Point-type curtain wall supporting structure

A supporting structure and curtain wall technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as difficult to meet requirements, glass deflection deformation, large indoor space, etc., and achieve reasonable structural design, reduced quantity, and clear force transmission path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical solution of the present invention clearer, the present invention will be described in further detail in conjunction with embodiment and accompanying drawing now:

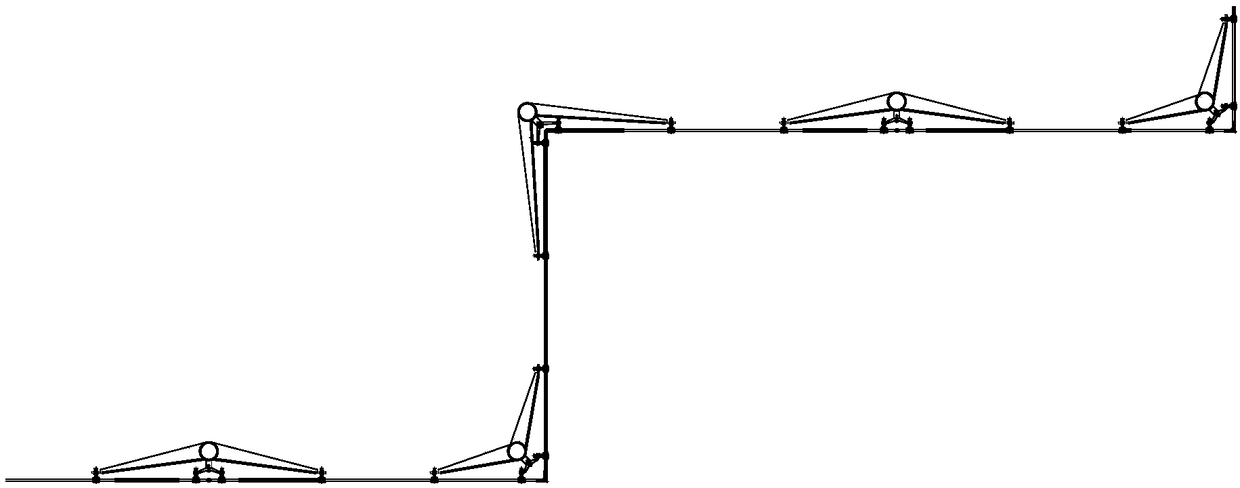

[0024] refer to Figure 1-7 , a point-type curtain wall support structure, comprising: a main body, in this embodiment the main body is a steel pipe 1 and two pieces of variable-section T-shaped steel 2; the variable-section T-shaped steel 2 is symmetrically welded on the side wall of the steel pipe 1, and the The variable cross-section T-shaped steel 2 is from one side close to the steel pipe 1 to the other side, its cross-sectional shape remains unchanged and its cross-sectional area gradually decreases;

