX TECH

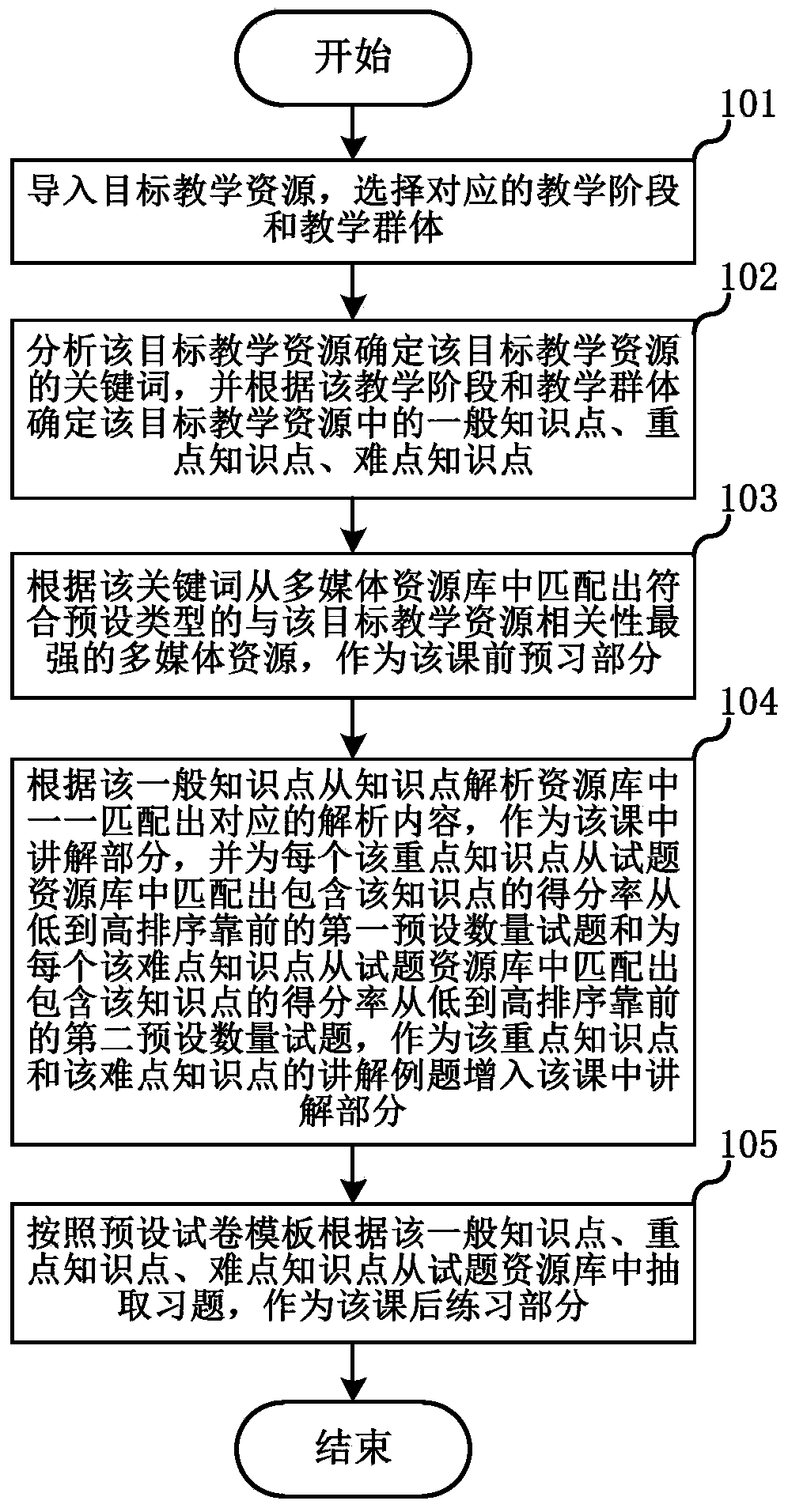

Multimedia teaching plan making method and system based on artificial intelligence

PendingCN111242816AMeet learning needsImprove lesson preparation efficiencyData processing applicationsNatural language data processingEngineeringTest question

The invention relates to the field of teaching, and discloses a multimedia teaching plan making method and system based on artificial intelligence, and the generated teaching plan meets the requirements of a teaching outline, and meets the learning demands of a specific teaching group. The method comprises the steps: importing target teaching resources, and selecting corresponding teaching stagesand teaching groups; analyzing the target teaching resources to determine keywords of the target teaching resources, and determining general knowledge points, key knowledge points and difficult knowledge points of the target teaching resources according to teaching stages and teaching groups; matching a multimedia resource with the strongest correlation with the target teaching resource from a multimedia resource library according to the keyword to serve as a pre-class preview part; according to the general knowledge points, matching corresponding analysis content from a knowledge point analysis resource library to serve as an in-class explanation part, and matching explanation examples from a test question resource library for each key knowledge point and each difficult knowledge point; and extracting exercises from the test question resource library as an after-class practice part according to the general knowledge points, the key knowledge points and the difficult knowledge points based on a preset test paper template.

