Patents

Literature

50results about How to "Prevent transfer out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

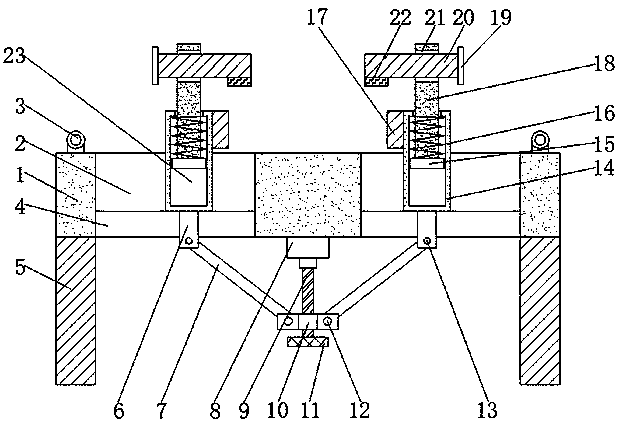

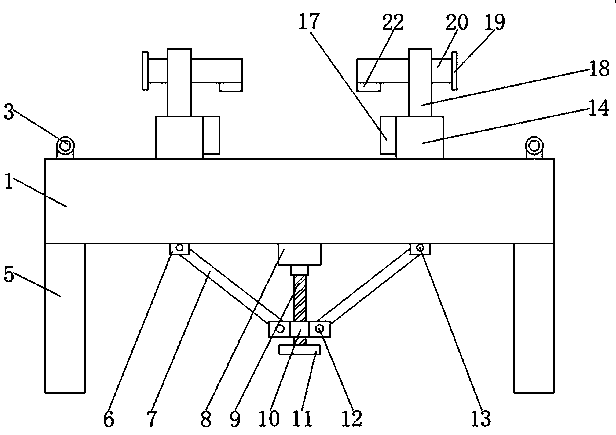

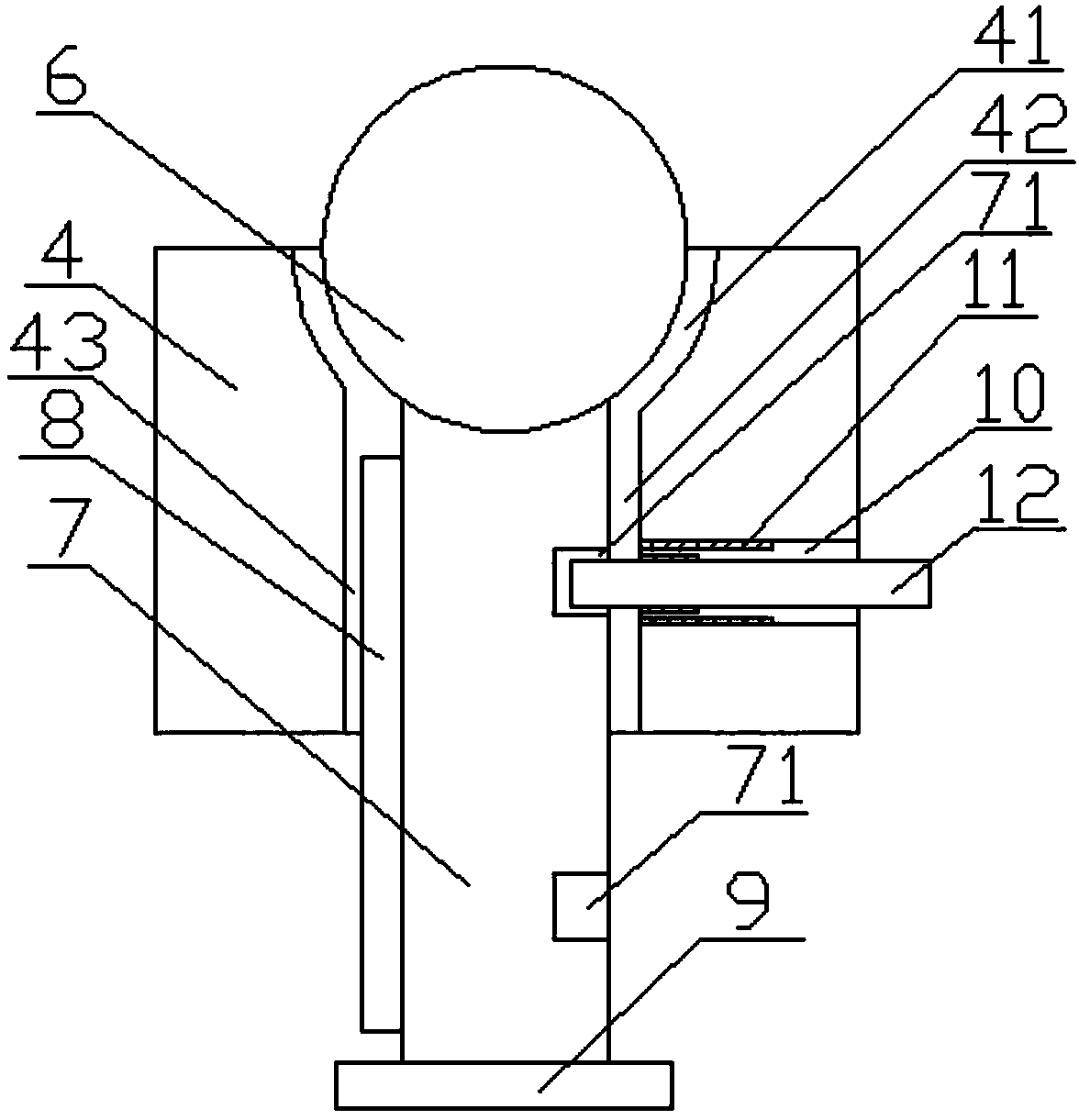

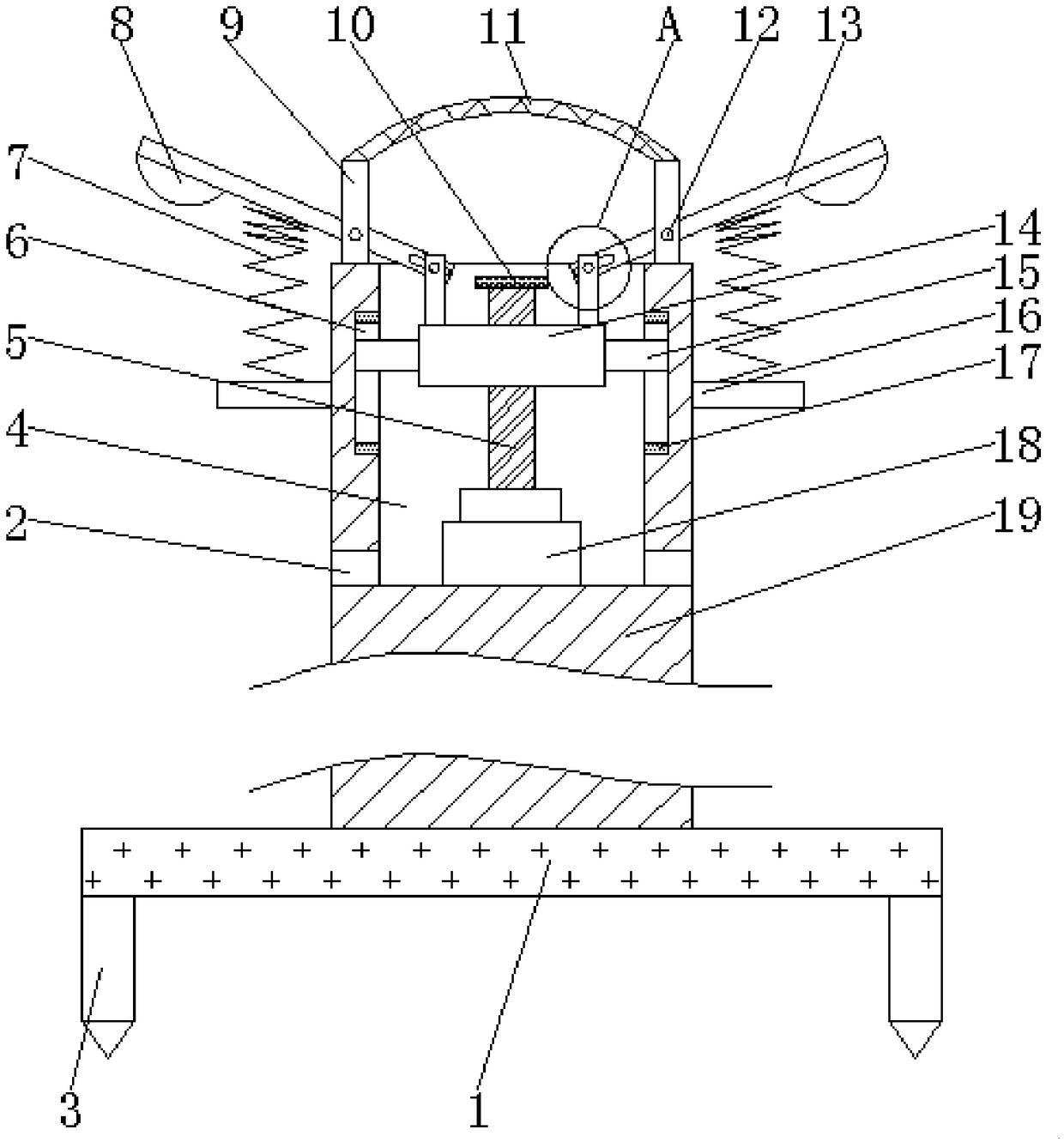

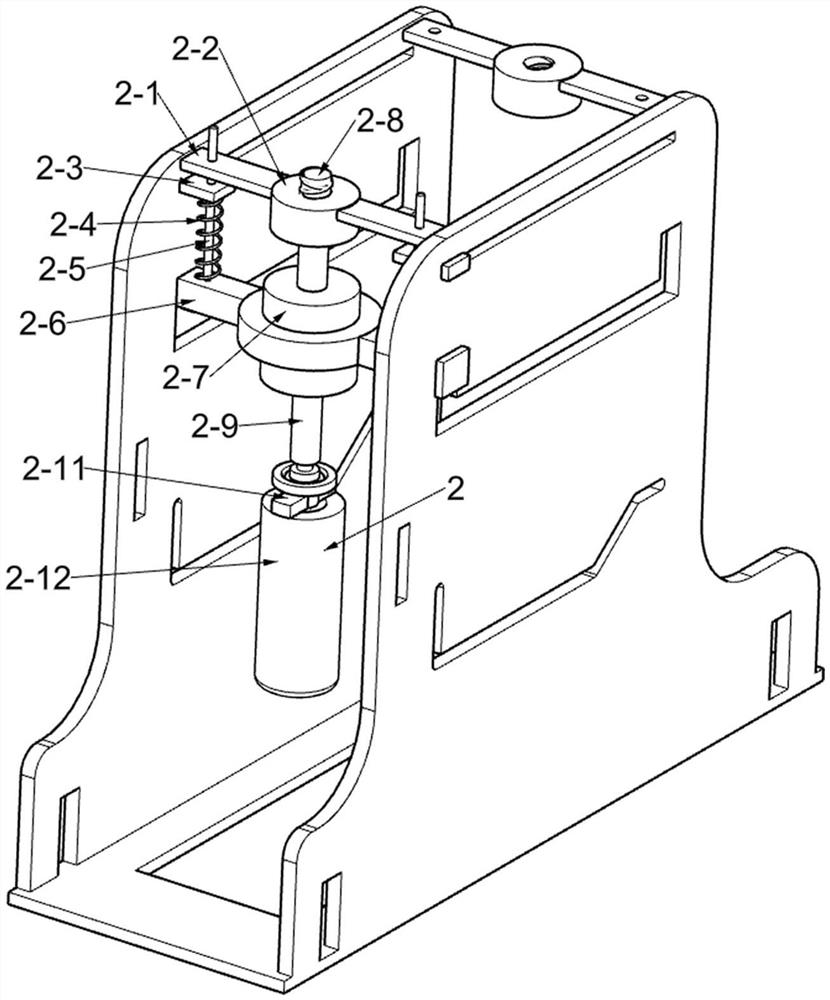

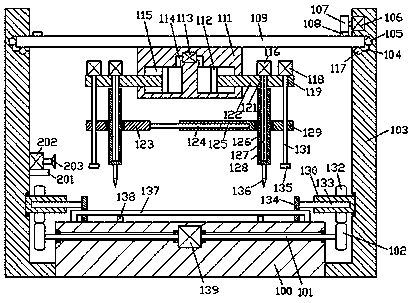

Clamping device for industrial automation

InactiveCN108500684AEasy clampingImprove fastnessPositioning apparatusMetal-working holdersEngineeringBlock match

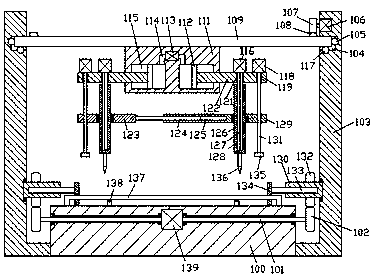

The invention discloses a clamping device for industrial automation. The clamping device comprises a fixing block, the upper surface of the fixing block is provided with two symmetrical sliding grooves, sliding blocks matched with the sliding grooves are arranged in the sliding grooves in a clamped connection mode correspondingly, each sliding block is internally provided with a cavity, first movable rods are placed inside the cavities correspondingly, the top ends of the two first movable rods penetrate through the two cavities and extend to the positions above the sliding blocks, and movableplates matched with the sliding blocks are placed inside the sliding blocks correspondingly. According to the clamping device for industrial automation, since a forward-reverse rotation motor is arranged, the two sliding blocks are made to be close to each other under the effect of push rods, a screw rod and a screw ring, and workpieces can be clamped in the horizontal direction conveniently; since sliding rods are arranged, under the effect of springs, the first movable rods and through holes, the first movable rods can ascend and descend, the sliding rods can move left and right, accordingly, the workpieces are fastened in the vertical direction conveniently, and the purpose that the machined workpieces are longitudinally clamped is achieved.

Owner:芜湖市涵润智能科技有限公司

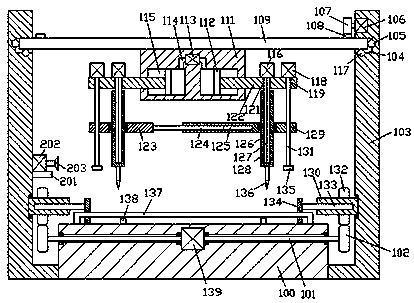

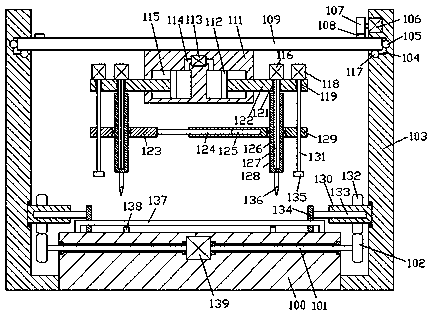

Thermoplastic polymer material equipment

InactiveCN109015879ASimple and convenient clamping workImprove work efficiencyMetal working apparatusEngineeringPneumatic cylinder

The invention discloses thermoplastic polymer material equipment. The equipment comprises a bottom frame and supports fixedly arranged on the left and right sides of the bottom frame in a bilaterallysymmetric manner; a turning disk is mounted between the supports on the left and right sides in a running fit manner; a manufacturing frame is fixedly arranged on the end surface of the bottom of theturning disk; pneumatic cavities are bilaterally symmetrically formed in the manufacturing frame; ejecting push plates are mounted inside the pneumatic cavities in a sliding fit manner; adjusting frames are fixedly arranged on the end surfaces of the sides, opposite to each other, of the ejecting push plates on the left and right sides; the adjusting frames extend out of the outer side end of themanufacturing frame and are connected with the manufacturing frame in a sliding fit manner; pneumatic holes are formed in the top walls of the pneumatic cavities in a communicating manner; the pneumatic holes in the left and right sides are connected with a pneumatic cylinder; the pneumatic cylinder is fixedly arranged inside the manufacturing frame; first penetrating openings are formed in an up-and-down penetrating manner in the adjusting frames extending out of the outer side end of the manufacturing frame; and spline shafts are mounted inside the first penetrating openings in a clearance fit manner.

