A metal wire surface treatment process

A metal wire and surface treatment technology, applied in the field of metal wire surface treatment technology, can solve the problems of low efficiency of metal wire surface treatment, uneven surface quality of metal wire, etc., achieve good surface treatment effect, improve the scope of application, and improve surface treatment speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

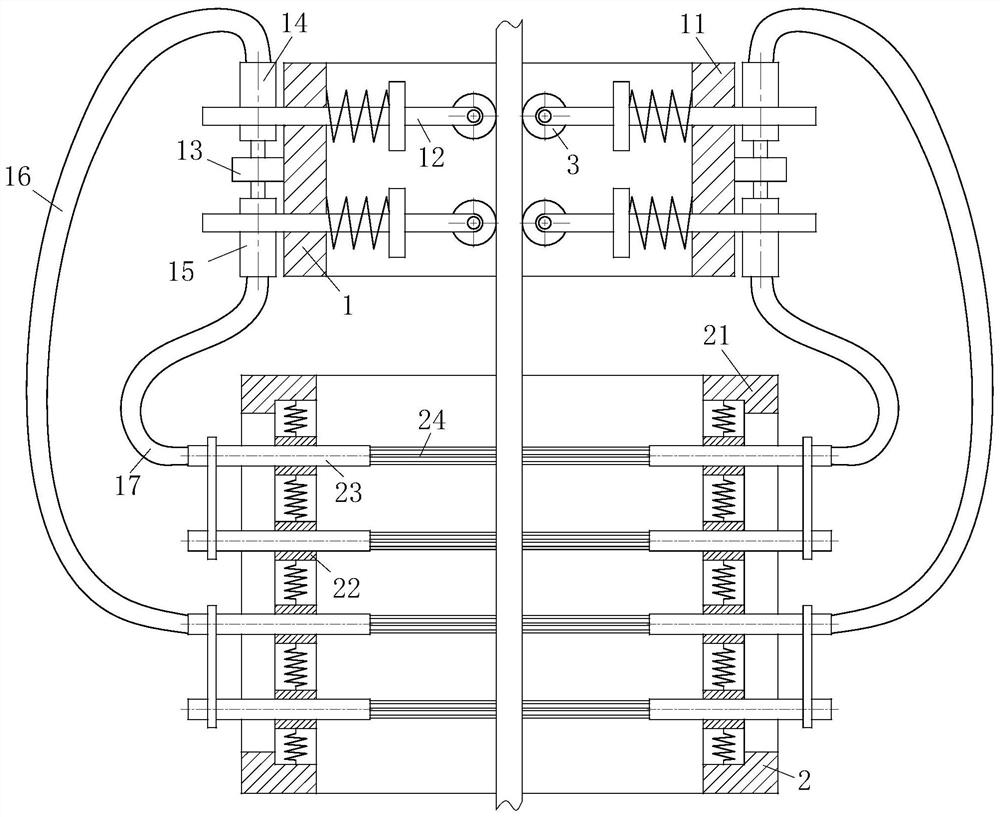

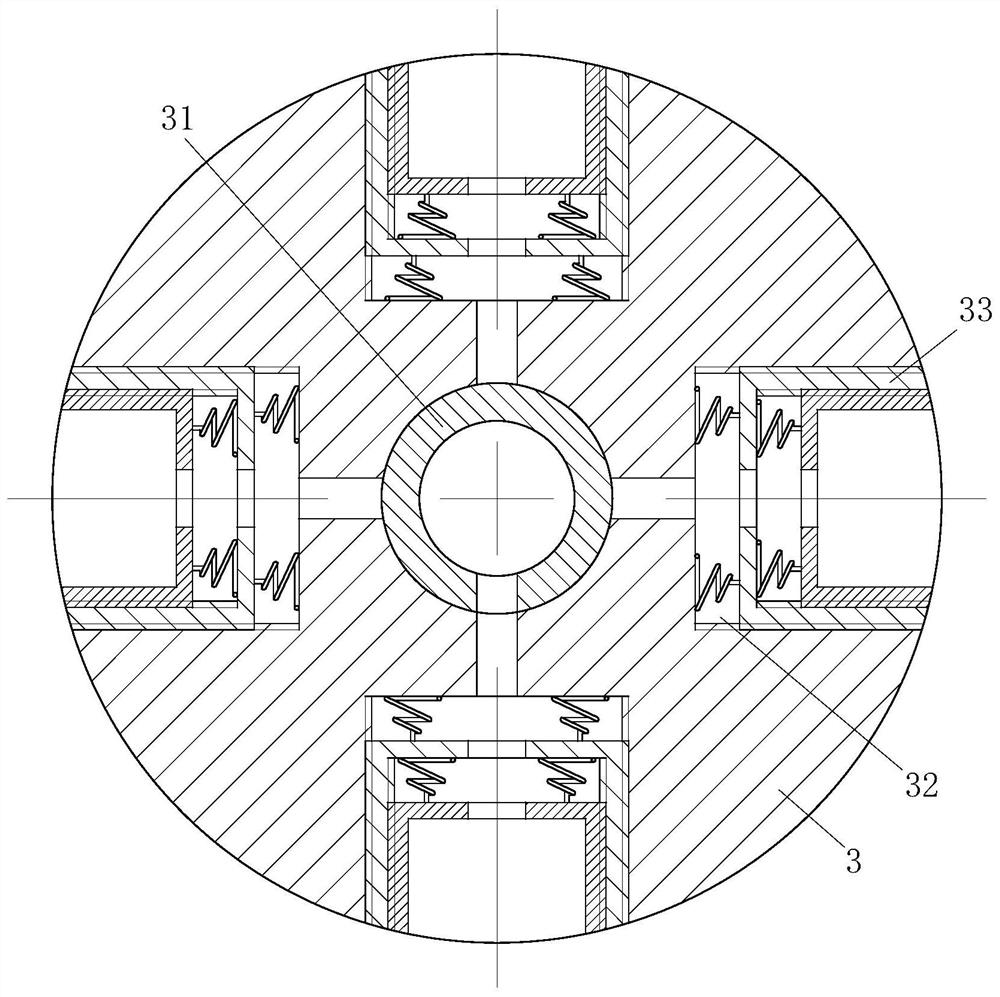

[0023] use as Figure 1-Figure 4 A metal wire surface treatment process according to an embodiment of the present invention is described as follows.

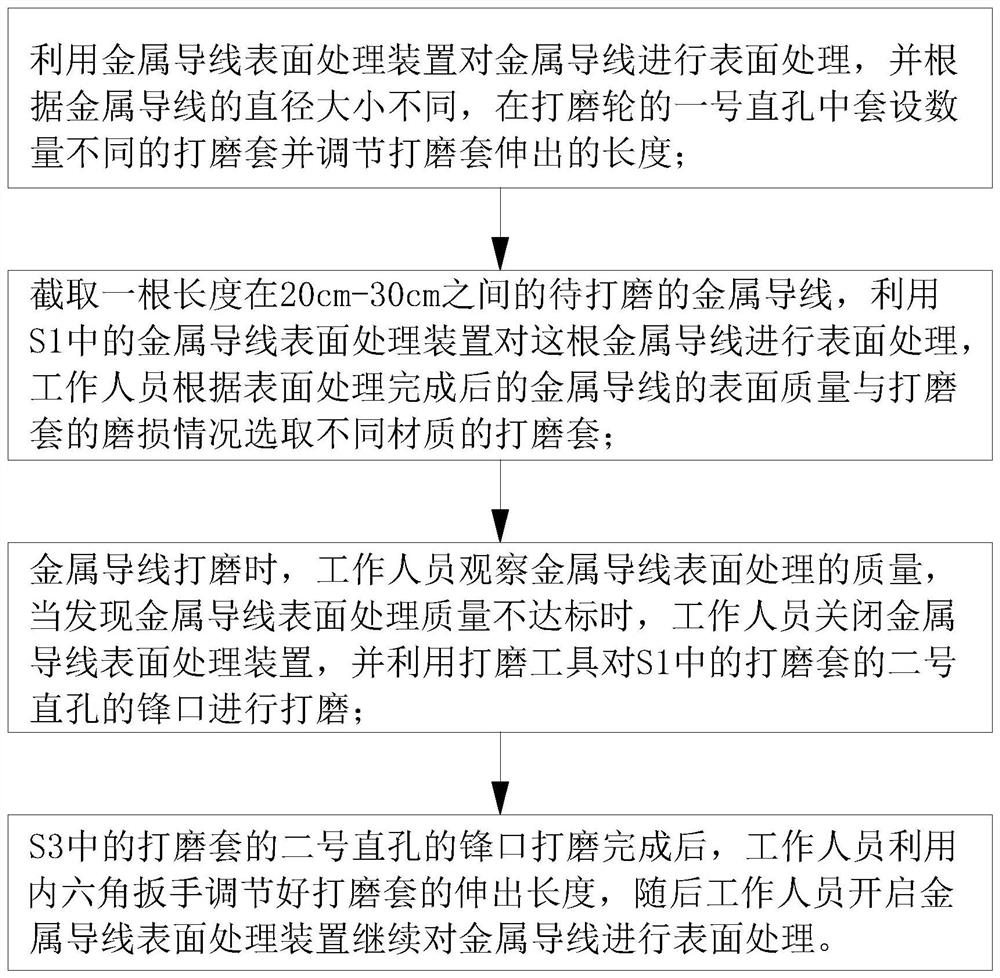

[0024] Such as figure 1 and figure 2 Shown, a kind of metal wire surface treatment process of the present invention, this process comprises the steps:

[0025] S1: Use the metal wire surface treatment device to carry out surface treatment on the metal wire, and according to the diameter of the metal wire, set different numbers of grinding sleeves in the No. 1 straight hole of the grinding wheel and adjust the protruding length of the grinding sleeve, so that Realize the grinding of metal wires with different diameters, improving the scope of application of the grinding process;

[0026]S2: Take a metal wire to be polished with a length between 20cm-30cm, use the metal wire surface treatment device in S1 to perform surface treatment on the metal wire, and the staff will use the surface quality of the metal wire after surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com