Cooling system for working fluid of machine tool and method for using thereof

A cooling system and processing fluid technology, applied in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as production capacity impact and stagnant work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

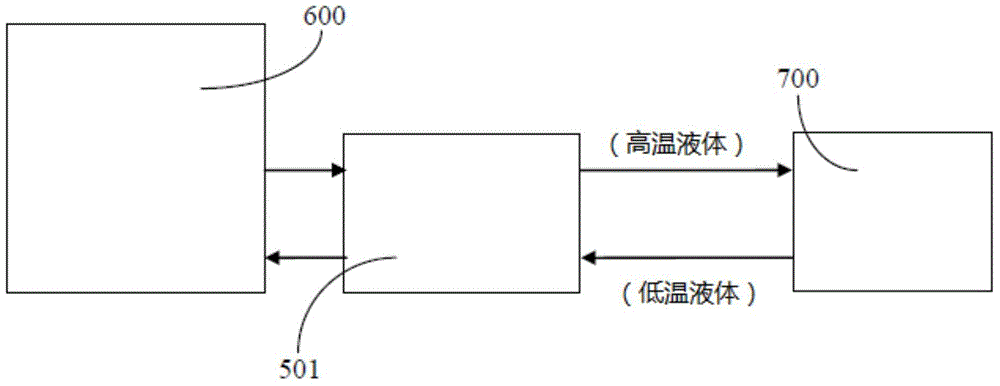

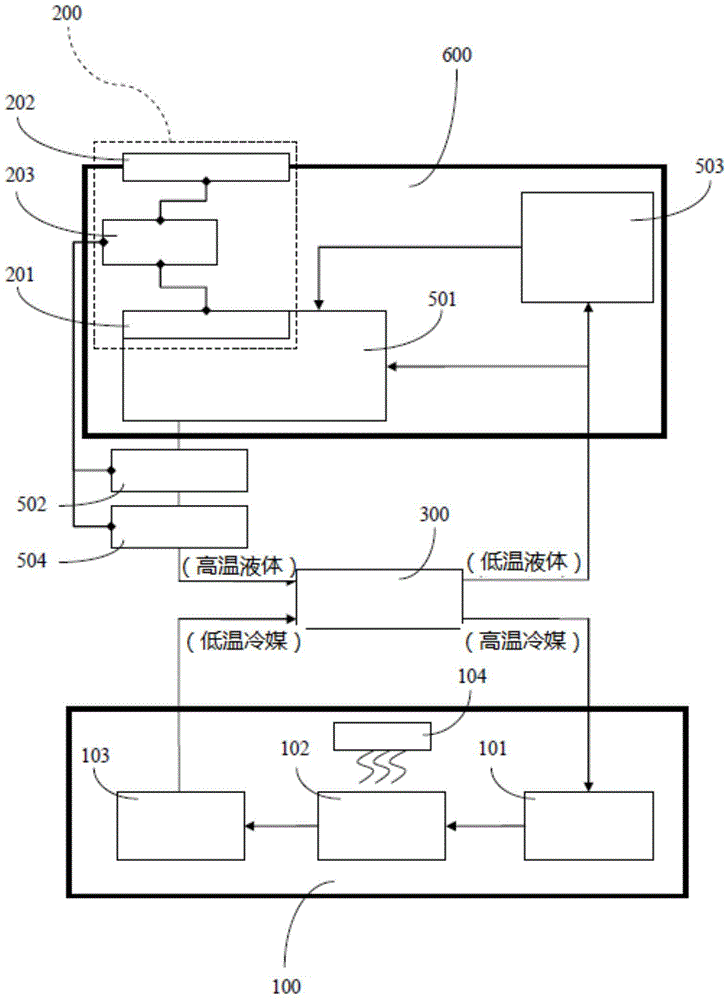

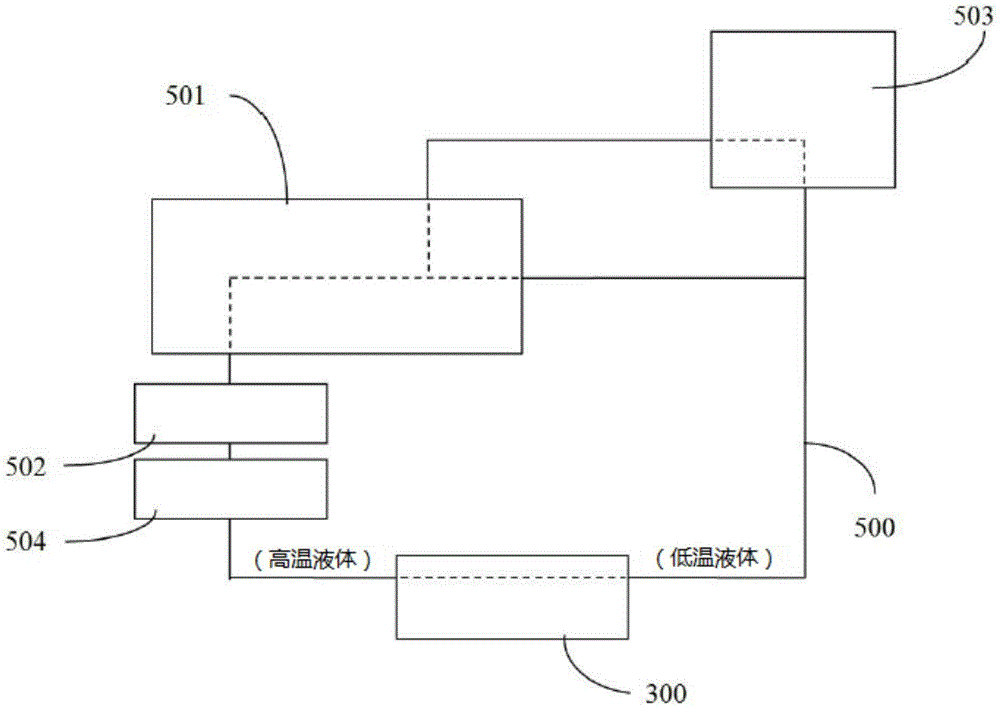

[0019] The present invention is an open cooling system using commercial-grade air-conditioning cooling hosts combined with heat exchangers on machine tools with liquid media, which can be referred to figure 2 The schematic diagram is an embodiment; the machining fluid cooling system of the present invention is applied to a machine tool 600 with machining fluid, and the machine tool 600 basically has a machining area (processing tank) 503, a machining fluid storage tank 501 or an equivalent structure with similar functions ; The machining fluid storage tank 501 stores the machining fluid.

[0020] The machining fluid cooling system of the present invention includes a cooling host 100 and a temperature sensing and controlling device 200 . The temperature sensing and control device 200 can be disposed in the machine tool 600 . The temperature sensing and control device 200 is used for detecting a temperature parameter of the machine tool 600 . The cooling host 100 includes a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com