Splicing type forging die strength analysis method based on uneven temperature and stress distribution

A technology of stress distribution and uniform temperature, which is applied in the field of metal hot forging, can solve problems such as unreliable simulation results, distortion of mold mechanical boundary conditions, uneven distribution of temperature and stress, etc., to achieve real mechanical and temperature boundary conditions and real boundary conditions , Simulation results are reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

[0033] It should be noted that: the English names used in this article, DEFORM is the commercial software for metal plastic forming simulation; ANSYSWORKBENCH is the structural analysis software; UG is the Unigraphics NX 3D drawing software produced by Siemens PLM Software. The English names of these three software are well-known in the industry. the term.

[0034] The present invention as Figure 1 to Figure 7 Shown:

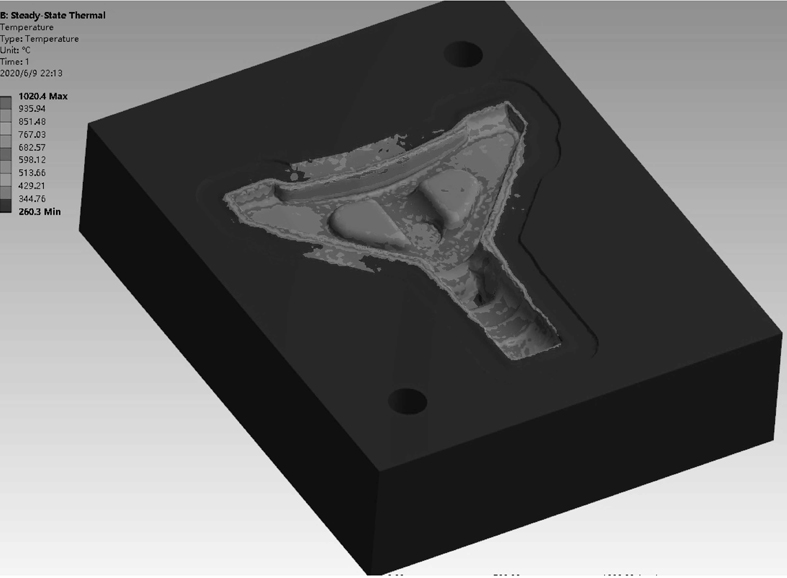

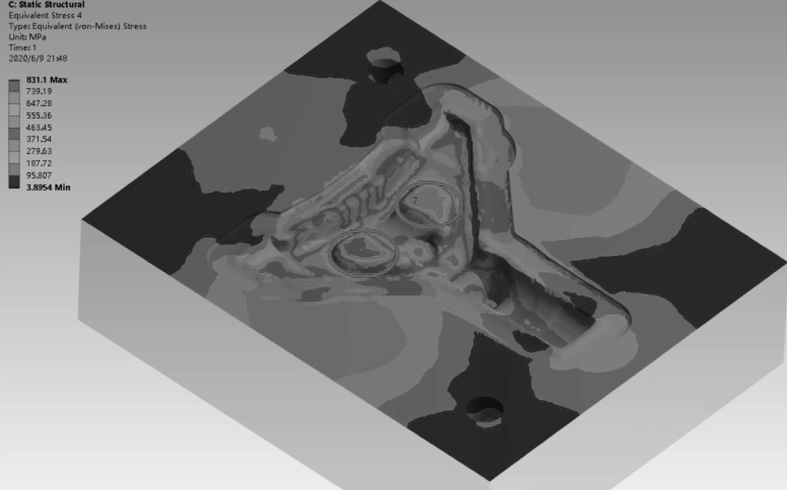

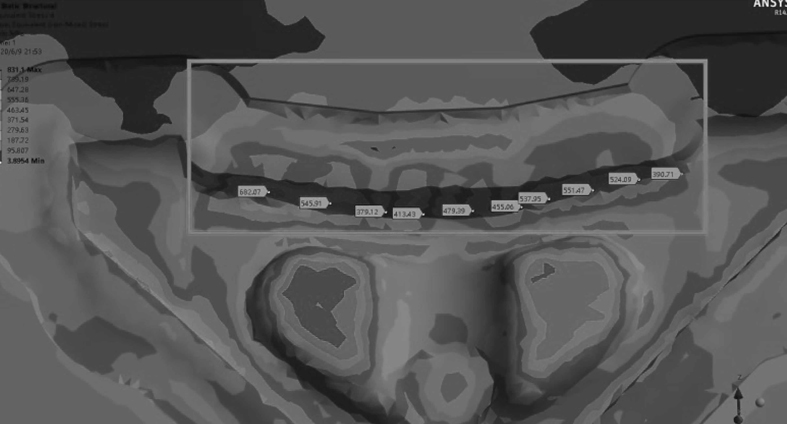

[0035] 1) Preliminary analysis of the high-temperature forging forming process of a forging in the DEFORM metal plastic forming simulation software, and obtained figure 1 The mold temperature field shown and figure 2 , image 3 The stress field on the mold surface is shown; from figure 1 It can be seen that during the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com