Owner:广州蓝鸽软件有限公司

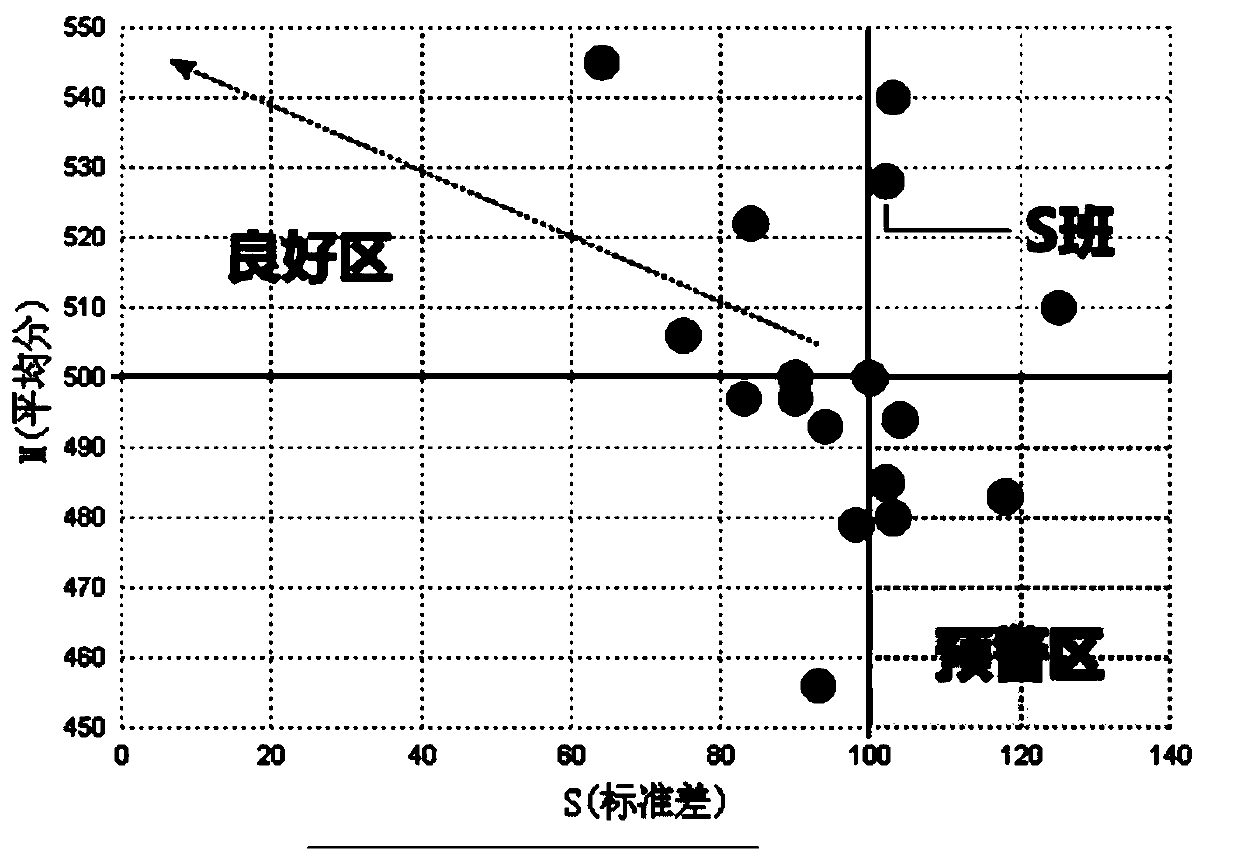

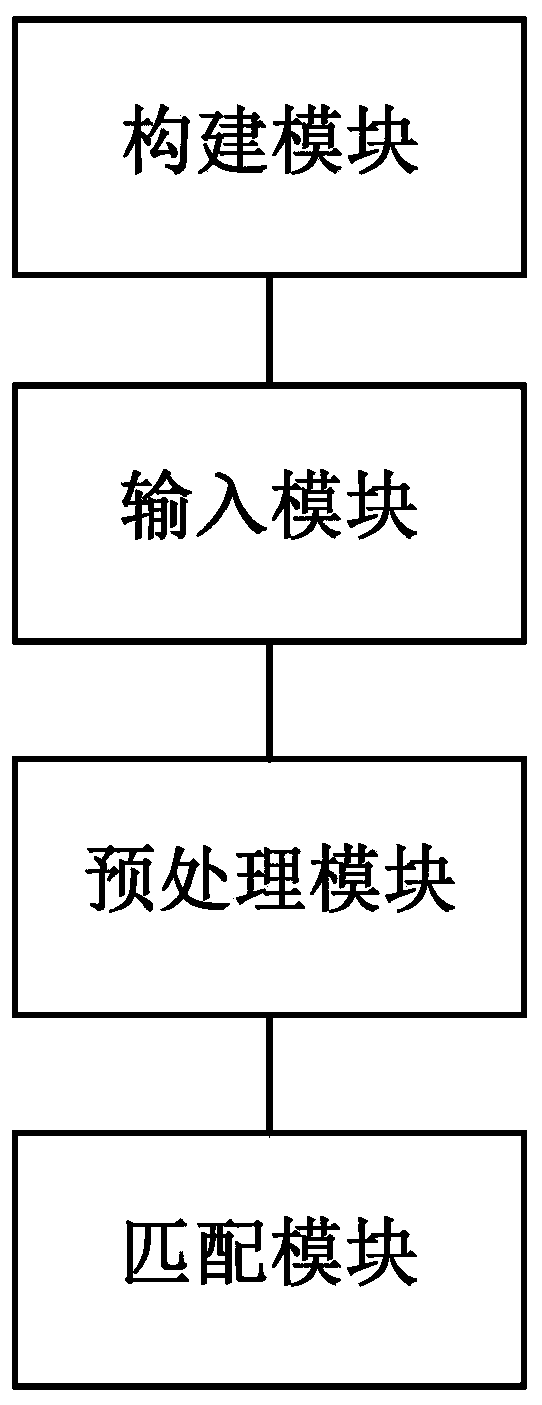

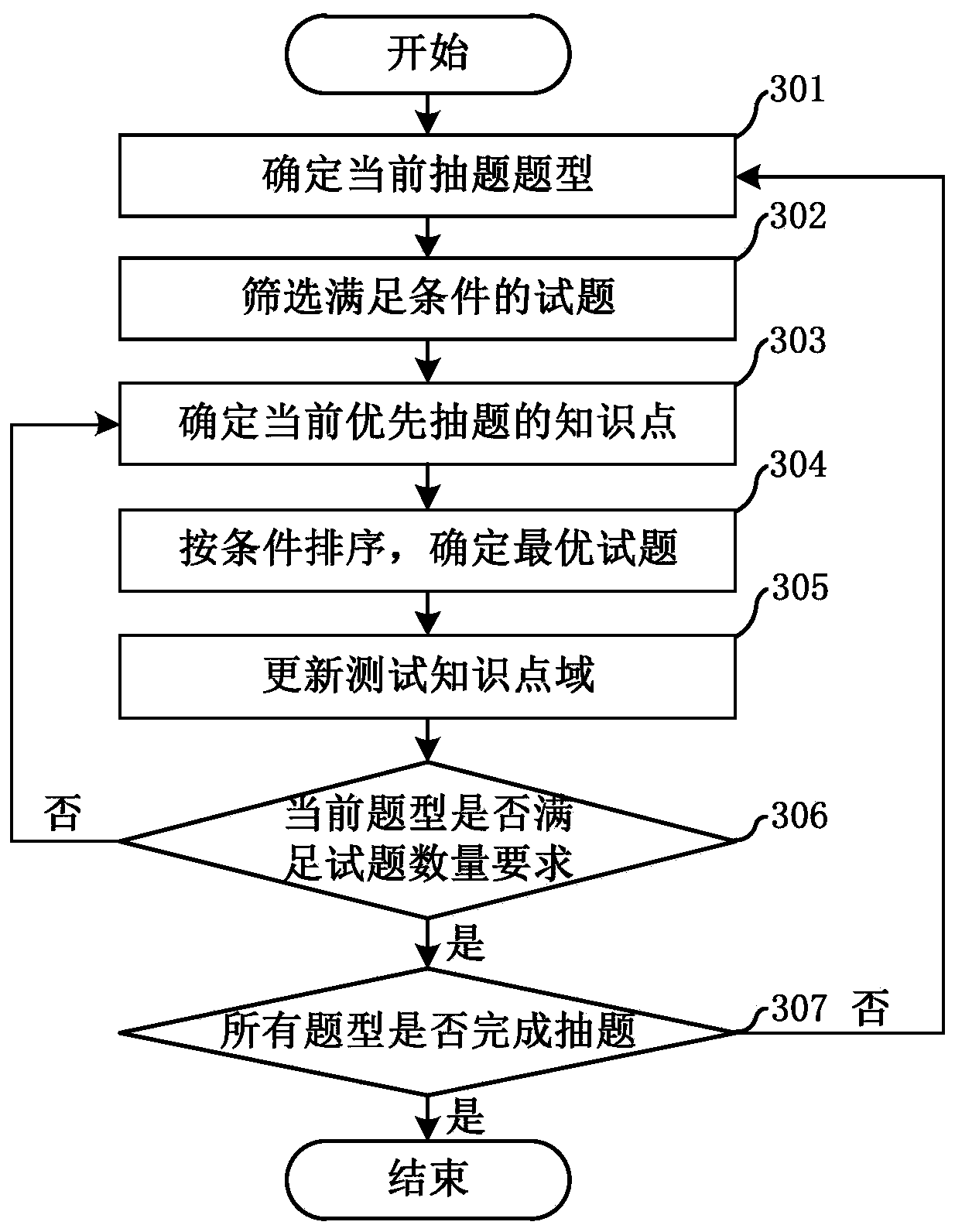

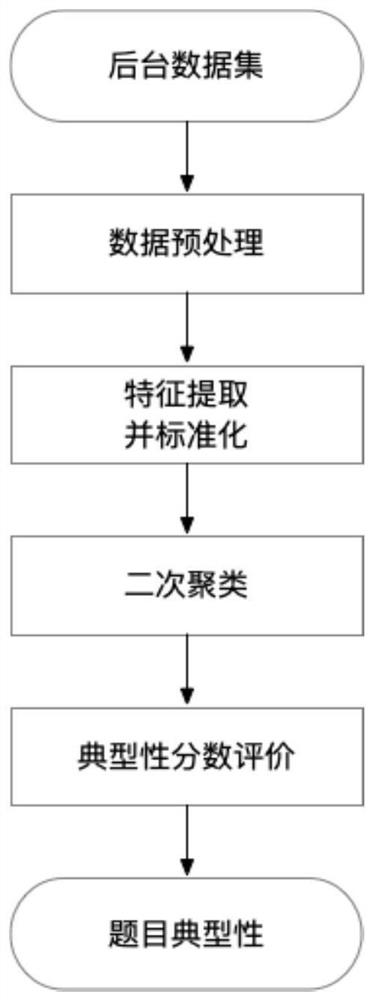

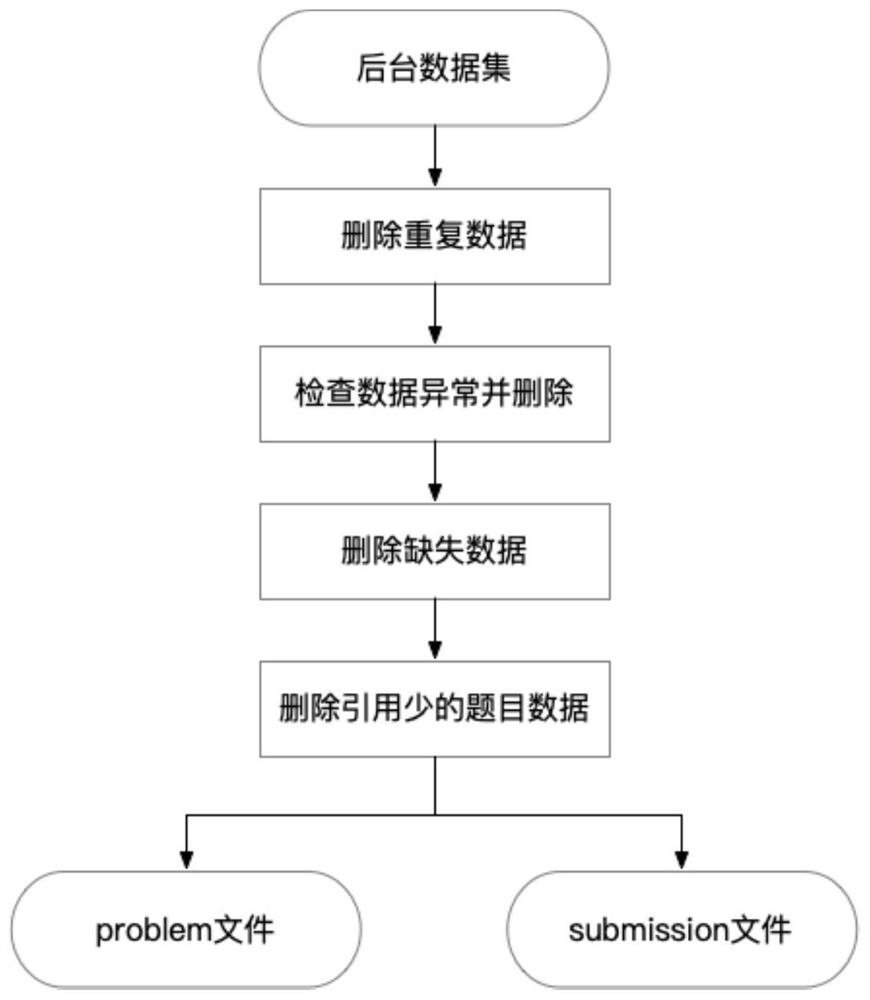

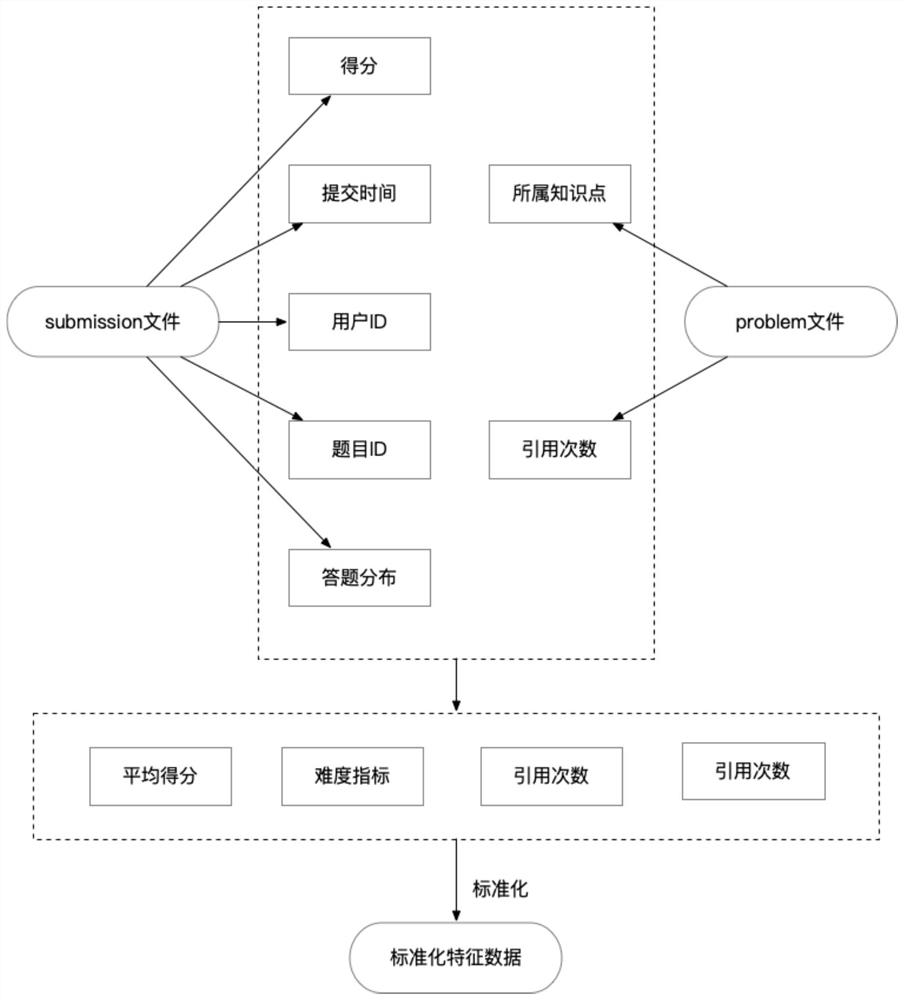

Question recommendation system based on answer statistical characteristics

ActiveCN111881172ASolve the problem of inefficient learning and trainingScience Scoring CriteriaData processing applicationsDigital data information retrievalTest questionComputer-aided

The invention discloses a question recommendation system based on answer statistical characteristics, which belongs to the field of computer aided teaching and the field of data mining. The method comprises a question acquisition module, a preprocessing module, a query characteristic configuration module, a user interface, a characteristic processing module, a clustering calculation module and a question recommendation module. According to the recommendation system, test questions capable of solving user requirements most specifically are efficiently screened