Thermal expansion type triaxial loading method and device

A three-axis loading and thermal expansion technology, applied in the field of mechanical testing, can solve the problems of high stress applied to large-scale model samples, large oil cylinders, large loading frames, and high cost, so as to reduce construction costs and personnel costs, and save loading links , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A thermal expansion triaxial loading method utilizes the temperature stress generated by the surrounding medium due to temperature changes to realize the loading and unloading process of the tested object.

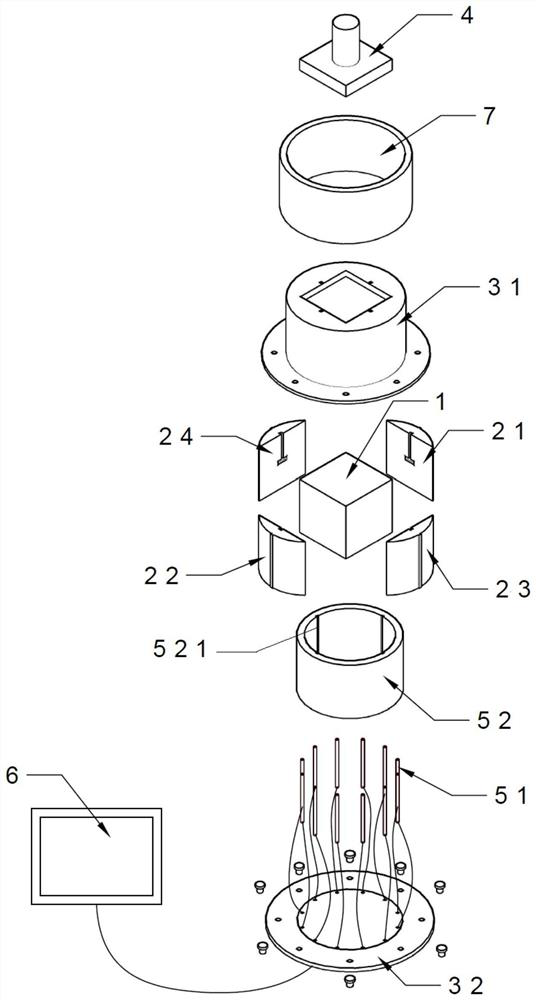

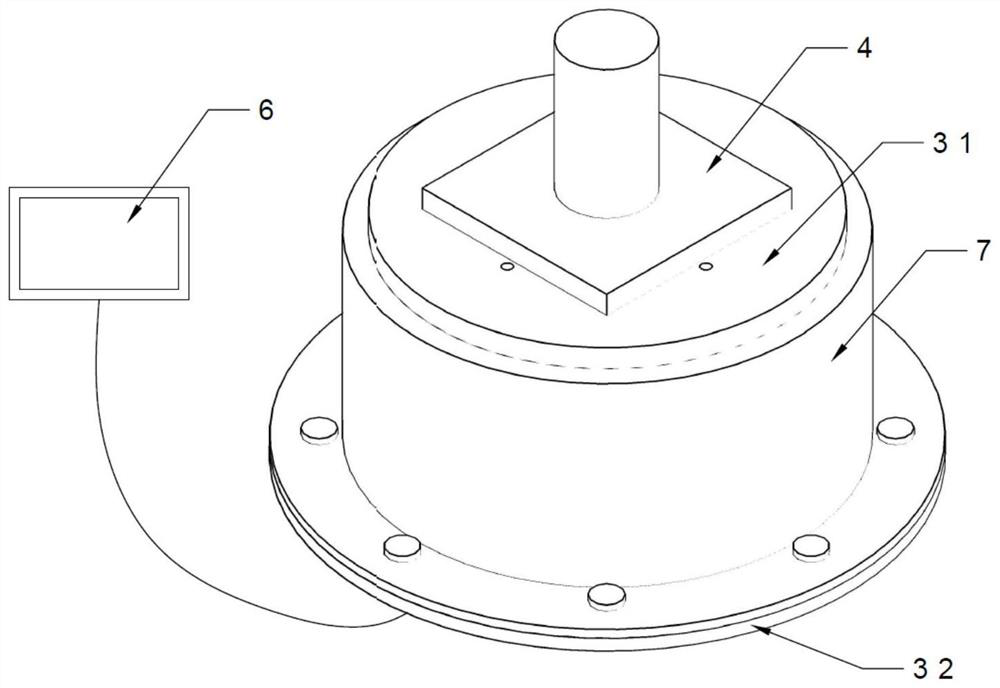

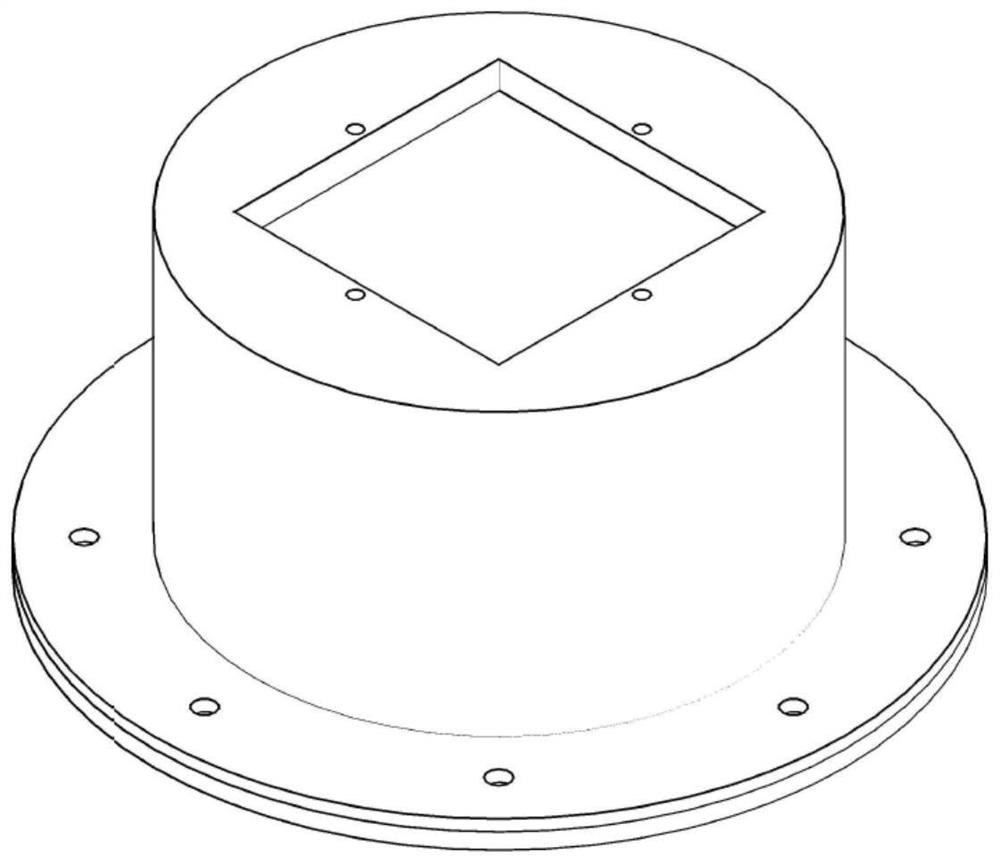

[0047] The thermal expansion type triaxial loading method specifically includes the following content: wrap the subject 1 in the surrounding medium 2, and closely fit the surrounding medium 2, and then heat the surrounding medium 2, and limit the surrounding medium 2 during the heating process. The deformation except the target loading direction is zero, so that the surrounding medium 2 produces temperature stress due to temperature changes and deformation constraints, which is applied to the test object 1 to realize the stress loading on the test object 1; after the loading is completed, the surrounding medium 2 is retreated. Temperature, so that the surrounding medium 2 is released due to temperature changes and deformation shrinkage, and the contact with the test ...

Embodiment 2

[0073] The core idea of the present invention is to use the temperature stress generated by the surrounding medium due to temperature changes to realize the loading and unloading process of the tested object.

[0074] A thermal expansion type triaxial loading method according to the present invention specifically includes: wrapping the subject 1 in the surrounding medium 2, and closely fitting it, and then heating the surrounding medium 2, and restricting the removal of the surrounding medium 2 during the heating process. The deformation outside the target loading direction is zero, so that the surrounding medium 2 produces temperature stress due to temperature changes and deformation constraints, which is applied to the test object 1 to realize the stress loading on the test object 1; further, the surrounding medium 2 is degraded. Temperature, so that the surrounding medium 2 is released due to temperature changes and deformation shrinkage, and the contact with the test obje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com