Owner:福建泉州远方致远自动化科技有限公司

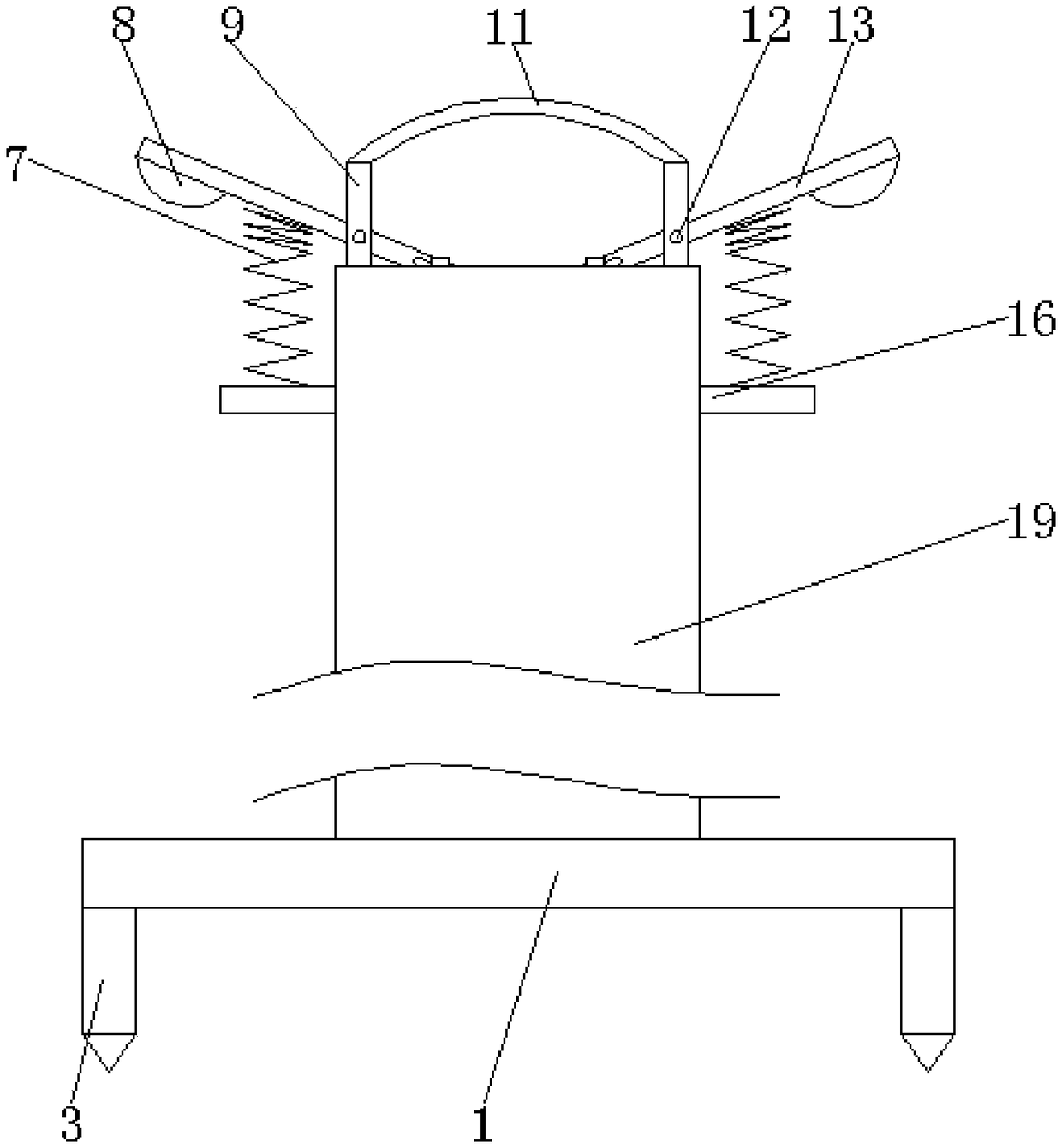

Municipal searchlight equipment

InactiveCN109093142ASimple and convenient clamping workImprove work efficiencyAutomatic control devicesFeeding apparatusBody right sideEngineering

The invention discloses municipal searchlight equipment comprises a base frame and supporting seats bilaterally symmetrically fixedly arranged on left and right sides of the base frame; a rotary tableis rotationally matched and installed between the supporting seats on left and right sides; a work frame is fixedly arranged on the end face of the bottom of the rotary table; atmospheric pressure cavities are bilaterally symmetrically arranged in the work frame; a movable plate is matched and installed in each atmospheric pressure cavity in a sliding manner; positioning frames are fixedly arranged on opposite end faces of the movable plates on left and right sides; the positioning frames stretch out of the outside ends of the work frame to be matched and connected with the same in a slidingmanner; atmospheric pressure holes are formed in the top walls of the atmospheric pressure cavities in a communicating manner; the atmospheric pressure holes on the left and right sides are separatelyconnected with a pneumatic cylinder; the pneumatic cylinder is fixedly arranged in the work frame; a first hole cavity is arranged in each positioning frame stretching out of the outside end of the work frame in an up-down penetrating manner; and a spline shaft is installed in each first hole cavity in a clearance fitting manner.

Owner:泉州睿骋企业管理咨询有限公司

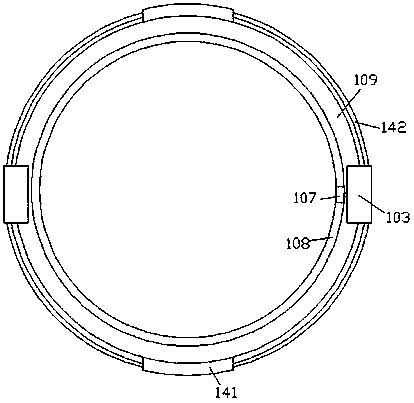

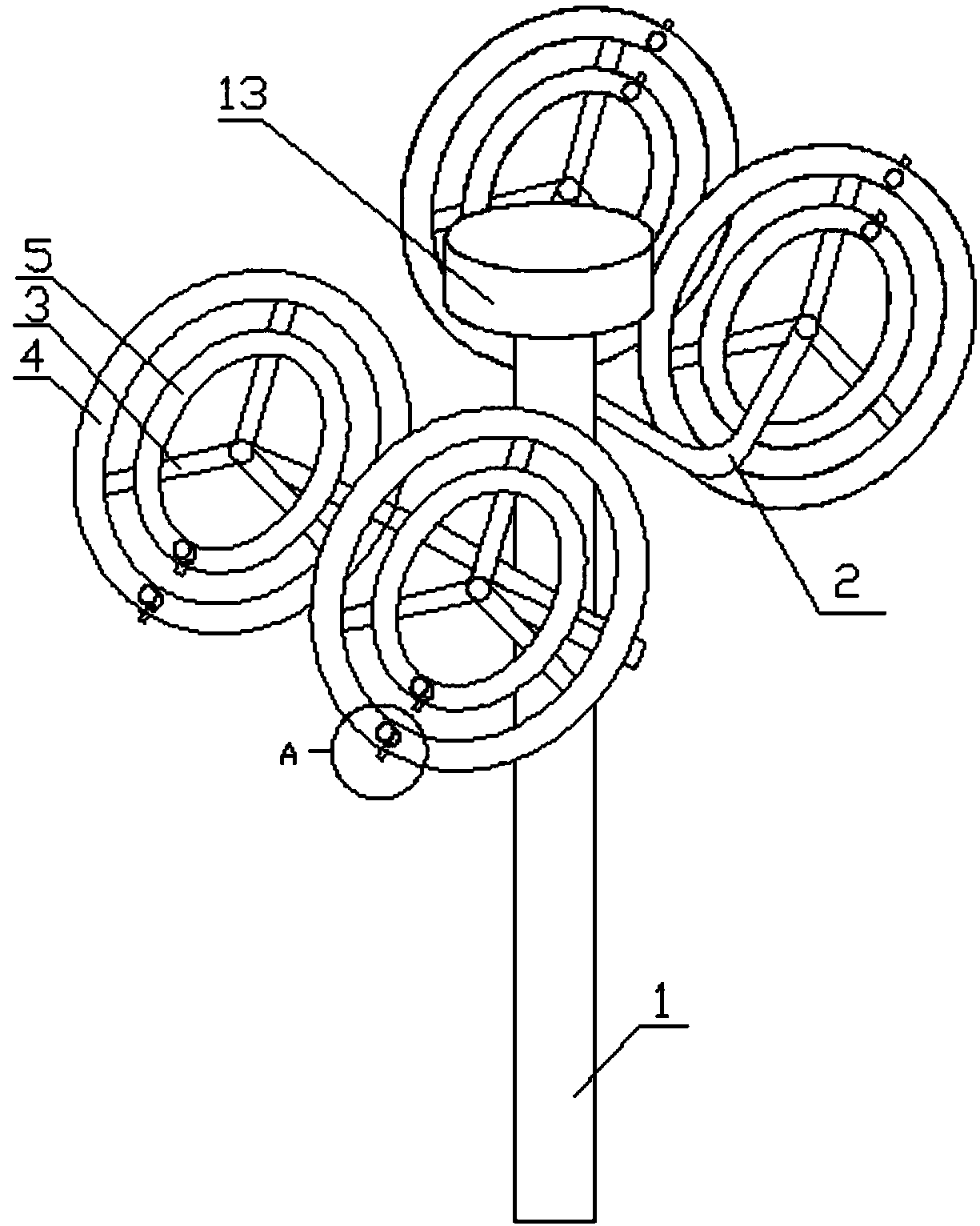

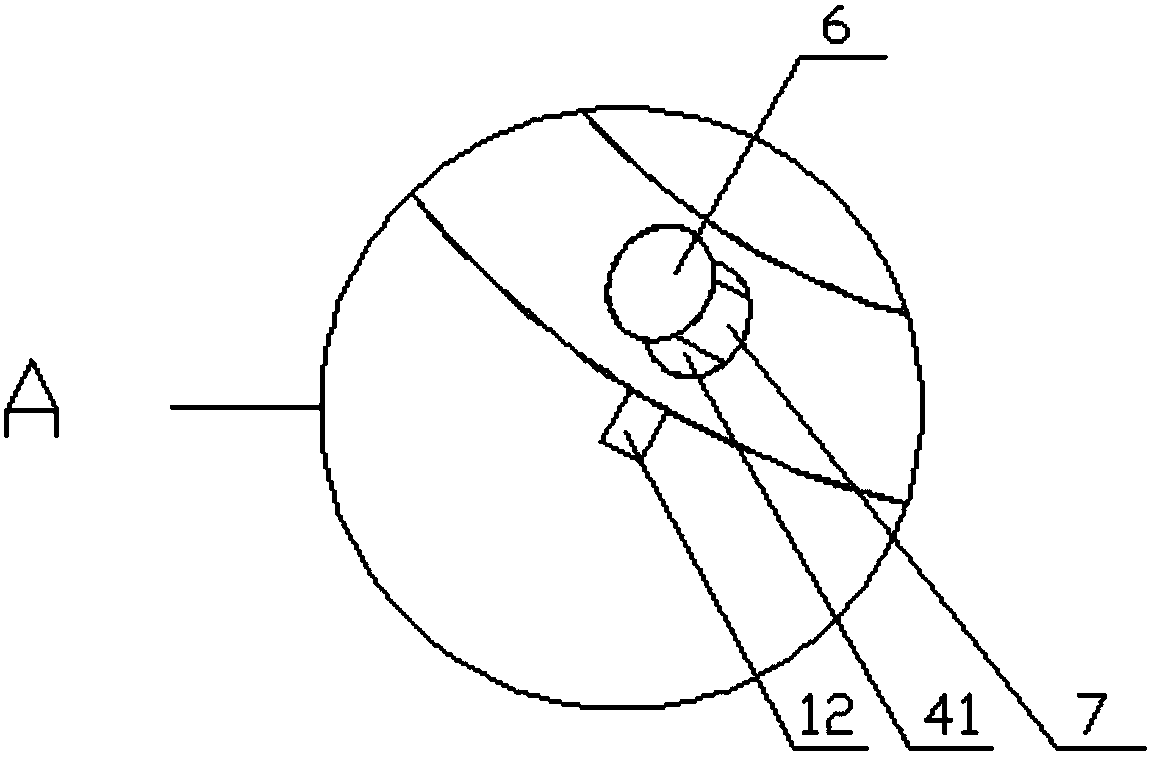

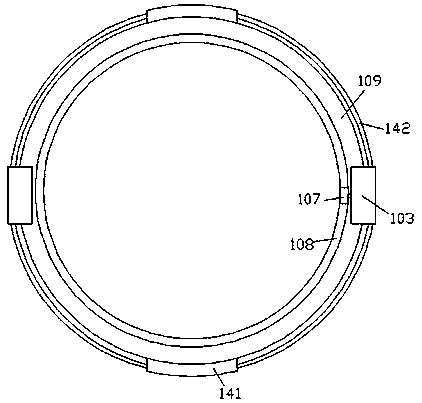

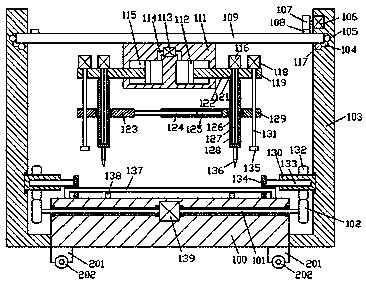

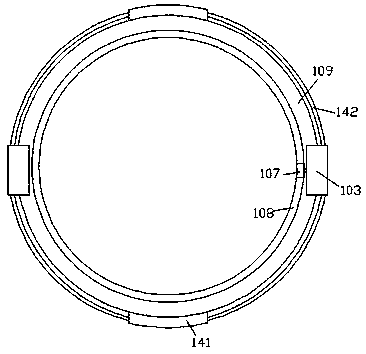

Taiji kneading pushing machine

The invention provides a Taiji kneading pushing machine. The Taiji kneading pushing machine comprises a stand column and supporting arms, and is characterized by comprising connecting rods, large rotating rings, small rotating rings, handles, an object containing box; the handles are installed on the large rotating rings, and arc-shaped grooves are formed in the large rotating rings; slides are formed in the bottom surfaces of the arc-shaped grooves, and sliding rods are installed at the bottoms of the handles; and fixing strips are installed on the side surfaces of the sliding rods, the sliding rods are installed in the slides, and clamping grooves are formed in the sliding rods. According to the Taiji kneading pushing machine, the handles are separately installed on the large rotating rings and the small rotating rings to meet the needs of exercise of people with different arm lengths; and by moving the sliding rods in the slides, whether the clamping groove with the high position orthe clamping groove with the low position correspond to screws or not is determined, and one ends of the screws can be rotated into the corresponding clamping grooves by rotating the screws, so thatthe height of the sliding rods is fixed, the adjustment of the height of the handles can be achieved, and the Taiji kneading pushing machine is more convenient for the people with the different arm lengths to catch the handles more properly.