out from a question set which is randomly given and obtained from a background of a teaching platform in a secondary clustering mode, a method of combining multiple evaluation modes is adopted, based on the answer statistical characteristics, the mastering condition of a user for each question in a certain time period can be strongly represented, and the numerical value of the characteristic value can be dynamically updated alongwith the improvement of the mastering degree and the improvement of the education quality. Intra-class information and inter-class information in clustering results are combined in recommendation, andit is guaranteed that recommended test questions have high representativeness. The defects that similar questions on an auxiliary teaching platform are too many and no typical question screening mechanism exists are overcome.

Owner:ZHEJIANG UNIV

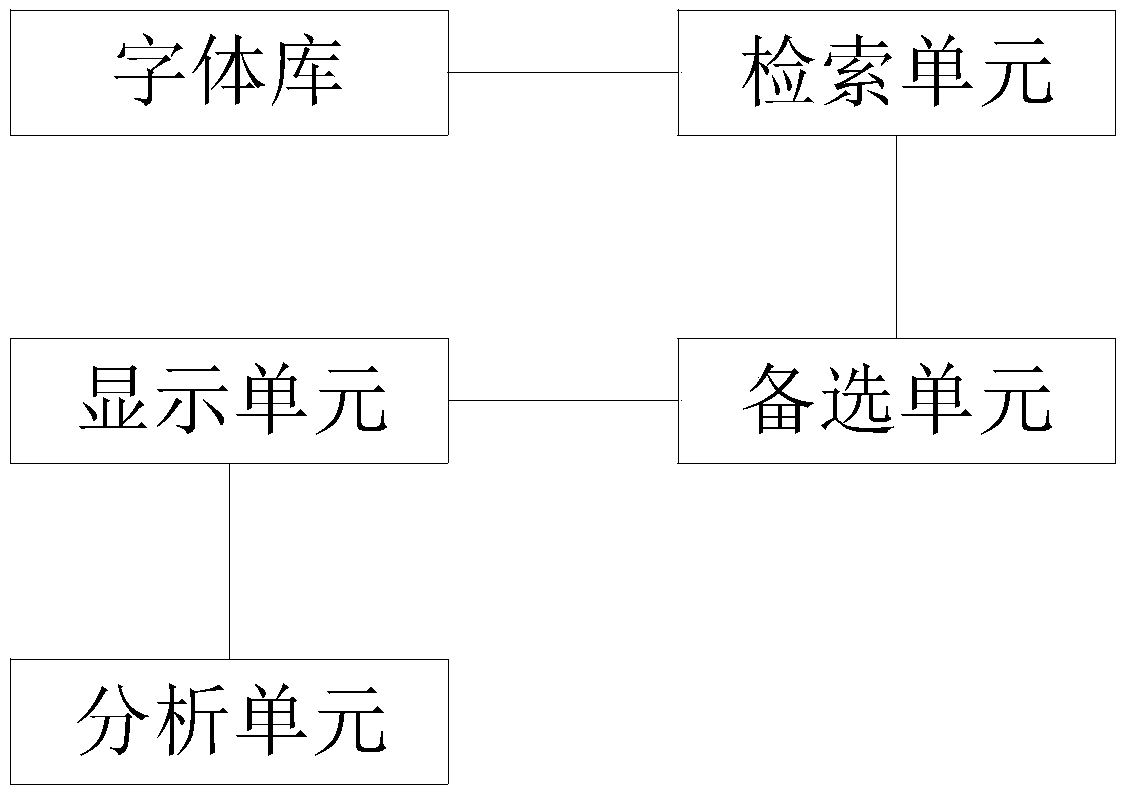

Calligraphy teaching system

InactiveCN108847062APrevent incomplete teachingPrevent the situationElectrical appliancesTeaching apparatusBasic knowledgeChinese characters

