Efficient cooling device for cable materials

A technology of cooling device and cable material, applied in coating and other directions, can solve problems such as affecting the quality of cable material, and achieve the effect of simple structure, high work efficiency and good air-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

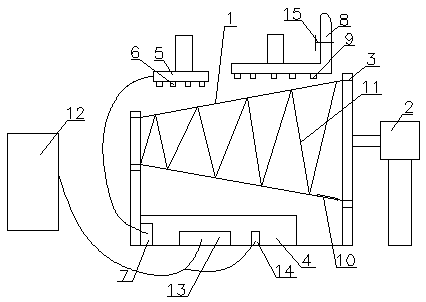

[0013] A high-efficiency cooling device for cable materials, including a conical screen cylinder 1 and a drive motor 2, the conical screen cylinder 1 is placed horizontally, and the two ends of the conical screen cylinder 1 are respectively installed on the bearing housing 3 through bearings. The large mouth end of the conical screen cylinder 1 is connected with the rotating shaft of the drive motor 2 through a rotating disk, a water collection tank 4 is provided below the conical screen cylinder 1, and a spray main pipe is provided above the small mouth end of the conical screen cylinder 1 5. The spray main pipe 5 is provided with a number of downward spray heads 6, and the sump 4 is provided with a water pump 7, and the water pump 7 is connected to the spray main pipe 5 through a pipeline, and the conical screen A main air duct 8 is provided above the large mouth end of the barrel 1, and a plurality of downward blowing pipes 9 are arranged on the main air duct 8, and a discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com