Friction stir welding device capable of removing welding holes

A friction stir and welding device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of unsightly materials, welding holes cannot be effectively removed, etc., and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

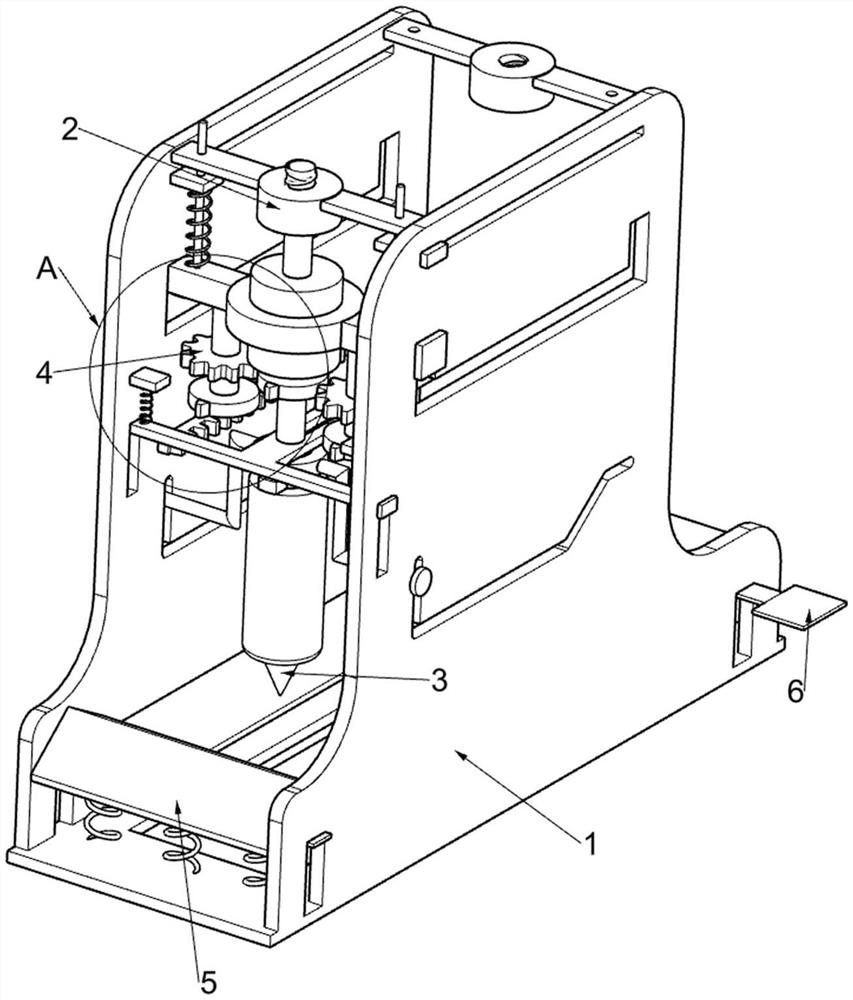

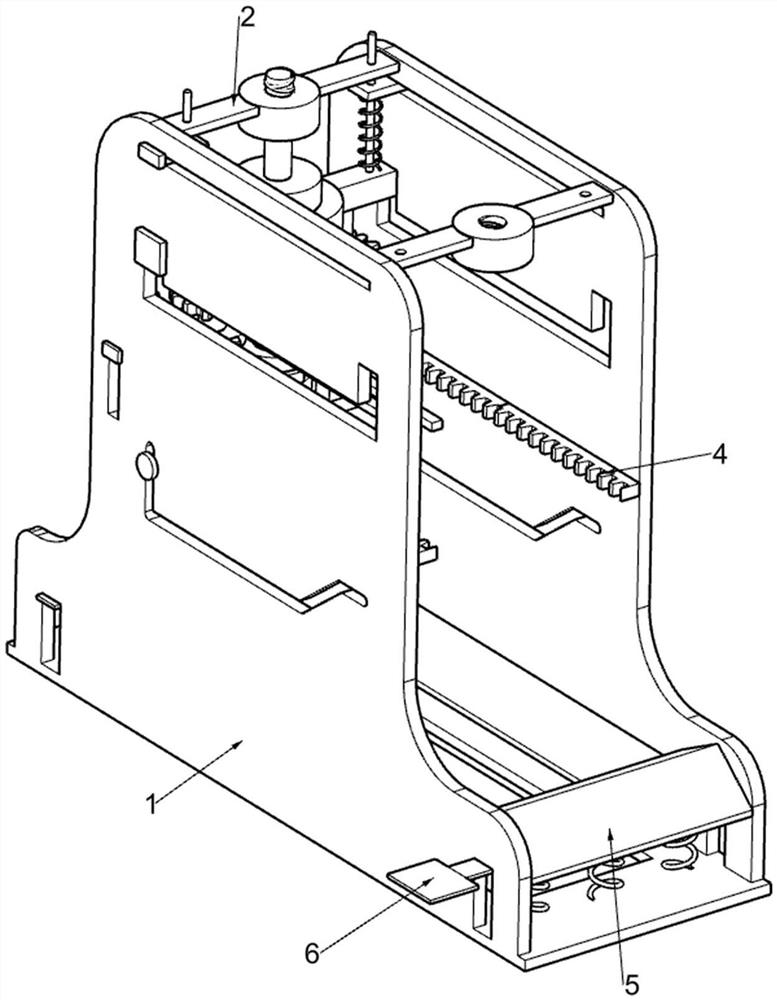

[0024] A friction stir welding device that removes weld holes, such as Figure 1-7 As shown, it includes a support frame 1, a rotating mechanism 2, a drilling mechanism 3, a moving mechanism 4 and a clamping mechanism 5. The drilling mechanism 3, the moving mechanism 4 are arranged on the rotating mechanism 2, and the clamping mechanism 5 for clamping the metal material plate is arranged on the support frame 1.

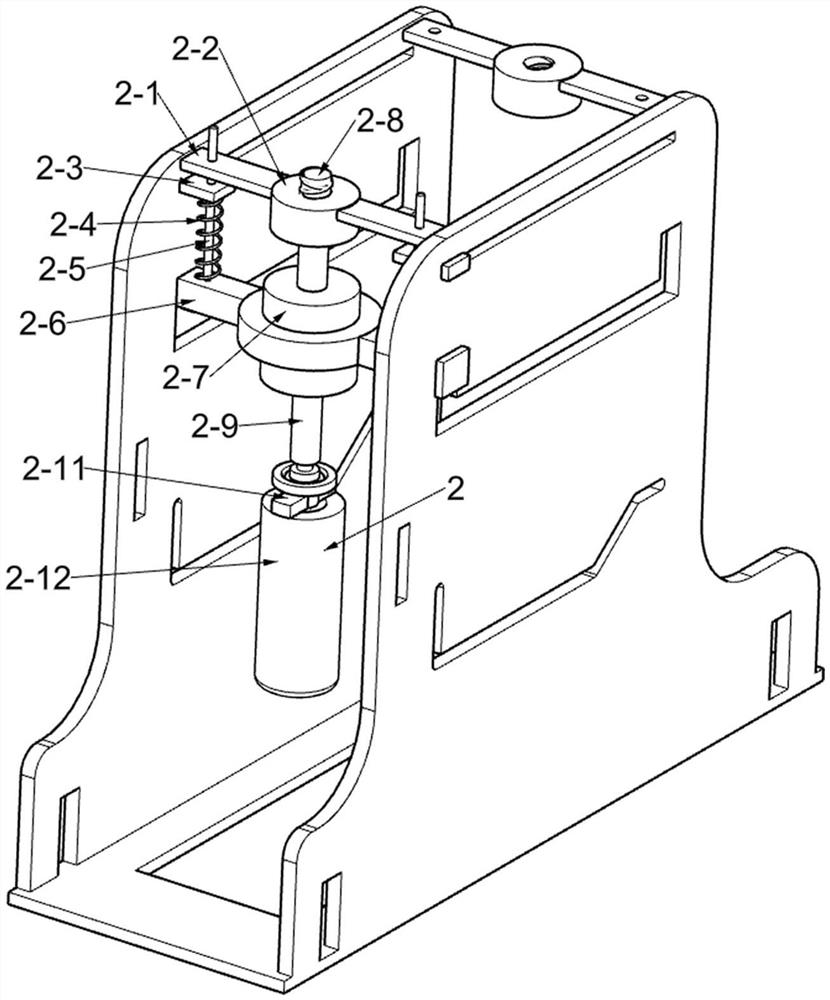

[0025] Turning mechanism 2 includes fixed plate 2-1, fixed nut 2-2, sliding plate 2-3, first return spring 2-4, slide bar 2-5, first sliding frame 2-6, two-way motor 2-7 , two-way screw rod 2-8, rotating shaft 2-9, first fixed block 2-11 and grinding disc 2-12, two fixed plates 2-1 are fixed symmetrically on the inner side of support frame 1, away from the two fixed plates 2 of support frame 1 -1 is jointly fixed with a fixed nut 2-2, two sliding plates 2-3 are slidably connected on the support frame 1 close to the fixed plate 2-1, and a slide bar 2-5 is slidably con...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 7 Shown, also include pedal 6, one side away from the wedge-shaped plate 5-2 of sliding block 5-3 is fixedly connected with the pedal 6 that is convenient to take out metal material plate, and pedal 6 slides with support frame 1 formula fit.

[0034] After polishing, the user steps down on the pedal 6 to drive the wedge-shaped plate 5-2 to move downward, so that the staff can take out the welded metal material plate from the fixed support plate 5-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com