The invention discloses a calligraphy teaching system comprising: a font library; a retrieval unit used for receiving a retrieval request of a user and searching out Chinese characters satisfying theretrieval request of the user from the font library; an alternative unit for displaying the Chinese characters satisfying the user's retrieval request for selection by the user; a display unit including a first display module, a second display module, and a third display module, wherein the first display module is used for displaying basic knowledge and evolution process of the target Chinese characters, the second display module is used for displaying stroke features and spatial features of the target Chinese characters and the third display module is used for displaying the writing process of the target Chinese characters; an analysis unit used for analyzing and displaying the evolution process of the target Chinese characters from four aspects including the character shape, stroke, structure and writing method of the target Chinese characters.

Owner:安徽翰达文化科技有限公司

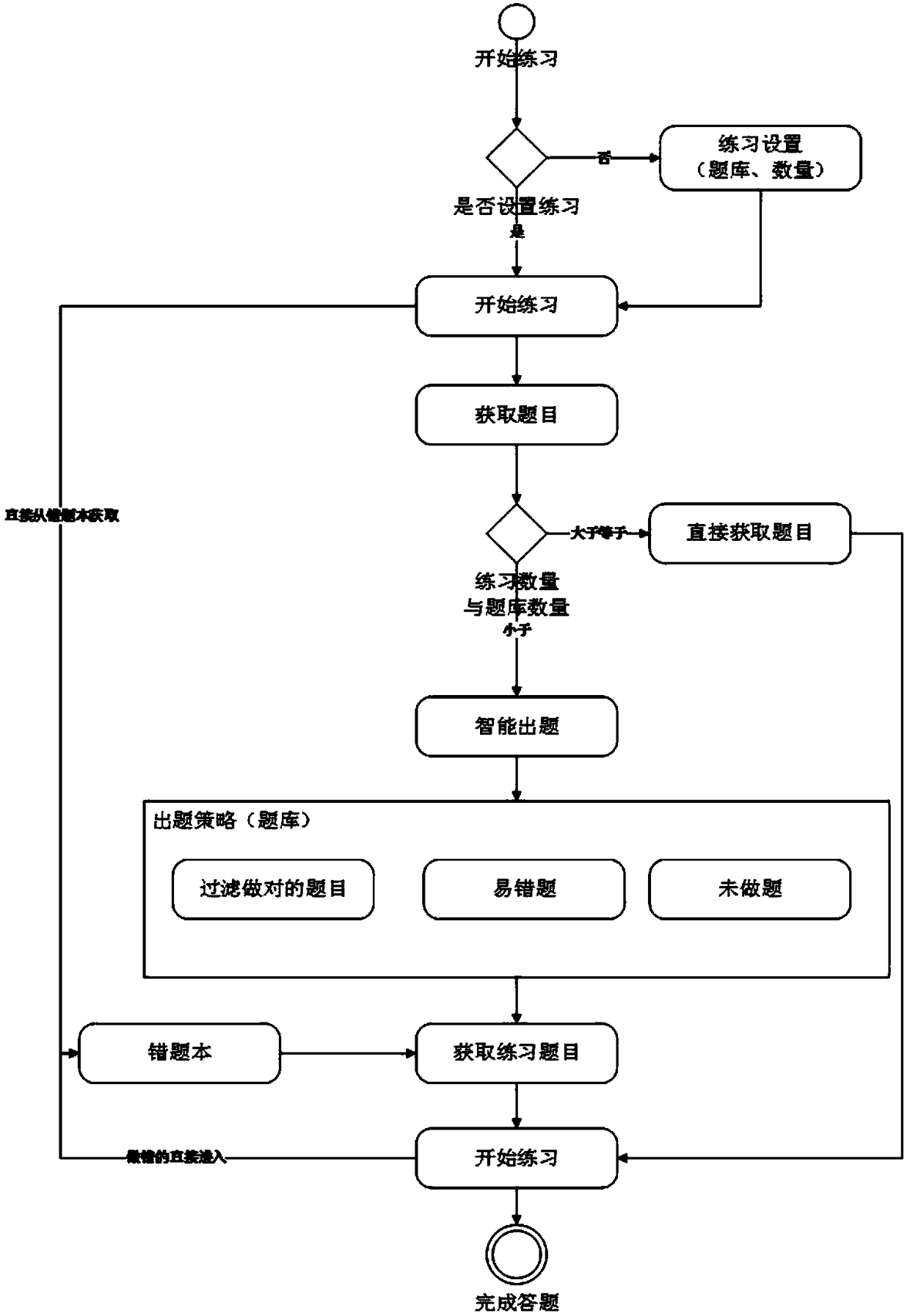

Intelligent exercise system and realization method

InactiveCN108509579AImprove practice efficiencyImprove masteryData processing applicationsElectrical appliancesComputer scienceKnowledge level

The invention relates to an intelligent exercise system. The intelligent exercise system is an application system based on an SaaS platform and comprises an exercise setting module, a question settingstrategy module and a wrong question management module, wherein the exercise setting module is used for setting the number of exercise question banks and the number of questions in one exercise; thequestion setting strategy module is used for selecting questions for exercises according to the number of the question banks, the number of questions in each exercise of a user and historical exercises; and the wrong question management module is used for unified management of wrong questions to form a wrong question book so as to facilitate multiple exercises of the wrong questions. Through the intelligent question setting system, the questions needed to be exercised by the user are selected to make the user grasp learnt knowledge through a large quantity of exercises so as to cope with enterprise examinations; and through the intelligent exercise system, the exercise efficiency and grasp level of the user can be greatly improved, and as much as knowledge can be grasped in as short as time.

Owner:南京红松信息技术有限公司

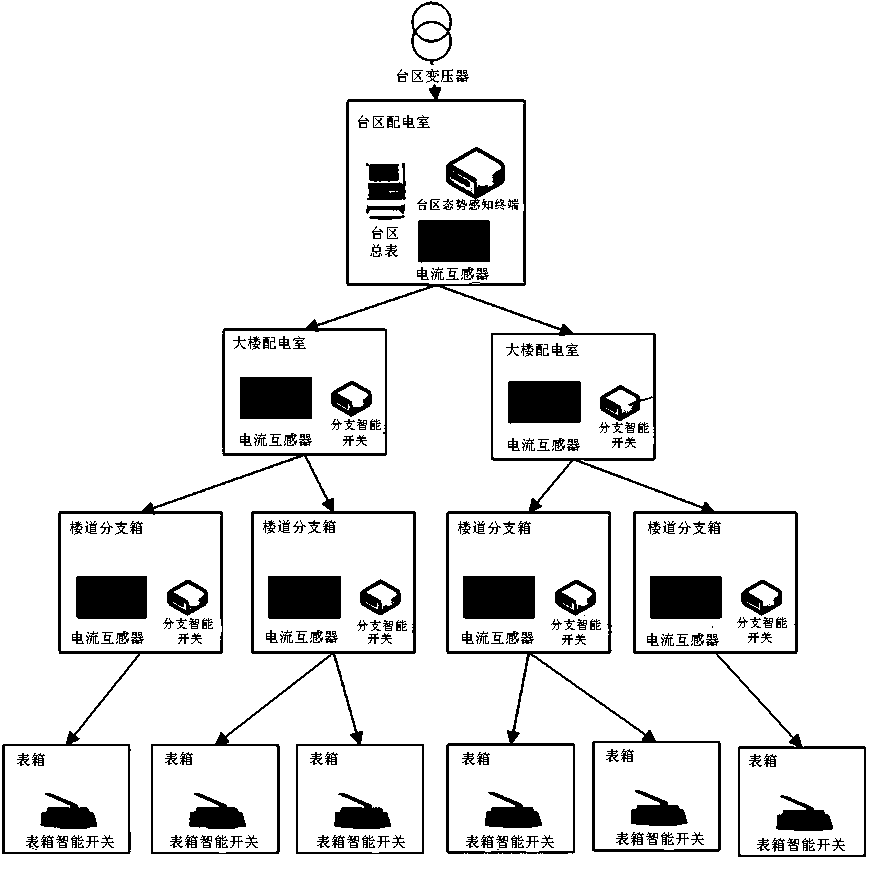

Transformer area topological structure generation algorithm

InactiveCN110278116AImprove masteryImprove the quality of serviceData switching networksData synchronizationTransformer

