A pay-off pulley for a UAV wire-mounting system

A technology of pay-off pulley and rack wire, applied in the direction of overhead line/cable equipment, etc., can solve the problems of time-consuming and labor-intensive, easy to be affected by the environment, no centering system and pay-off system, etc., and achieve simple operation and structure. The effect of uniform force and increased connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

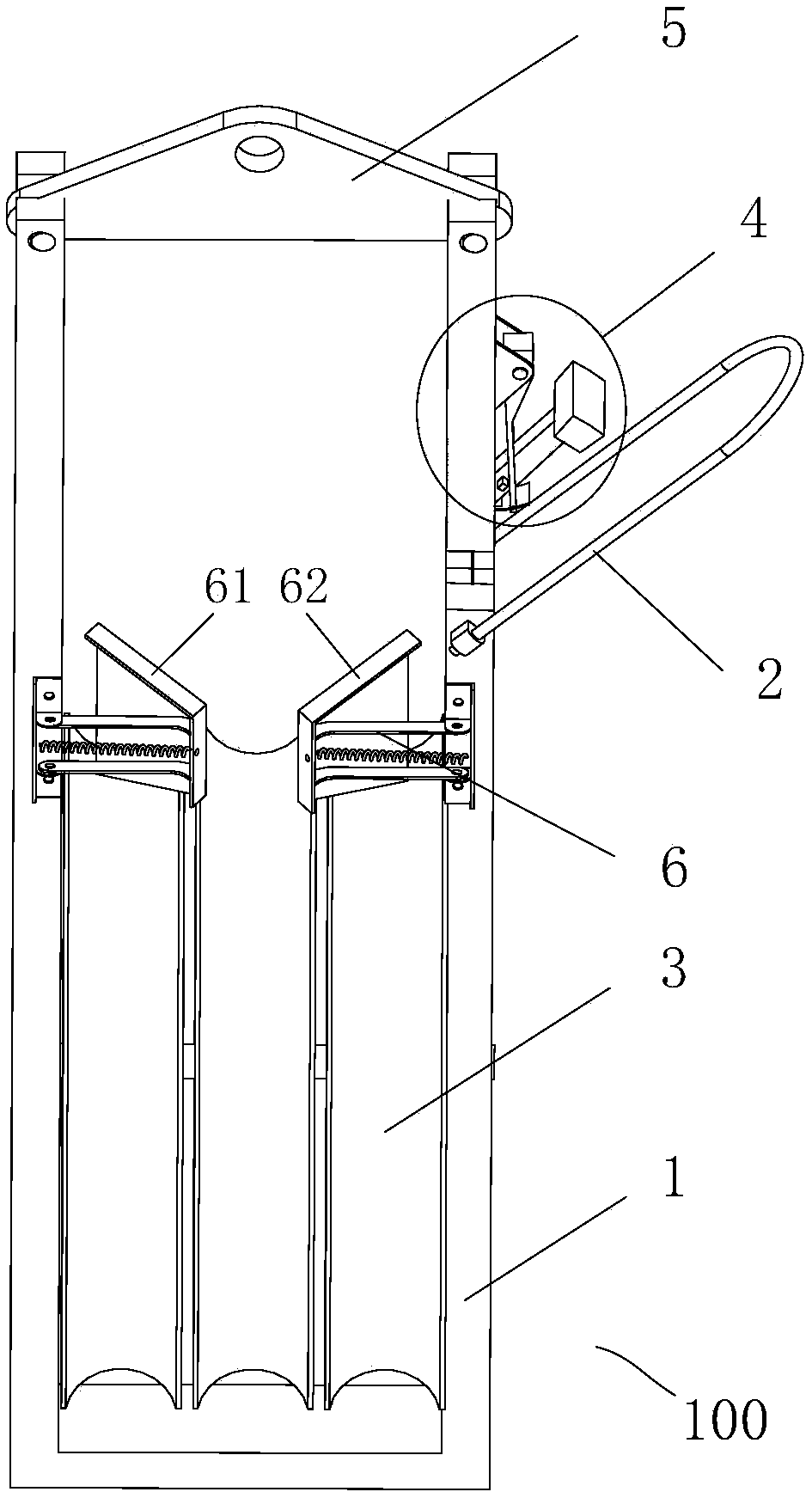

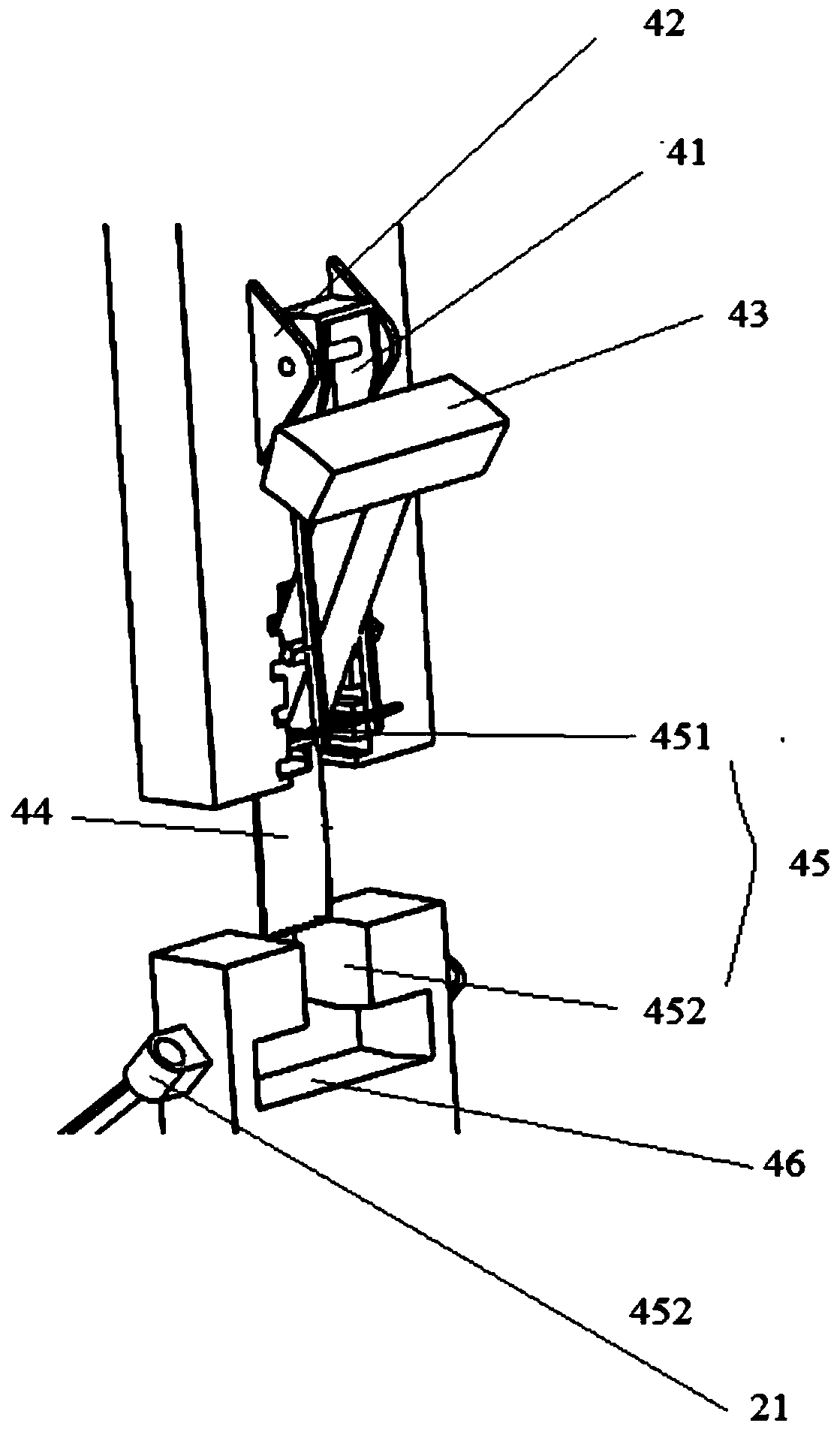