Owner:TIANJIN CHUNHE SCHOOLYARD ATHLETIC FACILITY

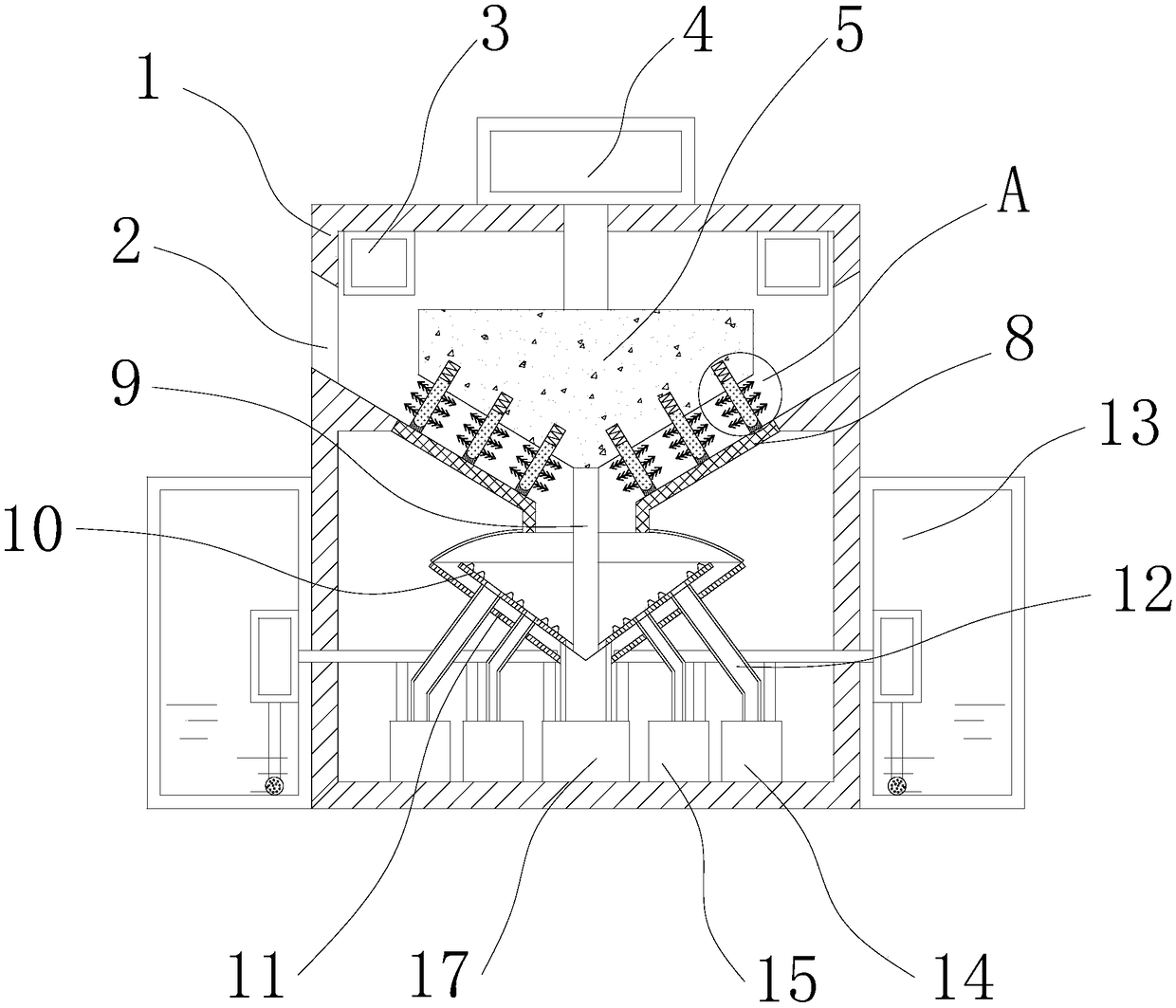

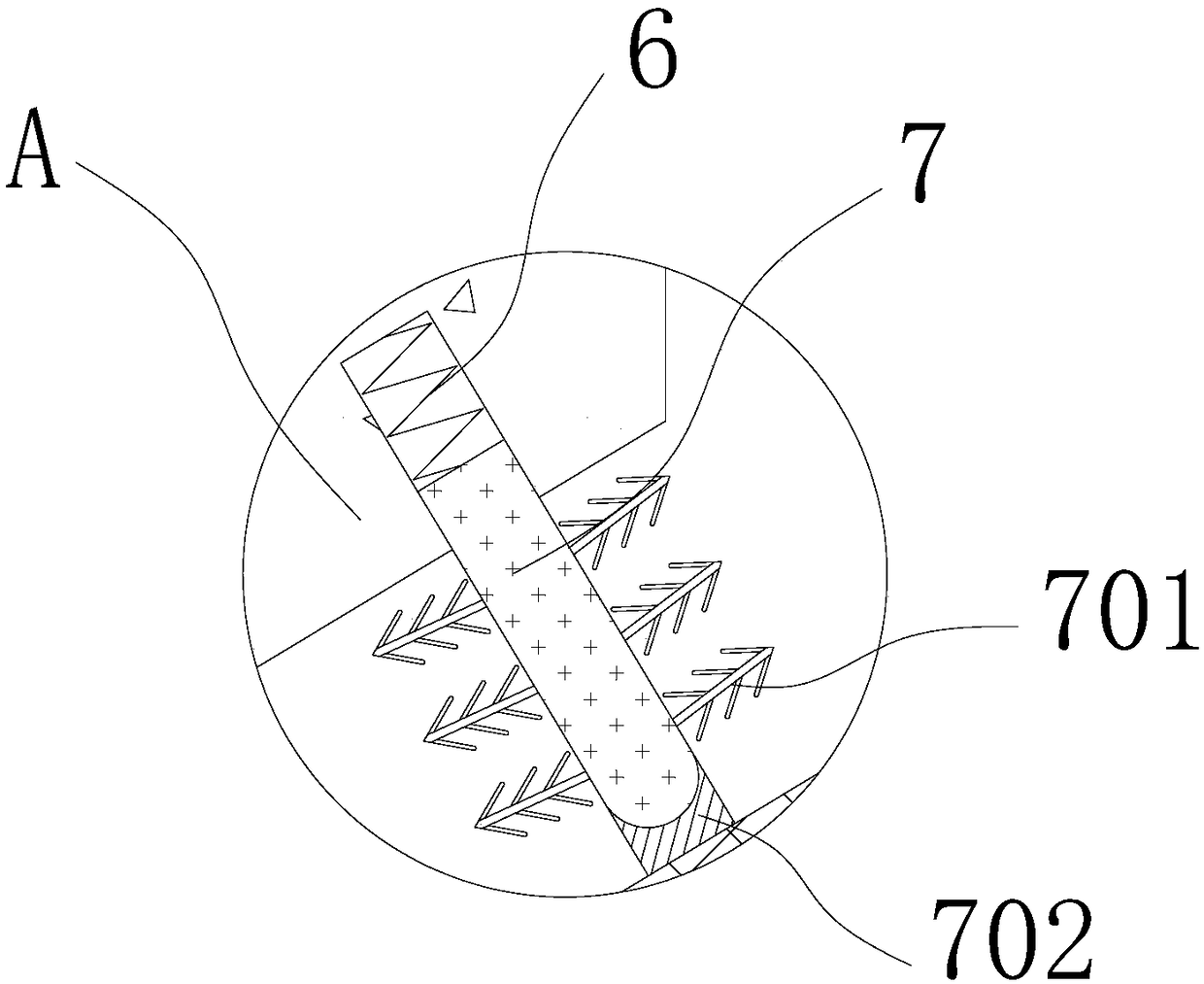

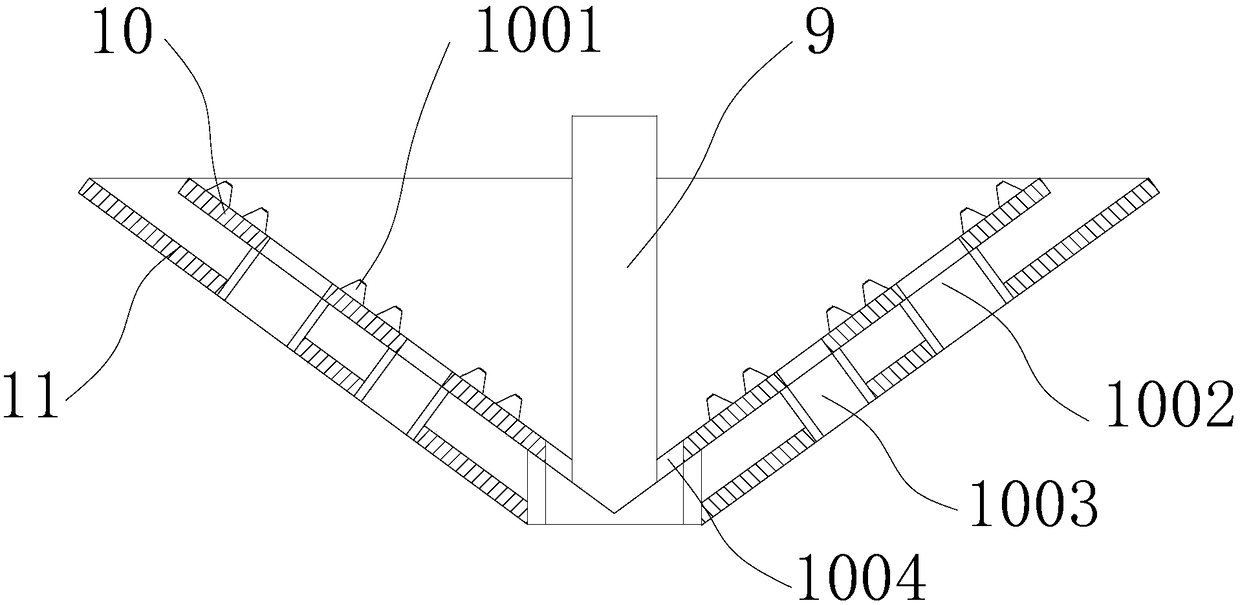

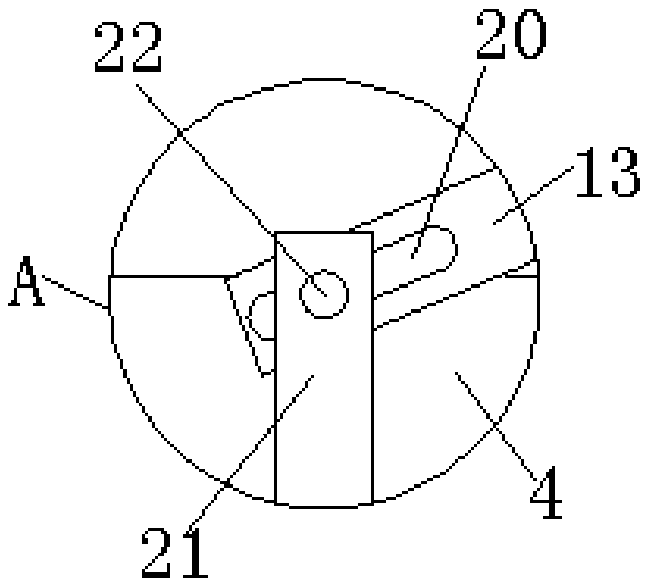

Refuse landfill soil remediation device

InactiveCN109332375APromote fragmentationIncrease the number of cornersContaminated soil reclamationLitterSoil remediation

The invention provides a refuse landfill soil remediation device which comprises a shell, soil inlets, dryers, a motor, a joint, a spring, a crushing rod, a protruding rod, a scraper blade, a baffle,a connecting shaft, a movable disc, a projection, a first discharge port, a second discharge port, a third discharge port, a fixed disc, a connecting pipe, a liquid supply device, a first mixing drum,a stirring blade, a second mixing drum, a third mixing barrel, a fixed shaft, a rotary disc, an open area and a narrow area. The soil inlets are formed in the upper portions of the two sides of the shell, the dryers are fixedly connected to the two sides of the top of the inner wall of the shell, the motor is fixedly mounted on the top of the shell, and the bottom of the motor is in rotary connection with the joint. In the using process, the rotary disc is in an arc edge triangular shape, the fixed shaft is located at the eccentric position of the rotary disc, the fixed shaft is rotatably connected with the rotary disc, so that the rotary disc is capable of rotating around the fixed shaft, the rotary disc transfers soil in the open area to the narrow area, the soil is stirred and ground,the soil with small weight is further refined, and practicability is high.

Owner:赵鹏

Manufacturing equipment for monitors

InactiveCN109175439ASimple and convenient clamping workImprove work efficiencyBoring/drilling machinesEngineeringAtmospheric pressure

The invention discloses manufacturing equipment for monitors. The manufacturing equipment comprises a bottom plate and supports, wherein the supports are fixedly arranged on the left and right sides of the bottom plate in a bilateral symmetry mode. A rotating frame is mounted between the supports on the left and right sides in a rotating fit mode. A production frame is fixedly arranged on the bottom end face of the rotating frame. Air pressure cavities are formed in the production frame in a bilateral symmetry mode. Pushing plates are mounted in the air pressure cavities in a sliding fit mode.Adjusting frames are fixedly arranged on the end faces of the opposite sides of the pushing plates on the left and right sides, and the adjusting frames stretch out of the outer side end of the production frame and are connected with the production frame in a sliding fit mode. Air pressure holes are formed in the top walls of the air pressure cavities in a communicating mode. The air pressure holes in the left and right sides are connected with an air pressure cylinder which is fixedly arranged in the production frame. First penetrating grooves are formed in the adjusting frames stretching out of the outer side end of the production frame in a vertically penetrating mode, and spline shafts are mounted in the first penetrating grooves in a clearance fit mode.

Owner:泉州市华泽数字科技有限公司

Thin-wall microcellular foaming material and preparation facility thereof

InactiveCN109129696ASimple and convenient clamping workImprove work efficiencyMetal working apparatusAtmospheric pressureBilateral symmetry

The invention discloses a thin-wall microcellular foaming material and a preparation facility thereof. The preparation facility comprises a base and supporting seats fixedly arranged on the left and right sides of the base in a bilateral symmetry mode. A rotary connecting disc is installed between the supporting seats on the left and right sides in a rotary fit mode. A machining frame is fixedly arranged on the bottom end face of the rotary connecting disc. Air pressure cavities are formed in the machining frame in a bilateral symmetry mode. Piston plates are installed in the air pressure cavities in a sliding fit mode. Adjusting frames are fixedly arranged on the end faces of the opposite sides of the piston plates on the left and right sides. The adjusting frames stretch out of the outerside end of the machining frame and are connected with the machining frame in a sliding fit mode. The top walls of the air pressure cavities are provided with air pressure holes in a communicating mode. The air pressure holes in the left and right sides are connected with air pressure cylinders. The air pressure cylinders are fixedly arranged in the machining frame. The parts, stretching out of the outer side end of the machining frame, of the adjusting frames are provided with first penetrating cavities in a vertical penetrated mode. Spline shafts are installed in the first penetrating cavities in a clearance fit mode.

Owner:泉州市披风熊科技有限公司

Rapid forming method of fiber reinforced composite board

InactiveCN109015878ASimple and convenient clamping workImprove work efficiencyLighting elementsMetal working apparatusFiber-reinforced compositeEngineering

The invention discloses a rapid forming method of a fiber reinforced composite board. The method includes a base board, and vertical frames which are symmetrically fixedly arranged at the left side and the right side of the base board, wherein a rotating ring is mounted between the vertical frames at the left side and the right side in a rotating fitting manner; a manufacturing frame is fixedly arranged on the end surface of the bottom part of the rotating ring; air pressure chambers are symmetrically arranged at the inner left and right of the manufacturing frame; compressing boards are mounted in the air pressure chambers in a sliding fitting manner; distance adjusting frames are fixedly arranged on the end surfaces of the opposite sides of the compressing boards at the left side and theright side; the distance adjusting frames extend out of the outer side end of the manufacturing frame and are connected to the outer side end of the manufacturing frame in a sliding fitting manner; air pressure holes are formed in the top walls of the air pressure chambers in a communication manner; the air pressure holes in the left side and the right side are correspondingly connected to air pressure cylinders which are fixedly arranged in the manufacturing frame; the distance adjusting frames which extend out of the outer side end of the manufacturing frame are provided with first slots which penetrate the top and the bottom; and spline shafts are mounted in the first slots in a clearance fit manner.

Owner:惠安县正和机械设备有限公司

Low temperature resistant flame-retardant PVC material and preparation method thereof

InactiveCN109227734ASimple and convenient clamping workImprove work efficiencyMetal working apparatusAtmospheric pressurePneumatic cylinder

The invention discloses a low temperature resistant flame-retardant PVC material and a preparation method thereof. The material comprises a base and supporting frames bilaterally symmetrically and fixedly arranged on the left and right sides of the base. A rotating disc is in rotating fit between the supporting frames on the left and right sides. A preparation frame body is fixedly arranged at theend face of the bottom of the rotating disc. Pneumatic cavities are bilaterally symmetrically arranged inside the preparation frame body. Top pressing plates are in sliding fit with the interiors ofthe pneumatic cavities, an adjusting frame is fixedly arranged at the end face of the sides opposite to the top pressing plates, the adjusting frame stretches out of the outer side end of the preparation frame body and is in sliding fit with the preparation frame body, pneumatic holes are communicated with the top wall of the pneumatic cavities, the pneumatic holes in the left and right sides areconnected with pneumatic cylinders, the pneumatic cylinders are fixedly arranged inside the preparation frame body, first through holes vertically run through the adjusting frame stretching out of theouter side end of the preparation frame body, and spline shafts are in clearance fit with the interiors of the first through holes.

Owner:安溪杰创新能源科技有限公司

Municipal administration street lamp facilitating lighting angle adjustment

InactiveCN108826162AEasy to adjust the lighting angleImprove securityLighting support devicesProtective devices for lightingEngineering

Owner:宿迁市众创空间科技有限公司

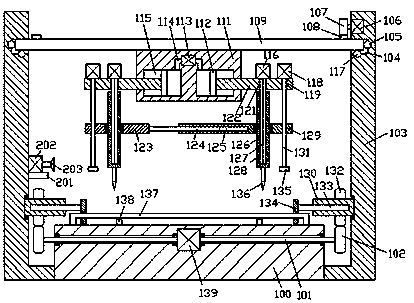

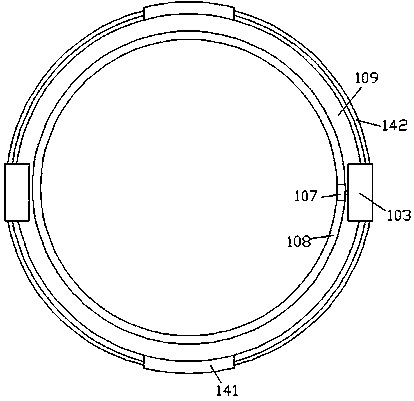

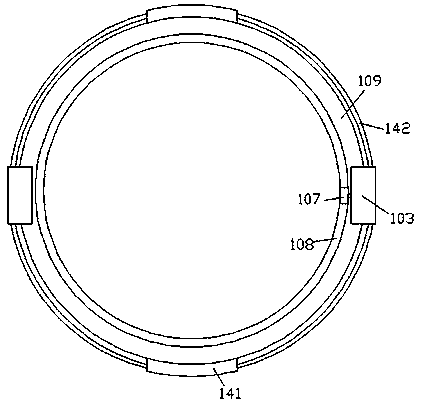

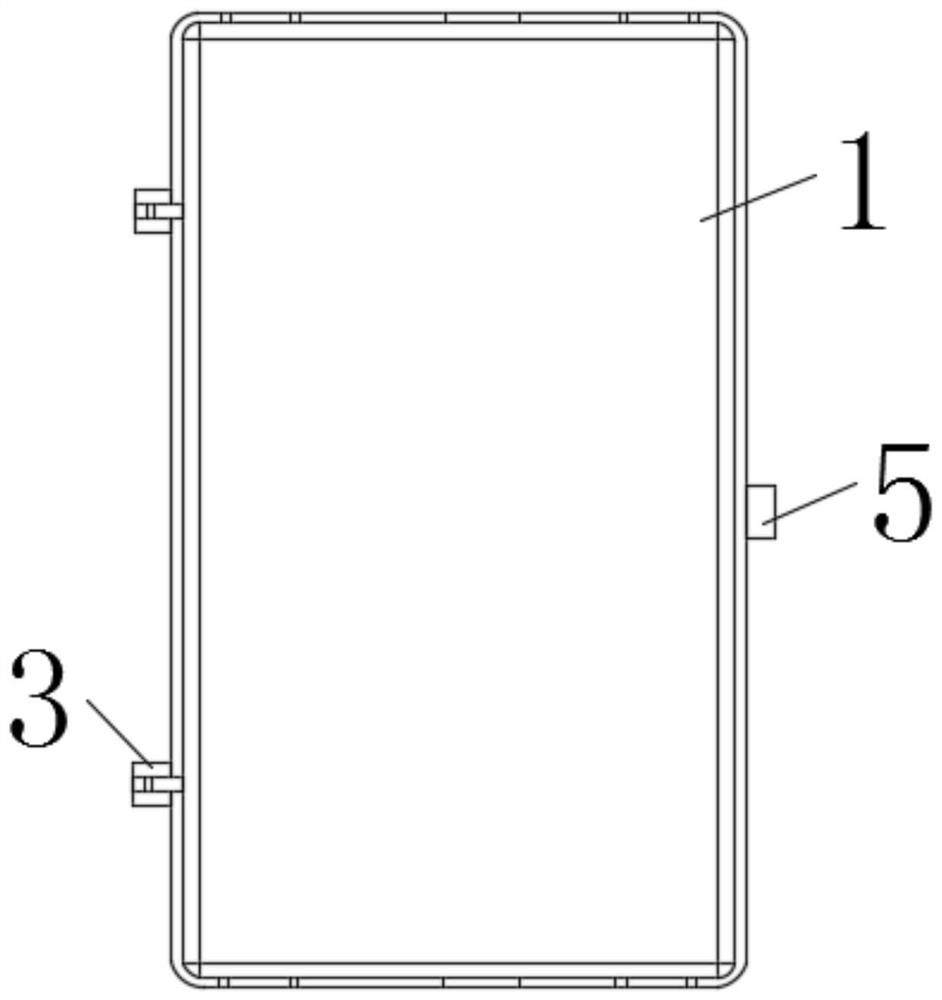

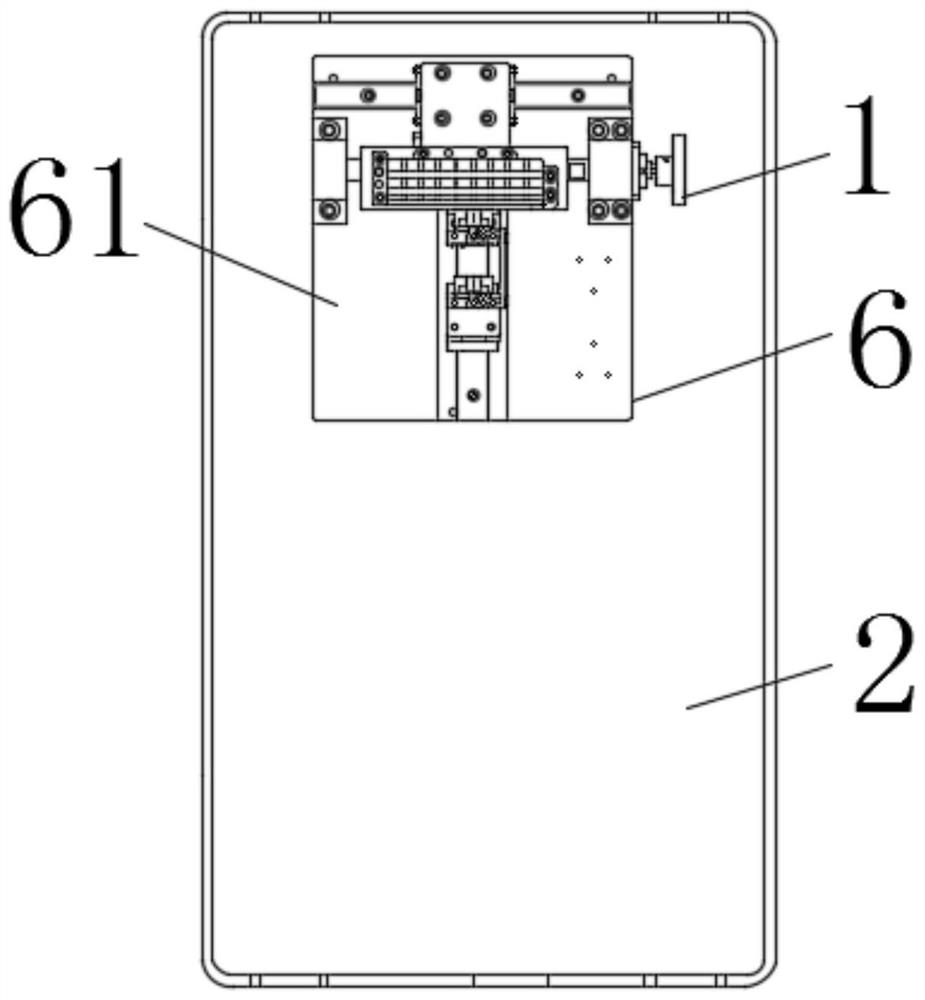

Converged gateway equipment based on multiple computer network communication technologies