The invention relates to a transformer area topological structure generation algorithm, which is completed by the following processes of (1) performing the network time synchronization with a lower-level sensing terminal via a network protocol by taking the time of a main sensing terminal as the reference time; (2) after the time synchronization, enabling all the nodes to start to collect and freeze the real-time current of the node line at the same frequency at the same time point of the time axis to enable each node to generate a string of numerical value sequences containing the time sequences, node positions and current vector values; (3) enabling each node to upload the numerical value sequence to the main sensing terminal; (4) enabling the main sensing terminal to convert the numerical value sequence uploaded by each node into a time sequence complex curve; (5) extracting the features of a time sequence complex curve by using a pattern recognition algorithm; and (6) generating a power supply network topological structure tree according to the inverse feature inheritance relationship. The method has the advantages that the power grid basic information mastering capacity is improved, and the technical support is provided for improving the high-quality service levels of the companies.

Owner:马晓琴

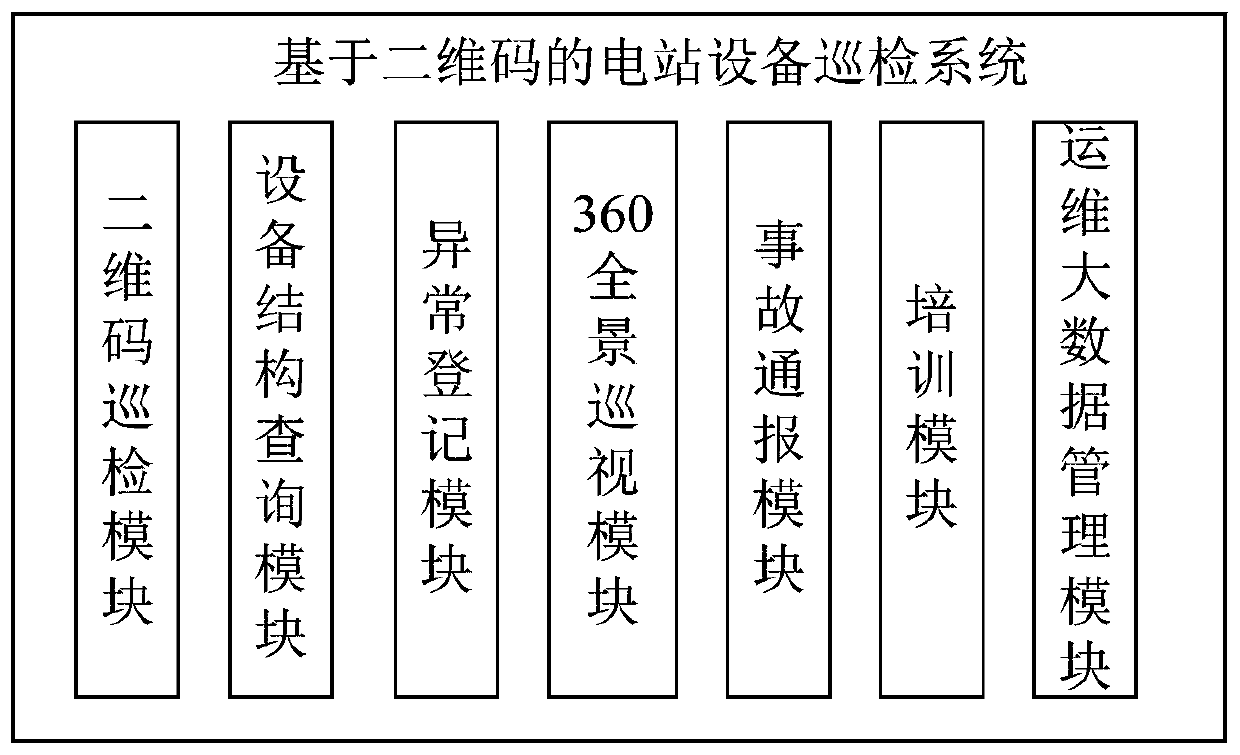

Power station equipment inspection system based on two-dimensional code

InactiveCN110176085AImprove inspection qualityImprove inspection efficiencyChecking time patrolsSensing by electromagnetic radiationPower stationElectric power system

The invention discloses a power station equipment inspection system based on a two-dimensional code, related to the field of electric system safety. The power station equipment inspection system basedon the two-dimensional code is used for solving a problem of unclear and inaccurate inspection information and difficulty in search of inspection materials generated when a worker of an electric system performs inspection for on-site equipment at present. According to the power station equipment inspection system based on the two-dimensional code of the invention, by a 3D modeling technology, theon-site equipment is stored in a server in the form of a 3D spatial model, when an on-site staff needs to perform detailed detection for certain equipment, the on-site staff can scan the two-dimensional code of the equipment and call a standard three-dimensional model to perform comparison, thus, degree of mastering the equipment of the on-site staff is improved. The system provided by the invention is suitable for inspection tasks of various equipment in a power station.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER COMPANY +1

