Detector and production mechanism thereof

A detector and end face technology, used in metal processing mechanical parts, clamping, support and other directions, can solve the problems of low processing efficiency of detectors, cumbersome operation steps, single drilling function, etc., to increase rotation flexibility and improve work. Efficiency, simple and convenient clamping work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

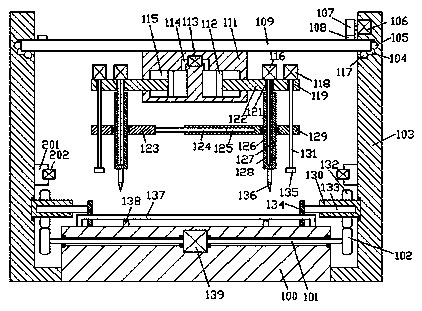

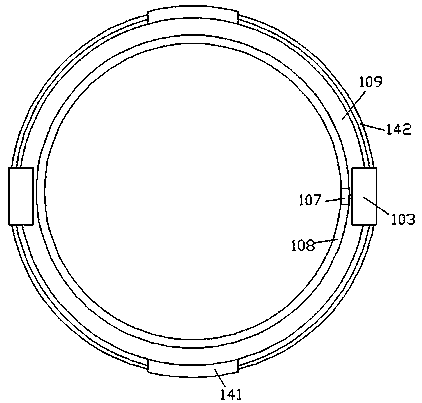

[0017] Combine below Figure 1-2 The present invention will be described in detail.

[0018] refer to Figure 1-2 , a detector and its production mechanism according to an embodiment of the present invention, comprising a base plate 100 and supports 103 symmetrically fixed on the left and right sides of the base plate 100, and the supports 103 on the left and right sides rotate between A turntable 109 is installed in conjunction with it, and a production frame 111 is fixed on the bottom end of the turntable 109. An air pressure chamber 115 is arranged symmetrically in the left and right sides of the production frame 111, and a pushing plate 112 is installed slidingly in the air pressure chamber 115. The opposite end faces of the push plates 112 on the left and right sides are fixed with an adjustment frame 122, and the adjustment frame 112 protrudes from the outer end of the production frame 111 and is slidably connected with it. The top of the air pressure chamber 115 The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com