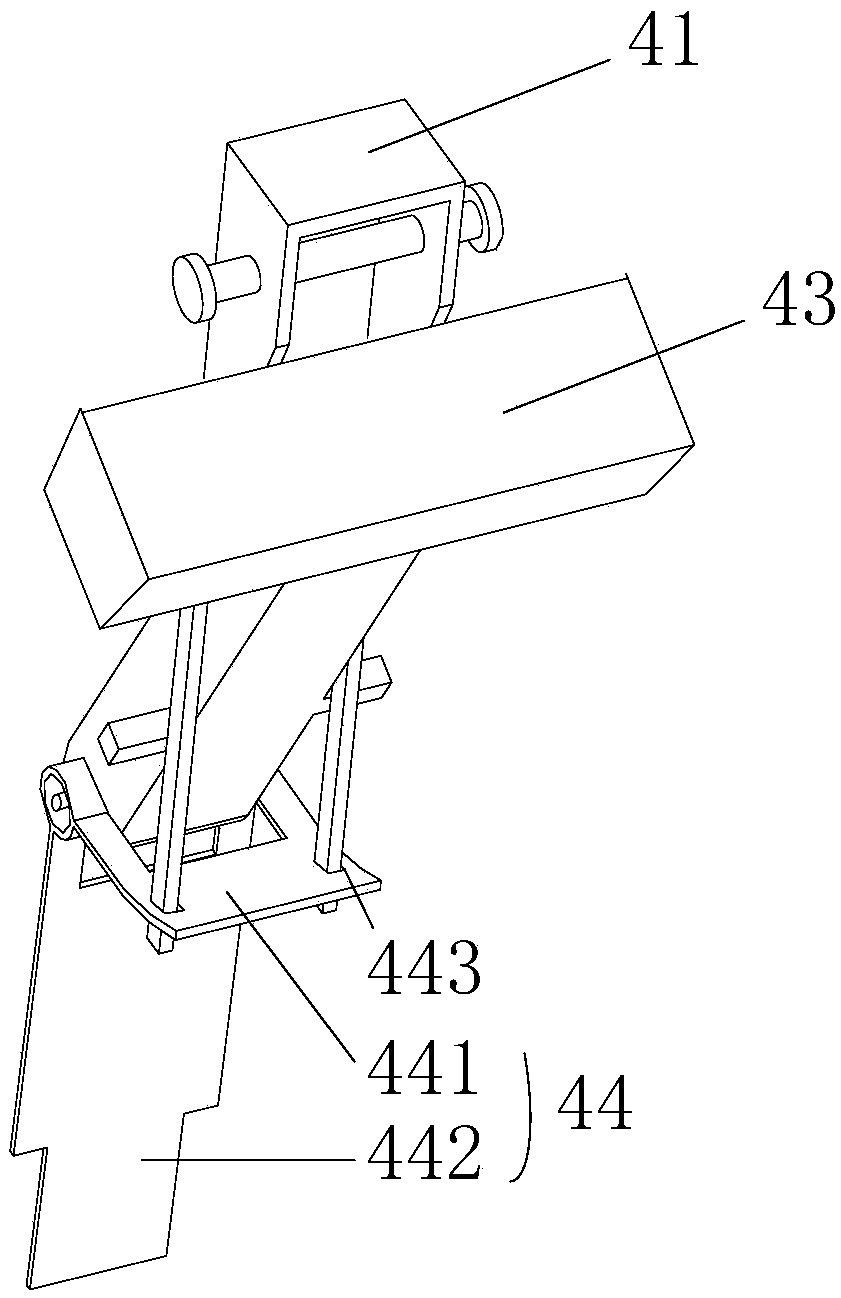

[0021] The pay-off tackle 100 for unmanned aerial vehicle wire system according to the embodiment of the present invention, such as Figure 1 to Figure 4 As shown, it includes a frame body 1, a guide rope guide rail 2, a pulley 3, a snap connection assembly 4, a connecting plate 5 and a centering valve system 6. The connecting plate 5 and the frame body 1 are connected through pin shafts. The pay-off block for UAV stringing system also includes centering valve system 6. The pulley 3 is a nylon pulley, and the circumferential surface of the pulley 3 is provided with arc-shaped grooves for accommodating guide ropes or cables. The number of pulleys 3 is odd, each pulley is coaxial, and each pulley has a common support shaft. The two ends of the support shaft are respectively connected to the frame body 1 and supported by the frame body 1. A plurality of pulleys form a pulley block. figure 1 In the embodiment, the number of nylon pulleys is three, which are respectively the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com