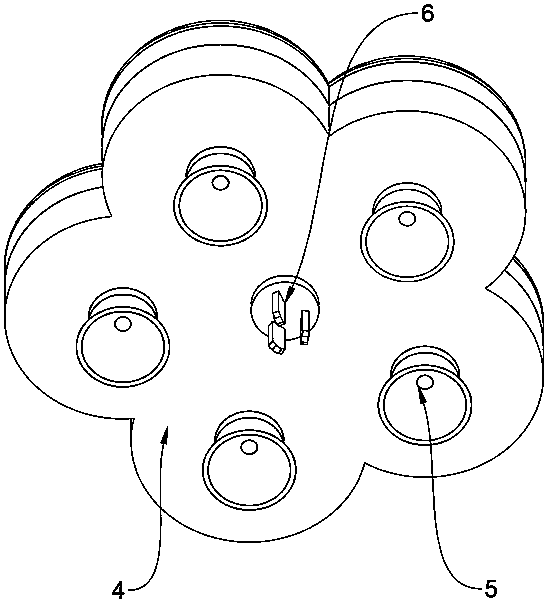

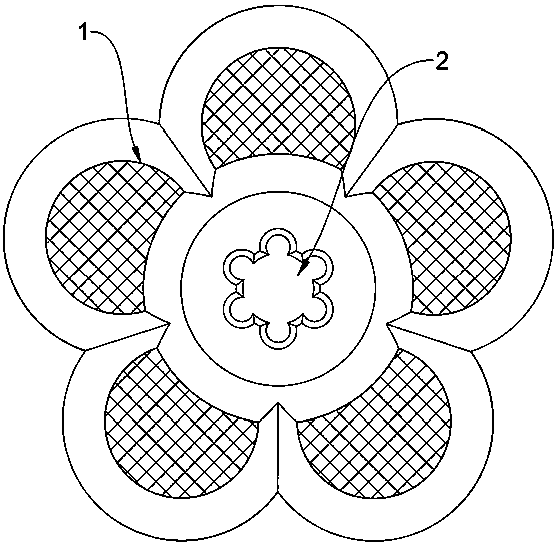

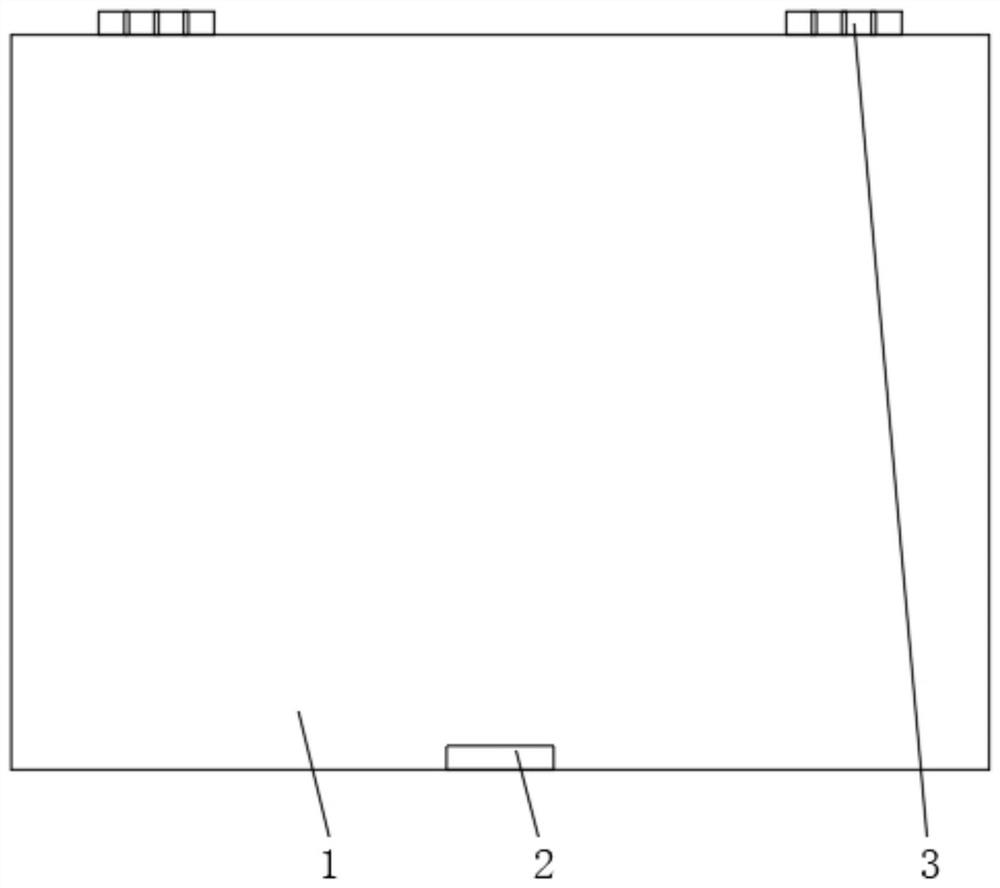

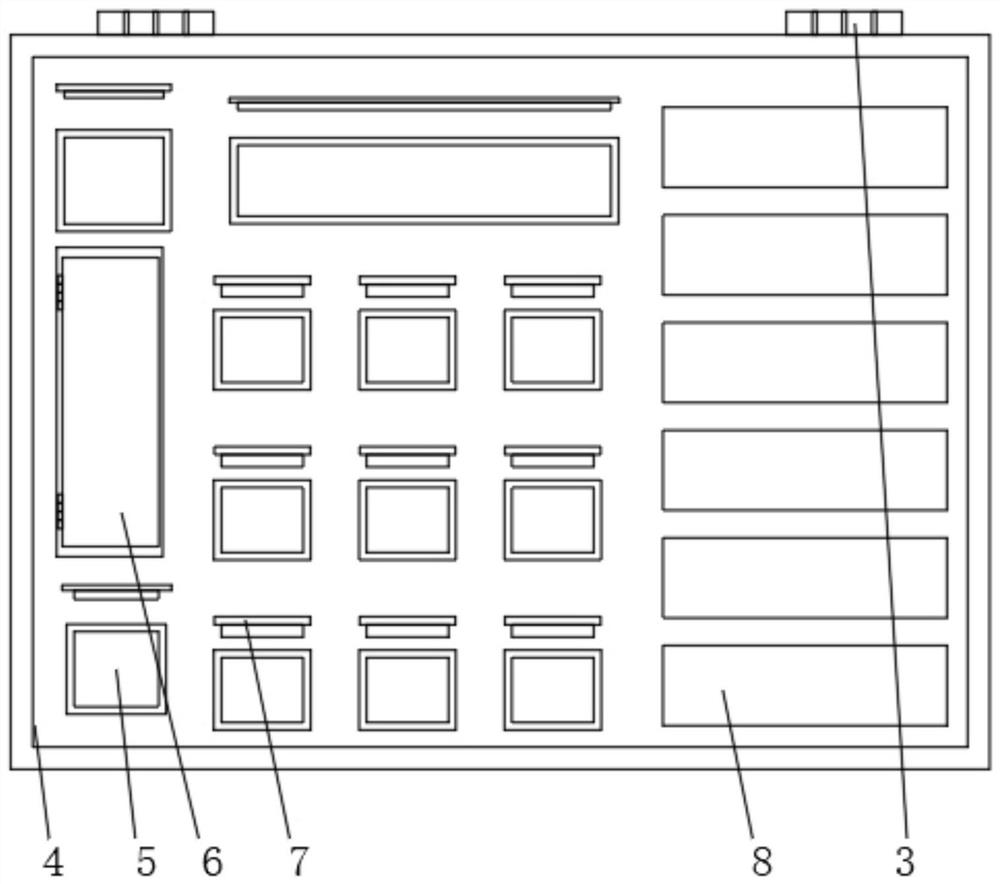

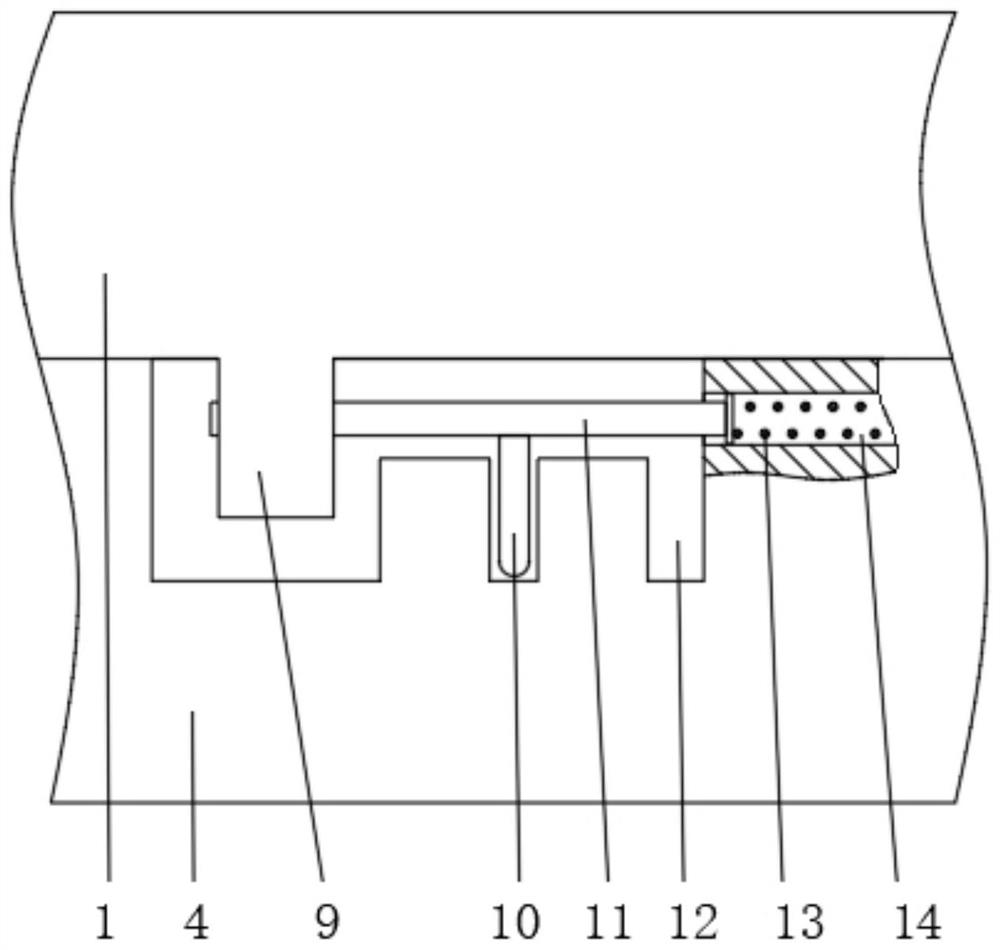

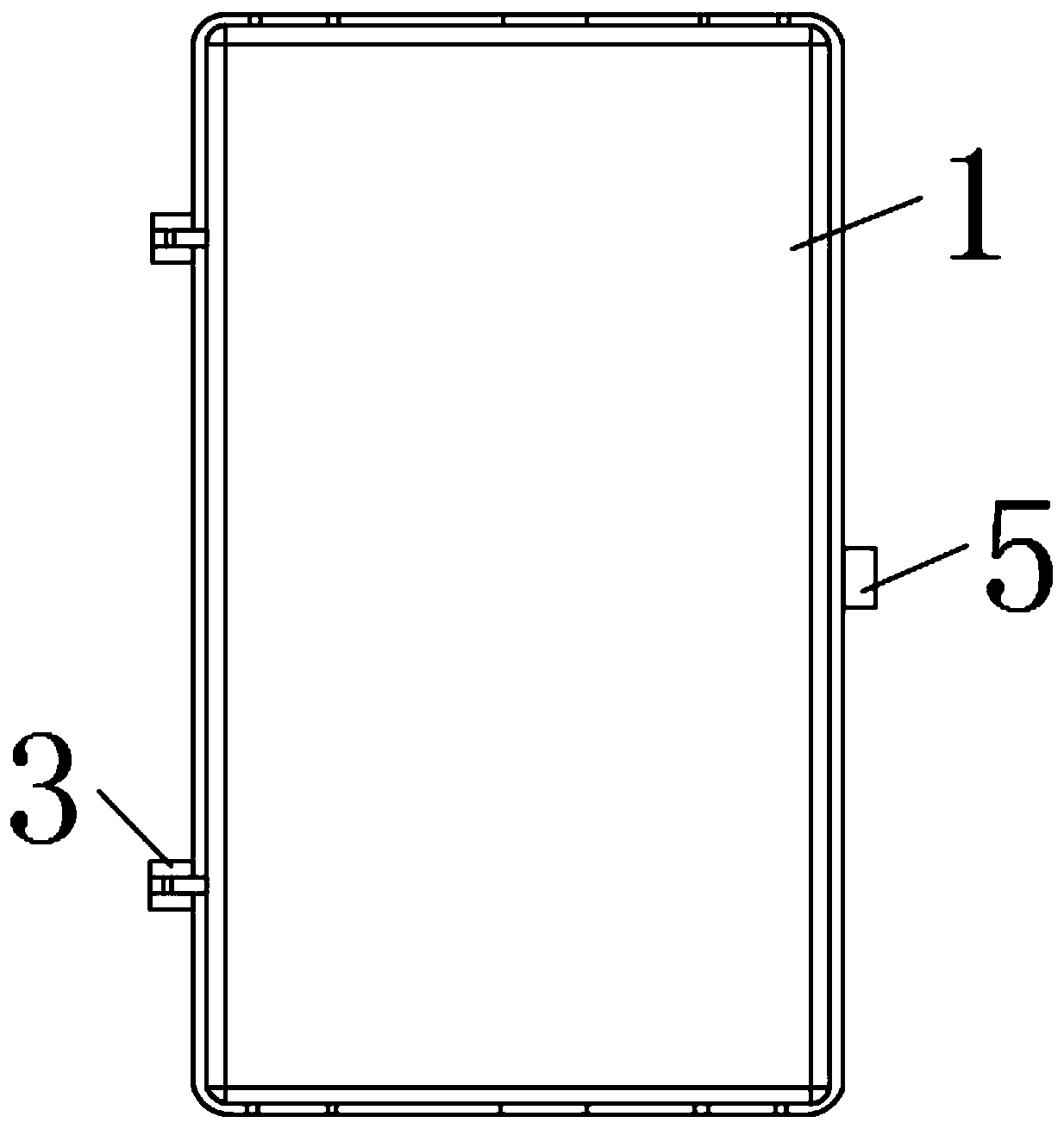

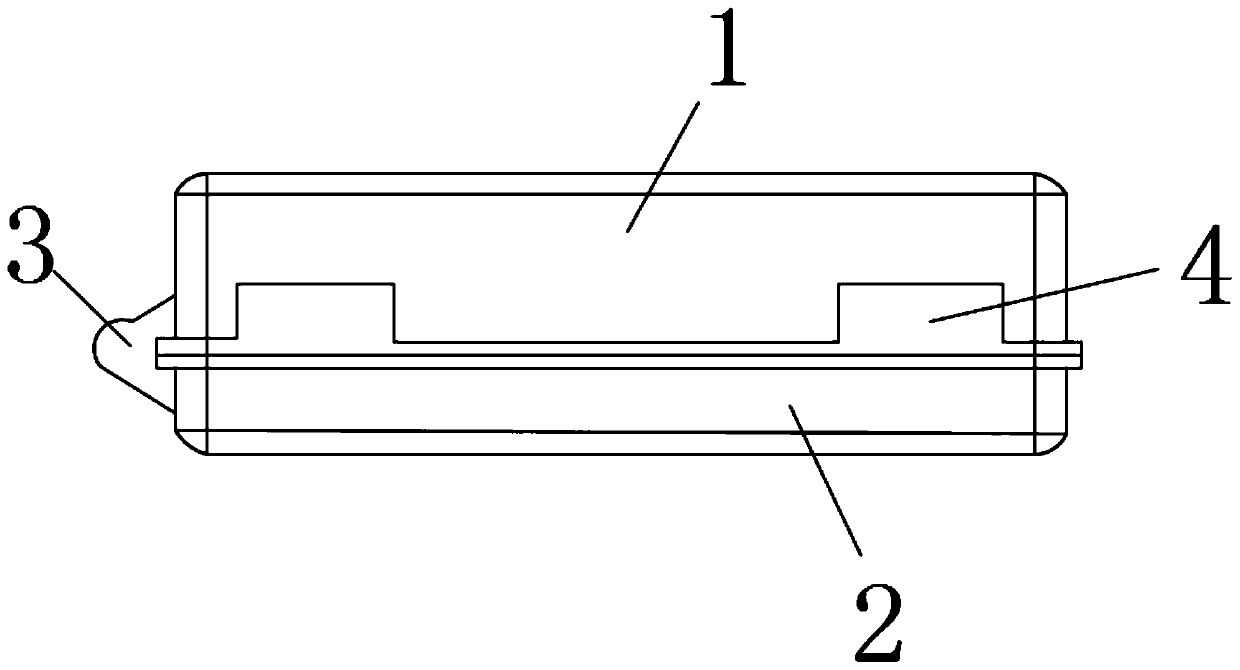

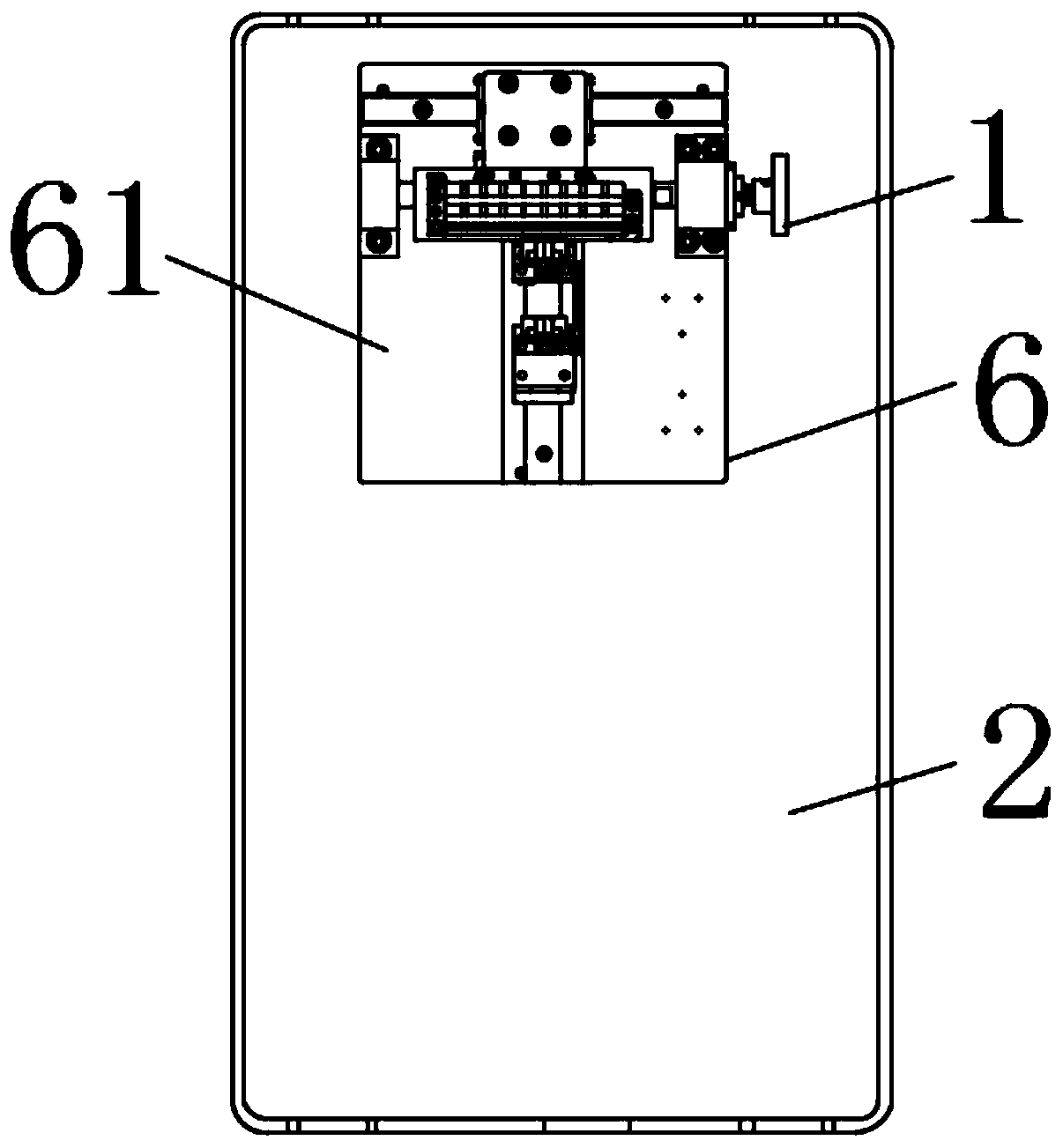

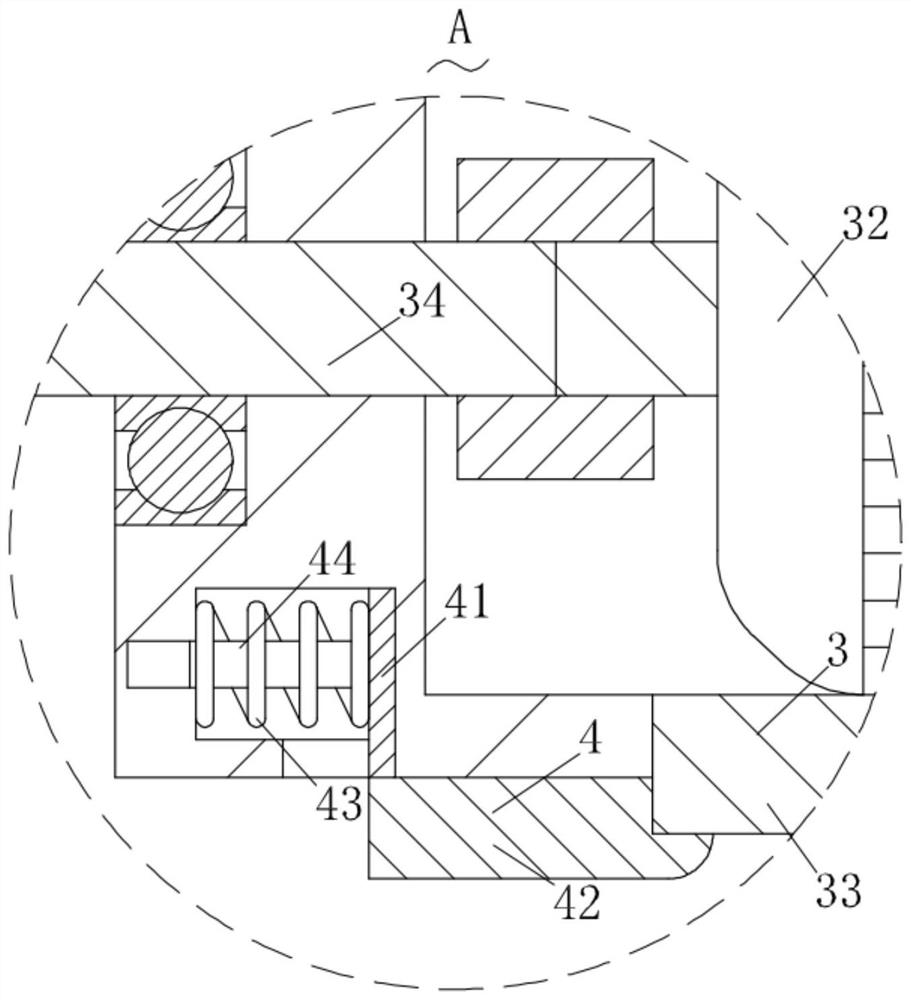

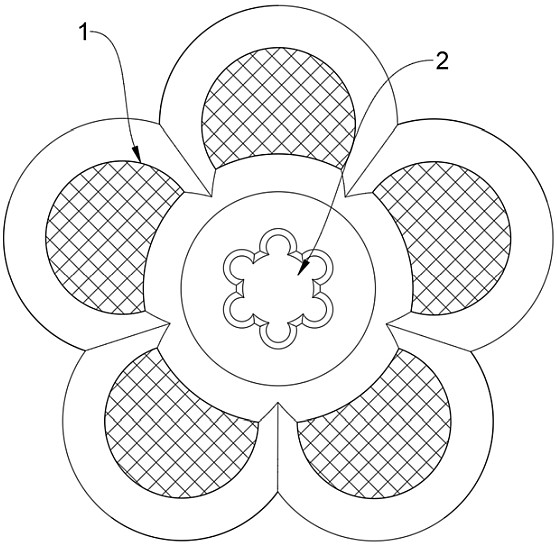

ActiveCN111048937AEliminate the phenomenon of being blocked and unable to useImprove aestheticsCoupling device detailsNetwork connectionsTelecommunicationsNetwork communication

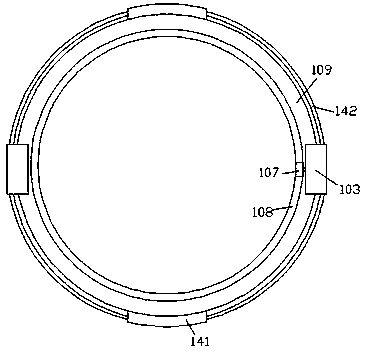

The invention discloses converged gateway equipment based on multiple computer network communication technologies. The converged gateway equipment comprises a bottom electronic installation box; an equipment decorative cover is fixedly mounted on the top side of the bottom electronic mounting box; a mounting interval is formed between the equipment decorative cover and the bottom electronic mounting box; and a hidden plugboard is annularly arranged between the equipment decorative cover and the bottom electronic mounting box. According to the converged gateway equipment based on the multiple computer network communication technologies, the hidden plugboard is coupled to the upper side end surface of the bottom electronic mounting box; the hidden plugboard is in transmission connection witha driving turntable through a transmission rod; the hidden plugboard, the transmission rod and the driving turntable form a crank sliding principle mechanism; the driving turntable can be driven to rotate through a rotating handle, so that the hidden plugboard can be pushed out and retracted quickly through the transmission rod, and therefore, the use adjustment performance and display form of the equipment are effectively improved; and jacks are hidden, so that potential safety hazards caused by the touch of children are effectively prevented.

Owner:SUZHOU COLLEGE OF INFORMATION TECH

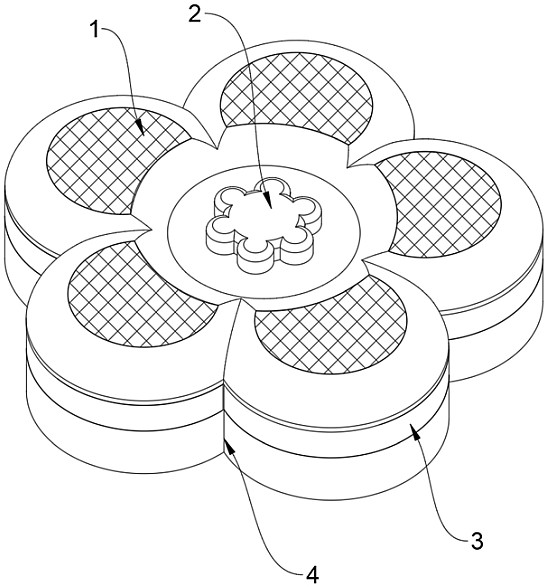

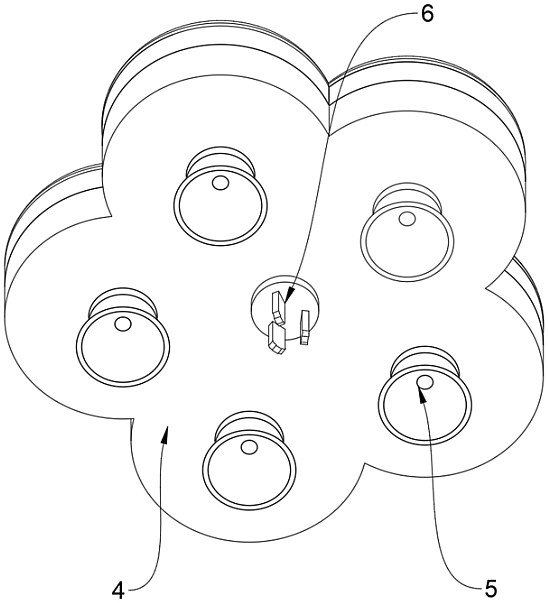

Nursing medical plate

InactiveCN111803307APrevent transfer outImprove securitySurgical furnitureNursing accommodationNursing careEngineering

The invention provides a nursing medical plate, and relates to the field of medical instruments. The nursing medical plate comprises an upper cover; a tray is arranged under the upper cover; one sideof the upper end of the tray is provided with holding holes; a silicone container is arranged in each holding hole; a sealing cover is arranged at a position, above each holding hole, on the upper endof the tray; a holding groove is arranged at a position, between the two holding holes, on one side of the upper end of the tray; a containing box is arranged in the holding groove; and holding grooves are equidistantly arranged at one side of the upper end of the tray; a bottom plate is arranged below the tray; support columns are fixedly connected with positions, below the side where the holding groove is arranged alone, under the tray; and the other ends of the support columns are fixedly connected with the bottom plate. According to the nursing medical plate, the silicone containers and acontaining box are further arranged on the basis of the tray, so that storage of nursing products is safer and cleaner; and meanwhile, the silicone containers and the containing box can be removed alone, so that quick replacement and cleaning and disinfection are facilitated.

Owner:刘夫玲

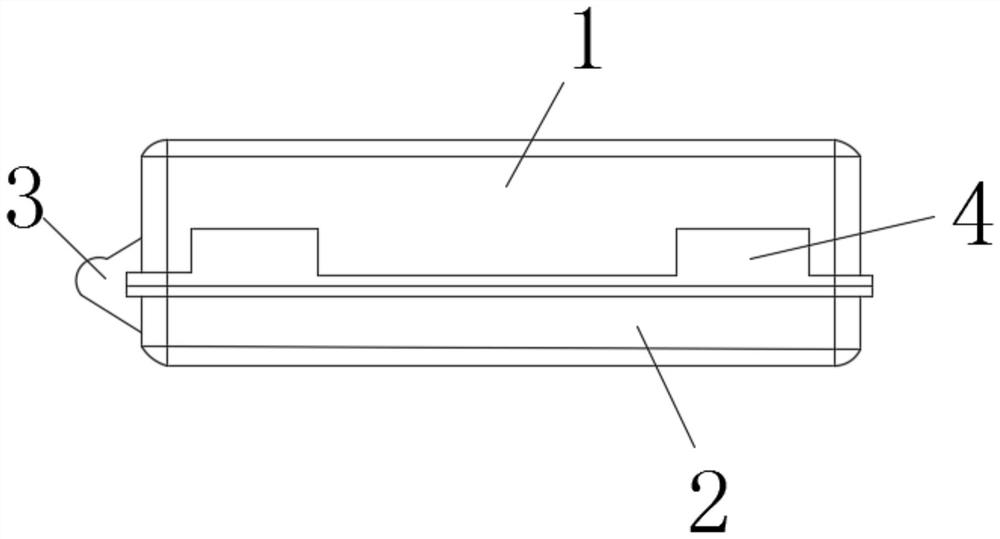

Wall-mounted optical fiber cable distribution box with wire trimming structure

The invention discloses a wall-mounted optical fiber cable distribution box with a wire trimming structure. The wall-mounted optical fiber cable distribution box comprises an upper shell, a lower shell, a connector, a wire hole, a convex block and the wire trimming structure, a second fixed plate is horizontally fixed to the top end of a third fixing base in a welded manner, clamping blocks are fixedly connected with movable blocks through bolts, the movable blocks are mounted in the second fixed plate, the two clamping blocks are oppositely arranged, stoppers are mounted on the outer sides ofthe two movable blocks through bolts, a first pin is twisted, so that the gap between the two clamping blocks is enlarged, an optical cable penetrates the space between the two clamping blocks, the first pin is twisted again, the optical cable is fixed between the clamping blocks and can slide relative to the clamping blocks without slip after being stressed, the optical cable penetrates a groovein a second fixing base and can be limited in the second fixing base by a retainer wheel, and the optical cable cannot be staggered with other optical cables in the wire trimming process and prevented from damaging the other optical cables when needing maintenance and wire trimming.

Owner:杭州奥克光电设备有限公司

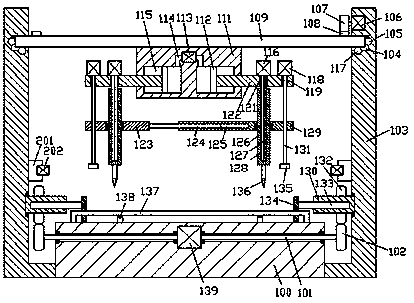

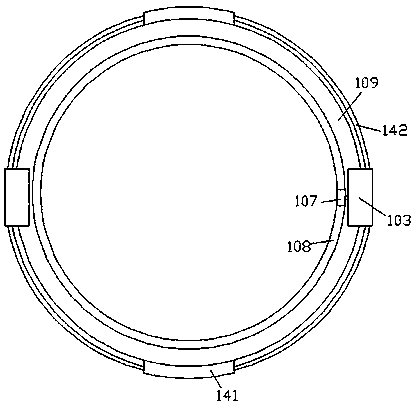

Detector and production mechanism thereof

InactiveCN109202118ASimple and convenient clamping workImprove work efficiencyLarge fixed membersPositioning apparatusEngineeringAtmospheric pressure

The invention discloses a detector and a production mechanism thereof. The detector comprises a bottom plate, and supporting seats which are bilaterally symmetrically fixedly arranged at the left sideand the right side of the bottom plate, wherein a rotating frame is mounted between the supporting seats at the left side and the right side in a rotating fitting manner; a production frame is fixedly arranged on the end surface of the bottom part of the rotating frame; air pressure chambers are bilaterally symmetrically arranged in the production frame, and pushing extruding plates are mounted in the air pressure chambers in a sliding fitting manner; adjusting frames are fixedly arranged on the end surfaces of the opposite sides of the pushing extruding plates at the left side and the rightside; the adjusting frames extend out of the outer side end of the production frame and are connected to the production frame in a sliding fitting manner; air pressure holes are formed in the top walls of the air pressure chambers in a communication manner and are correspondingly connected to air pressure cylinders; the air pressure cylinders are fixedly arranged in the production frame; a first through groove penetrates the top and bottom of each adjusting frame which extends out of the outer side end of the production frame; and a spline shaft is mounted in each first through groove in a clearance fit manner.

