High-freezing point liquid heating device for explosive production

A high freezing point, heating device technology, used in fluid heaters, explosives processing equipment, explosives, etc., can solve the problems of difficult temperature control, unfavorable production, low efficiency, etc., and achieve the effect of preventing serious collision and preventing water evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

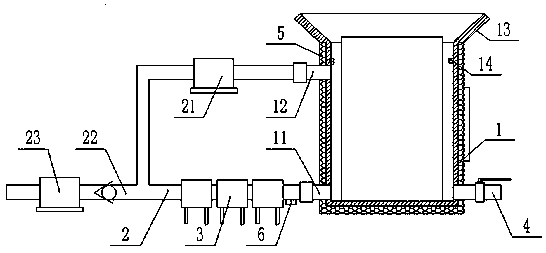

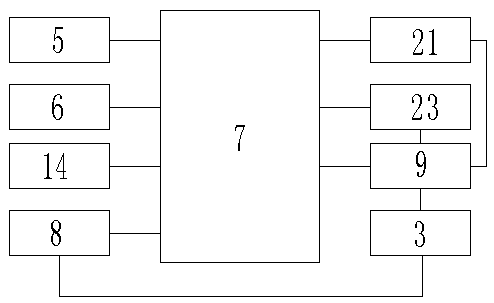

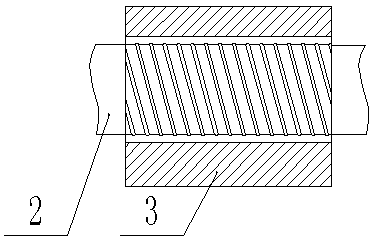

[0022] High freezing point liquid heating device for explosive production, including: constant temperature barrel 1, circulating heating pipe 2, heating group 3, drain outlet 4, temperature sensor 5 in the barrel, circulating pipeline temperature sensor 6, single chip microcomputer 7, heating group controller 8 and Power supply 9; the lower part of the constant temperature barrel 1 is provided with a circulating water inlet 11, the upper part of the constant temperature barrel 1 is provided with a circulating water outlet 12, and a circulating heating pipe 2 is arranged between the circulating water inlet 11 and the circulating water outlet 12. A heating group 3 is arranged on the circulating heating pipe 2 at the water inlet 11, the heating group 3 is connected to the heating group controller 8, and a circulating water pump 21 is arranged between the circulating water outlet 12 and the heating group 3, and the circulating water pump 21 is arranged between the circulating water ...

Embodiment 2

[0030] High freezing point liquid heating device for explosive production, including: constant temperature barrel 1, circulating heating pipe 2, heating group 3, drain outlet 4, temperature sensor 5 in the barrel, circulating pipeline temperature sensor 6, single chip microcomputer 7, heating group controller 8 and Power supply 9; the lower part of the constant temperature barrel 1 is provided with a circulating water inlet 11, the upper part of the constant temperature barrel 1 is provided with a circulating water outlet 12, and a circulating heating pipe 2 is arranged between the circulating water inlet 11 and the circulating water outlet 12. A heating group 3 is arranged on the circulating heating pipe 2 at the water inlet 11, the heating group 3 is connected to the heating group controller 8, and a circulating water pump 21 is arranged between the circulating water outlet 12 and the heating group 3, and the circulating water pump 21 is arranged between the circulating water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com