A kind of film shooting wire and method

A film and slider technology, applied in the field of Wia, can solve the problems of controlling self-safety and the inability of actors to save themselves, and achieve the effect of ensuring life safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

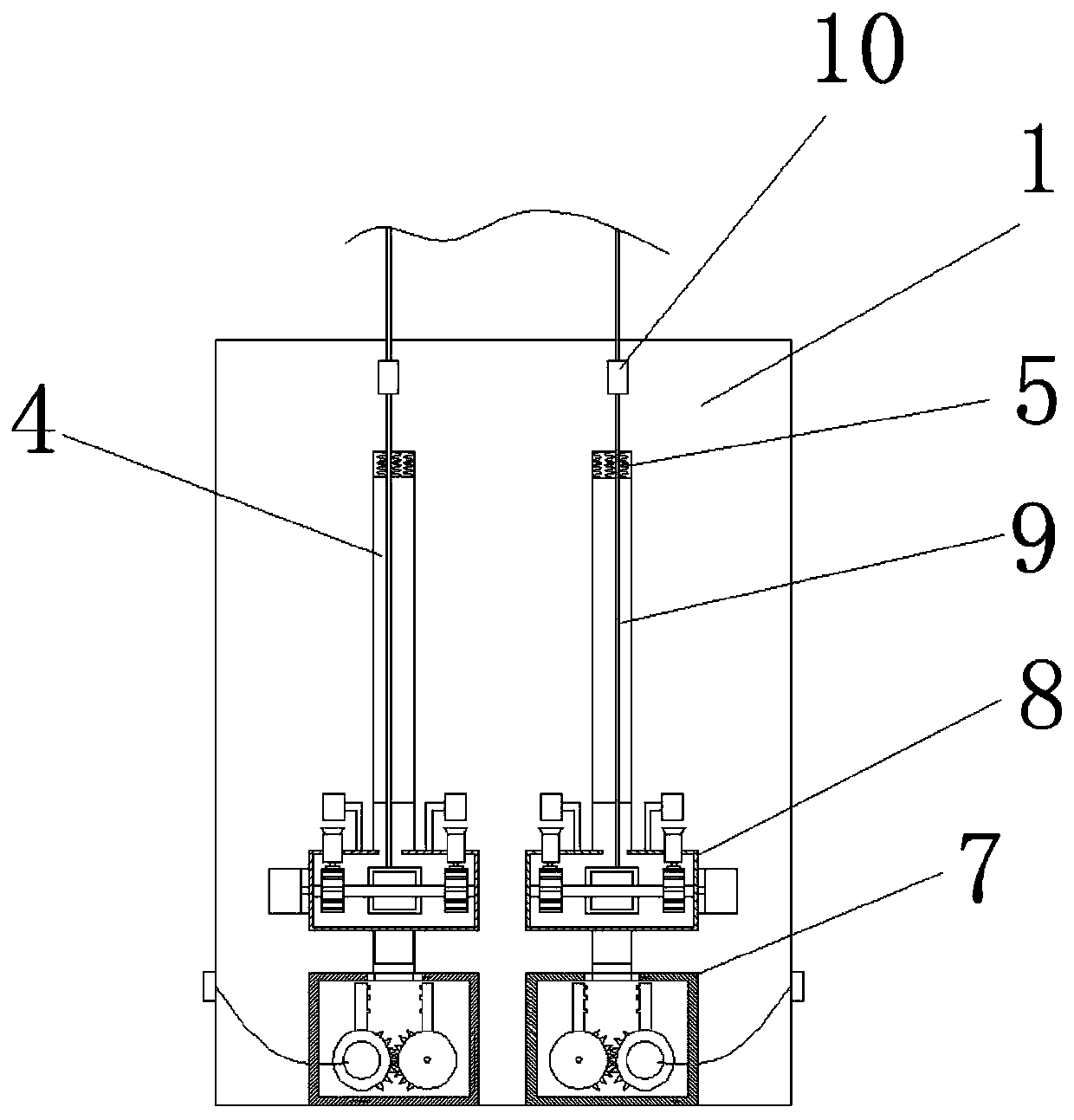

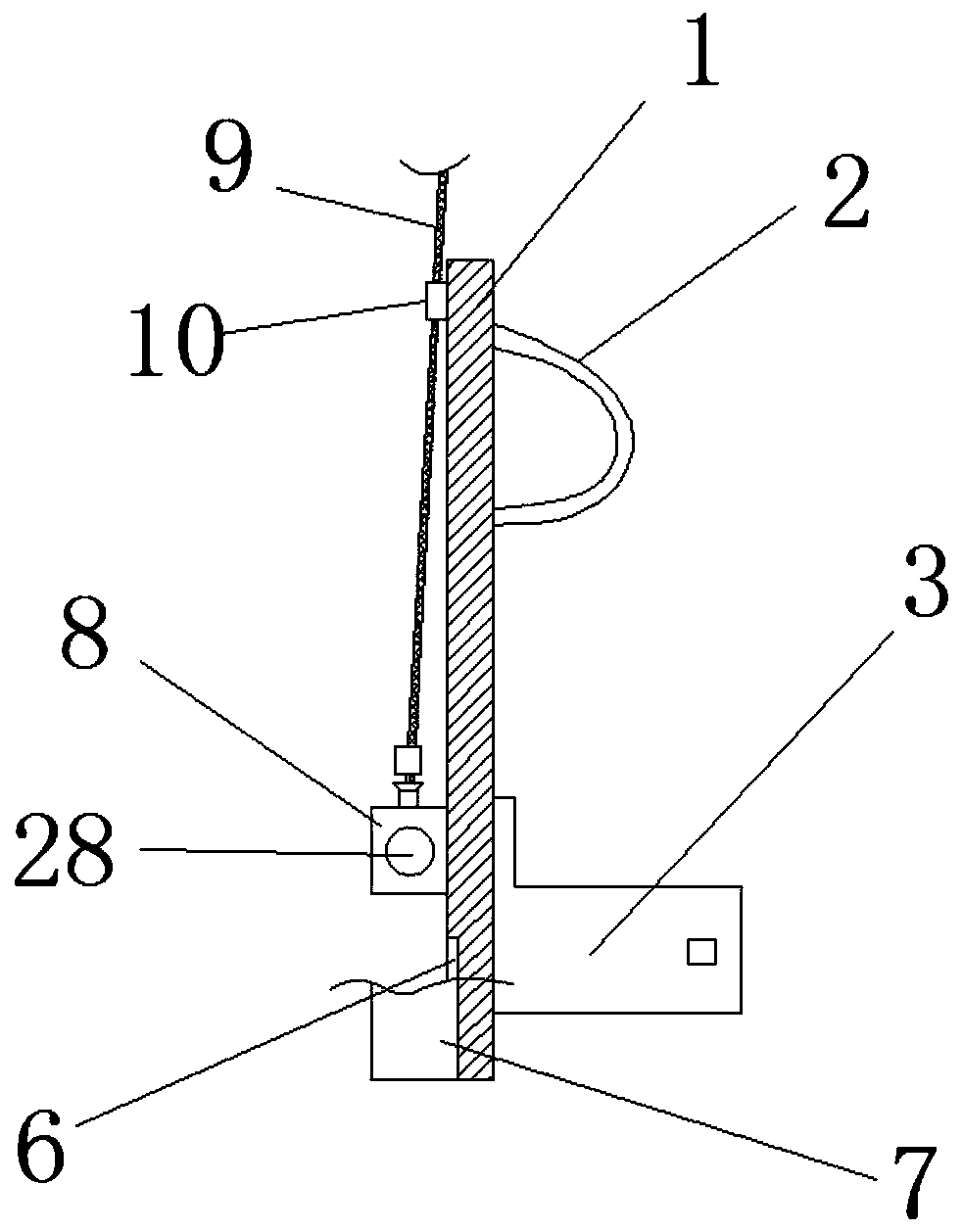

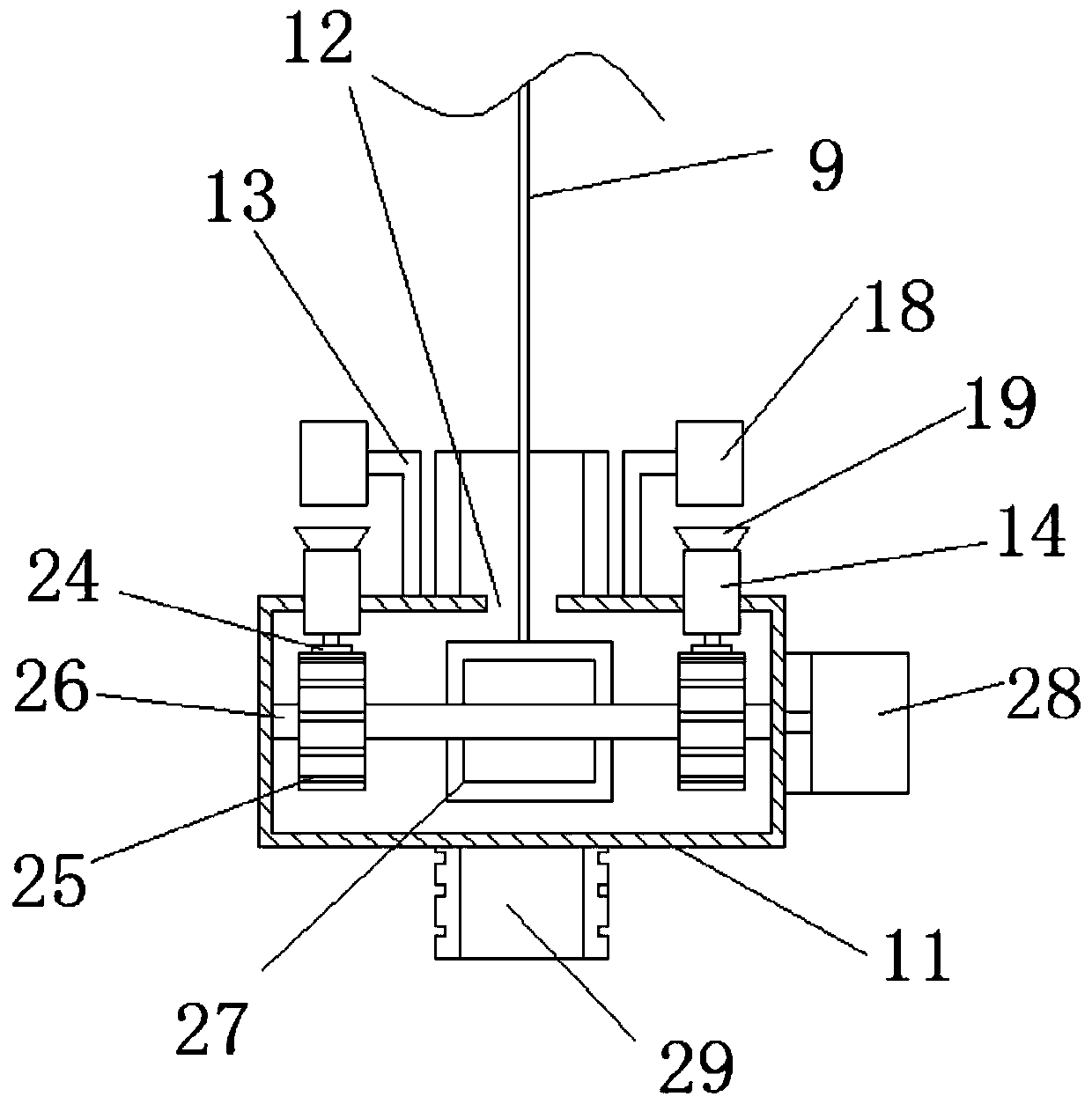

[0037] Such as Figure 1 to Figure 5 As shown, a film shooting wire disclosed in this embodiment includes a backboard 1, a strap 2, a waist belt 3, a shock absorbing spring 5, a fixed box 7, a control device 8, a steel wire 9 and a casing 10; the backboard 1. There is a strap 2 on the front end, a waist belt 3 on the bottom of the strap 2, a T-shaped chute 4 is symmetrically opened on the rear end of the back plate 1, a shock-absorbing spring 5 is arranged on the upper end of the T-shaped chute 4, and a square groove is symmetrically opened on the lower end. 6. There is a fixed box 7 inside the square