Method for spray pickling, polishing and passivating stainless steel composite board and devices thereof

A spray pickling and composite board technology, which is applied in the coating process of metal materials, etc., can solve problems such as poor surface quality, achieve high production efficiency, reduce production costs, and ensure surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

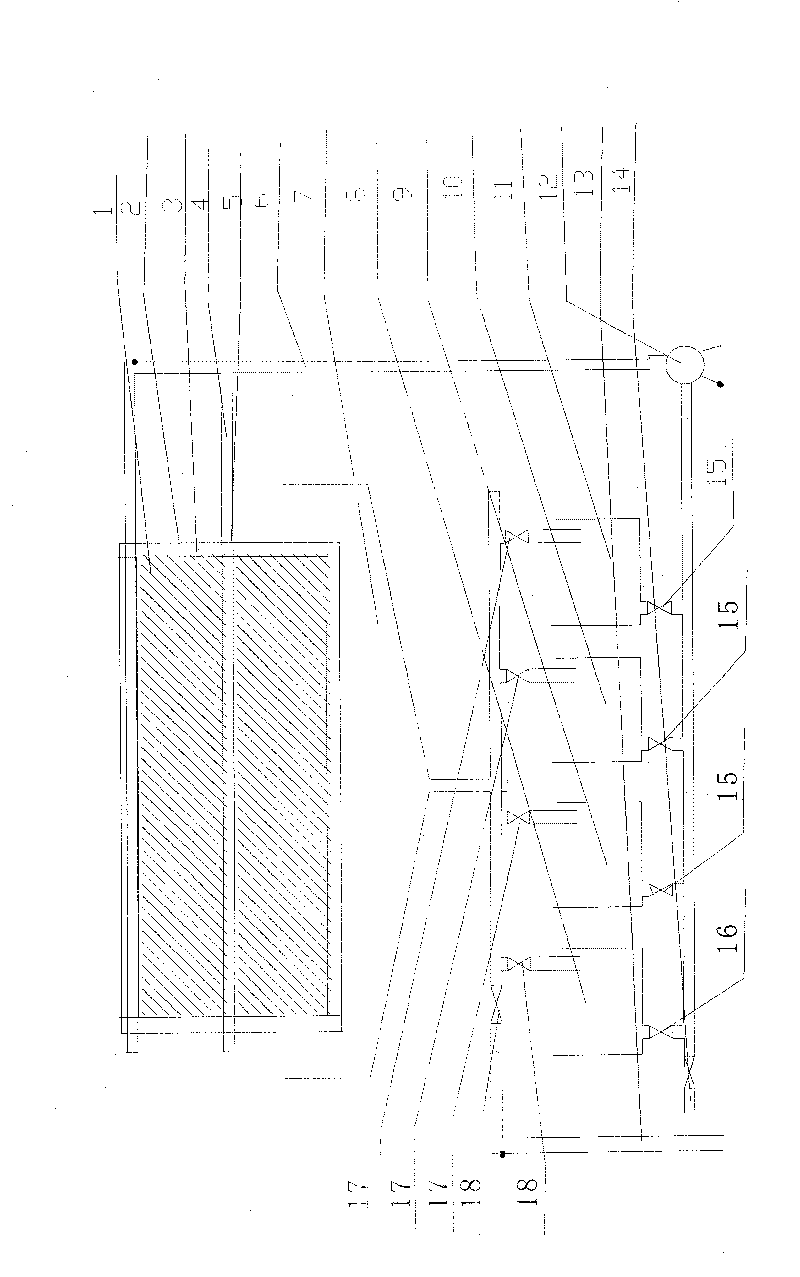

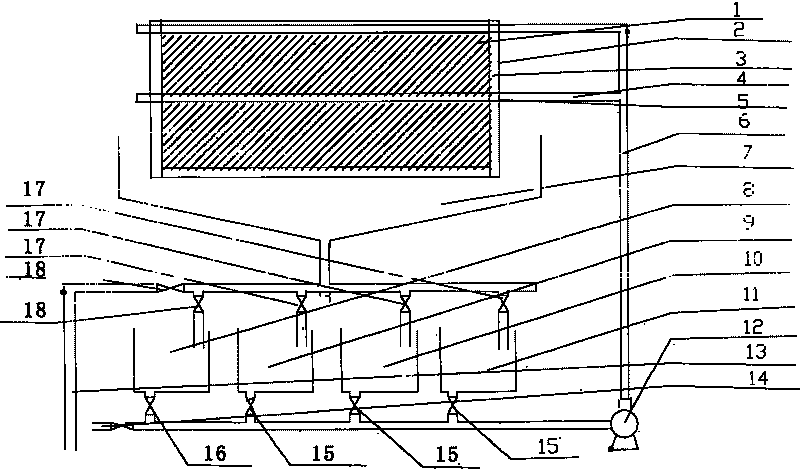

[0021] Composite panels with a length of 6m and a width of 3m are placed on the installation frame with the stainless steel cladding facing upwards, and the inclination angle is adjusted so that the composite panel is inclined to the ground at 70-80 degrees. Thick self-adhesive tape is pasted on the side of the composite board, and polypropylene shielding boards are installed on the periphery. A polypropylene liquid spray pipe with a length of 6 m and a diameter of 6 points is fixed on the shield plate with a bracket. And horizontally fix one on the top and one in the middle of the composite board. There are two rows of holes equidistant from 6 mm to 2 mm in diameter on the liquid spray pipe, and the distance between the two rows is 4 mm, and the center of the holes in one row is located in the middle of the other row of two holes. For the convenience of operation, a 6-point pressure-resistant rubber tube is used as the infusion tube. The recovery tank is a steel tank lined ...

Embodiment 2

[0023] For the stainless steel clad plate that does not require surface brightness improvement, the chemical polishing tank is not used, and the tank can be used as another pickling tank. That is, austenitic stainless steel is pickled in one tank, and martensitic stainless steel is pickled in another tank, and the rest are the same as in Example 1.

Embodiment 3

[0025] The device for pickling, chemical polishing and passivation of three kinds of stainless steels of austenite, martensite and ferrite preferably uses three pickling tanks, and the rest are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com