Double-sided double-arc welding system and method for wide-diameter pipes based on k-tig

A double-sided double-arc welding system technology, applied to welding equipment, arc welding equipment, tubular objects, etc., can solve the problems of reducing the degree of deformation of the workpiece, reducing the perforation current, and deteriorating stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

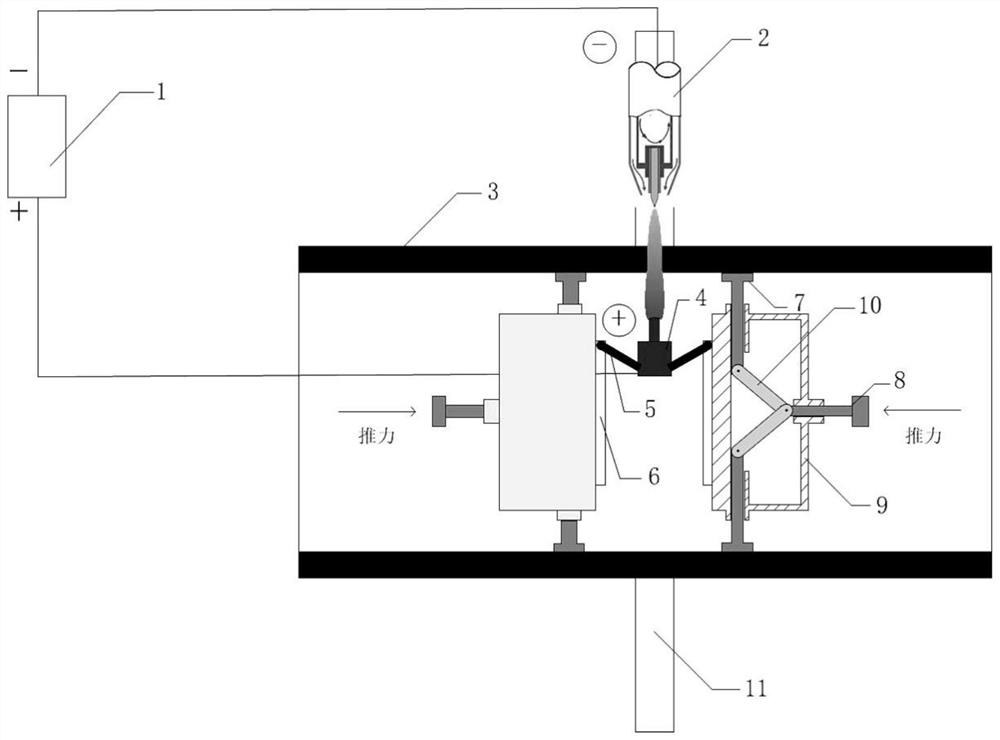

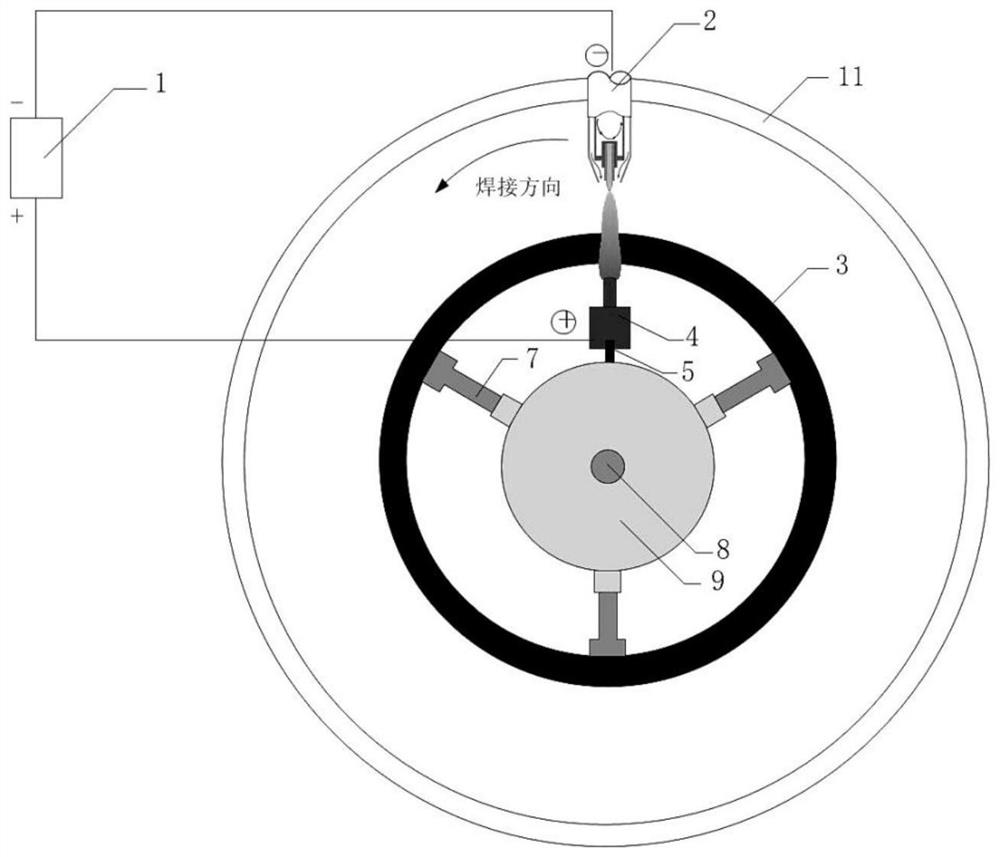

[0020] Such as figure 1 with figure 2 As shown, the present invention discloses a wide-diameter pipe double-sided double-arc welding system based on K-TIG, which mainly includes a welding machine power supply 1, a K-TIG welding torch 2 (keyhole high-efficiency penetration argon arc welding torch), a welded pipe Road 3, GTAW torch 4 (tungsten inert gas shielded welding torch), first track 6 and second track 11, which are suitable for wide-diameter welded pipes 3, and the nominal diameter of such welded pipes 3 is generally greater than 200mm.

[0021] The negative electrode of the welding machine power supply 1 is connected with the K-TIG welding torch 2 , and the positive electrode of the welding machine power supply 1 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com