A Vehicle Scheduling Optimization Method

An optimization method and vehicle scheduling technology, applied in the computer field, can solve the problems of scattered unloading points, poor transportation conditions, and large demand, and achieve the effects of improving loading efficiency, reducing distribution costs, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A vehicle scheduling optimization method of the present invention comprises the following steps: S1: Acquiring vehicle information, distribution center information and destination information, and generating constraint conditions; S2: Allocating unloaded vehicles to the distribution center according to the constraint conditions; the constraint conditions It is a combination of one or more of time constraints, vehicle constraints, demand constraints, and distance constraints; S3: Design the distribution route for the allocated vehicles.

[0028]When this embodiment is implemented, vehicle information, distribution center information, and destination information are acquired first, and constraints are generated; the constraints mentioned here are one or more of time constraints, vehicle constraints, demand constraints, and distance constraints. Combination, time constraints are generally cargo delivery time, loading and unloading time, empty time, etc. Vehicle constraints ...

Embodiment 2

[0030] In this embodiment, on the basis of Embodiment 1, step S2 includes the following sub-steps: S21: number all vehicles; S22: obtain each The idle vehicles corresponding to the distribution center; S23: arrange the idle vehicles to the distribution center.

[0031] During the implementation of this embodiment, in order to match idle vehicles to distribution centers, all vehicles are first numbered, and then the corresponding idle vehicles of each distribution center are obtained according to the total demand of each distribution center and the average distance from all idle vehicles to the distribution center. Vehicles, generally speaking, each distribution center needs more than one vehicle, so it is necessary to balance the demand of the distribution center and the distance from the idle vehicle to the distribution center, and then arrange the idle vehicles to the distribution center, which can reduce the distance of the vehicle , It can also meet the needs of the distri...

Embodiment 3

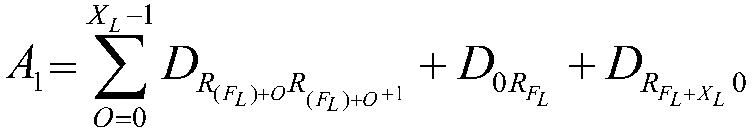

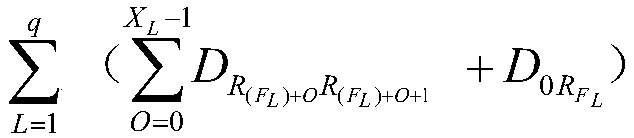

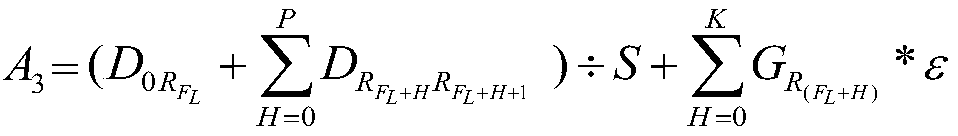

[0033] In this embodiment, on the basis of Embodiment 2, step S22 includes the following sub-steps: obtain the corresponding idle vehicle of the distribution center according to the following formula: In the formula, q is the number of vehicles, λ is the adjustment coefficient, Gi is the quantity of feed that the i-th distribution center needs to distribute, θ is the time required to load each ton of feed, is the delivery distance from the jth vehicle to the i delivery point.

[0034] When this embodiment is implemented, the demand of the distribution center and the distance from the idle vehicle to the distribution center can be integrated through the above formula, and the i components can be optimized and sorted, and the top k vehicles can be selected to be arranged in each distribution center of i, from which through Argmin The function is selected to achieve the purpose of allocating vehicles.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap