Transverse beam bearing structure of well-hole wagon and connecting structure with wagon side wall

A technology of load-bearing structure and drop hole car, which is applied to railway car body parts, freight cars, transport passenger cars, etc., can solve the problems of easy cracking and damage of welds, easy vibration of beams, weak cross-section rigidity of beams, etc., and achieves high structural reliability. , to avoid structural fatigue failure, to achieve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

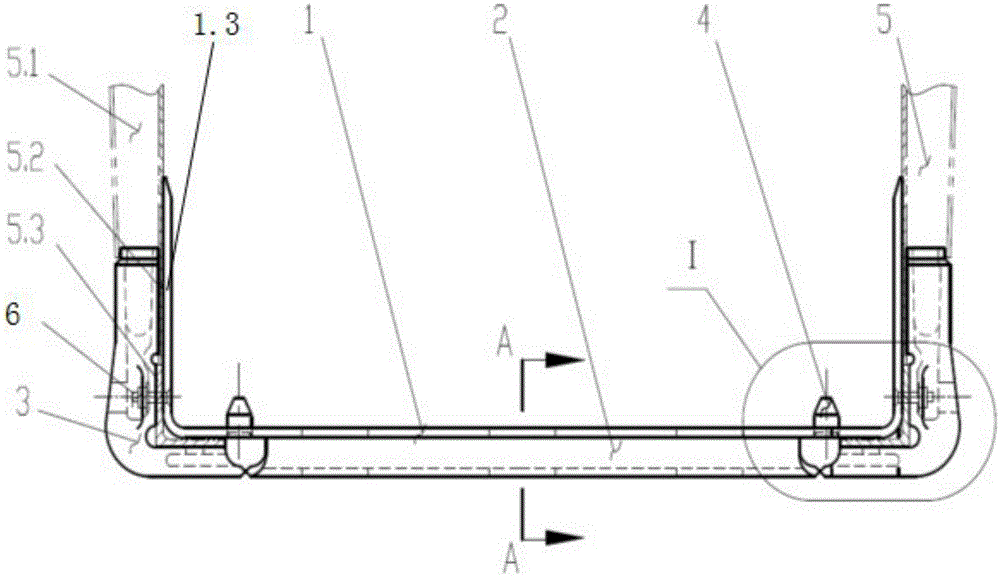

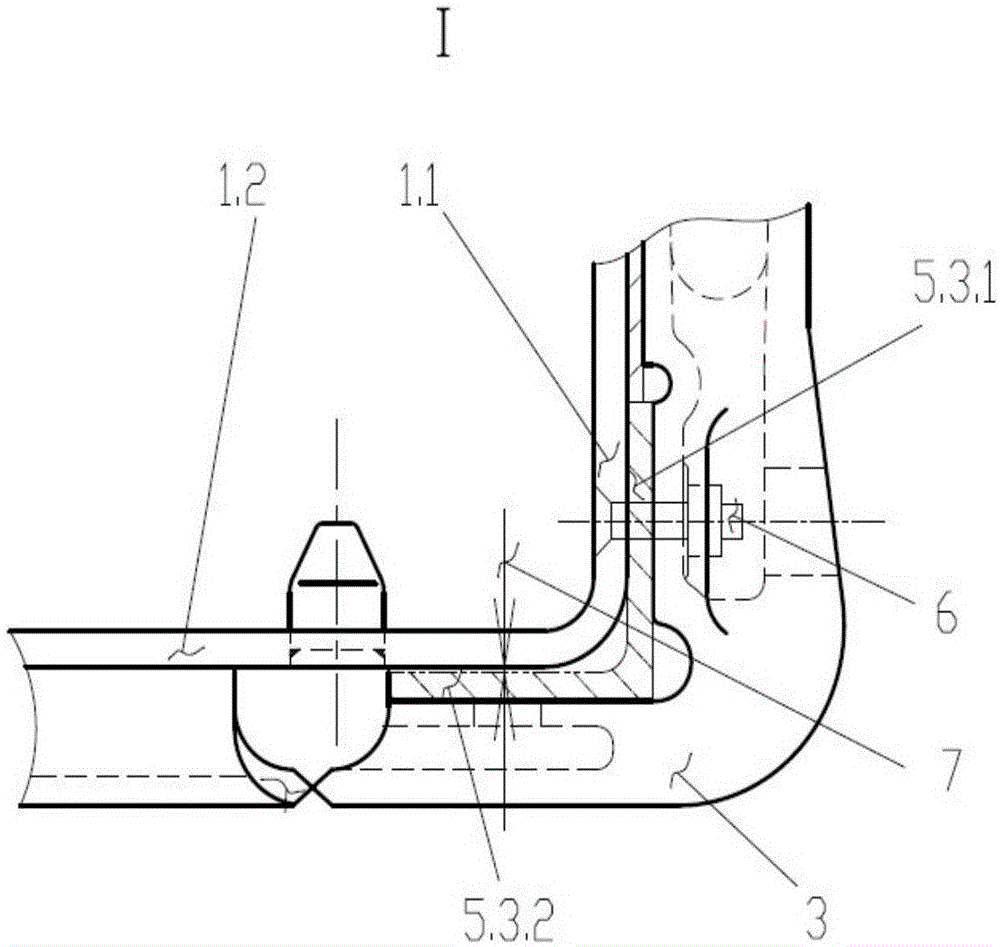

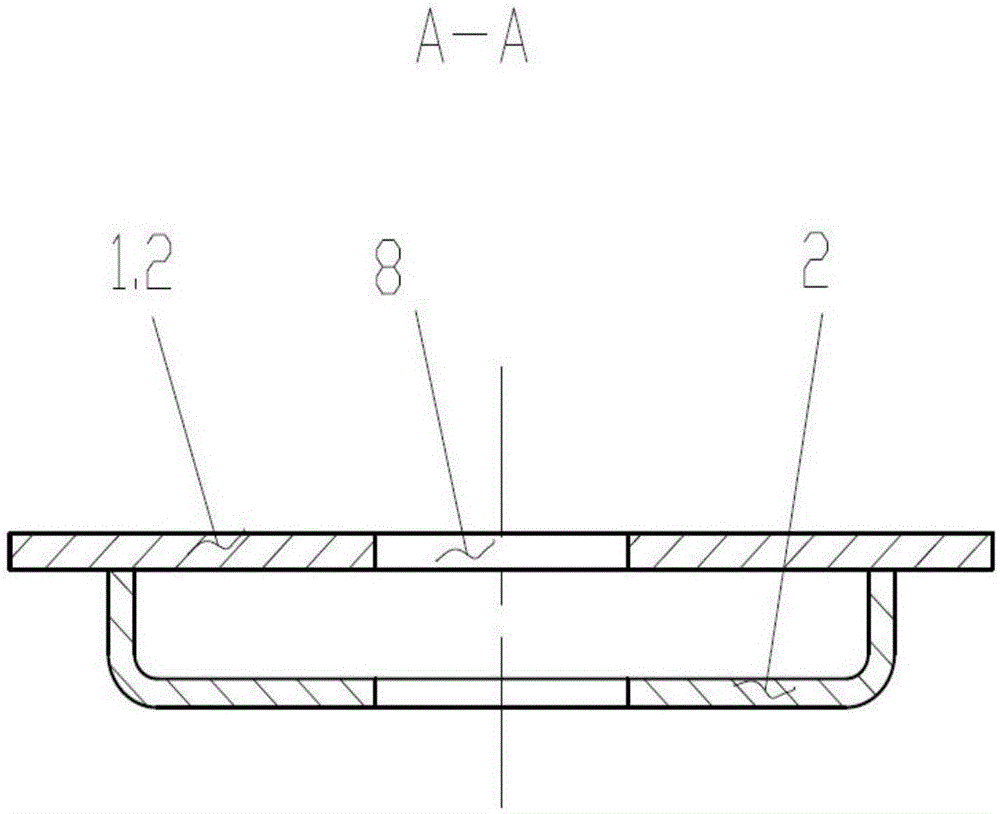

[0018] like Figure 1 ~ Figure 4 As shown, the beam load-bearing structure of the container drop hole car of the present invention is located at the two ends and the middle of the concave chassis of the car body, including the upper cover plate 1 and the grooved beam 2, and its key technology is to also include the angular bearing seat 3, the upper The cover plate 1 is folded and pressed into a wide U shape. The upper cover plate 1 includes the left elevation 1.3, the right elevation 1.1 and the bottom surface 1.2. The frame is connected into one and forms a box-shaped beam with a frame-shaped closed section; the angular bearing seat 3 is a corner-shaped hollow section steel casting, and the angular bearing seat 3 includes a vertical end and a horizontal end 3.3, and the vertical end is provided with an embedded opening 3.2.

Embodiment 2

[0020] like Figure 1 ~ Figure 4 As shown, the beam load-bearing structure of the container drop hole car of the present invention is located at the two ends and the middle of the concave chassis of the car body, including the upper cover plate 1 and the grooved beam 2, and its key technology is to also include the angular bearing seat 3, the upper The cover plate 1 is folded and pressed into a wide U shape. The upper cover plate 1 includes the left elevation 1.3, the right elevation 1.1 and the bottom surface 1.2. The frame is connected into one and forms a box-shaped beam with a frame-shaped closed section; the angular bearing seat 3 is a corner-shaped hollow section steel casting, and the angular bearing seat 3 includes a vertical end and a horizontal end 3.3, and the vertical end is provided with an embedded opening 3.2.

[0021] The two ends of the upper cover plate 1 are provided with fixed lock heads 4 corresponding to the corner fittings of the container.

[0022] The...

Embodiment 3

[0026] A connection structure between the beam load-bearing structure and the side wall of the car body of a container-loading drop-hole car, such as Figure 1 ~ Figure 4 As shown, the beam load-bearing structure of the container drop hole car of the present invention includes an upper cover plate 1 and a channel beam 2, and its key technology is that it also includes an angular bearing seat 3. The upper cover plate 1 is folded into a wide U shape, and the upper cover plate 1 The cover plate 1 includes the left elevation 1.3, the right elevation 1.1 and the bottom surface 1.2. The bottom surface 1.2 is interlocked and welded with the channel beam 2, so that the beam bearing structure and the side wall chassis are integrated to form a box-shaped box with a closed section. Beam; the angular bearing seat 3 is a steel casting with a knuckle-shaped hollow section, the angular bearing seat 3 includes a vertical end and a horizontal end 3.3, and the vertical end is provided with an em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com