Method for preparing sector-shaped diamond tool bit

A diamond cutter head and fan-shaped technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., to achieve the effect of good alloying, high hardness and stable batch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

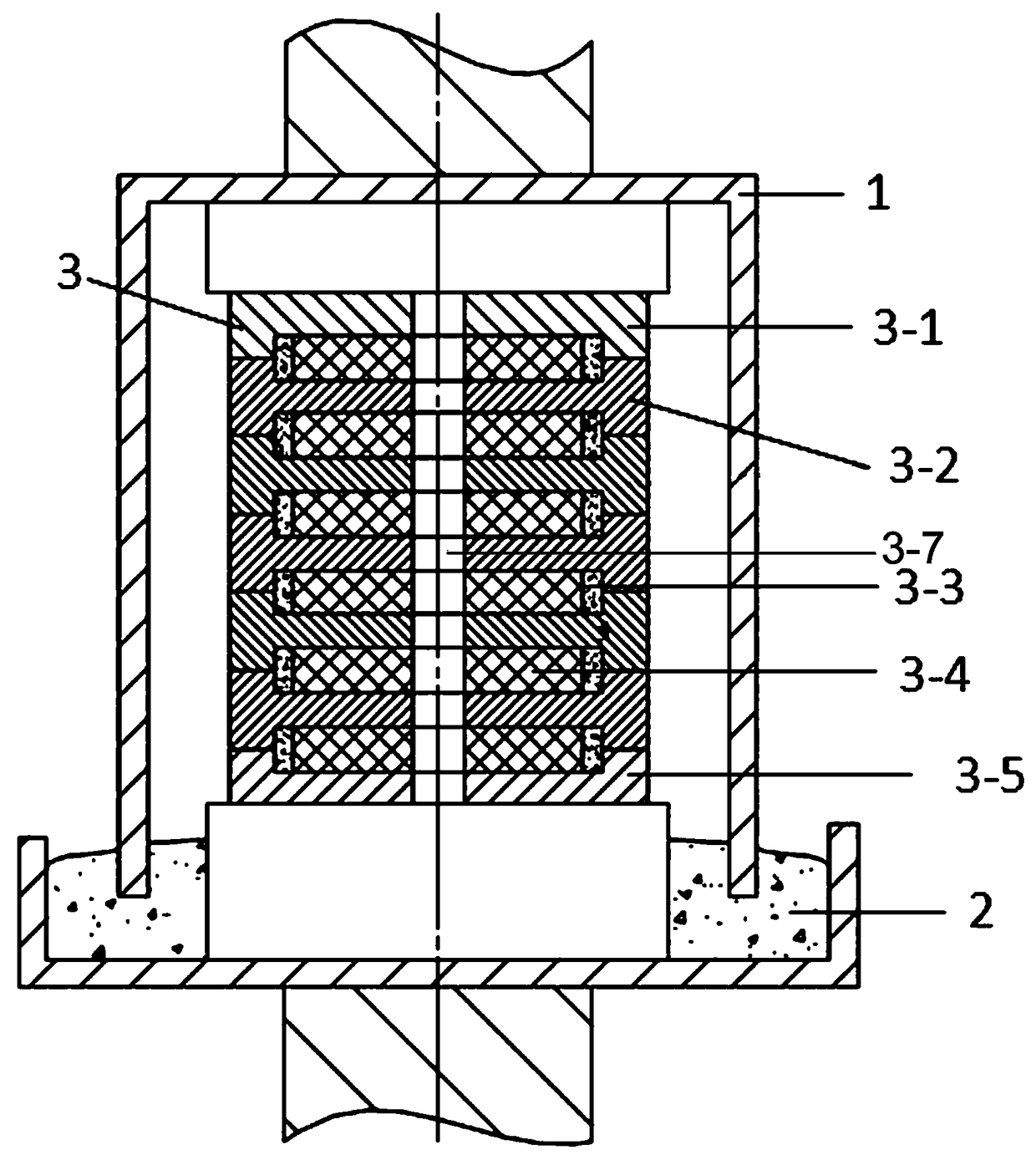

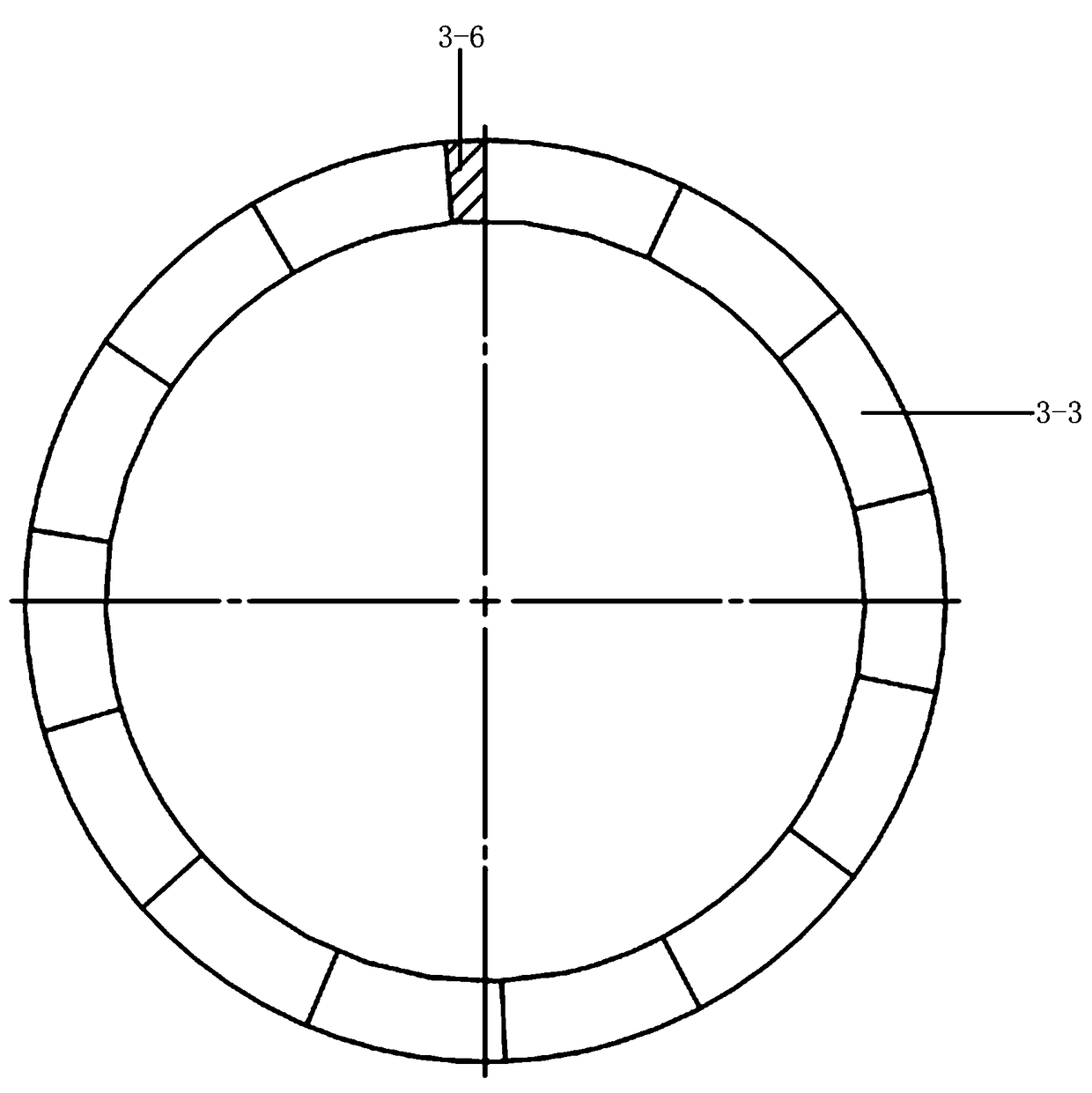

[0030] The invention provides a method for preparing a fan-shaped diamond cutter head, which includes forming, molding, sintering in a furnace, and demoulding, specifically:

[0031] (1) Molding: Mix diamond and metal powder evenly, and after granulation, press the mixed powder on a press to form a fan-shaped rough cutter head. When designing the forming mold of the fan-shaped blank cutter head, the height and length of the fan-shaped blank cutter head are slightly smaller than the size of the finished cutter head. The size of the work difference should be considered according to the elastic aftereffect of different diamond cutter head powders to ensure the shape of the blank cutter. The head can be smoothly loaded into the sintered steel mold.

[0032] (2) Die loading: Coat the contact surface between the heat-resistant steel mold and the fan-shaped blank cutter head, and the contact surface between the fan-shaped blank cutter head and the fan-shaped blank cutter head (that i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap