Refuse landfill soil remediation device

A landfill and soil remediation technology, which is applied in the field of landfill soil remediation equipment, can solve the problems that the soil cannot be quickly used with different types of plants, the soil cannot be repaired in layers, and it is not suitable for large plants, so as to improve the crushing effect , Strong practicability, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

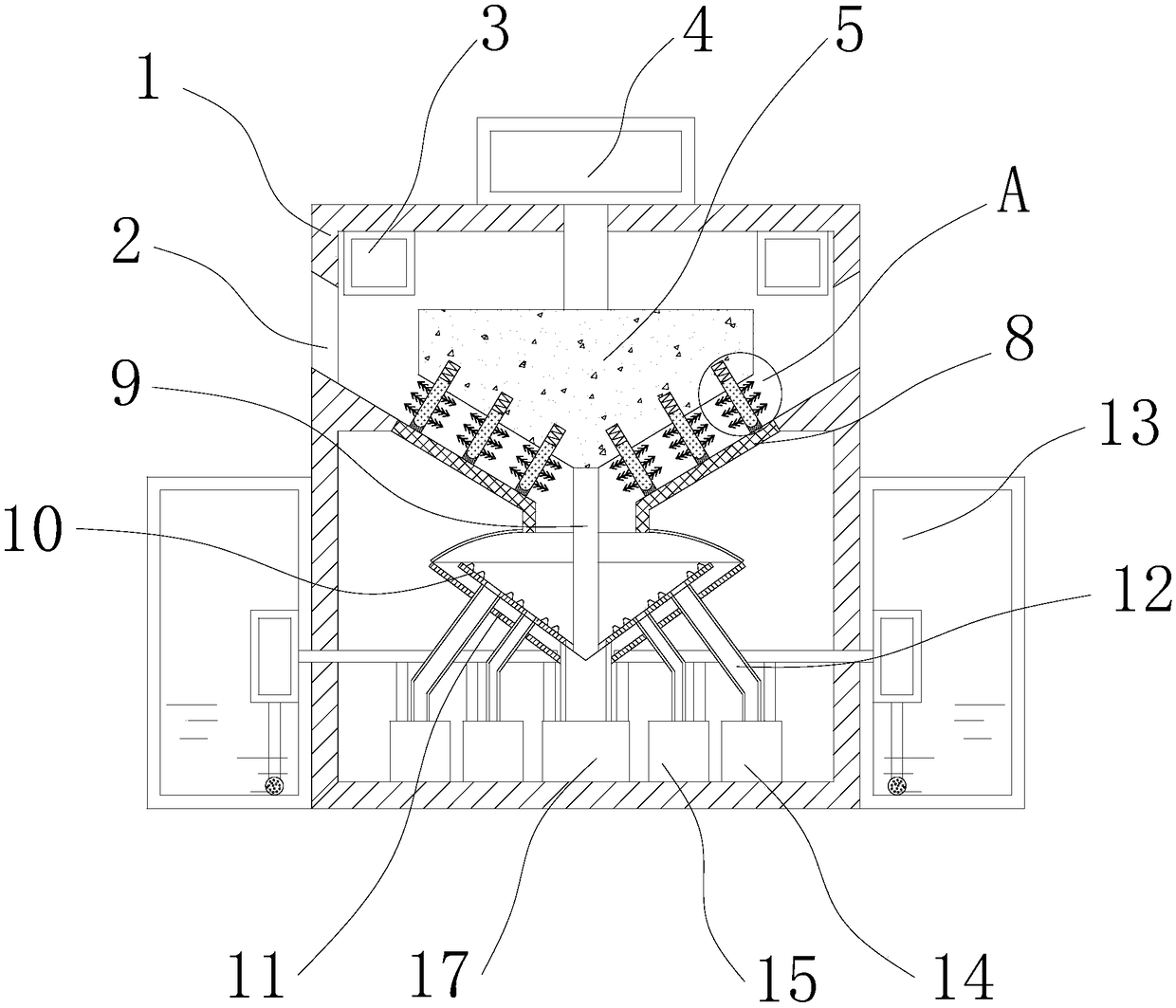

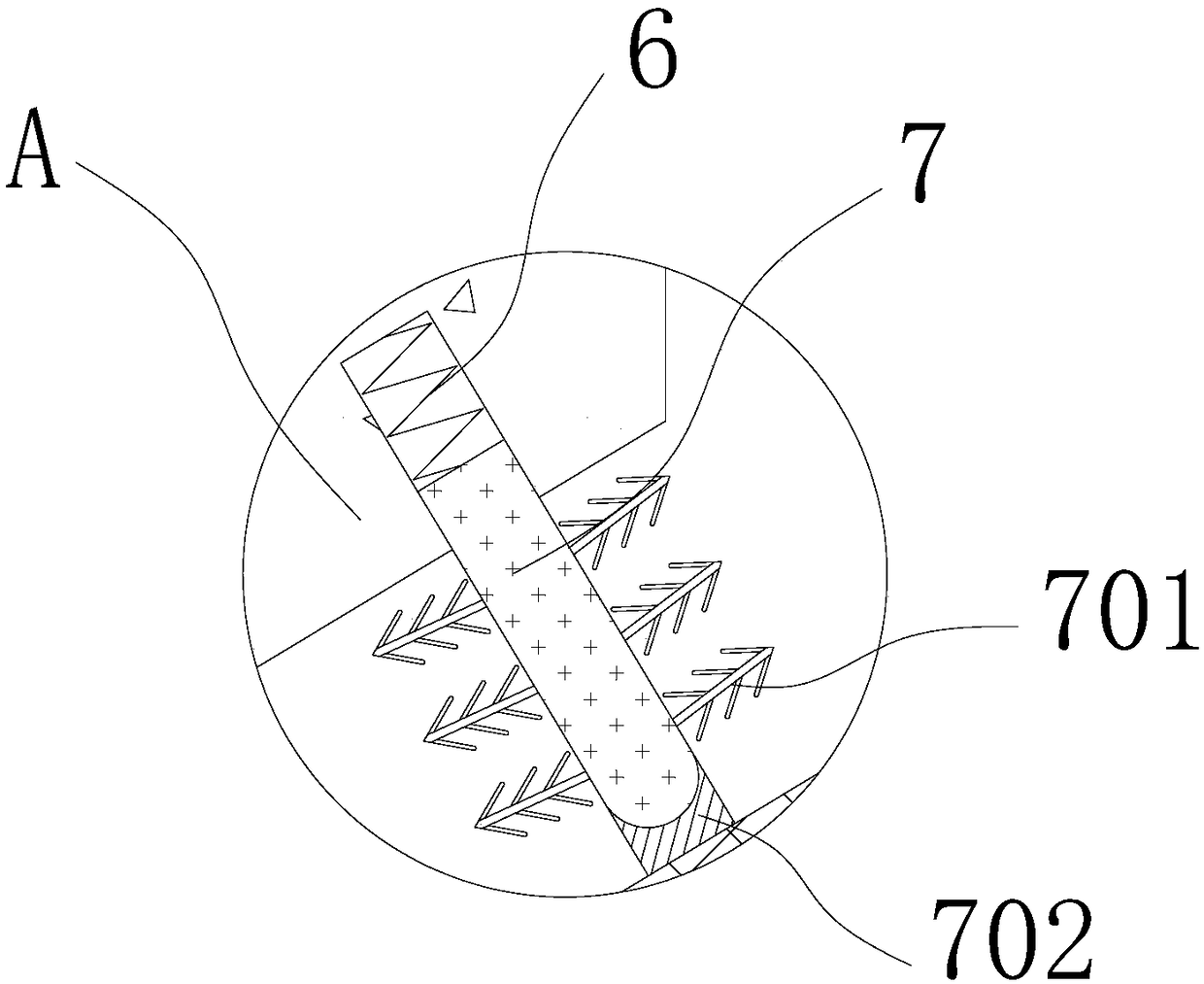

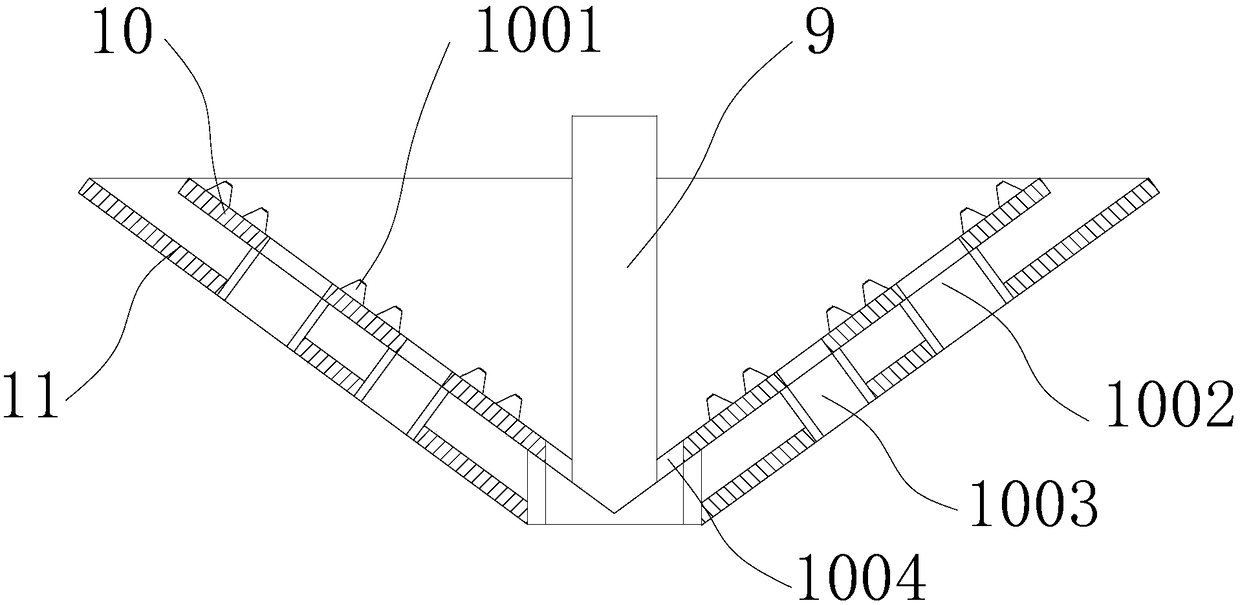

[0033] as attached figure 1 to attach Figure 5 Shown:

[0034]The present invention provides a soil remediation equipment for landfill, including: a housing 1, a soil inlet 2, a dryer 3, a motor 4, a connector 5, a spring 6, a crushing rod 7, a protruding rod 701, and a scraper 702, baffle plate 8, connecting shaft 9, movable plate 10, protrusion 1001, first discharge port 1002, second discharge port 1003, third discharge port 1004, fixed plate 11, connecting pipe 12, liquid supply device 13. The first mixing bucket 14, the mixing blade 15, the second mixing bucket 16, the third mixing bucket 17, the fixed shaft 18, the turntable 19, the open area 20, and the narrow area 21; Tukou 2, both sides of the top of the inner wall of the housing 1 are fixedly connected with a dryer 3, the top of the housing 1 is fixedly installed with a motor 4, and the bottom of the motor 4 is rotatably connected with a connector 5, and the two sides of the bottom of the connector 5 Both are embe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com