A liquid cooled chassis and a plug-in thereof

A liquid cooler and plug-in technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating renovation, etc., can solve the problem of low heat dissipation efficiency of integrated components, and achieve extended service life, fast and effective heat buildup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 3

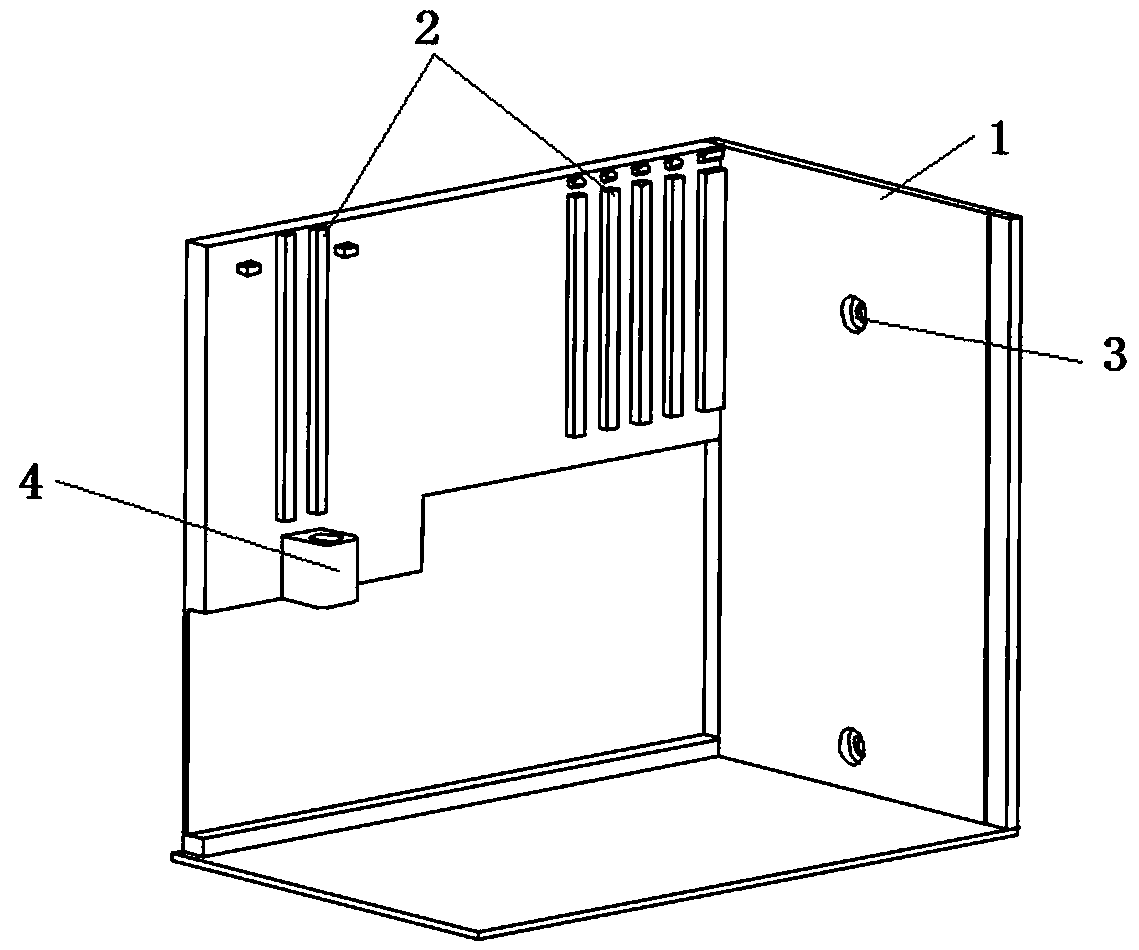

[0028] Embodiment 3 of the liquid-cooled cabinet of the present invention: the difference from Embodiment 1 is that no weight-reducing groove is provided on the outer wall of the cabinet.

