Sodium silicate-bonded sand regeneration system

A technology of water glass sand and regeneration system, which is applied in casting molding equipment, machinery for cleaning/processing of casting materials, metal processing equipment, etc., can solve the problems of low recovery rate of water glass dry regeneration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

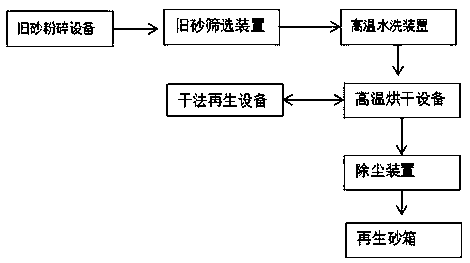

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] First, the old sand is crushed by crushing equipment, and then dried at 20-40 mesh, which can reduce the accumulation of old sand, and then washed at 90°C to remove the binder, and then dried at 300-350°C at high temperature. The dried sodium silicate sand is regenerated by dry method, and the regenerated sand is dried and dedusted for the second time, and finally enters the regenerated sand box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com