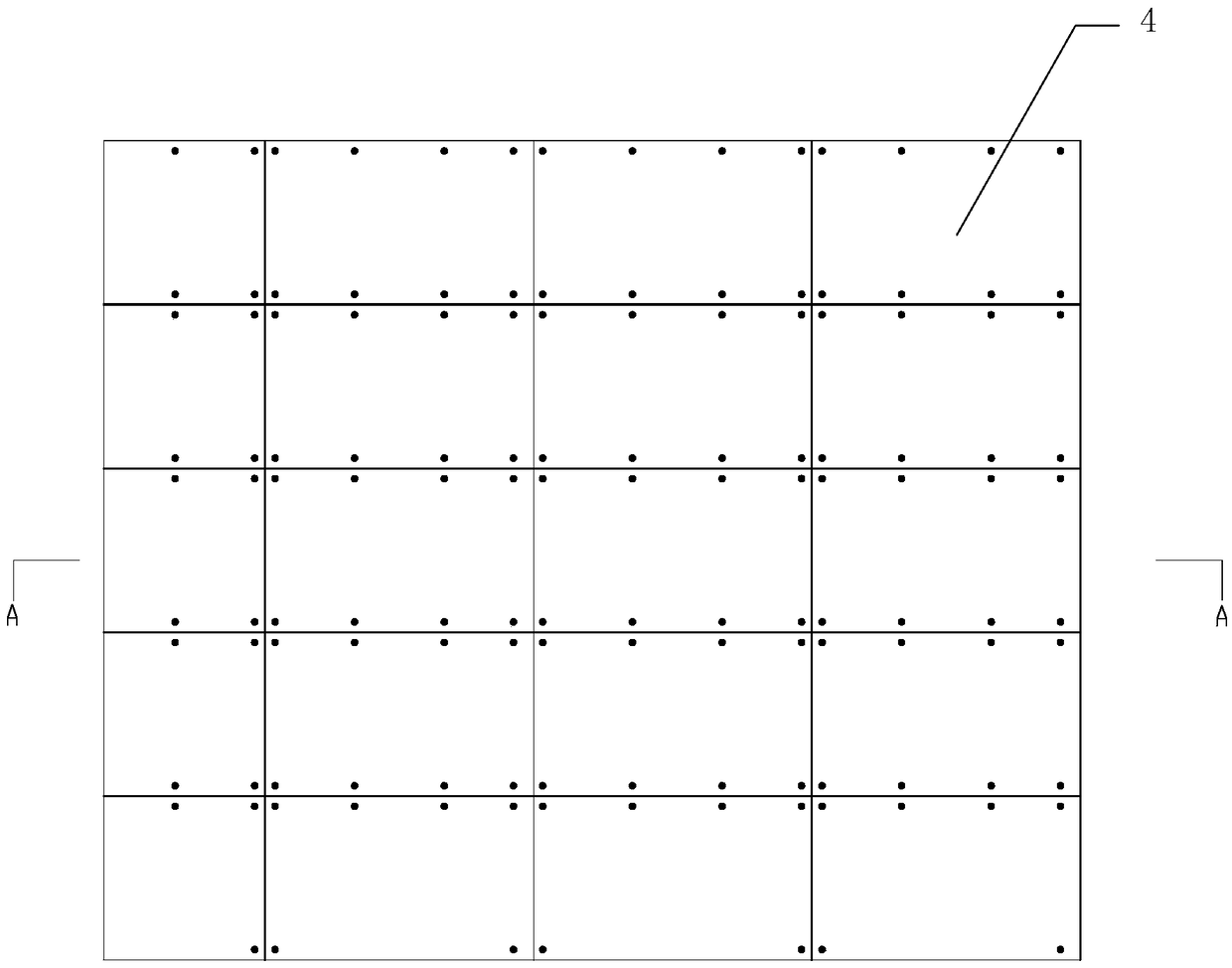

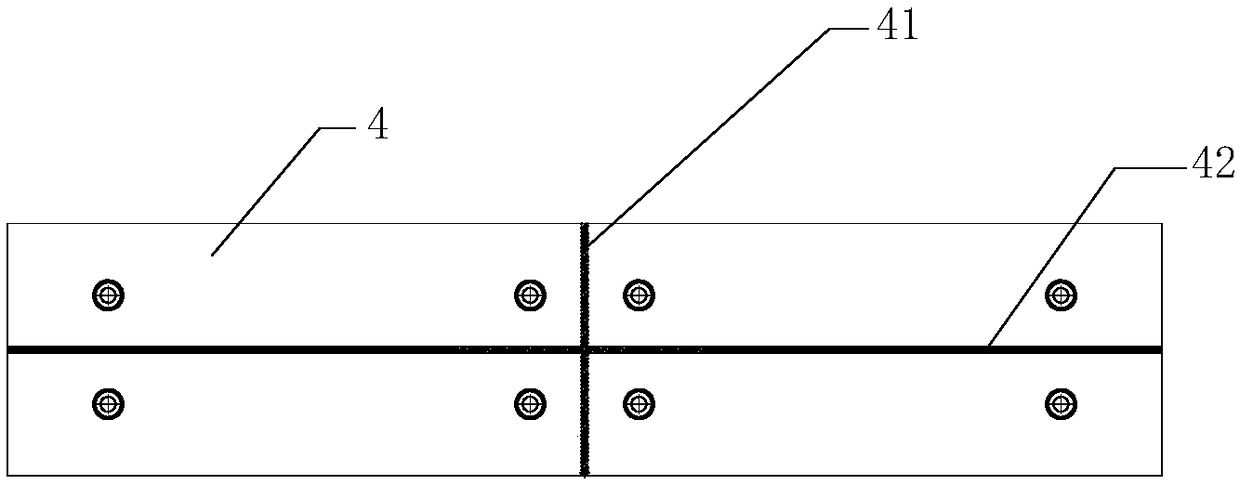

[0025] The support structure is arranged at each vertical division of the glass curtain wall, and the symmetry axis of the steel pipe 1 is aligned with the centerline of the vertical glue joint 41; the symmetry axis of the variable-section T-shaped steel 2 is aligned with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com