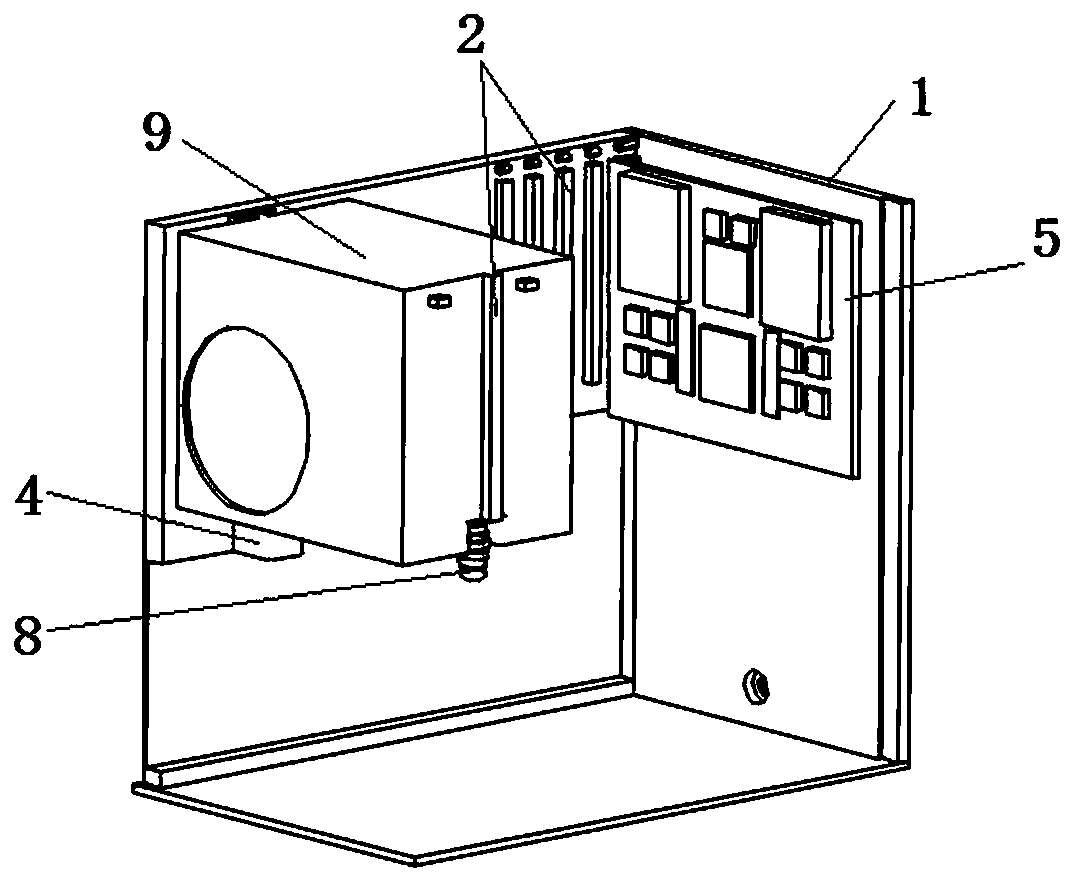

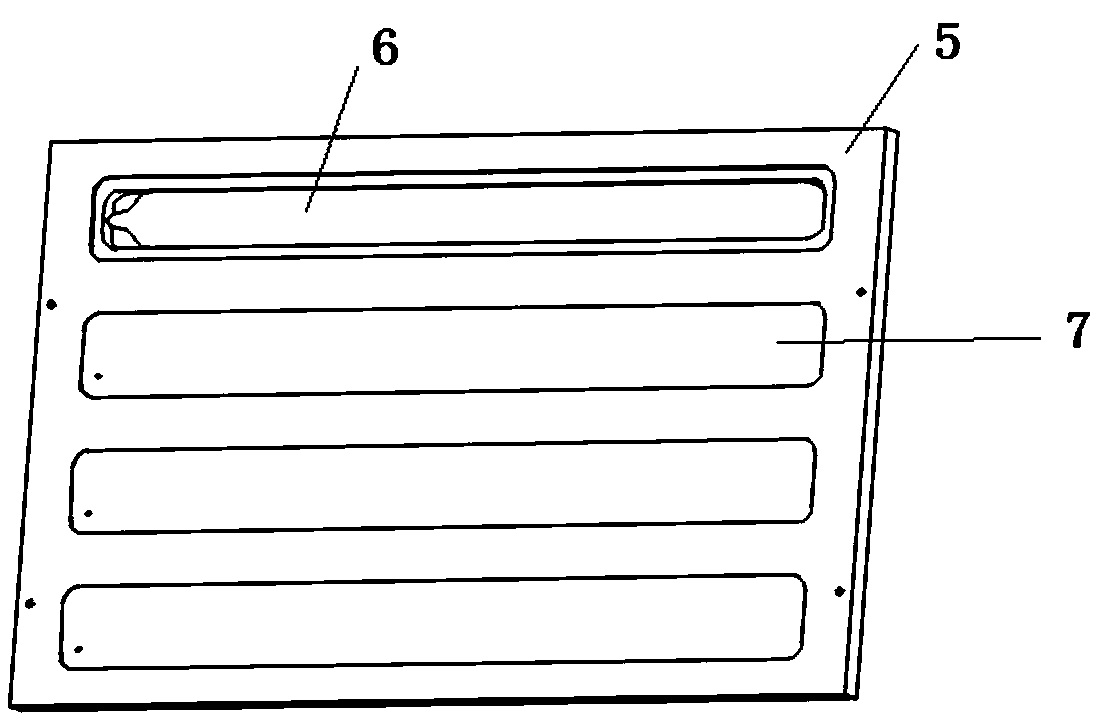

[0029] The liquid-cooled chassis of the present invention is installed in the groove on the plug-in through the heat pipe with high thermal conductivity, which realizes the strong heat conduction ability and temperature uniformity of the plug-in, and the multiple heat pipes embedded in the plug-in can rapidly dissipate the heat generated by the integrated components. Conducted to the liquid cooling pipe on the side wall of the chassis to achieve rapid and effective heat transfer.

[0030] The specific embodiment of the plug-in of the present invention has the same structure as that of any one of the plug-in in the first embodiment to the third specific embodiment of the above-mentioned liquid-cooled chassis, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com