Assembly chain cutter

A truncation device and chain technology, which is applied to metal chains, tools for repairing chains by metal processing, manufacturing tools, etc., can solve the problems of positional deviation of truncation, hand knock injury, movement, etc., so as to achieve convenient truncation and prevent smashing injuries. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

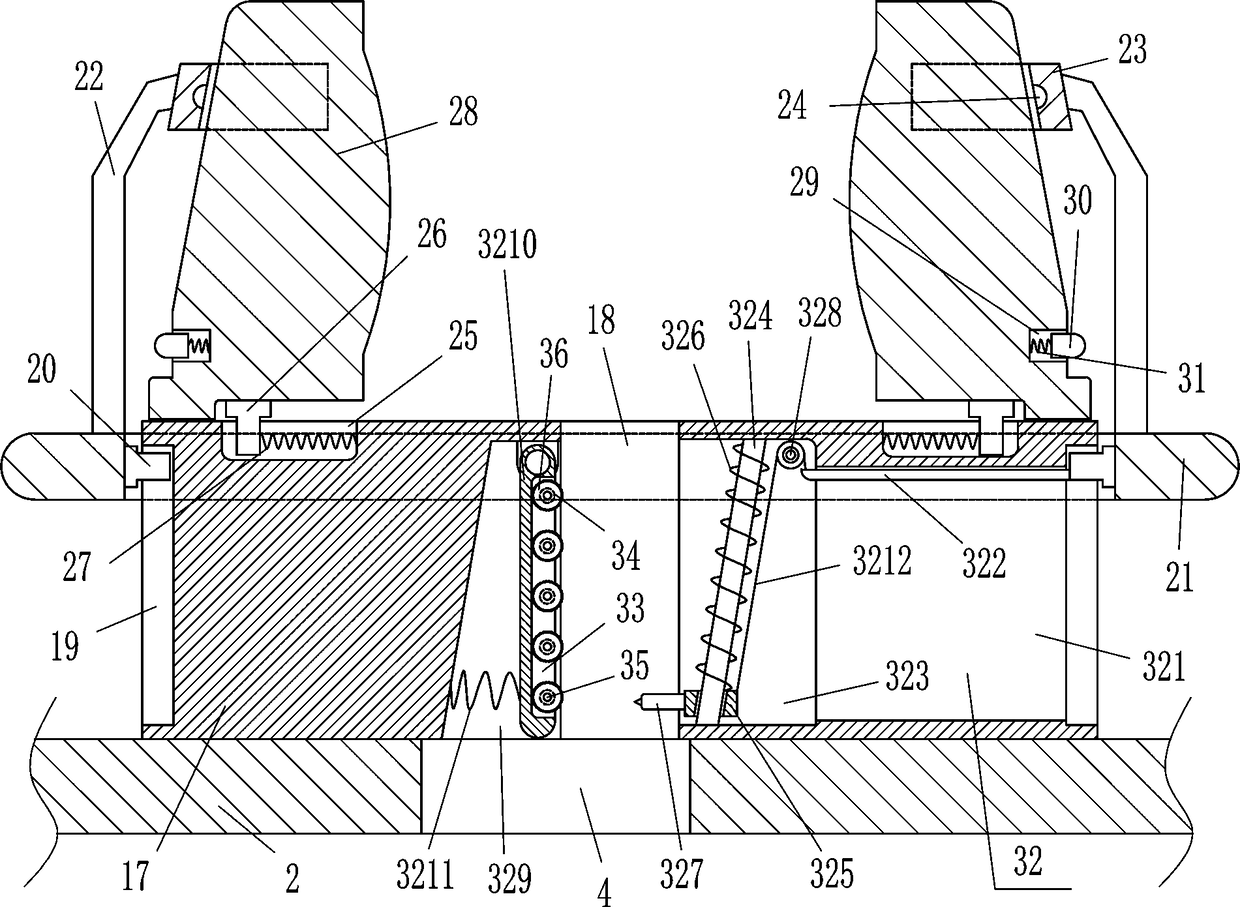

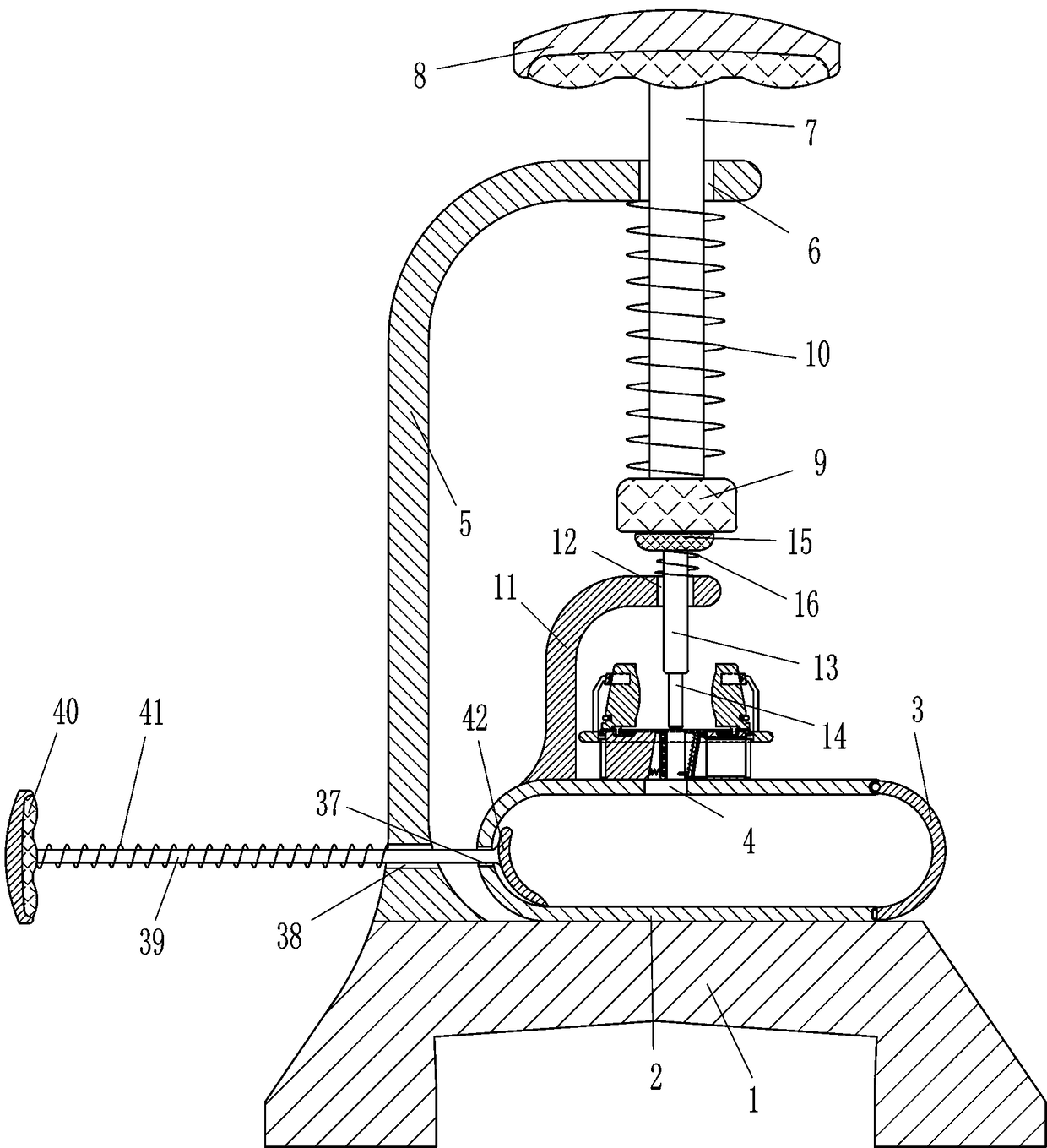

[0018] A chain cutter for assembly, such as Figure 1-2As shown, it includes a base 1, a box body 2, a cover plate 3, a first 7-shaped plate 5, a movable rod 7, a pull plate 8, a knocking block 9, a first spring 10, a second 7-shaped plate 11, and a guide rod 13 , latch 14, contact block 15, second spring 16, fixed block 17, vertical slider 20, annular plate 21, support rod 22, u-shaped sleeve 23, horizontal slider 26, third spring 27, pressure block 28, The block 30 and the fourth spring 31, the top right side of the base 1 is fixedly connected with the box body 2, the upper right side of the box body 2 is connected with the cover plate 3 in a rotatable manner, the cover plate 3 cooperates with the box body 2, and the top left side of the box body 2 There is a feed port 4 on the side, and a fixed block 17 is fixed on the left side of the outer top of the box body 2. The middle part of the fixed block 17 has a through hole 18. The through hole 18 is located directly above the ...

Embodiment 2

[0020] A chain cutter for assembly, such as Figure 1-2 As shown, it includes a base 1, a box body 2, a cover plate 3, a first 7-shaped plate 5, a movable rod 7, a pull plate 8, a knocking block 9, a first spring 10, a second 7-shaped plate 11, and a guide rod 13 , latch 14, contact