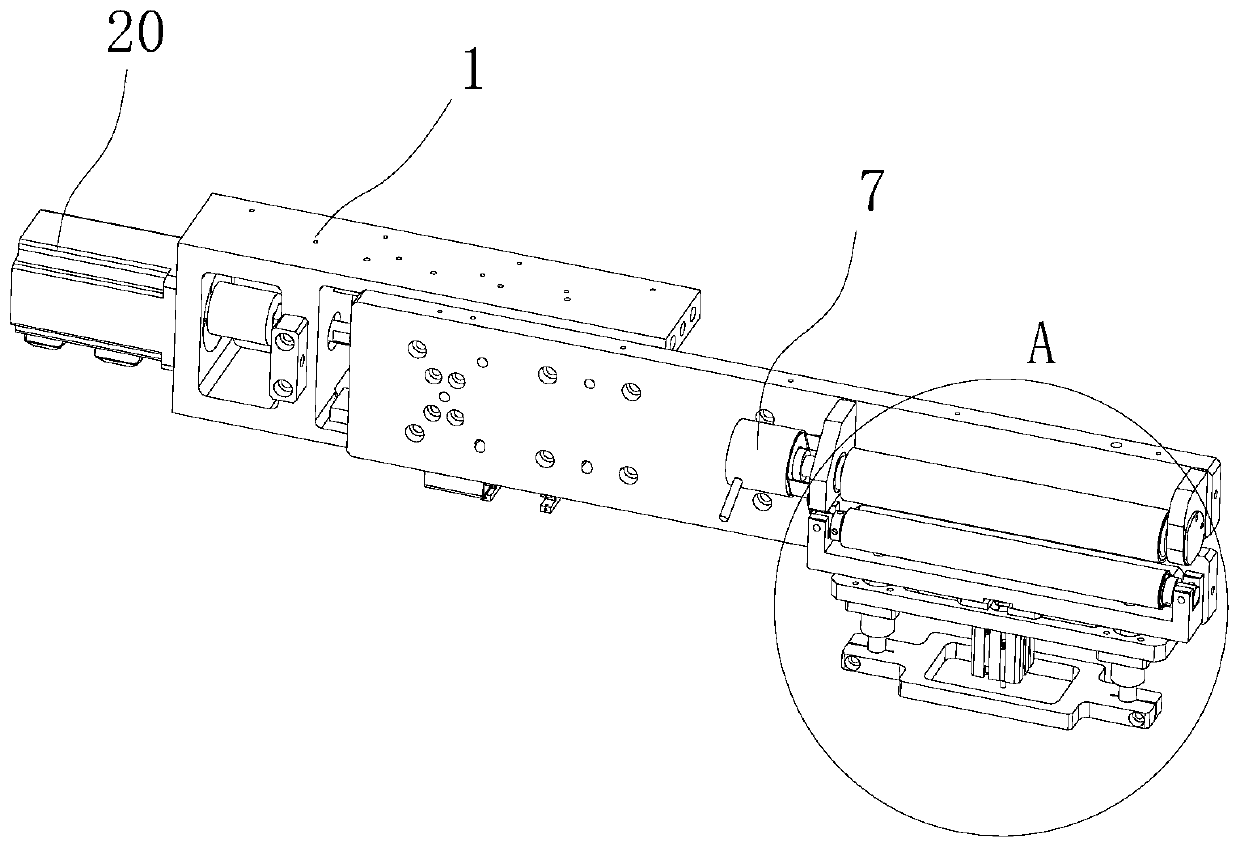

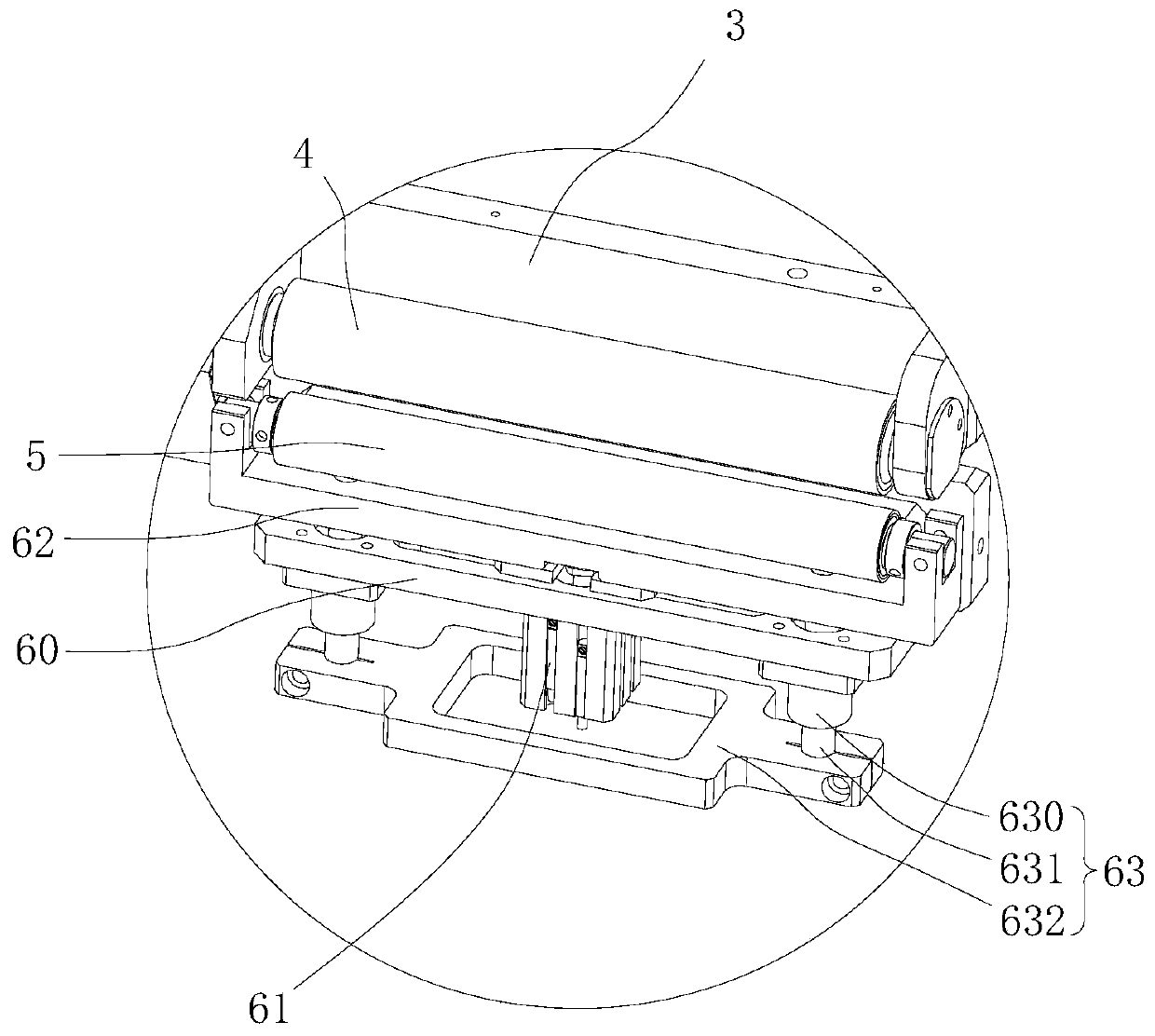

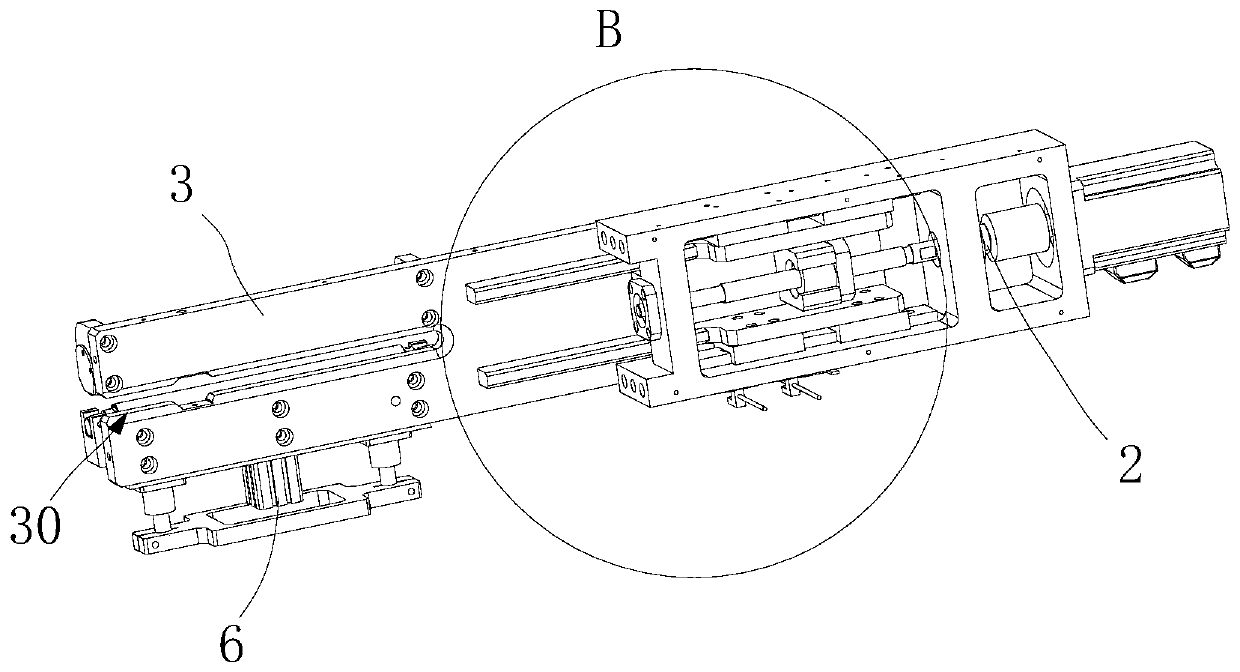

Pole piece deviation correction mechanism and method, encoder device and lithium battery winding machine

InactiveCN110127418AAccurate realizationSimple structureFinal product manufactureSecondary cellsWinding machineEngineering

The invention belongs to the technical field of lithium battery production devices, and particularly relates to a pole piece deviation correction mechanism and method, an encoder device and a lithiumbattery winding machine. The pole piece deviation correction mechanism comprises an installation base, an axial push assembly arranged in the installation base, a movable base arranged at the telescopic end of the axial push assembly, a fixed roller connected to the end portion of the movable base in a rotating manner, a radial push assembly arranged on the end portion of the movable base, and a movable roller arranged at the telescopic end of the radial push assembly; and the radial push assembly can push the movable roller and the fixed roller to cooperate to clamp a pole piece. Compared with the prior art, the pole piece deviation correction mechanism and method, the encoder device and the lithium battery winding machine have the beneficial effects that when deviation correction needs to be conducted, the axial push assembly drives the fixed roller and the movable roller to move in the axial direction at the same time, and therefore deviation correction is achieved; and the type ofstructure is simpler and higher in precision, and pole piece feeding is more convenient.

