Method and system for analysis and optimization of silk making process oriented to cigarette production index control

A technology for production index and process analysis, applied in tobacco, tobacco processing, application, etc., can solve the problems of shallow data processing and analysis, data isolation, and low overall data utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

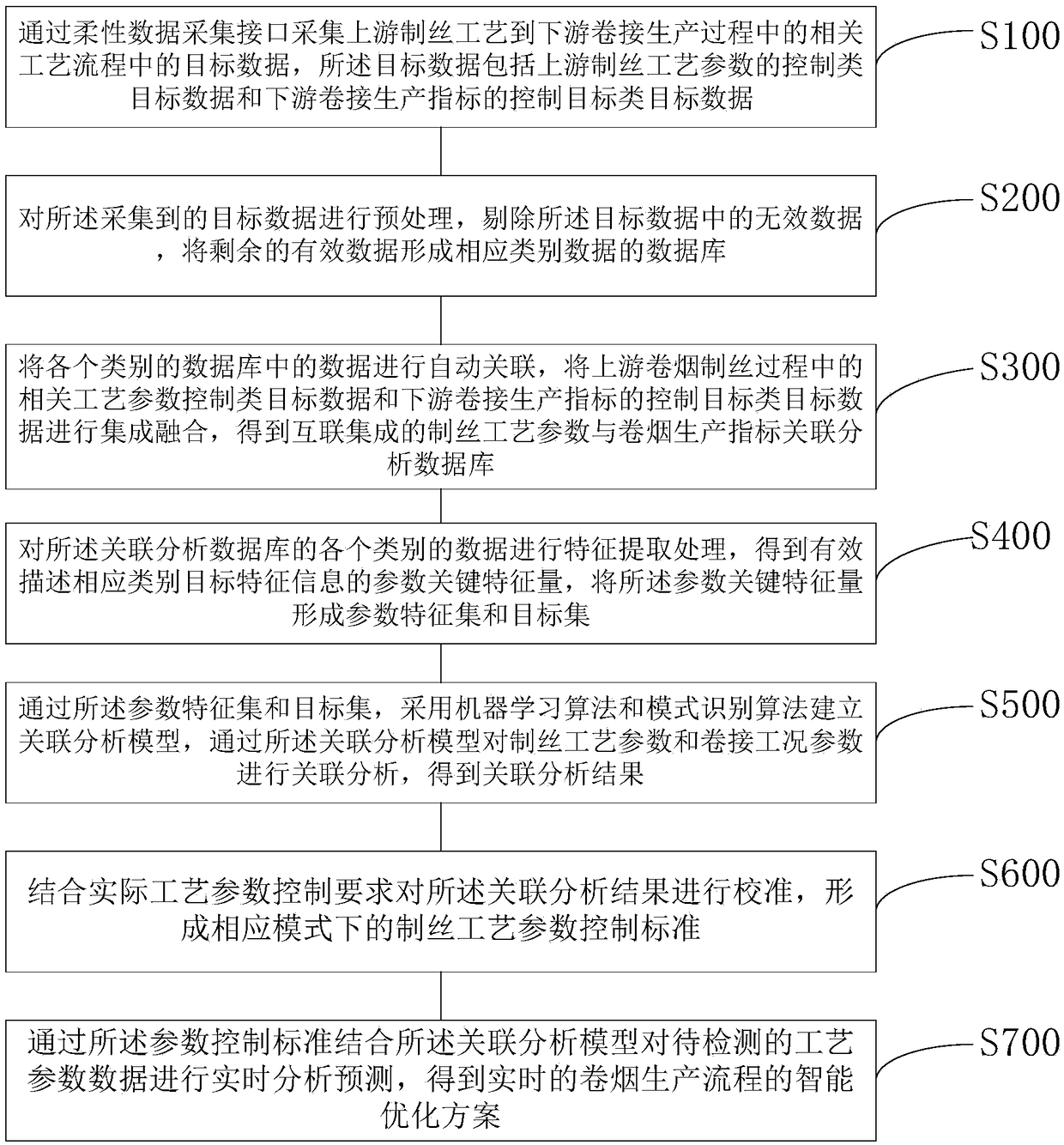

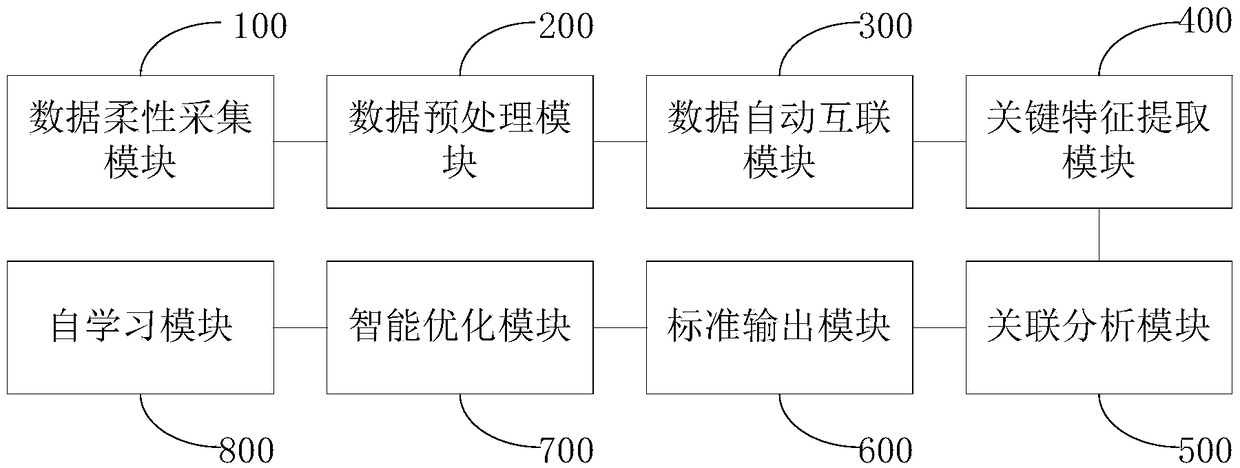

[0100] An analysis and optimization system for silk-making process oriented to cigarette production index control, such as figure 2 As shown, it includes a flexible data acquisition module 100, a data preprocessing module 200, an automatic data interconnection module 300, a key feature extraction module 400, an association analysis module 500, a standard output module 600, an intelligent optimization module 700 and a self-learning module 800:

[0101] The data flexible acquisition module 100 collects the target data in the relevant process flow from the upstream silk making process to the downstream coiling production process through the flexible data acquisition interface, and the target data includes the control target data of the upstream silk making process parameters and The target data of the control target class of the production index of the downstream volume connection;

[0102] The data preprocessing module 200 is configured to preprocess the collected target data, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com