block 15, second spring 16, fixed block 17, vertical slider 20, annular plate 21, support rod 22, u-shaped sleeve 23, horizontal slider 26, third spring 27, pressure block 28, The block 30 and the fourth spring 31, the top right side of the base 1 is fixedly connected with the box body 2, the upper right side of the box body 2 is connected with the cover plate 3 in a rotatable manner, the cover plate 3 cooperates with the box body 2, and the top left side of the box body 2 There is a feed port 4 on the side, and a fixed block 17 is fixed on the left side of the outer top of the box body 2. The middle part of the fixed block 17 has a through hole 18. The through hole 18 is located directly above the...

Embodiment 3

[0023] A chain cutter for assembly, such as Figure 1-2 As shown, it includes a base 1, a box body 2, a cover plate 3, a first 7-shaped plate 5, a movable rod 7, a pull plate 8, a knocking block 9, a first spring 10, a second 7-shaped plate 11, and a guide rod 13 , latch 14, contact block 15, second spring 16, fixed block 17, vertical slider 20, annular plate 21, support rod 22, u-shaped sleeve 23, horizontal slider 26, third spring 27, pressure block 28, The block 30 and the fourth spring 31, the top right side of the base 1 is fixedly connected with the box body 2, the upper right side of the box body 2 is connected with the cover plate 3 in a rotatable manner, the cover plate 3 cooperates with the box body 2, and the top left side of the box body 2 There is a feed port 4 on the side, and a fixed block 17 is fixed on the left side of the outer top of the box body 2. The middle part of the fixed block 17 has a through hole 18. The through hole 18 is located directly above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com