Loader with backhoe

A loader and self-contained technology, applied in the field of self-contained backhoe, can solve the problems of small downward rotation angle of the bucket, shallow excavation depth, low operation rate, etc. The effect of high loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

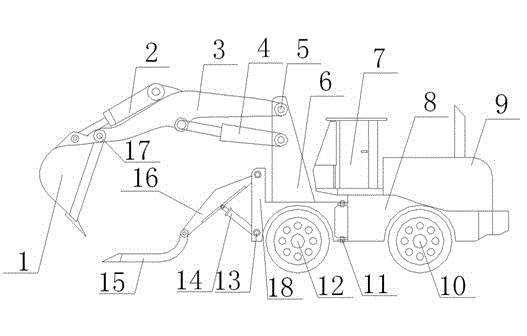

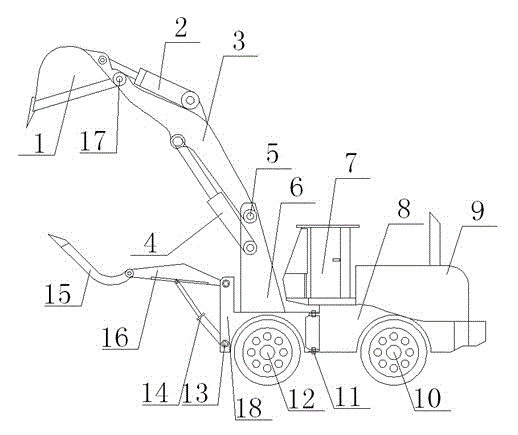

[0020] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the use status diagram of the present invention.

[0021] The present invention is a loader with backhoe, comprising front fuselage 18, power wheel 10, rear fuselage 8, steering wheel 12, driver's platform 7, lower wishbone 16, lower fork rotating shaft 13, backhoe arm rotating shaft 5 and the lower fork 15, wherein, the lower end of the front part of the front body 18 is provided with a lower fork rotating shaft 13, the upper part of the front end of the front body 18 is provided with a lower fork arm 16, and the lower fork arm 16 is connected to the upper end of the front part of the front body 18 , the other end of the lower fork arm 16 is provided with a lower fork 15, the lower fork 15 is connected to the lower fork arm 16, and the outer side of the lower part of the lower fork arm 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com