Owner:泉州市华泽数字科技有限公司

Thin-wall micro-foaming material preparation device

InactiveCN109159201ASimple and convenient clamping workImprove work efficiencyMetal working apparatusMaterials preparationEngineering

The invention discloses a thin-wall micro-foaming material preparation device. The device comprises a base and supporting seats which are left-right symmetrically and fixedly arranged on the left sideand the right side of the base, an adapter plate is installed between the supporting seats on the left side and the right side in a rotating mode, a machining frame is fixedly arranged on the end face of the bottom of the adapter plate, air pressure cavities are symmetrically formed in the left side and the right side in the machining frame, piston plates are arranged in the air pressure cavitiesin a sliding fit mode, adjusting frames are fixedly arranged on the end face, facing the opposite side, of the piston plates on the left side and the right side, the adjusting frames extends out of the outer side end of the machining frame and is in sliding fit connection with the machining frame, the top wall of the air pressure cavities are communicated with air pressure holes, the air pressureholes in the left side and the right side are respectively connected with an air pressure cylinder, the air pressure cylinder is fixedly arranged in the machining frame, a first penetrating cavity isformed in the adjusting frame which is extends out of the outer side end of the machining frame in an up-and-down manner, a spline shaft is arranged in a clearance fit manner in the first penetratingcavity.

Owner:泉州满谦科技有限公司

Street lamp holder device

InactiveCN109128263ASimple and convenient clamping workImprove work efficiencyDriving apparatusPositioning apparatusEngineeringBilateral symmetry

The invention discloses a street lamp holder device. The street lamp holder device comprises a bed frame and supporting seats fixedly arranged on the left and right sides of the bed frame in bilateralsymmetry. A rotary table is mounted between the supporting seats on the left and right sides in a rotating fit mode. The end face of the bottom of the rotary table is fixedly provided with a workingframe. The working frame is internally provided with pneumatic cavities in bilateral symmetry. Movable plates are mounted in the pneumatic cavities in a sliding fit mode. The end faces of the sides, far away from each other, of the movable plates on the left and right sides are fixedly provided with positioning supports. The positioning supports extend out of the outer side ends of the working frame are connected with the working frame in a sliding fit mode. The top walls of the pneumatic cavities are provided with pneumatic holes in a communicating mode. The pneumatic holes on the left and right sides are connected with pneumatic cylinders correspondingly. The pneumatic cylinders are fixedly arranged in the working frame. The portions, extending out of the outer side ends of the working frame, of the positioning supports are provided with first hole cavities in a vertical through mode. Spline shafts are mounted in the first hole cavities in a clearance fit mode.

