Shearing part for plasticising screw

A technology of plasticizing screw and screw, which is applied in the direction of plastic recycling and recycling technology, can solve the problem of no macro homogenization operation, and achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

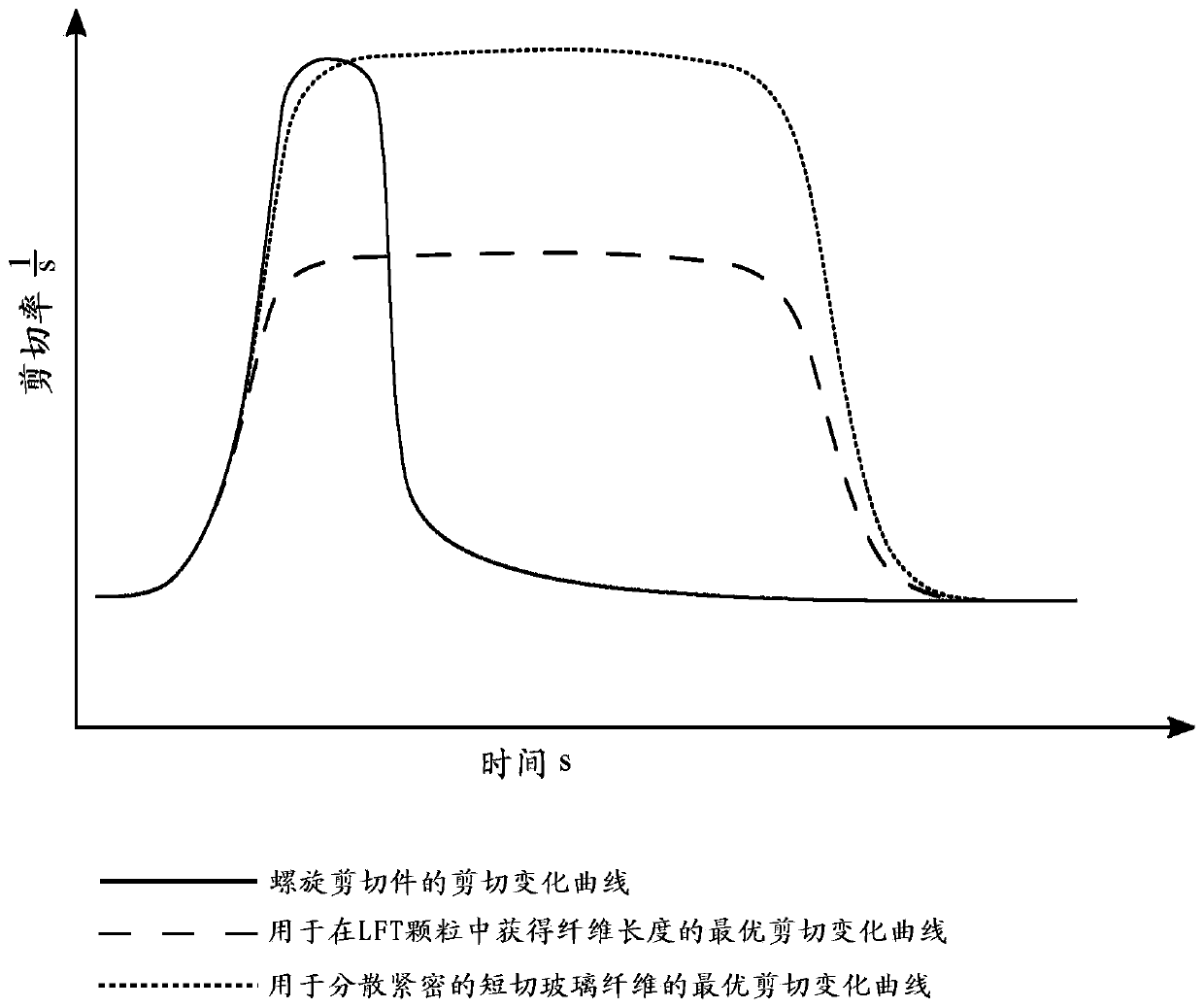

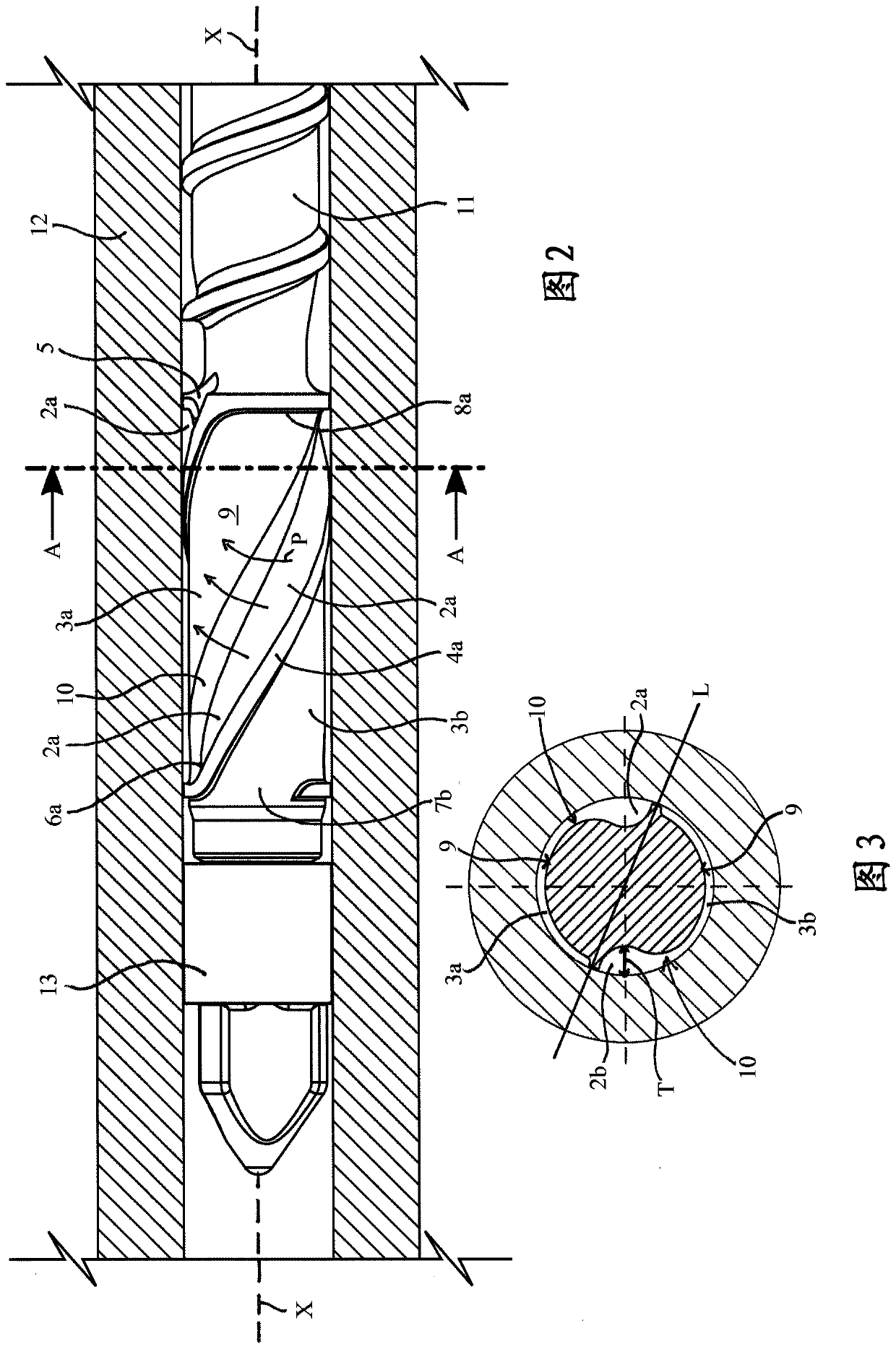

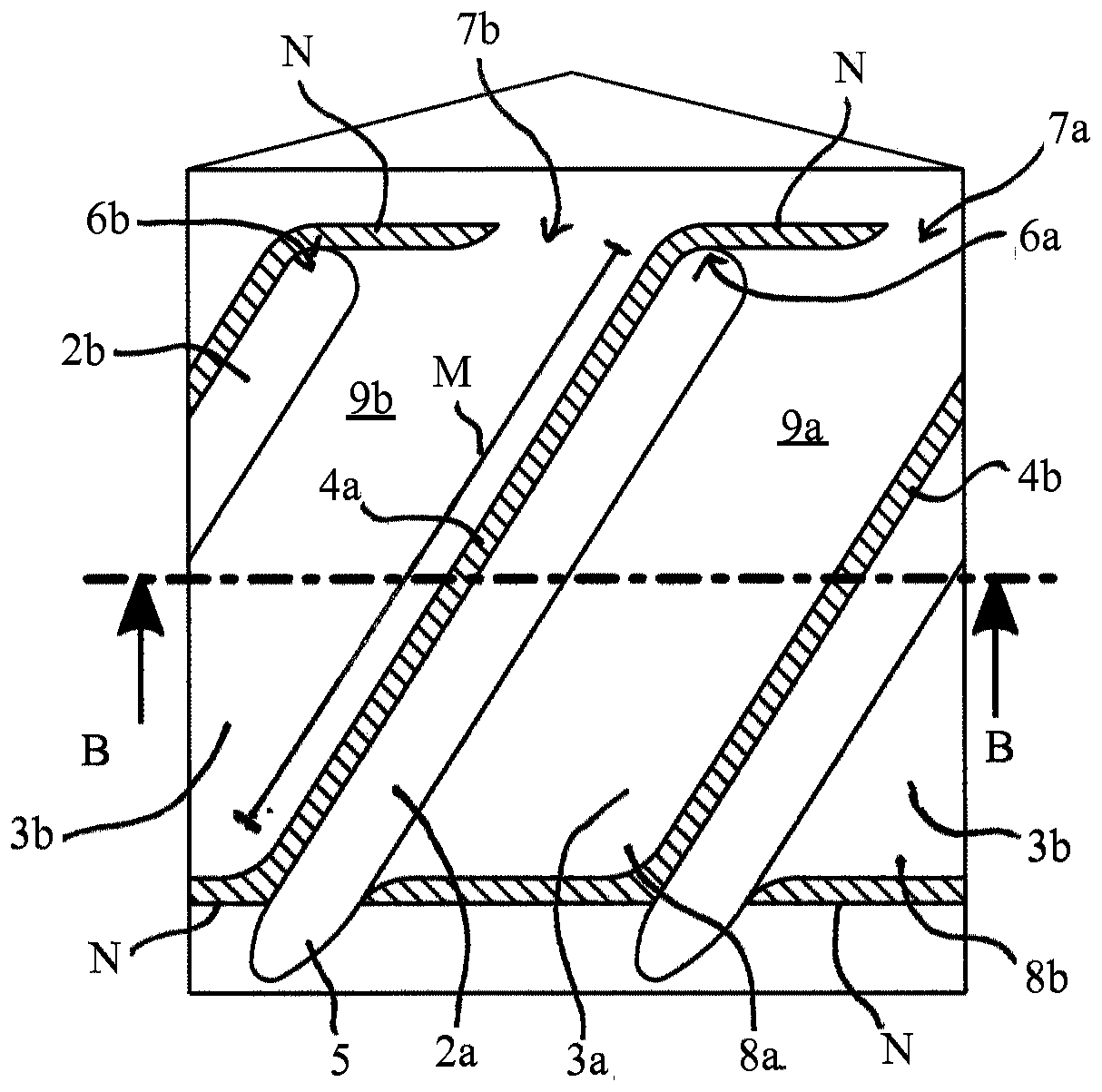

[0044] figure 2 The use of the shear element according to the invention is shown at the conveying downstream end of a screw 11 which is arranged rotatably and linearly drivably in a cylinder 12 . A non-reverse flow valve 13 is provided on the downstream side of the shearing piece. according to figure 2 and image 3 , the shearing element 1 according to the invention has two inlet channels 2a, 2b and two outlet channels 3a, 3b, which are respectively connected to each other in terms of flow and form each half of the shearing element 1, as in this case image 3 As indicated by the line L in the The two halves are arranged helically around the longitudinal axis X of the shear element 1 and are separated from one another in terms of flow by shut-off webs 4a, 4b. One half of the cutout is described in detail below. This half comprises an inlet channel 2 a and an outlet channel 3 a which extend helically around the longitudinal axis X of the shear element 1 . The inlet chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com