An intelligent operation box with inrush current suppression function

An intelligent operation box and inrush current suppression technology, which is applied in the direction of overcurrent protection, electrical components, information technology support systems, etc., can solve the problem of fixed position and quantity of operation box modules, lack of ability to suppress excitation inrush current, and uncontrollable Circuit breaker opening and closing angle and other issues, to reduce intermediate links, improve accurate control, and suppress the effect of excitation inrush current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] This embodiment uses multi-CPU technology and large-scale FPGA technology to realize the intelligent transformation design of the traditional operation box; uses the main board to control the CPU to implement the inrush current suppression algorithm to complete the integrated design of the intelligent operation box with the inrush current suppression function.

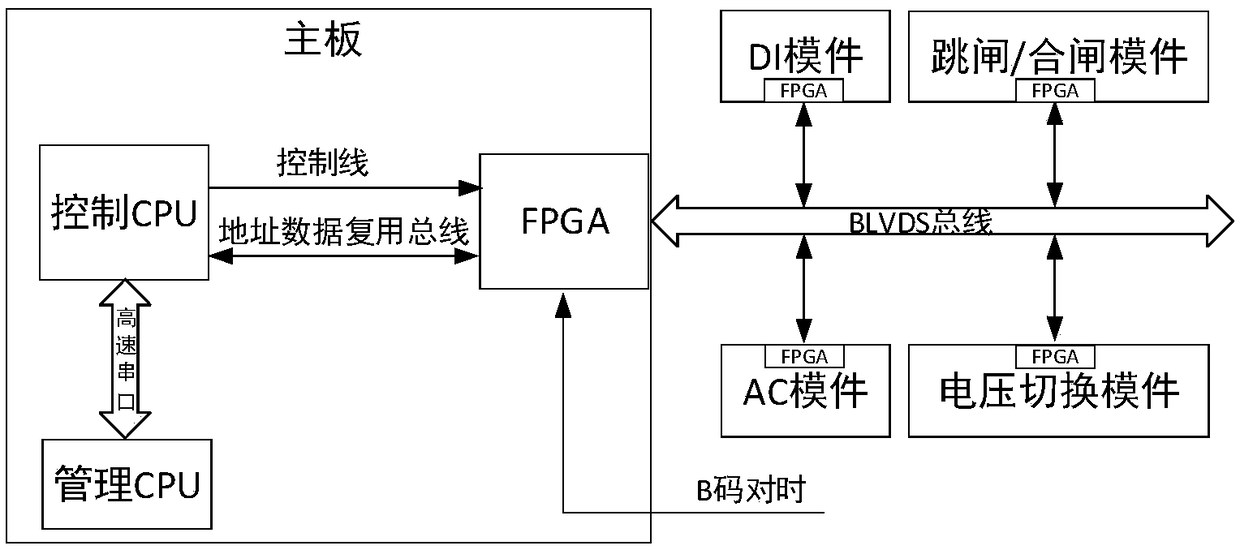

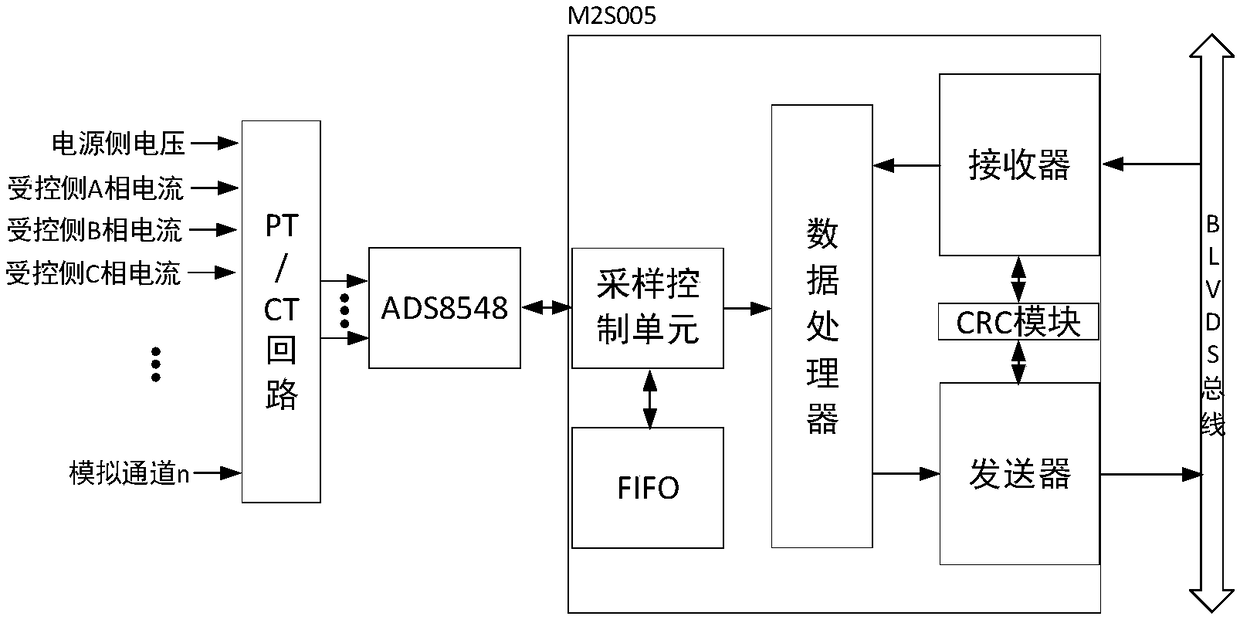

[0061] Such as figure 1 As shown, the intelligent operation box with inrush suppression function includes a main board, an intelligent AC module for collecting AC voltage / current, an intelligent DI module (that is, an input module) for collecting opening and closing commands and circuit breaker position information, and a control circuit breaking module. The tripping / closing module (that is, the output module) of the device opening and closing and the voltage switching module of the switching bus PT.

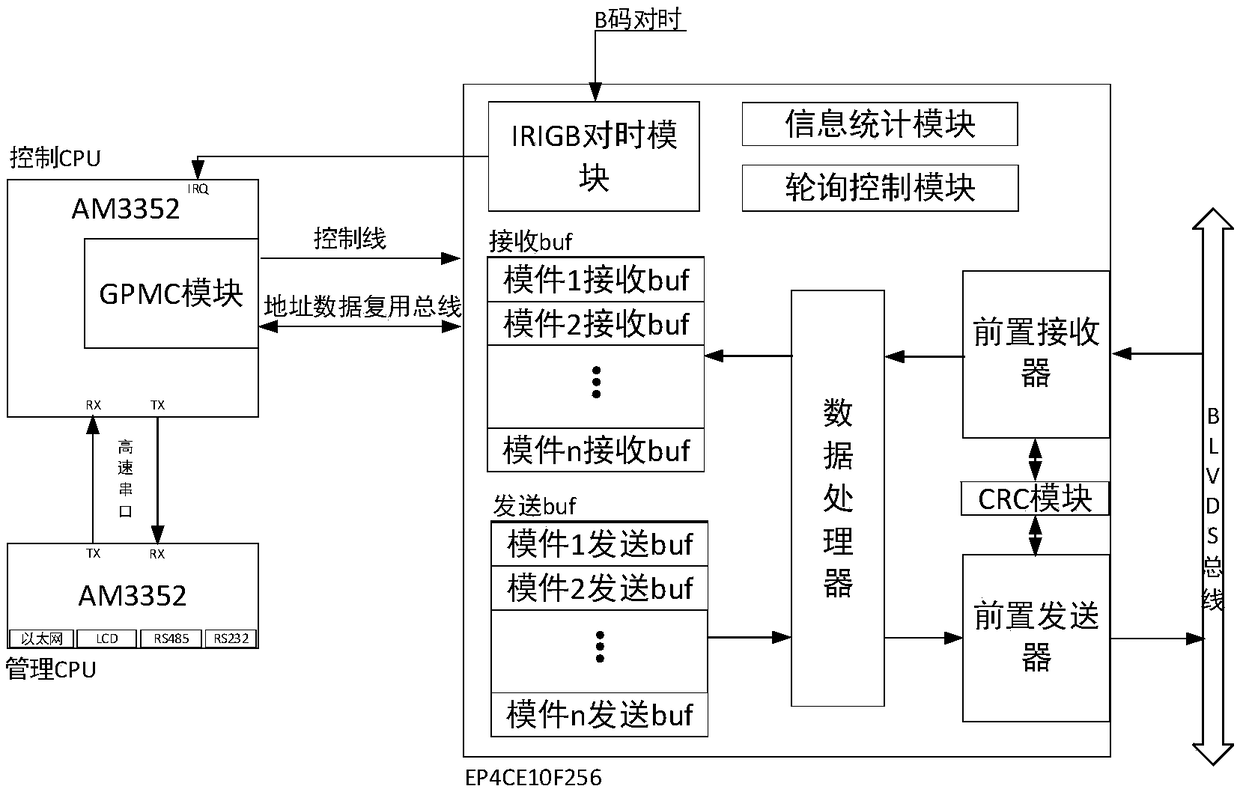

[0062] combine figure 1 and figure 2 , dual CPUs and FPGAs are designed on the motherboard, the dual CPUs ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com