Owner:泉州睿骋企业管理咨询有限公司

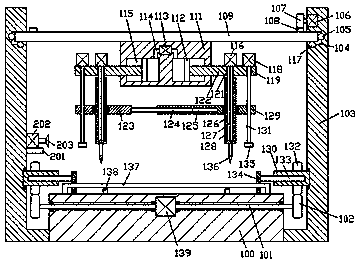

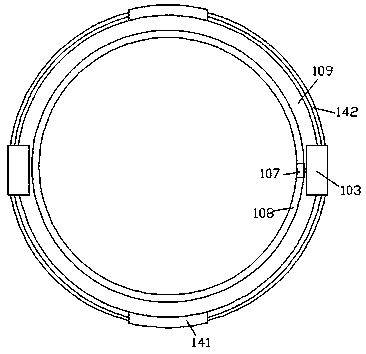

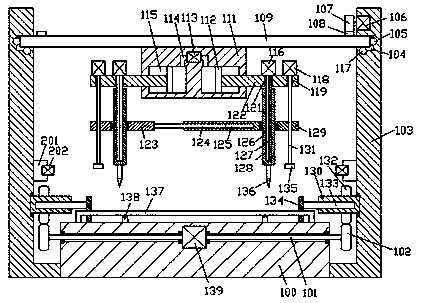

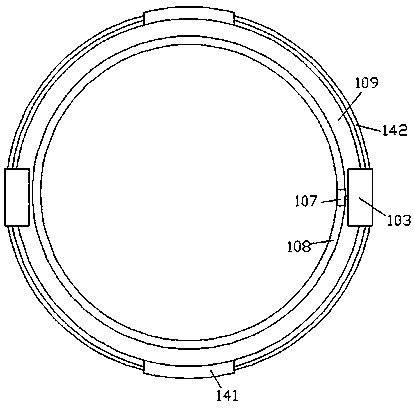

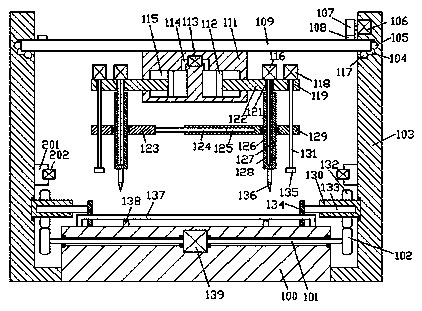

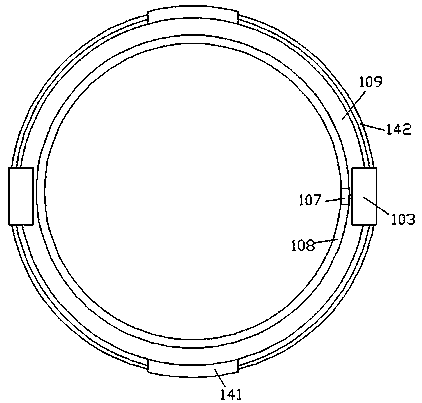

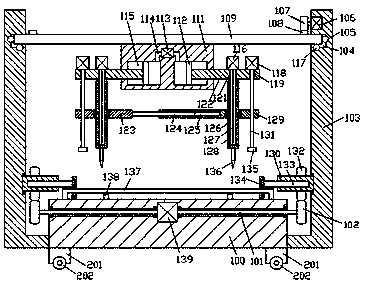

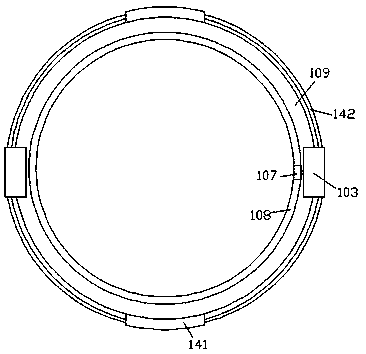

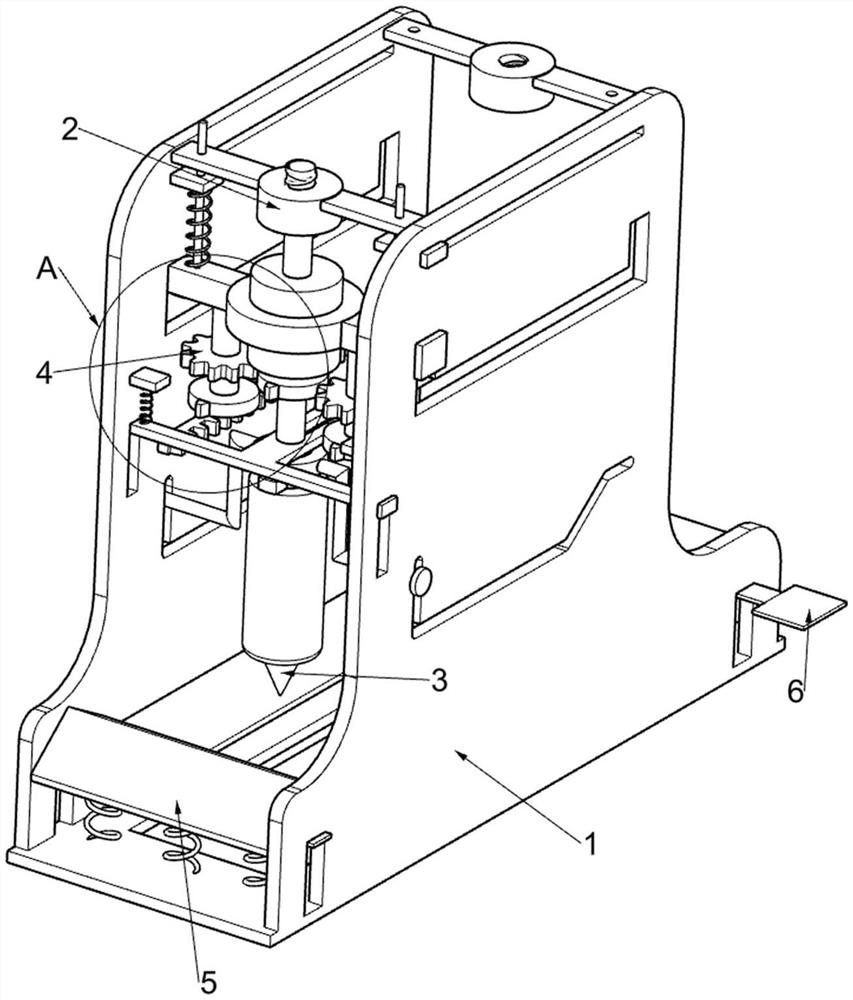

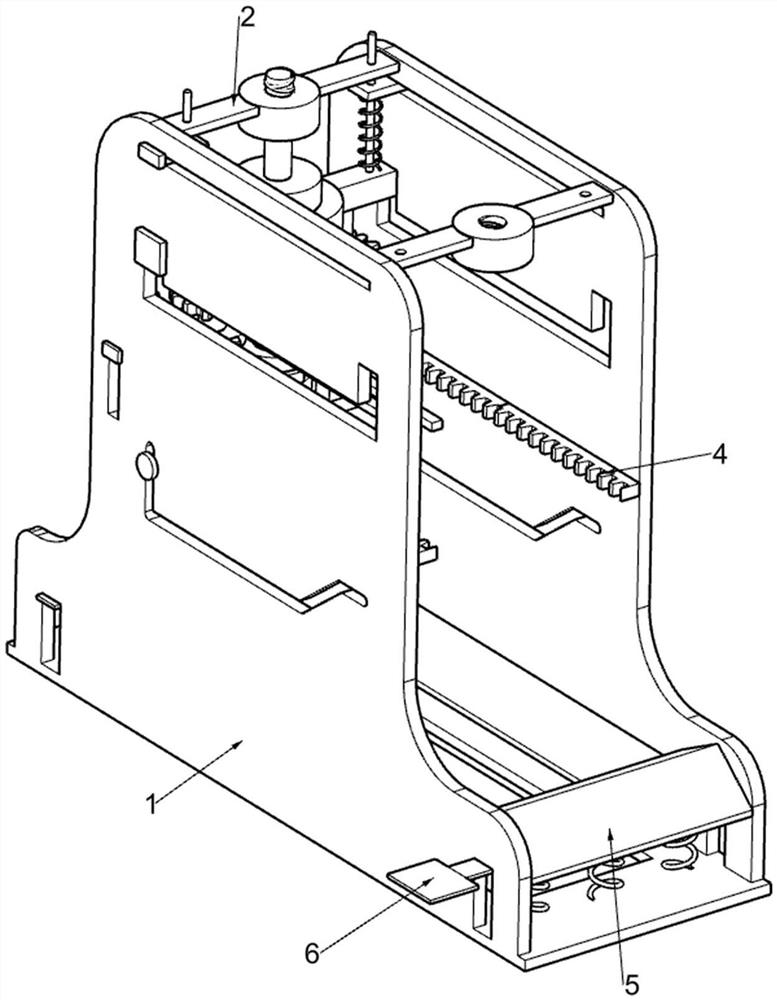

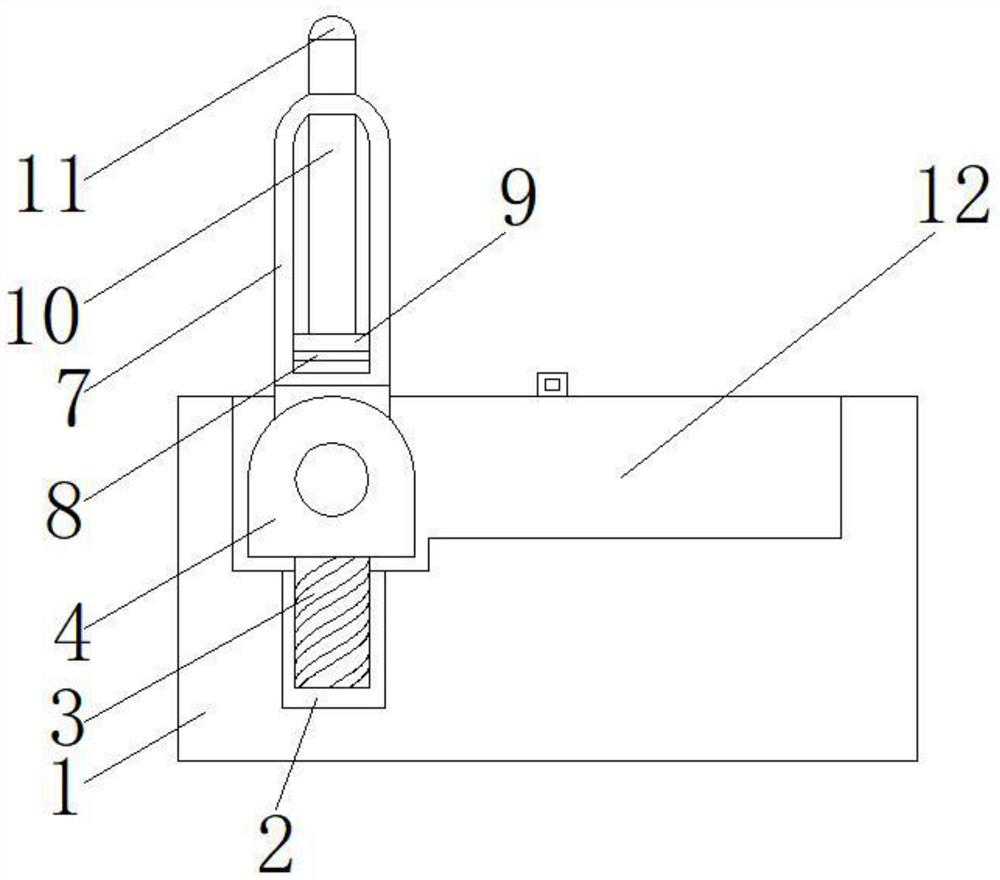

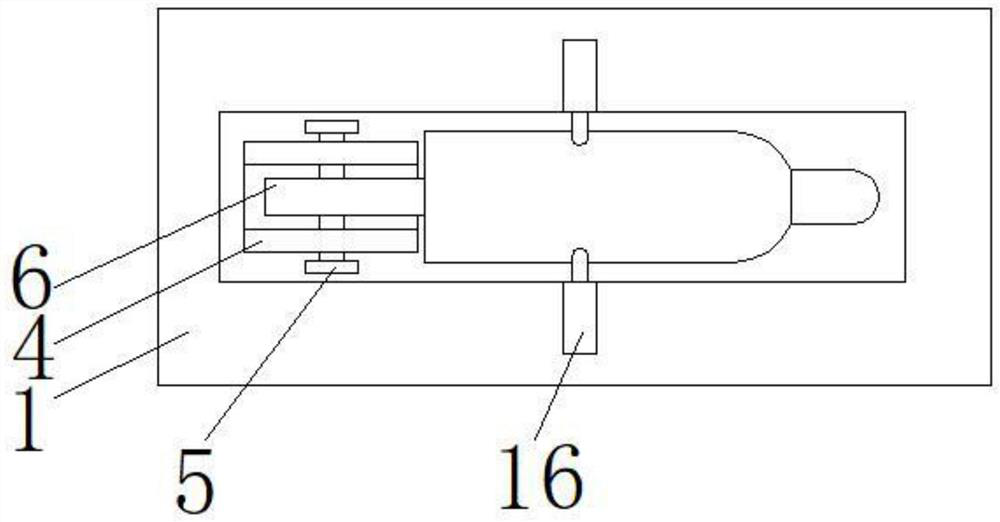

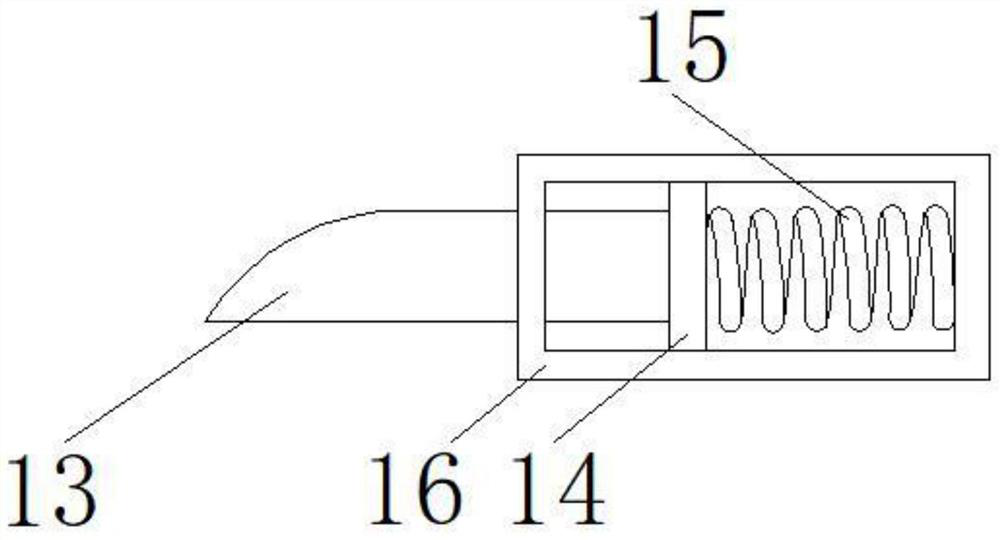

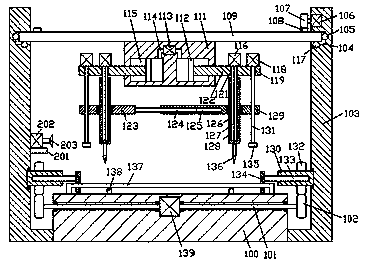

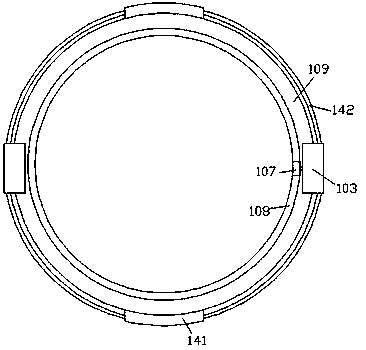

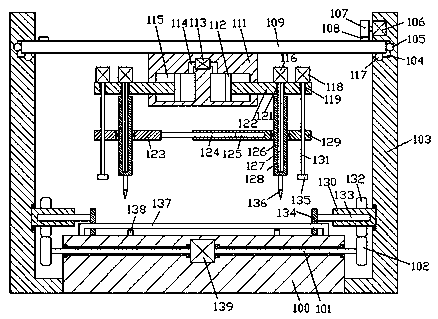

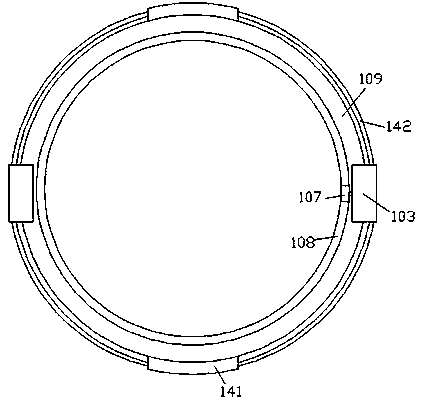

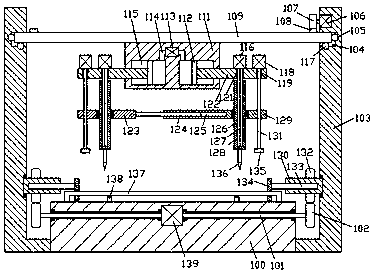

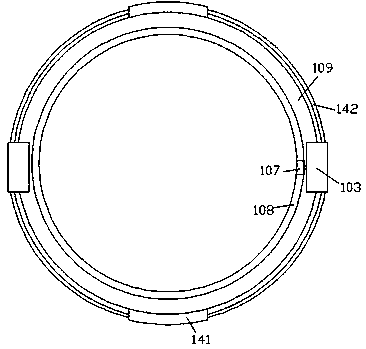

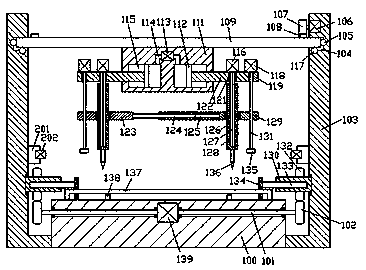

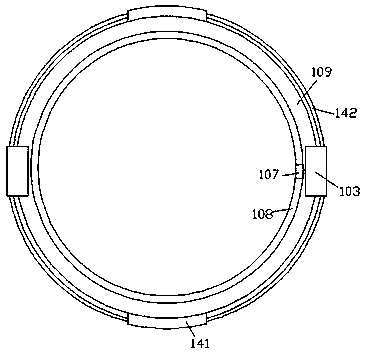

Friction stir welding device capable of removing welding holes

PendingCN112894121APrevent transfer outAchieve weldingNon-electric welding apparatusFriction weldingMetallic materials

The invention relates to the field of friction stir welding, in particular to a friction stir welding device capable of removing welding holes. The friction stirring welding device comprises a support frame, a rotating mechanism, a drilling mechanism, a moving mechanism and the like, wherein the rotating mechanism is arranged on the support frame; the drilling mechanism is arranged on the rotating mechanism; and the moving mechanism is arranged on the rotating mechanism. Through arrangement of the drilling mechanism and the moving mechanism, a friction welding head rapidly rotates to drill metal material plates, a first sliding frame and a device thereon slowly move in the direction away from a third sliding frame, and the friction welding head rapidly rotates and slowly moves in the direction away from the third sliding frame, so that welding seams of the two metal material plates are fully welded, and excessive welding holes are prevented from being formed in the metal material plates by the friction welding head.

Owner:熊有子

Antenna structure of electronic equipment

InactiveCN112787063AEasy to disassembleEasy to receivePivotable antennasAntenna supports/mountingsStructural engineeringMechanical engineering

The invention discloses an antenna structure of electronic equipment, which comprises an electronic equipment main body, a connecting block and an accommodating groove, a threaded groove is formed in the electronic equipment main body, a fixed block is fixed above the threaded block, the connecting block is located above a positioning pin, a rubber block is arranged in a sleeve rod, a supporting rod is arranged above the sliding block, the accommodating groove is located above the electronic equipment body, a check block is arranged above the accommodating groove, a limiting block is fixed behind the check block, a spring is arranged behind the limiting block, and a fixing rod is arranged outside the spring. Compared with an existing common antenna structure, the antenna structure for the electronic equipment can be accommodated in the accommodating groove, so that the space can be saved, the antenna structure can be prevented from being damaged, and meanwhile, the antenna structure is provided with an adjusting structure, so that the height and the angle of the antenna structure can be adjusted, and the signal receiving strength of the equipment can be improved.

Owner:XIAN RENKE ELECTRONICS TECH CO LTD

Polyvinyl chloride material preparation equipment

