Back-to-back HVDC transmission system and control method based on virtual synchronous machine

A technology of direct current transmission system and virtual synchronous machine, which is applied in the direction of AC network circuits, electrical components, circuit devices, etc., to achieve the effects of reducing rotational inertia, ensuring operational reliability, and good technological advancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0034] An embodiment of a back-to-back direct current transmission system based on a virtual synchronous machine of the present invention:

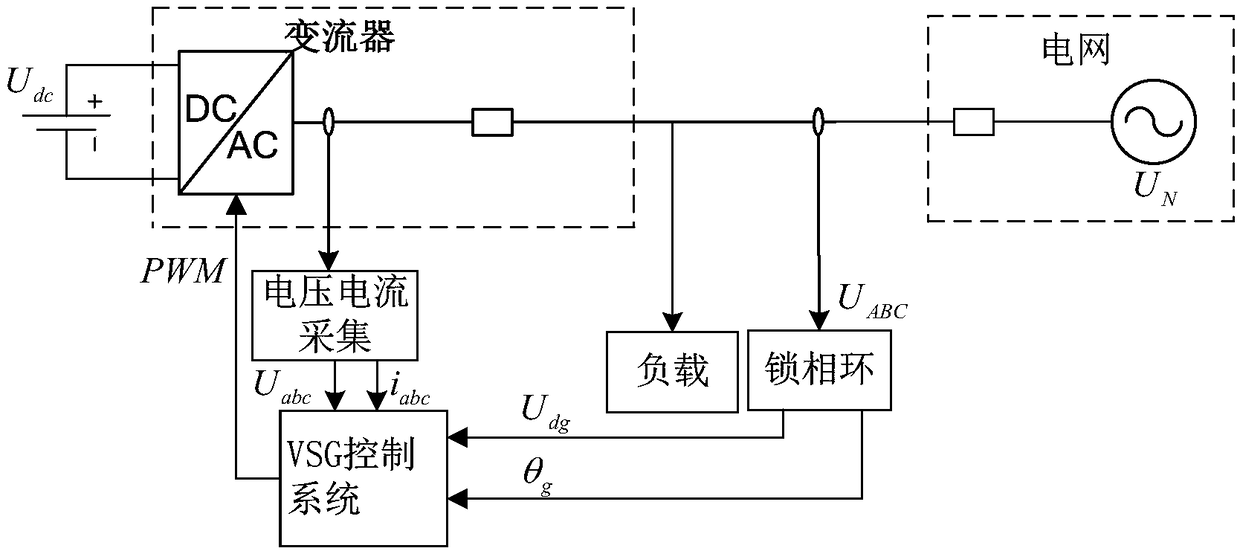

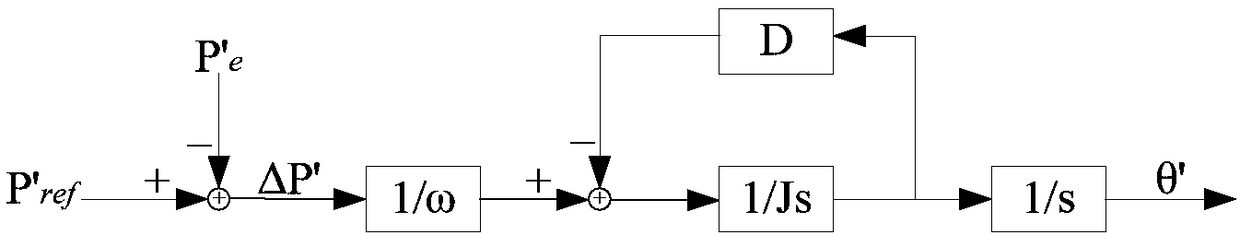

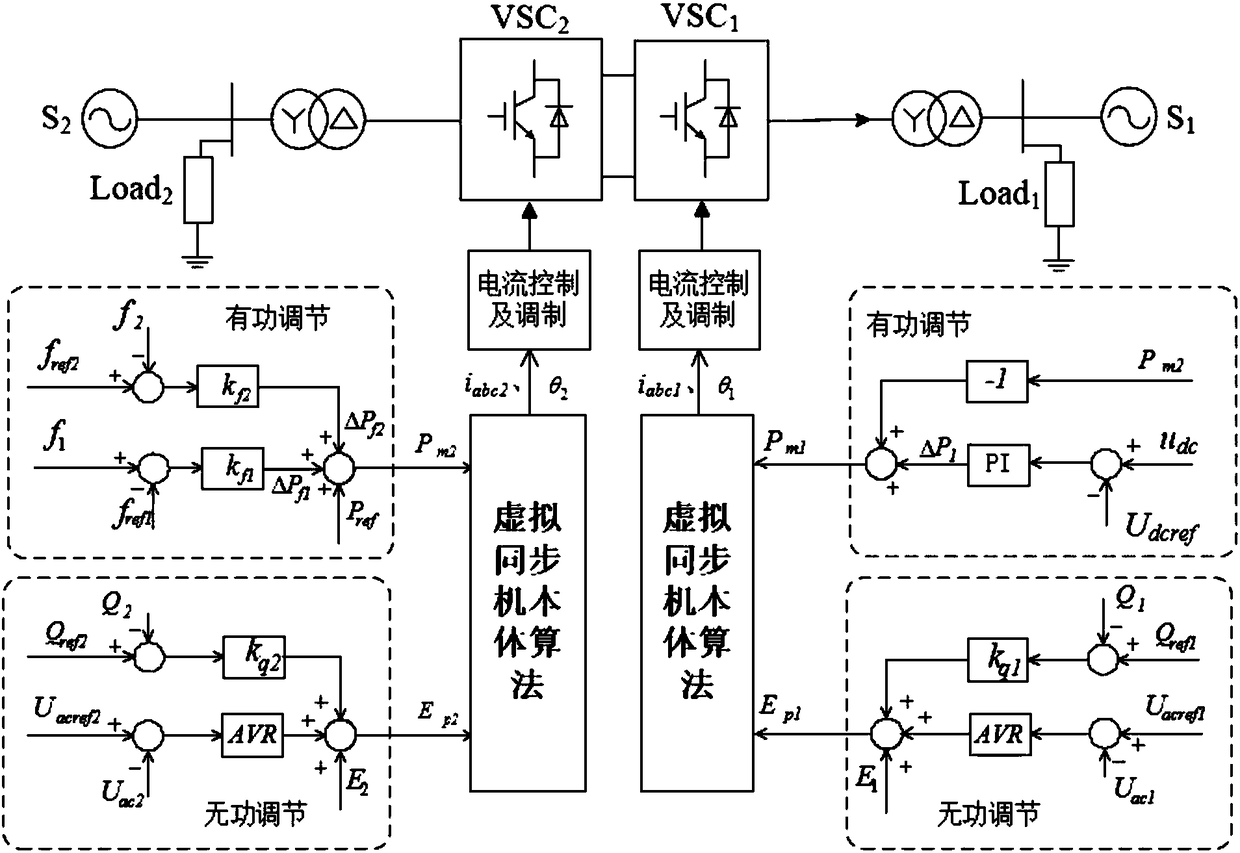

[0035] Such as image 3 VSC-HVDC shown, the system contains two converters VSC 1 and VSC 2 , where VSC1 is the first converter, its active power regulation part performs DC voltage control, VSC 2 is the second converter, and its active power regulation part performs active power control. VSC 1 and VSC 2 The control system consists of two parts: virtual synchronous machine control, current control and modulation. Among them, the virtual synchronous machine control part is composed of the first active power adjustment module, the first reactive power adjustment module, the second active power adjustment module, the second reactive power adjustment module and the virtual synchronous machine body algo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com