slot 6. The upper end of the fixed box 7 is connected to the lower end of the control device 8. The control device 8 is symmetrically slid on the T-shaped chute 4. One end of the steel wire 9 is connected to the control device 8, and the other end is through the casing 10;

[0038]Through the function of the back strap 2 and the waist belt 3 provided on the front surface of the ...

specific Embodiment approach 2

[0044] combine Figure 6 As shown, this embodiment is based on the first embodiment, the difference is that the two side walls of the bottom end of the T-shaped slider 29 are provided with limiting grooves 30;

[0045] The bottom side walls of the T-shaped slide block 29 have limit grooves 30, which can be more stably fixed on the fixed box 7 through the limit grooves 30 on the T-shaped slide block 29, fully ensuring the stability, and then ensuring the performance of the actors. It is safe, and can be fixed or separated by human control to achieve the required state.

specific Embodiment approach 3

[0047] combine Figure 7 This embodiment is based on the first embodiment, the difference is that the fixed box 7 includes a fixed box 31, a driving incomplete gear 33, a driven incomplete gear 34, a second motor 35 and a limit bar 36; The front end of the fixed box 31 is fixed in the square groove 6, and the upper end of the fixed box 31 has a T-shaped through hole 32, and the driving incomplete gear 33 and the driven incomplete gear 34 are arranged on the fixed box 31 through the rotation of the rotating shaft. Inside, the second motor 35 is arranged on the rear wall of the fixed box body 31, and the output end of the second motor 35 is connected with the driving incomplete gear 33 through the rotating shaft, and the driving incomplete gear 33 and the driven incomplete gear 34 mesh, and the active Both the incomplete gear 33 and the driven incomplete gear 34 are provided with limiting bars 36, and the two limiting bars 36 are arranged parallel and symmetrically;

[0048] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com