InactiveCN109129697ASimple and convenient clamping workImprove work efficiencyMetal working apparatusMating connectionMaterials preparation

The invention discloses polyvinyl chloride material preparation equipment. The polyvinyl chloride material preparation equipment comprises a base and support frames fixedly arranged on the left and right sides of the base in bilateral symmetry. A rotary disk is mounted between the support frames on the left and right sides in a rotating fit mode. The end face of the bottom of the rotary disk is fixedly provided with a preparation frame. The preparation frame is internally provided with pneumatic cavities in bilateral symmetry. Pressing plates are mounted in the pneumatic cavities in a slidingfit mode. The end faces, far away from each other, of the pressing plates on the left and right sides are fixedly provided with adjusting supports. The adjusting supports extend out of the outer sideends of the preparation frame and are connected with the preparation frame in a sliding fit mode. The top walls of the pneumatic cavities are provided with pneumatic holes in a communication mode. Thepneumatic holes on the left and right sides are connected with pneumatic cylinders correspondingly. The pneumatic cylinders are fixedly arranged in the preparation frame. The portions, extending outof the outer side ends of the preparation frame, of the adjusting supports are provided with first through holes in a vertical through mode. Spline shafts are mounted in the first through holes in a clearance fit mode.

Owner:安溪杰创新能源科技有限公司

Rapid forming method of thermoplastic fiber reinforced composite material board

InactiveCN109159200ASimple and convenient clamping workImprove work efficiencyMetal working apparatusEngineeringFiber-reinforced composite

The invention discloses a rapid forming method of a thermoplastic fiber reinforced composite material board. A base plate and vertical frame which are fixedly arranged on the left side and the right side of the base plate in a left-and-right symmetry mode are involved in the rapid forming method, a rotating ring is arranged between the vertical frames on the left side and the right side in a rotating mode, a manufacturing frame is fixedly arranged on the end face of the bottom of the rotating ring, and air pressure cavities are formed in the manufacturing frame in a left-right symmetry mode; compression plates are arranged in the air pressure cavities in a sliding fit mode, distance adjusting frames are fixedly arranged on the end faces of one sides, facing the opposite directions, of thecompression plates on the left side and the right side, and the distance adjusting frames extend out of the outer side end of the manufacturing frame and are in sliding fit connection with the manufacturing frame; and the top walls of the air pressure cavities communicate with air pressure holes, the air pressure holes in the left side and the right side are respectively connected with an air pressure cylinder, the air pressure cylinder is fixedly arranged in the manufacturing frame, first hole grooves are formed in the outer side ends, extending out of the manufacturing frame, of the distanceadjusting frames in an up-down penetrating mode, and spline shafts are arranged in the first hole grooves in a clearance fit manner.

Owner:惠安县正和机械设备有限公司

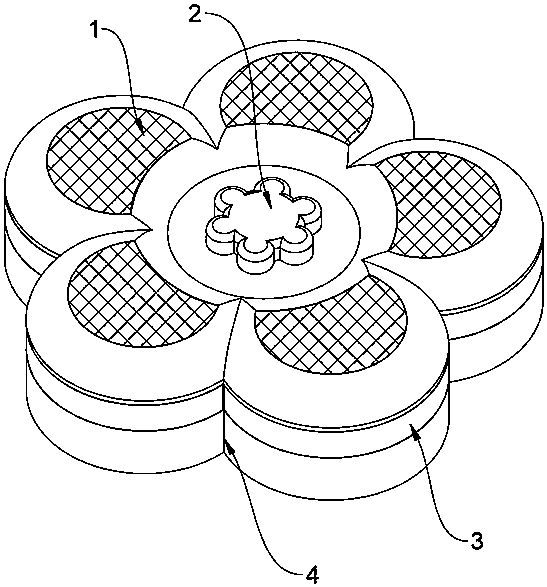

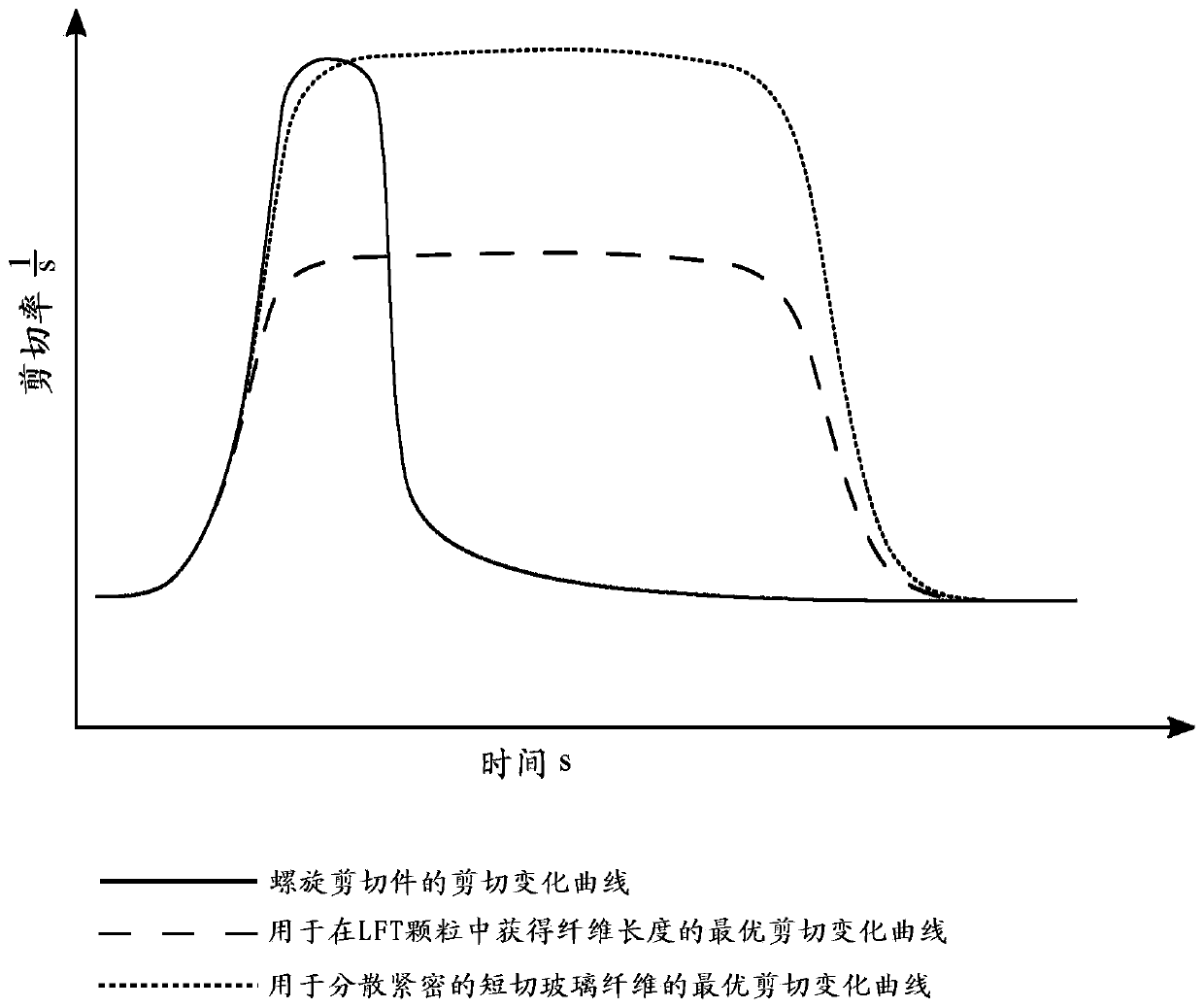

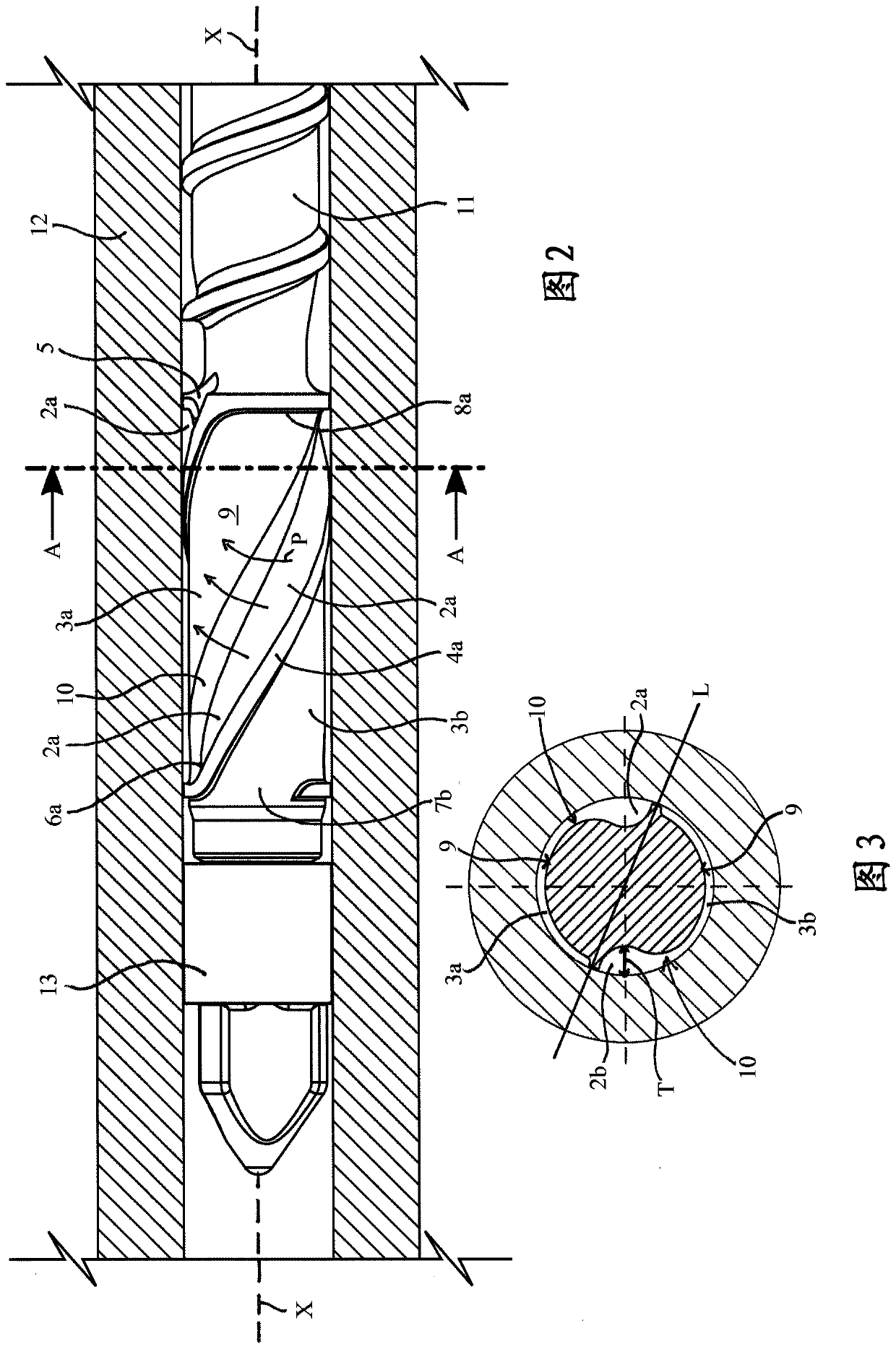

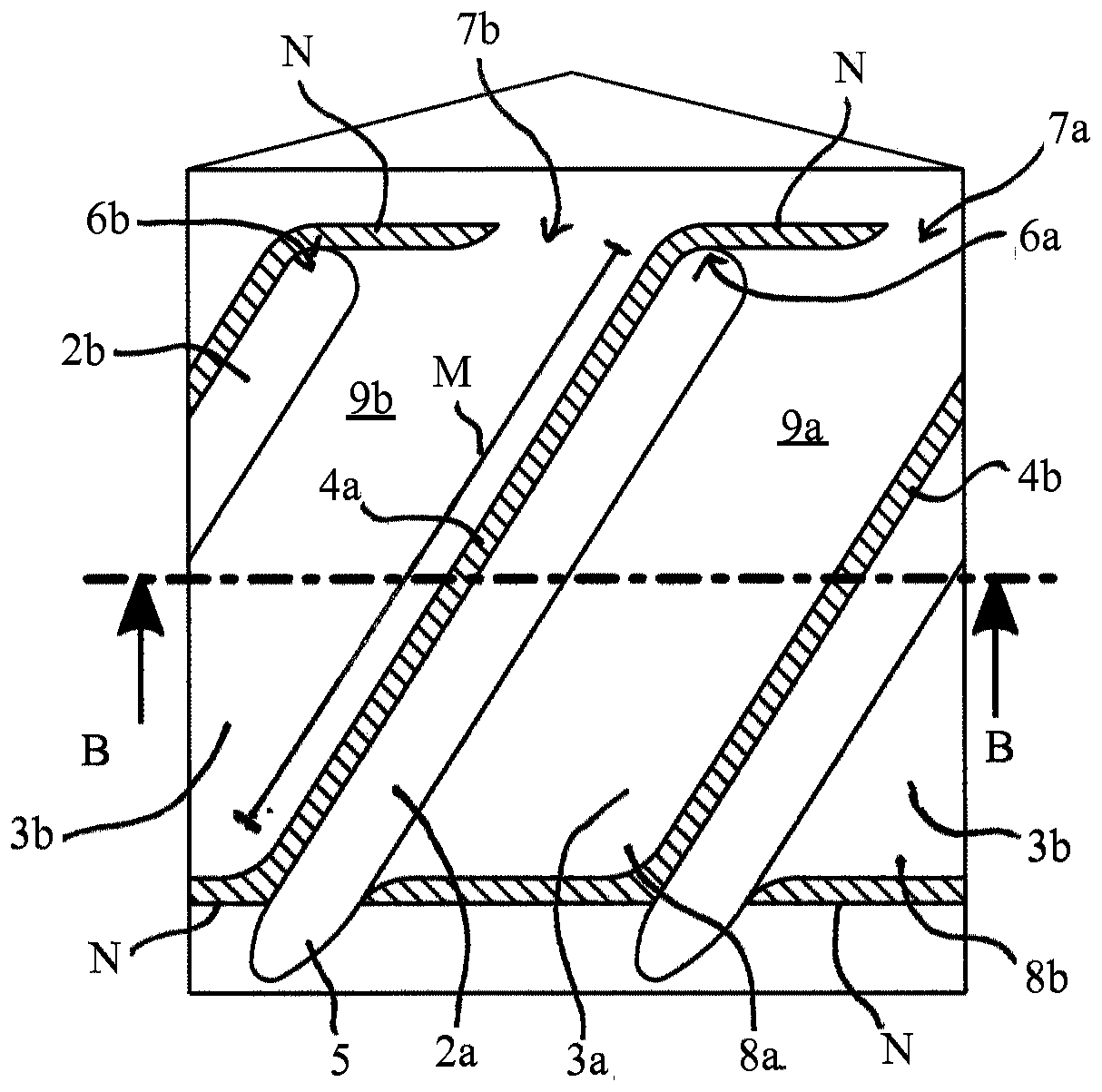

Shearing part for plasticising screw

ActiveCN111163916AReduced risk of breakageGood dispersionPlastic recyclingEngineeringMechanical engineering

