Series 1 aluminum alloy sheet production process

A technology of aluminum alloy plate and production process, which is applied in the production process of 1 series aluminum alloy plate, can improve the process field of aluminum alloy plate surface, can solve problems such as color difference, electrical conductivity can not meet the requirements, chatter marks, etc., to reduce width, Optimize the production process and reduce the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A production process of a 1-series aluminum alloy plate, comprising the following steps:

[0028] A. Melting and casting: Prepare aluminum alloy raw materials according to the following weight ratios: Si: 0.05%, Fe: 0.12%, Cu: 0.001%, Mn is 0, Mg: 0.004%, Zn: 0.002%, V: 0.008%, Ti : 0.004%, impurity 0.03%, Al: 99.81%, put the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly, and then smelt them into liquid aluminum alloys. Ingot;

[0029] B. Homogenization: heat the aluminum alloy ingot obtained by melting and casting to 490°C and keep it warm for 13 hours to obtain a homogenized aluminum alloy ingot;

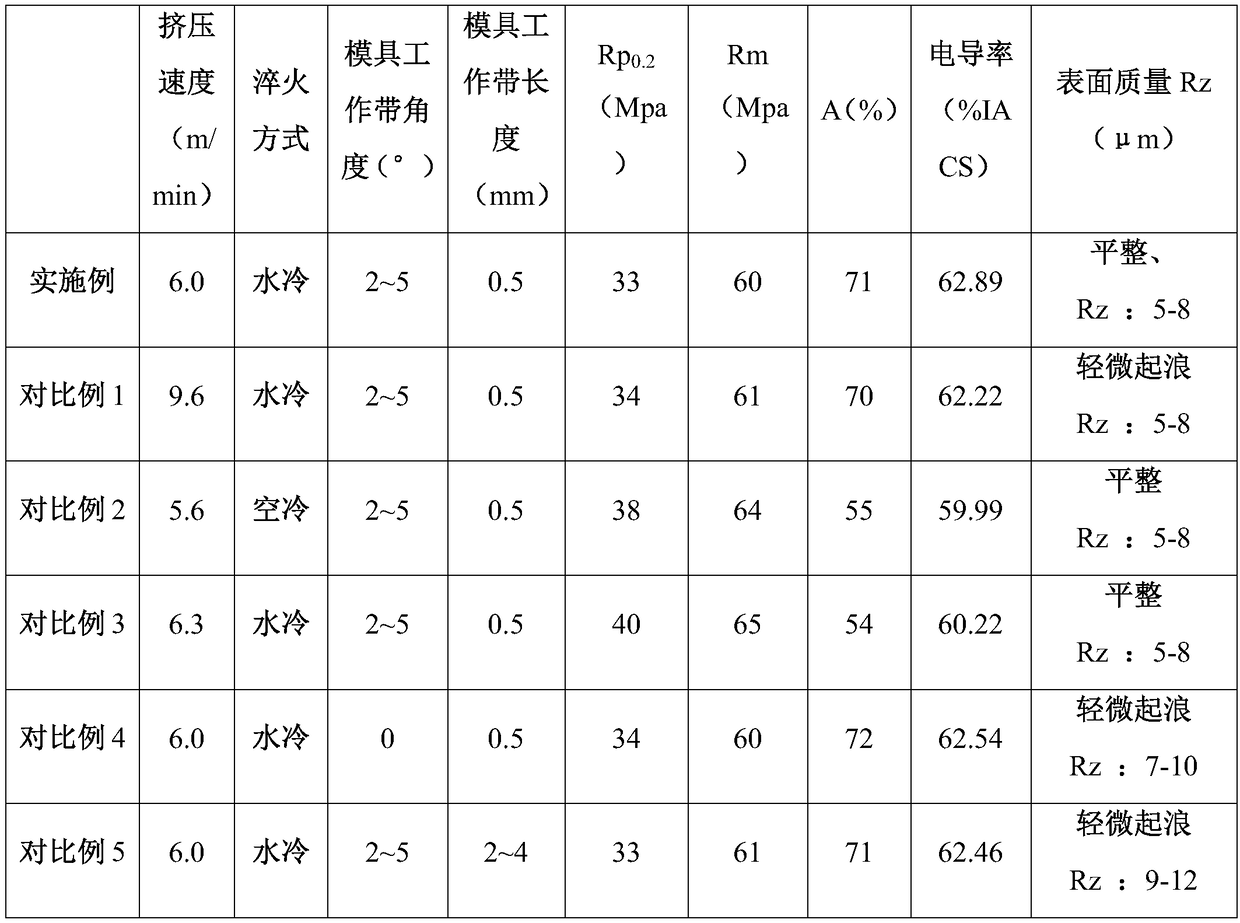

[0030] C. Extrusion: Send the homogenized aluminum alloy ingot into the extrusion cylinder of the extruder for extrusion to obtain aluminum alloy sheets. The extrusion machine is 1000T tonnage, and the temperature of the extrusion cylinder is 430±10°C. The extrusion ratio of the extrusion cylinder is 21.2, the extrusion speed is 6.0m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com