Owner:温在东

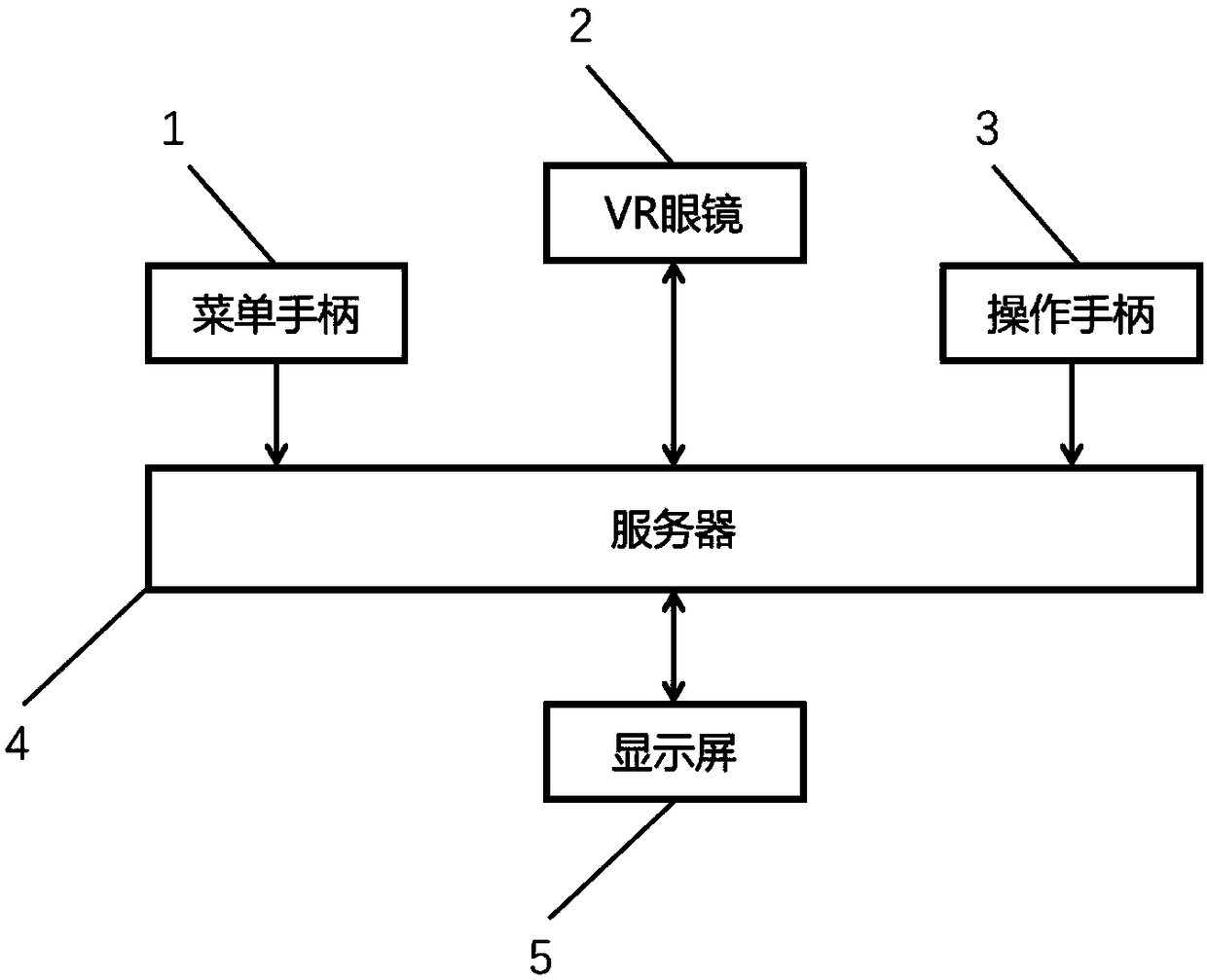

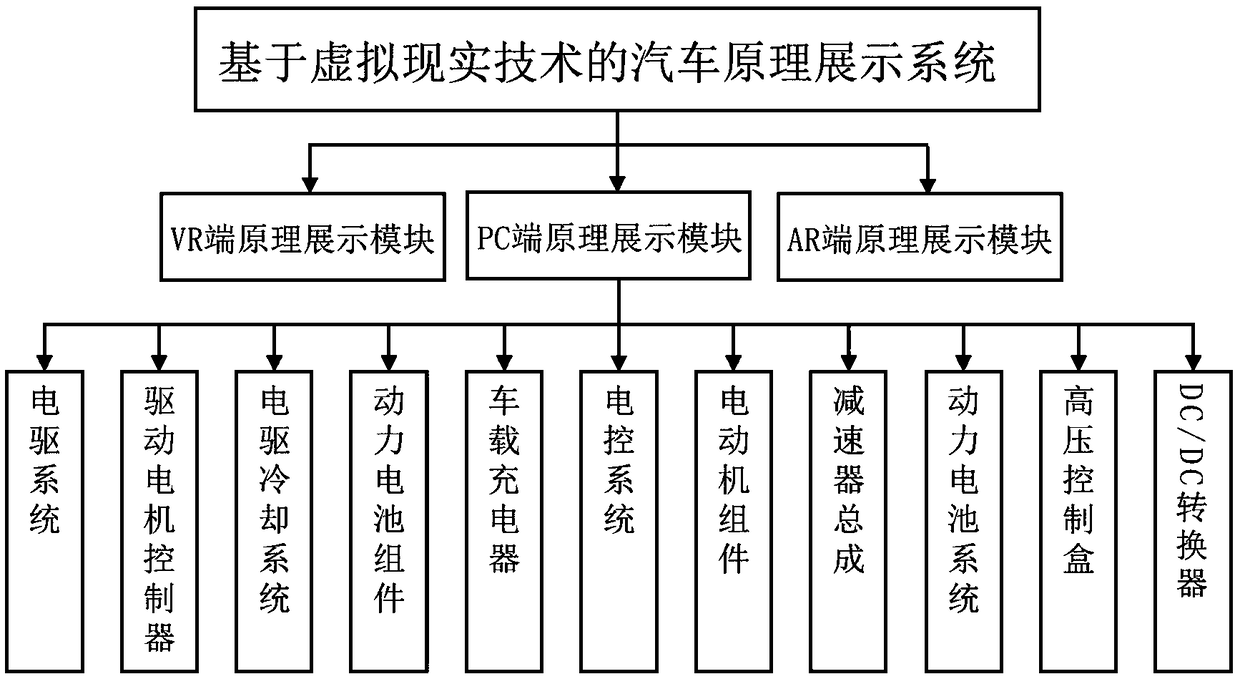

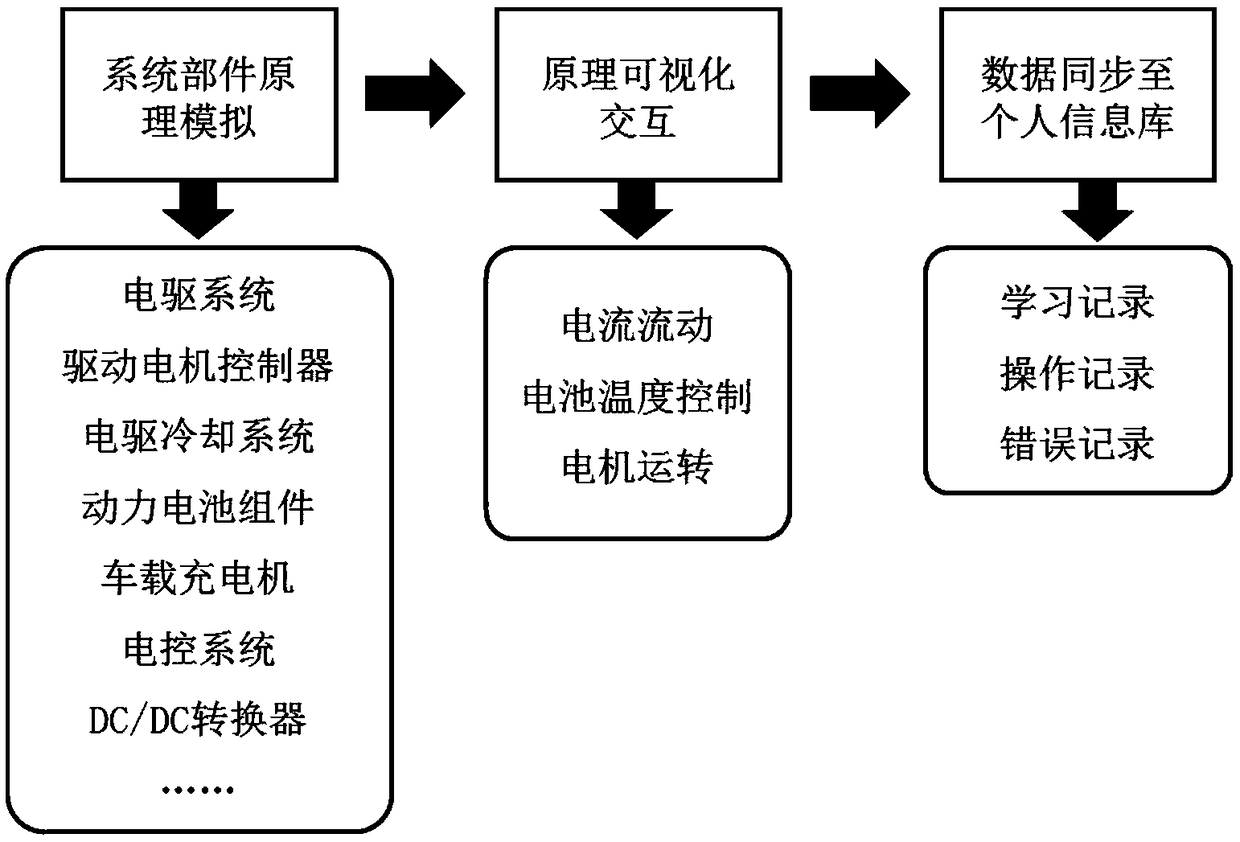

Automobile principle display system based on virtual reality (VR) technology

InactiveCN108766082AIncrease interest in learningImprove understandingCosmonautic condition simulationsSimulatorsVirtual realityOperating environment

The invention discloses an automobile principle display system based on a virtual reality (VR) technology, which comprises a VR-side principle display module and a PC-side principle display module installed in a PC server and an AR-side principle display module installed in a trainee mobile terminal, wherein the server is connected with the display screen of the PC; each principle display module is used for carrying out visualized explanation and display on a complicated automobile principle, and when entering the operating environment of each principle display module, the trainee can performrotation, disassembly, moving and introduction click interaction operation, and a principle phenomenon which can not be watched in reality can be felt intuitively. Through the PC side, the VR side andthe AR side, the trainee can learn the automobile principle knowledge comprehensively from multiple angles, and through interaction operation of the VR side and the AR side, understanding and mastering of the knowledge are enhanced.

