Inflation and deflation integrated valve for emptying pump pressure plate for barrel

A technology for pump pressure and barrel, applied in the direction of valve, valve device, functional valve type, etc. for ventilation, which can solve the problems of complicated mechanism and troublesome operation, and achieve the effect of enhancing safety, convenient use and avoiding human contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

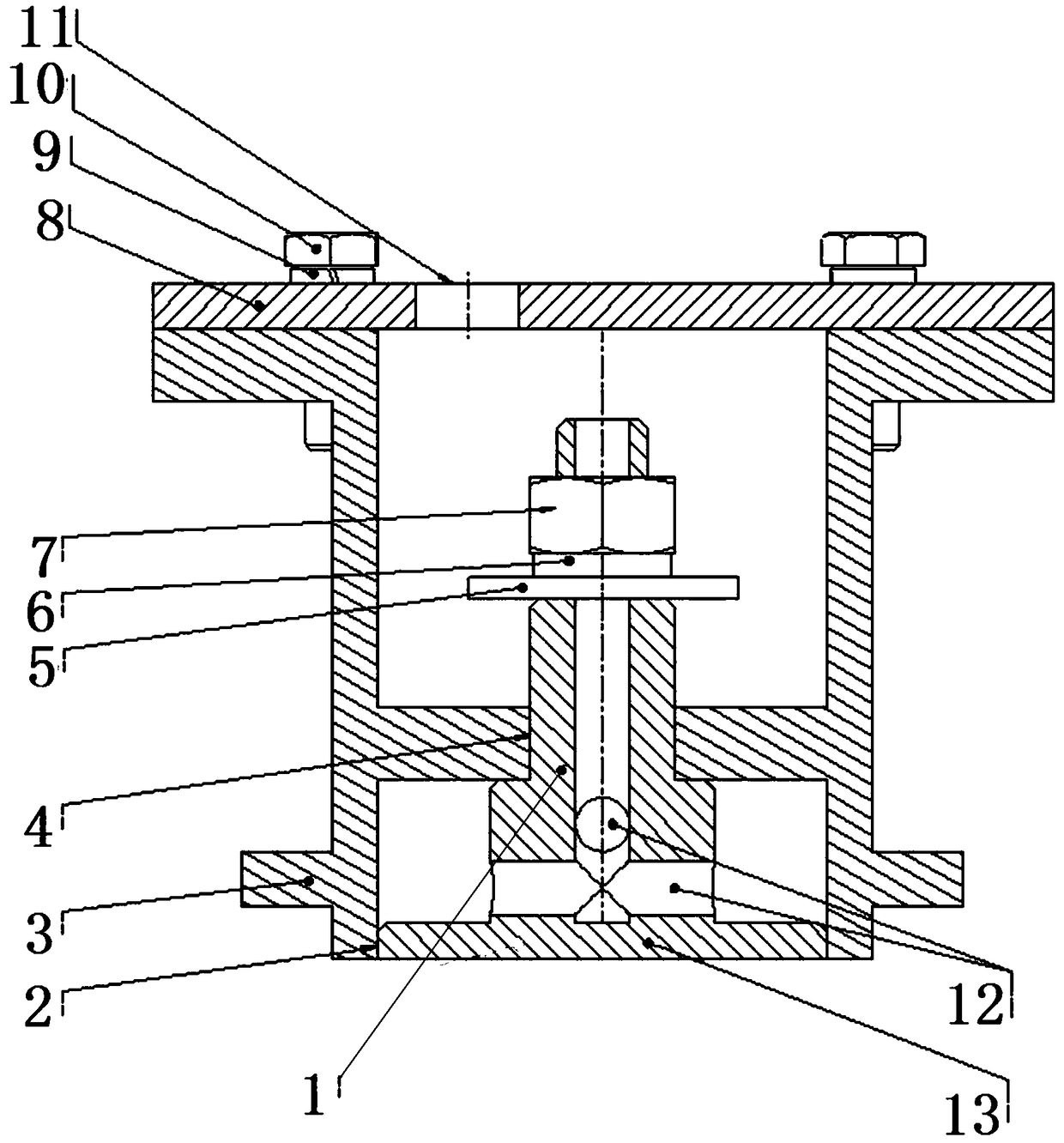

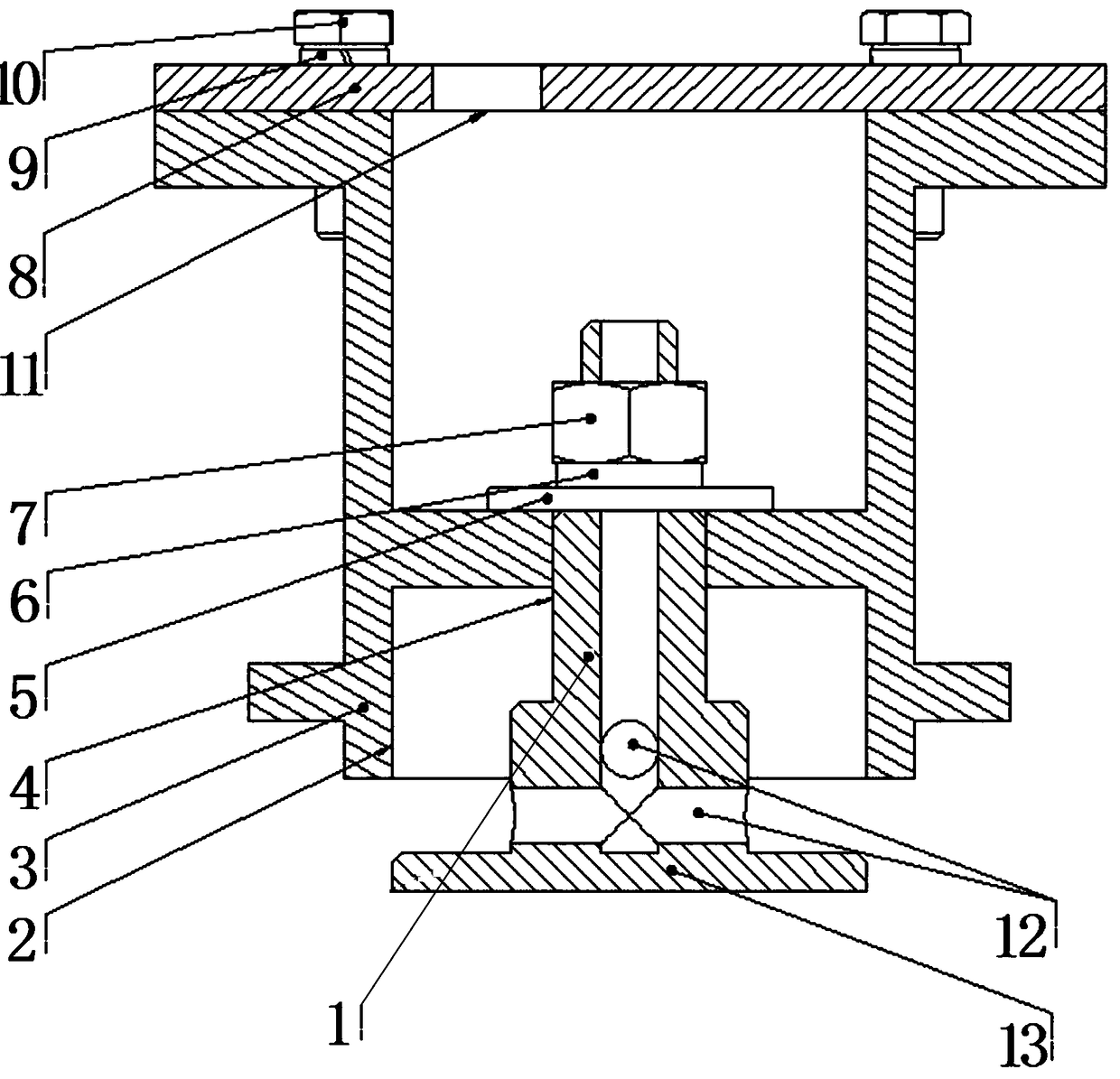

[0022] Below in conjunction with accompanying drawing, the present invention is further explained and illustrated;

[0023] like figure 1 As shown, an integrated inflation and exhaust valve for the pressure plate of the emptying pump for barrels includes an emptying pump barrel body, the pressure plate is located in the barrel body and is used in conjunction with it, the pressure plate is covered with a cylindrical valve body 3, and the barrel The lower end of the valve body 3 is fixed in phase with the bottom surface of the pressure plate, and the upper opening of the valve body 3 covers the valve cover 8, and the two are fixedly connected by bolts 10. The valve cover 8 has an inflation and exhaust port 11, and the valve body 3. The interior is divided into upper and lower chambers by a partition, and a spool hole is provided in the middle of the partition, and the inner diameter of the spool hole matches the outer diameter of the spool 1. The spool goes through the hole, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com