Double-sided double-arc piercing welding method based on k-tig

A perforation welding, double-sided double-arc technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of stability deterioration, reduction of perforation current, etc., to reduce welding heat input, reduce perforation current, and energy concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

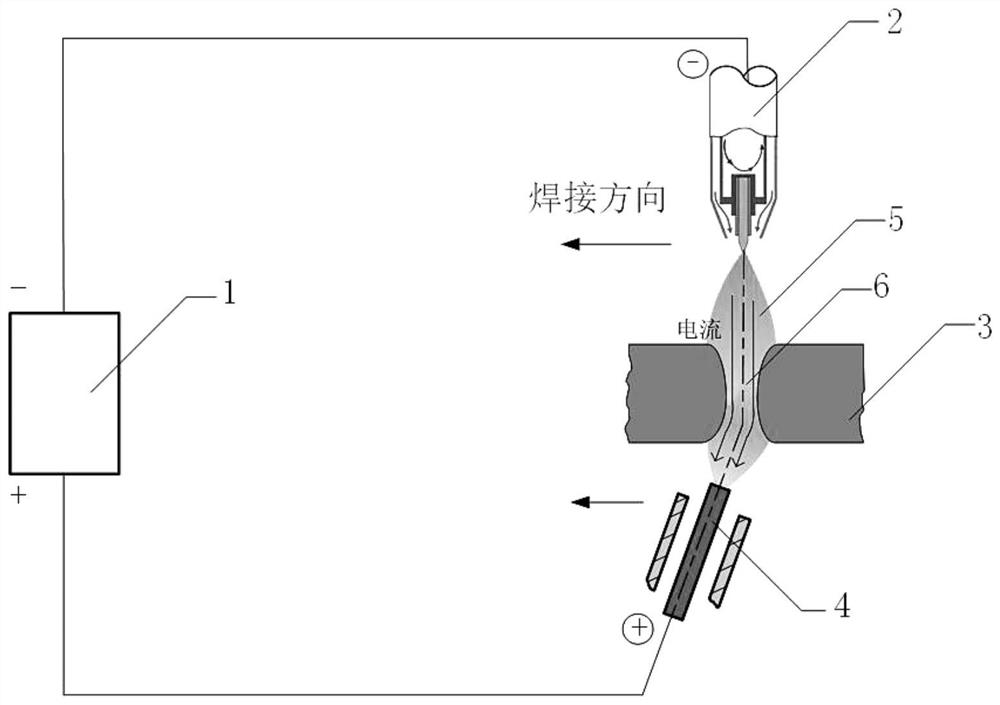

[0020] Such as figure 1 As shown, an embodiment of the present invention discloses a K-TIG-based double-sided double-arc piercing welding method, mainly using a welding machine power supply 1 , a K-TIG welding torch 2 , and a GTAW welding torch 4 .

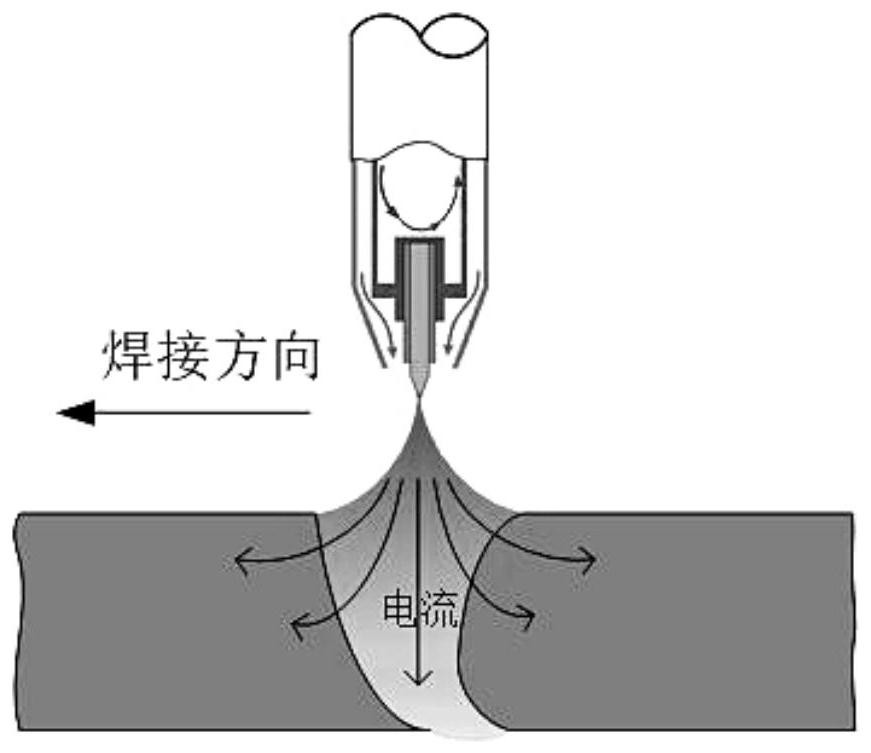

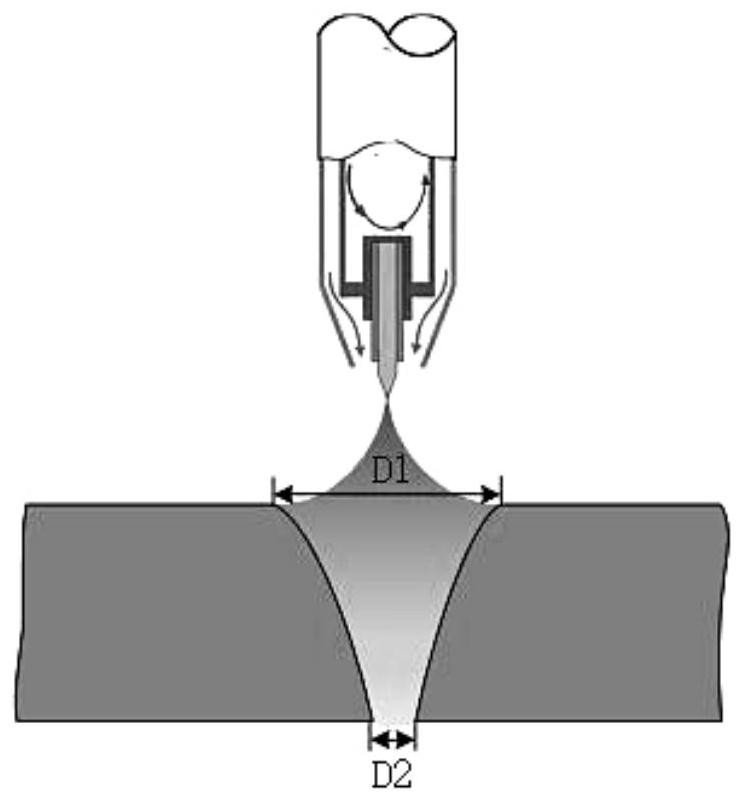

[0021] K-TIG welding torch 2 and GTAW welding torch 4 are relatively placed on both sides of the welded part 3 butt joints, and simultaneously weld the welded part 3 butt joints, wherein the spray head of K-TIG welding torch 2 is paired with the welded part 3 The welding position of the seam is vertical so that the welding arc 5 passes through the small hole 6 . The negative pole of the welding power supply 1 is connected to the K-TIG welding torch 2 as the output end of the welding arc 5; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com