Owner:中汽数据(天津)有限公司

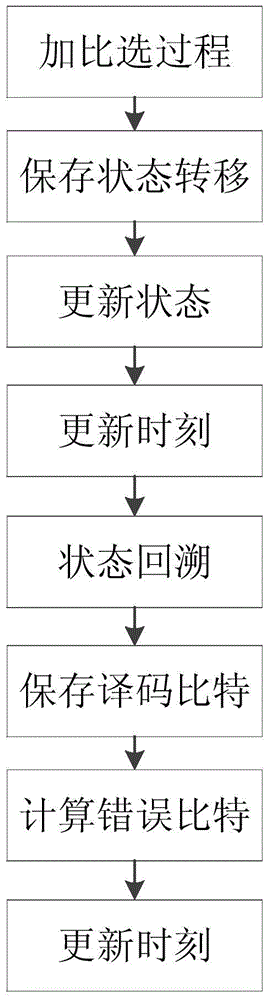

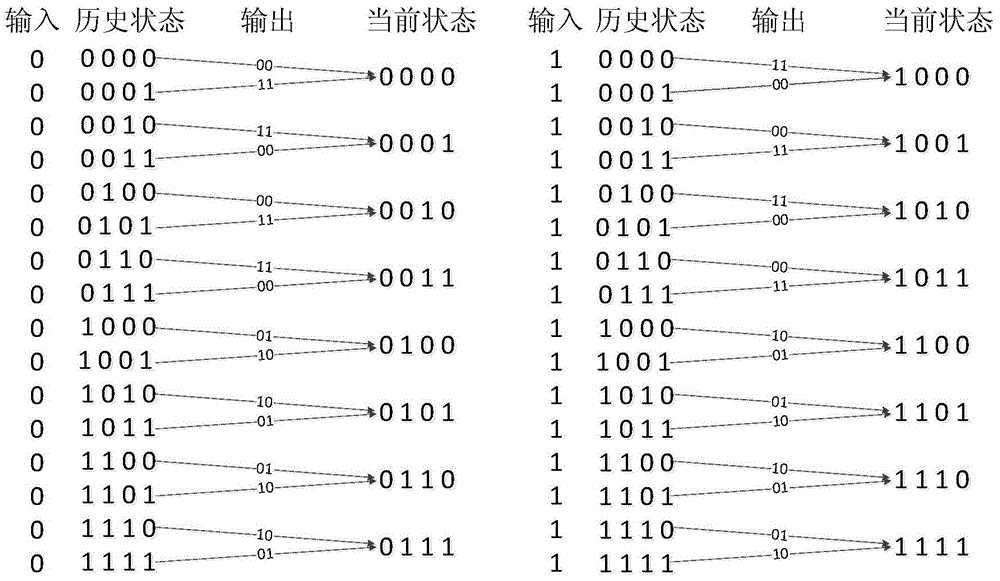

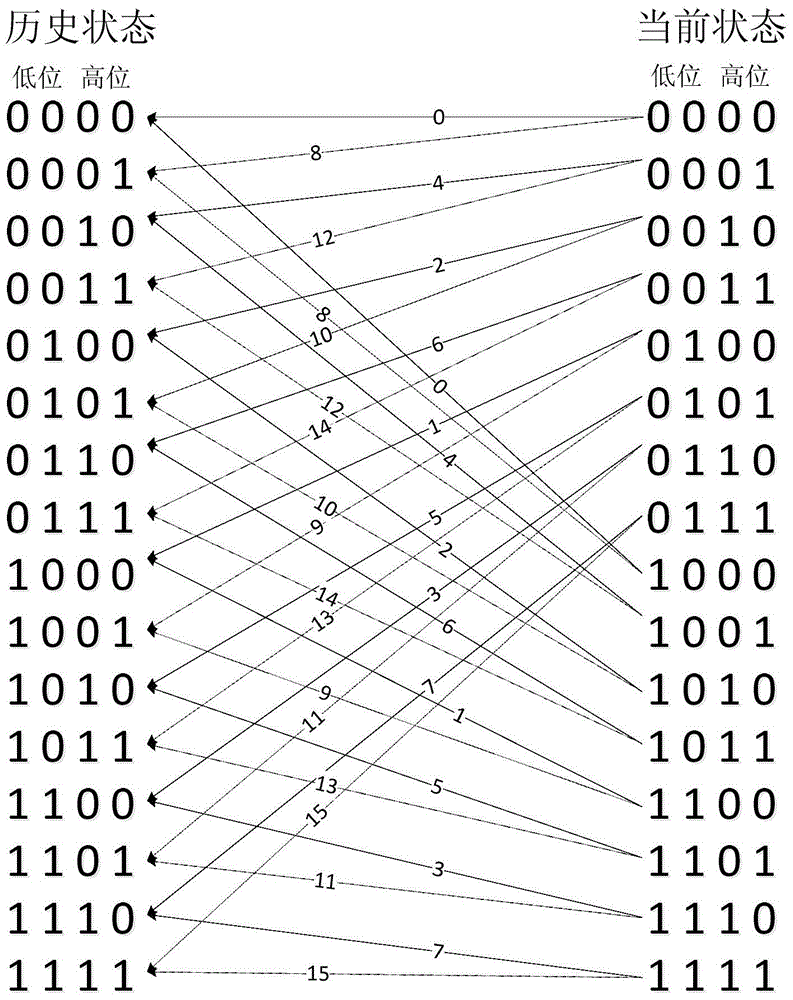

Viterbi decoding realizing method

ActiveCN105721104AImprove masteryReduce storage computing complexityError preventionComputation complexityRound complexity

The invention relates to a viterbi decoding realizing method, and belongs to the satellite mobile communication technology field. The viterbi decoding realizing method comprises S1, addition comparison selection process; S2, storage of state transfer; S3, state updating; S4, time updating; S5, state backtracking; S6, storage of decoding bits; S7, calculating of error bits; S8, time updating. By adopting the viterbi decoding realizing method, the storage calculation complexity in the addition comparison selection process can be reduced, and the number of the error bits before the channel decoding can be acquired, and therefore under the precondition of only increasing the calculation complexity of the receiving end a little, the degree of mastering the receiving signal quality of the receiving end can be improved obviously, and then the necessary precondition can be provided for the further optimization of the system performance of the receiving end.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com