Integrated lens structure and working method thereof

A technology of lens and rear mirror, which is applied in the direction of cameras, projection devices, printing devices, etc., can solve the problems that the optical axis affects system performance indicators, the structure is not compact enough, and the imaging requirements cannot be met. Large amount, clear and stable imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

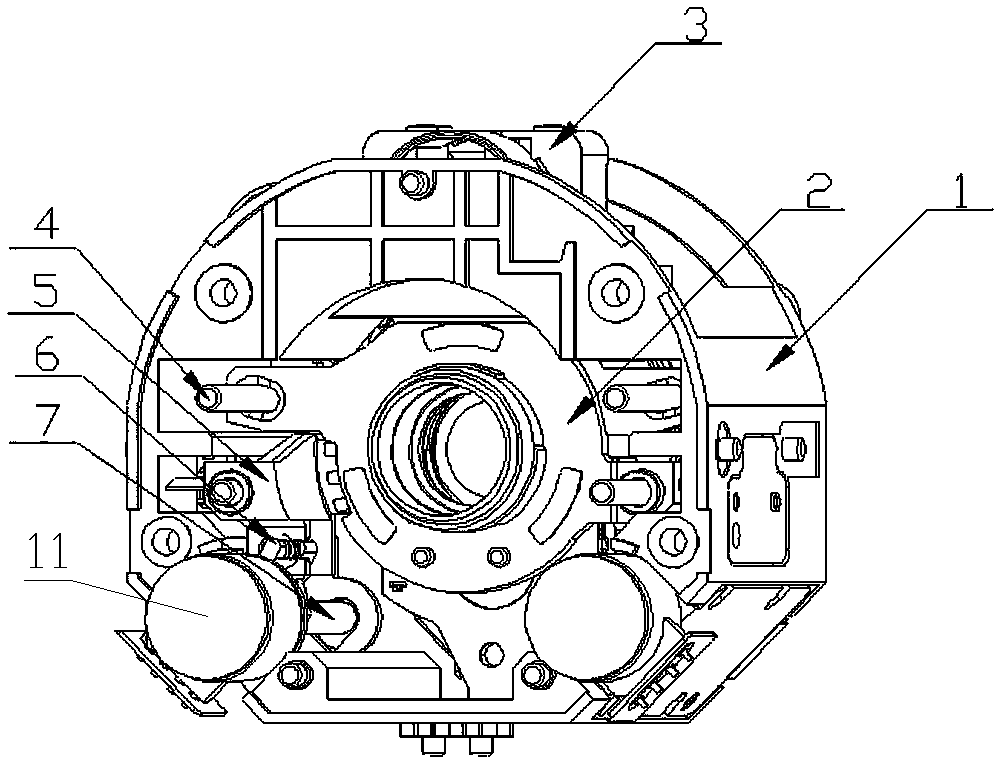

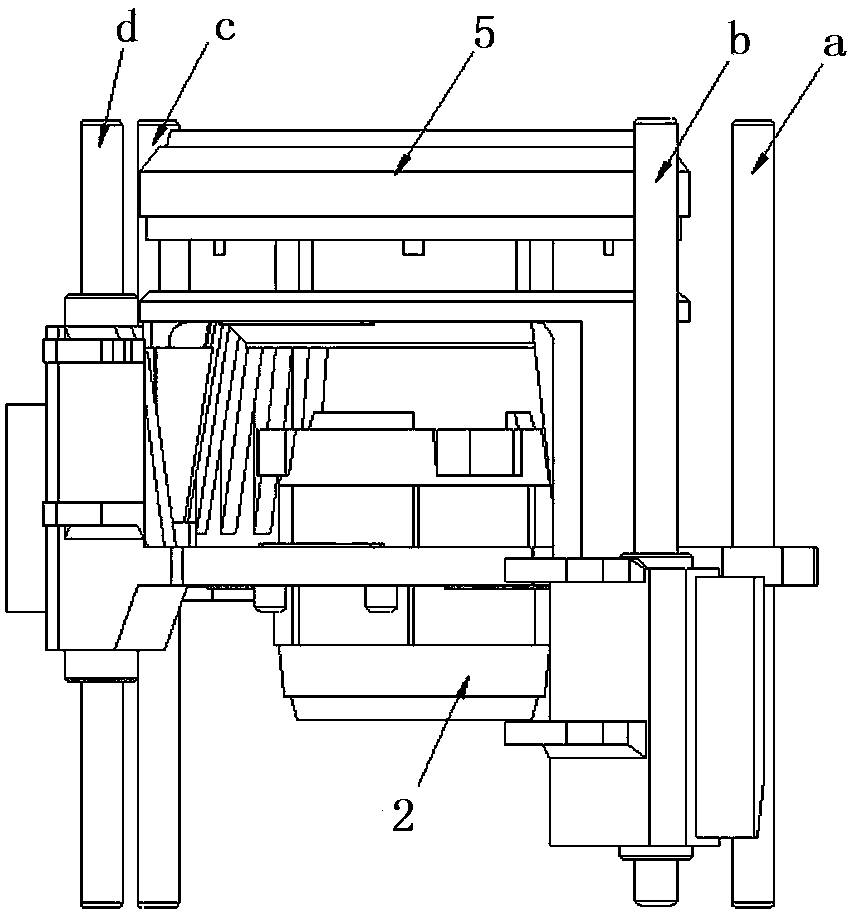

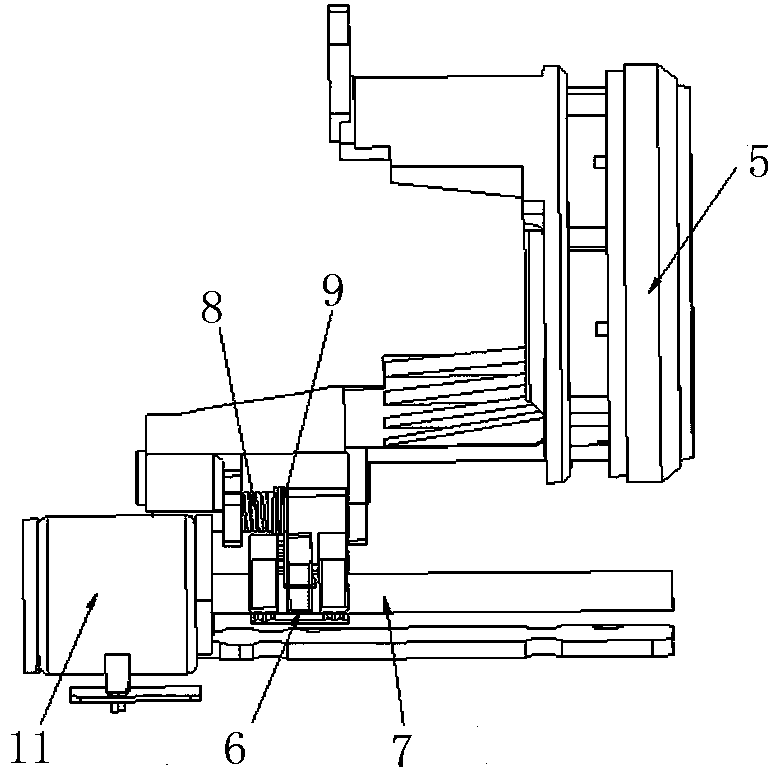

[0018] Such as Figure 1~4 As shown, an integrated lens structure includes a base body 1, and an FPC is inserted into the upper part of the base body 1; a front mirror base 5 and a rear mirror base that can move back and forth relative to the base body are arranged in the seat hole in the middle of the base body 1 2. Two guide rods 4 parallel to the axis of the seat hole are arranged on both sides of the seat hole, and two guide rods (namely, guide rod b and guide rod c) are arranged on both sides of the front mirror holder 5. The other two guide rods (that is, guide rod a and guide rod d) pass through the two sides of the rear mirror holder 2 and slide with it; the two sides of the seat hole are also provided with two respectively To drive the screw rod 7 that the front mirror base and the rear mirror base move back and forth, the front mirror base 5 and the rear mirror base 2 are respectively provided with a driving rod 6 that is threadedly matched with the corresponding scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com