The invention relates to a shearing part (1) for a plasticising screw. Th shearing part comprises at least one inlet channel (2, 2a, 2b) and at least one outlet channel (3, 3a, 3b) which run helicallyaround or parallel to the longitudinal axis (X) of the shearing part. The at least one inlet channel is open upstream and closed downstream, and the at least one outlet channel is open downstream andclosed upstream, wherein the inlet channel and the outlet channel are arranged directly adjacent and contiguous to one another, and are directly fluidically connected to one another such that the inflowing melt can flow directly from the inlet channel into the outlet channel, resulting in a flow direction running transversely to the longitudinal axis (X) of the shearing part. The at least one inlet channel has a depth (T) at which a shearing action on the melt is substantially avoided. The at least one outlet channel is designed as a shearing surface (9, 9a, 9b) such that a shearing action occurs on the melt flowing through the outlet channel.

Owner:KRAUSSMAFFEI TECH GMBH

Preparation facility for high polymer materials

InactiveCN109159202ASimple and convenient clamping workImprove work efficiencyMetal working apparatusEngineeringAtmospheric pressure

The invention discloses a preparation facility for high polymer materials. The preparation facility comprises a base and supporting bases, wherein the supporting bases are symmetrically and fixedly arranged on the left side and the right side of the base, an adapter plate is installed between the supporting bases on the left side and the right side in a rotating mode, a machining frame is fixedlyarranged on the end face of the bottom of the adapter plate, and air pressure cavities are symmetrically formed in the left side and the right side in the machining frame; piston plates are installedin the air pressure cavities in a sliding fit mode, adjusting frames are fixedly arranged on the end faces, facing the opposite sides, of the piston plates on the left side and the right side, and theadjusting frames extend out of the outer side end of the machining frame and are in sliding fit connection with the machining frame; and the top walls of the air pressure cavities are arranged with air pressure holes in a communicating mode, the air pressure holes in the left side and the right side are connected with an air pressure cylinder respectively, the air pressure cylinder is fixedly arranged in the machining frame, the adjusting frame extending out of the outer side end of the machining frame penetrates through a first penetrating cavity in an upper and down mode, and a spline shaftis installed in the first penetrating cavity in a clearance fit manner.

Owner:泉州市披风熊科技有限公司

Predicting memory instruction punts in a computer processor using a punt avoidance table (PAT)

Predicting memory instruction punts in a computer processor using a punt avoidance table (PAT) are disclosed. In one aspect, an instruction processing circuit accesses a PAT containing entries each comprising an address of a memory instruction. Upon detecting a memory instruction in an instruction stream, the instruction processing circuit determines whether the PAT contains an entry having an address of the memory instruction. If so, the instruction processing circuit prevents the detected memory instruction from taking effect before at least one pending memory instruction older than the detected memory instruction, to preempt a memory instruction punt. In some aspects, the instruction processing circuit may determine, upon execution of a pending memory instruction, whether a hazard associated with the detected memory instruction has occurred. If so, an entry for the detected memory instruction is generated in the PAT.

Owner:QUALCOMM INC

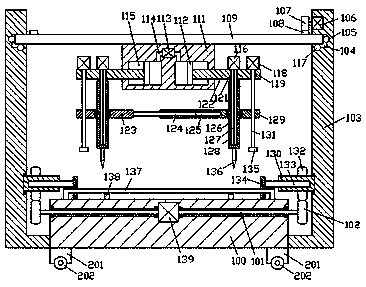

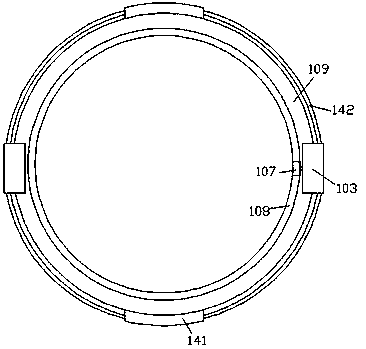

Detector and production facility therefore

InactiveCN109203068AImprove work efficiencySimple and convenient clamping workMetal working apparatusPneumatic pressureMarine engineering

The invention discloses a detector and a production facility of the detector. The production facility comprises a base plate and supporting bases, wherein the supporting bases are fixedly arranged onthe left side and the right side of the base plate in a left-and-right symmetry mode. A rotating frame is installed between the supporting bases on the left side and the right side in a running fit mode, and a production frame is fixedly arranged on the end face of the bottom of the rotating frame. Air pressure cavities are formed in the production frame in a left-and-right symmetry mode, and pushplates are installed in the air pressure cavities in a sliding fit mode. Adjusting frames are fixedly arranged on the end faces of the opposite sides of the push plates on the left side and the rightside, stretch out of the outer side end of the production frame and are connected with the production frame in a sliding fit mode. Air pressure holes are formed in the top walls of the air pressure cavities in a communicating mode, the air pressure holes formed in the left side and the right side are connected with an air pressure cavity, and the air pressure cylinder is fixedly arranged in the production frame. First penetrating grooves are formed in the adjusting frames in a vertical penetration mode, the adjusting frames stretch out of the outer side end of the production frame, and splined shafts are installed in the first penetrating grooves in a clearance fit mode.

Owner:泉州市华泽数字科技有限公司

A wall-mounted optical fiber distribution box with cable management structure

ActiveCN109799586BNot staggeredAvoid damageFibre mechanical structuresMechanical engineeringOptical fiber cable

The invention discloses a wall-mounted optical fiber cable distribution box with a wire trimming structure. The wall-mounted optical fiber cable distribution box comprises an upper shell, a lower shell, a connector, a wire hole, a convex block and the wire trimming structure, a second fixed plate is horizontally fixed to the top end of a third fixing base in a welded manner, clamping blocks are fixedly connected with movable blocks through bolts, the movable blocks are mounted in the second fixed plate, the two clamping blocks are oppositely arranged, stoppers are mounted on the outer sides ofthe two movable blocks through bolts, a first pin is twisted, so that the gap between the two clamping blocks is enlarged, an optical cable penetrates the space between the two clamping blocks, the first pin is twisted again, the optical cable is fixed between the clamping blocks and can slide relative to the clamping blocks without slip after being stressed, the optical cable penetrates a groovein a second fixing base and can be limited in the second fixing base by a retainer wheel, and the optical cable cannot be staggered with other optical cables in the wire trimming process and prevented from damaging the other optical cables when needing maintenance and wire trimming.

Owner:杭州奥克光电设备有限公司

Low temperature resisting and flame resisting PVC material and preparation and application thereof

InactiveCN109176715ASimple and convenient clamping workImprove work efficiencyMetal working apparatusAtmospheric pressureRotating disc

The invention discloses a low temperature resisting and flame resisting PVC material and a preparation and application thereof. A base and brackets which are horizontally symmetrically and fixedly arranged on the left and right sides of the base are included. A rotating disc is mounted between the brackets on the left and right sides in a rotating-fit mode. A preparation bracket body is fixedly arranged on the bottom end face of the rotating disc. Atmospheric pressure cavities are horizontally symmetrically formed in the preparation bracket body. An ejecting pressing plate is mounted in each atmospheric pressure cavity in a sliding-fit mode. Adjusting brackets are fixedly arranged on the end faces of the opposite sides of the ejecting pressing plates on the left and right sides. The adjusting brackets extend out of the outer side end of the preparation bracket body, and are connected with the preparation bracket body in a sliding-fit mode. Atmospheric pressure holes are formed in the top walls of the atmospheric pressure cavities in a communicating mode. The atmospheric pressure holes on the left and right sides are respectively connected with an atmospheric pressure cylinder. Theatmospheric pressure cylinder is fixedly arranged in the preparation bracket body. First penetrating holes are formed in the adjusting brackets extending the outer side end of the preparation bracketbody in an up and down penetrating mode. Spline shafts are mounted in the first penetrating holes in a clearance-fit mode.

Owner:安溪杰创新能源科技有限公司

Modified ABS material and preparation method and application

InactiveCN109203069ASimple and convenient clamping workImprove work efficiencyMetal working apparatusEngineeringAtmospheric pressure

Owner:福建泉州远方致远自动化科技有限公司

Movable air purification and disinfection robot with automatic line patrol function

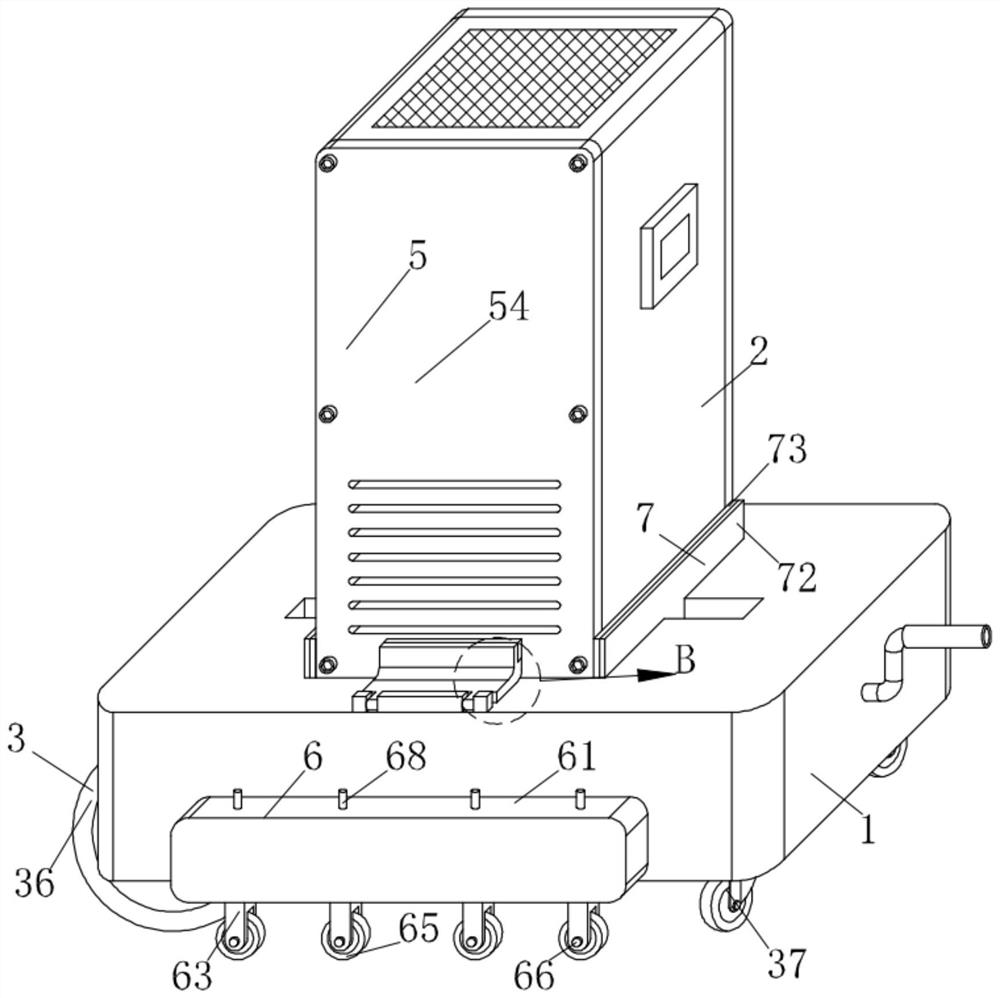

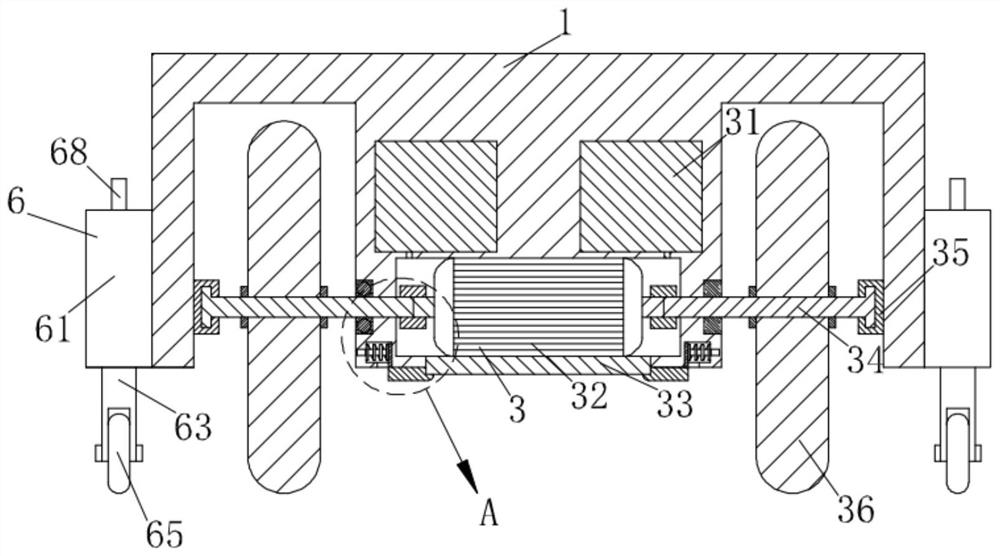

PendingCN113899049AGood purification and disinfectionAvoid leaningFluid heatersMechanical apparatusAir pollutantsEnvironmental engineering

The invention relates to the technical field of air purification, and particularly relates to a movable air purification and disinfection robot with an automatic line patrol function. The movable air purification and disinfection robot comprises a base, a box body is arranged at the top end of the base, a line patrol structure is arranged at the bottom end of the base, a fixing structure is arranged at the bottom end of the base, a purification structure is arranged inside the box body, a protection structure is arranged at the side end of the base, a clamping structure is arranged at the side end of the base, and a limiting structure is arranged at the top end of the base. The line patrol structure is arranged at one end of the base, the box body can be positioned and moved, and therefore air can be better purified and disinfected; meanwhile, a positioning line patrol moving device can be taken down through the fixing structure, and the positioning line patrol moving device can be conveniently cleaned and replaced; the purification structure is arranged inside the box body, various air pollutants can be purified, and the air cleanliness is effectively improved; and meanwhile, through the protection structure, the base can be prevented from inclining when the base moves and encounters the uneven ground.

Owner:山东吉特工业科技股份有限公司

A fusion gateway device based on multiple computer network communication technologies

ActiveCN111048937BEliminate the phenomenon of being blocked and unable to useImprove aestheticsCoupling device detailsNetwork connectionsEngineeringNetwork communication

A fusion gateway device based on various computer network communication technologies, including a bottom electronic installation box; a device decoration cover is fixedly installed on the top side of the bottom electronics installation box, and an installation distance is set between the equipment decoration cover and the bottom electronics installation box ; There is a hidden plugboard arranged in the middle of the equipment decoration cover and the electronic installation box at the bottom. The hidden plug-in board provided by the fusion gateway device based on various computer network communication technologies is axially connected to the upper end surface of the electronic installation box at the bottom, and the hidden plug-in board is connected to the drive turntable through a transmission rod. The hidden plug-in board It forms a crank sliding principle mechanism with the transmission rod and the drive turntable, which is beneficial to drive the drive turntable to rotate by turning the handle, so that the hidden insert plate can be quickly pushed out and retracted through the drive rod, effectively improving the use adjustment performance and display form of the device, and for The jack is hidden to effectively prevent children from touching and causing safety hazards.

Owner:SUZHOU COLLEGE OF INFORMATION TECH

Novel streetlamp holder device

InactiveCN109058828ASimple and convenient clamping workImprove work efficiencyMechanical apparatusLighting support devicesEngineeringAtmospheric pressure

Owner:泉州睿骋企业管理咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com