A sugar beet digging device

An excavation device and sugar beet technology, applied in the direction of excavation harvesters, rigid working parts, agricultural machinery and implements, etc., can solve the problem of unstable depth of excavation parts, inconvenient adjustment of row spacing of excavation parts, poor adaptability and working stability, etc. problem, to achieve the effect of improving the pulling effect, simple manufacturing process, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

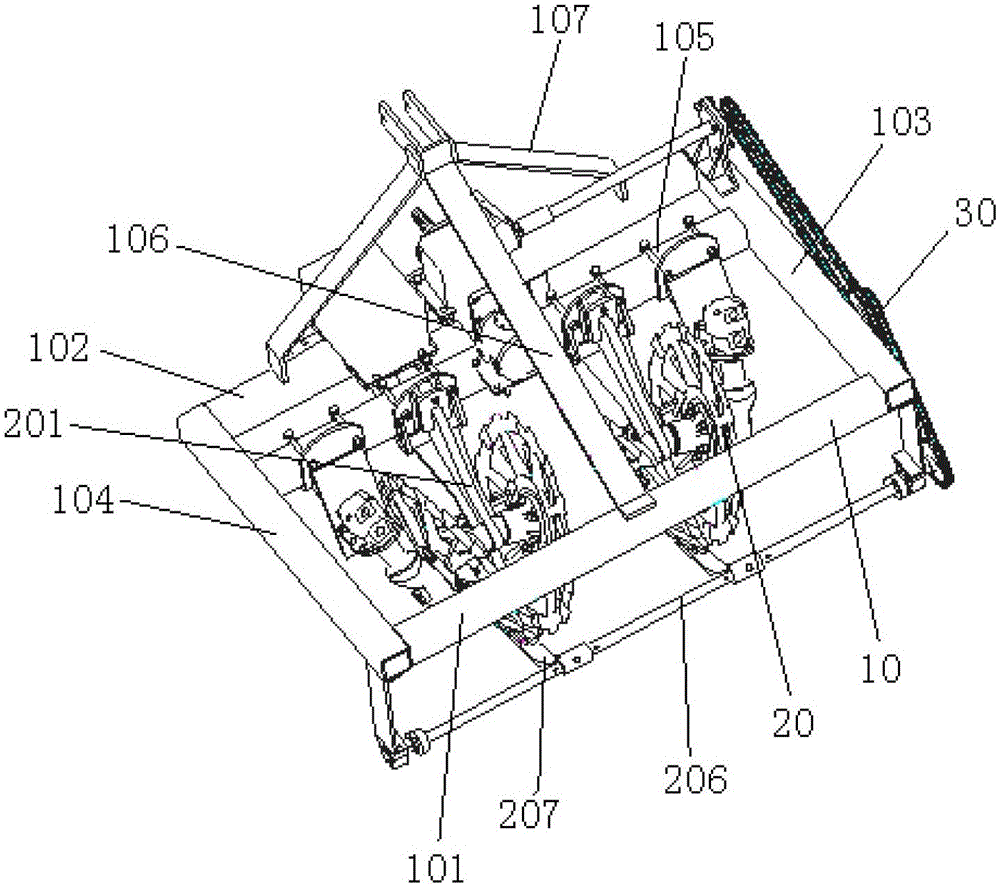

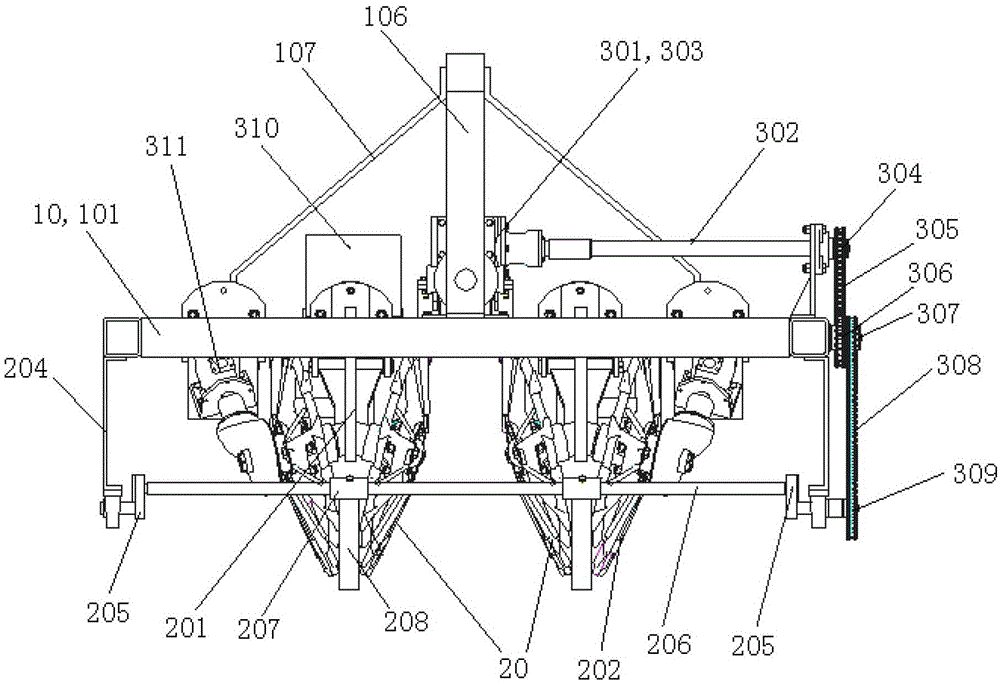

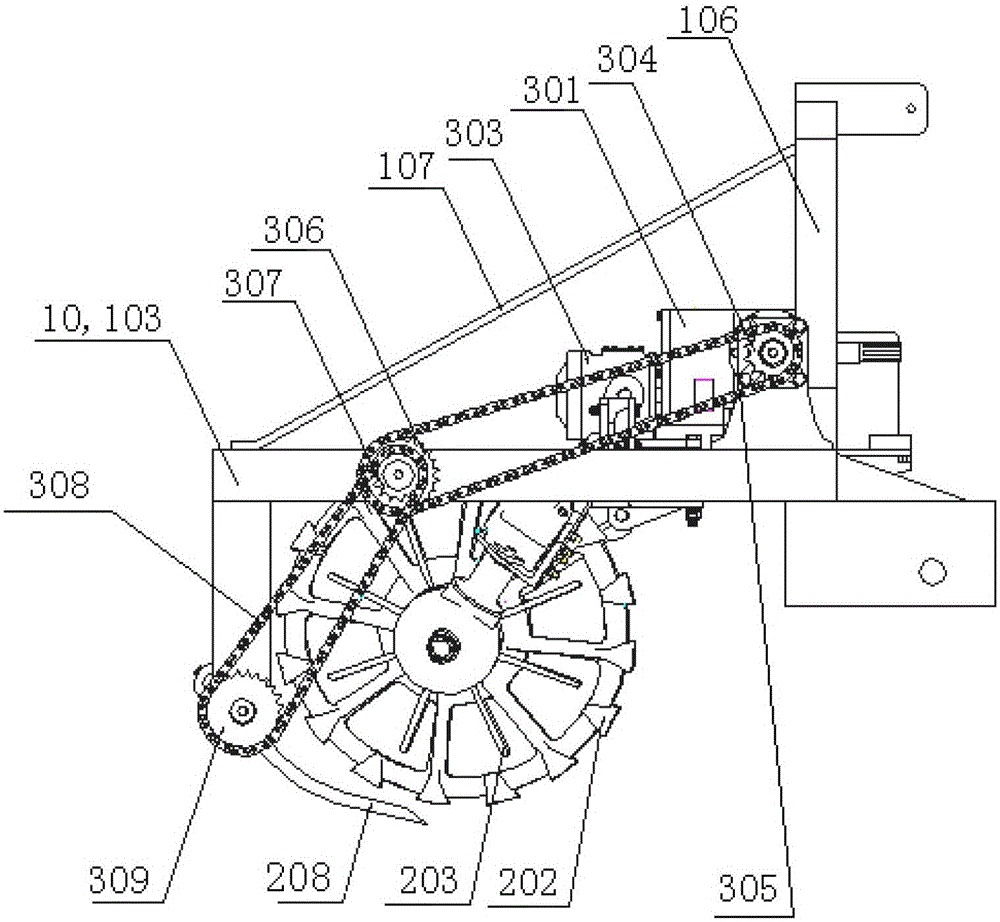

[0018] Such as figure 1 As shown, the present invention includes a frame 10 , a modular excavating component 20 and a transmission system 30 .

[0019] Such as figure 1 As shown, the frame 10 of the present invention is welded by rectangular pipes, and the whole is rectangular, which includes a first transverse beam 101 and a second transverse beam 102, a first longitudinal beam 103 and a second longitudinal beam 104, and two transverse beams The length is greater than the length of the two longitudinal beams; between the first transverse beam 101 and the second transverse beam 102, a third transverse beam 105 is arranged near the second transverse beam 102, and the third transverse beam 105 and the first transverse beam 101 and the second transverse beam 102 are parallel. A traction frame 106 is arranged on the first transverse beam 101, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com