A method for sending beads to detect

A detector and detection point technology, which is applied to the mechanism of embroidery machines, automatically controlled embroidery machines, textiles and paper making, etc., can solve the problems of inaccurate bead feeding and easy out-of-step, so as to avoid needle strikes and out-of-step phenomena. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

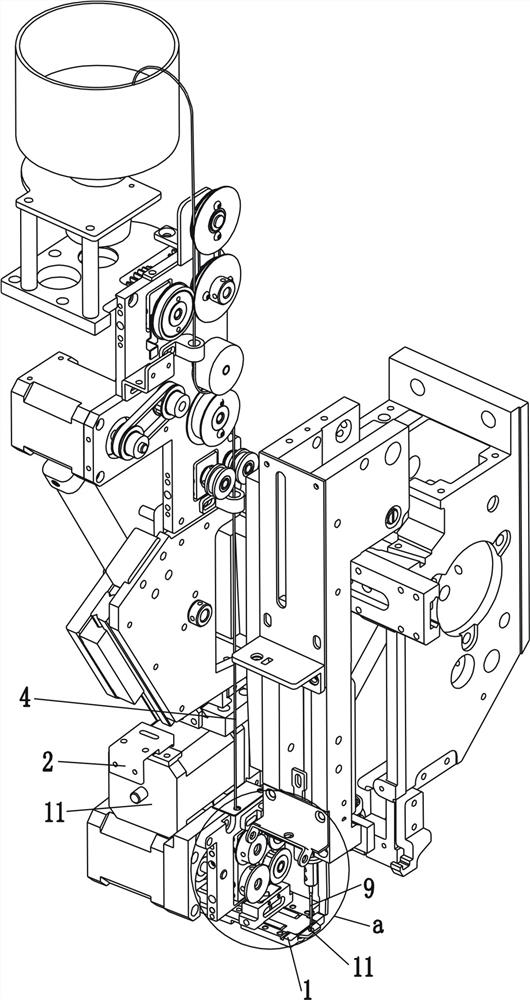

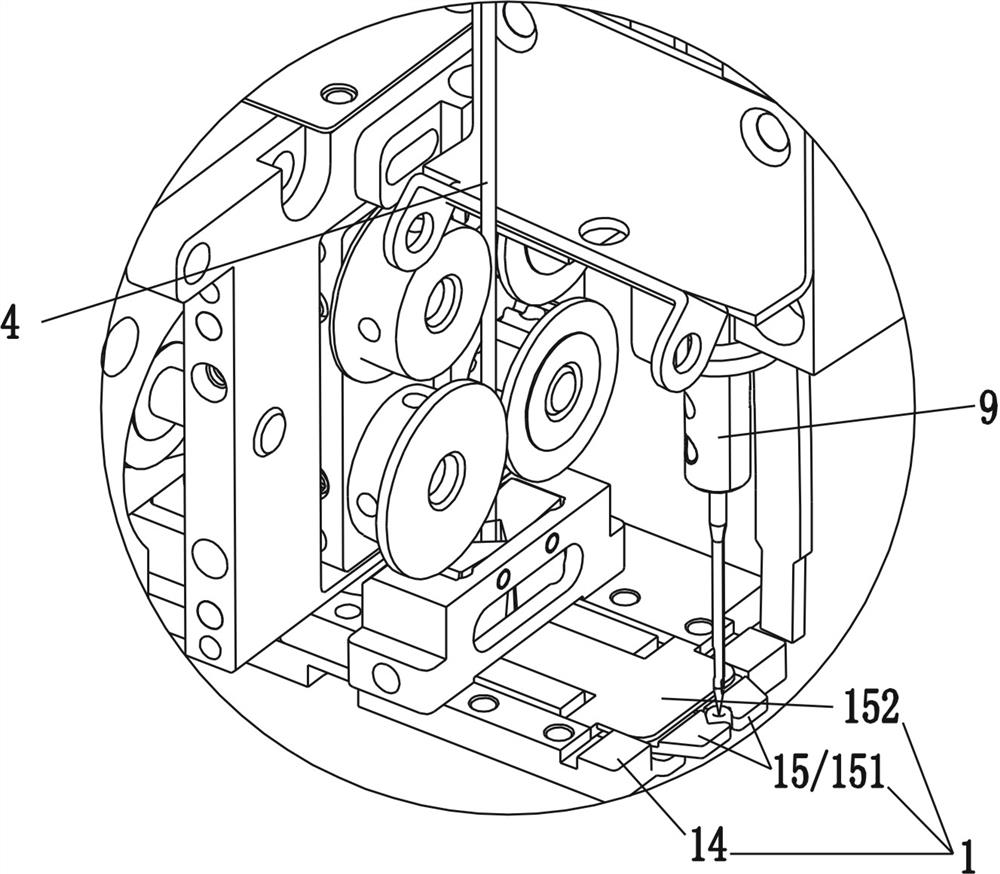

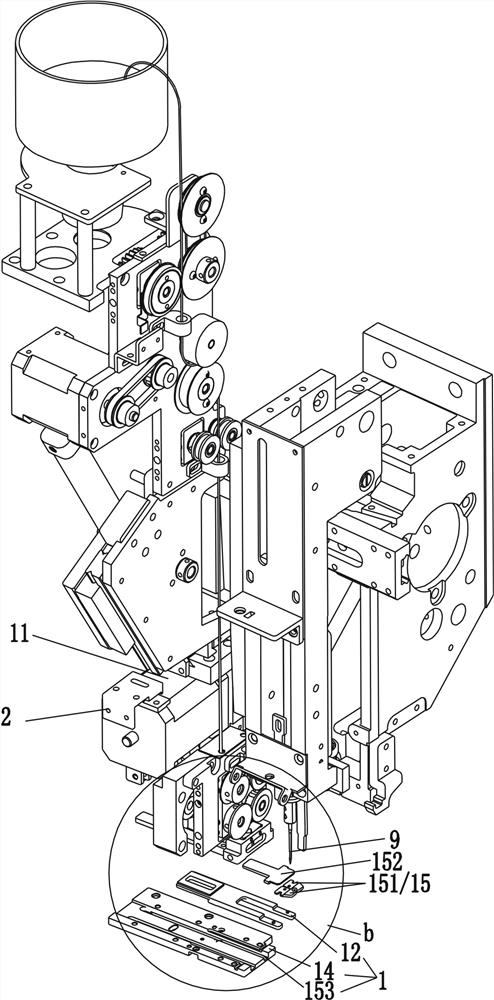

[0023] see Figure 1-7 , this implementation case, a method for detecting beads by a bead-feeding device, setting a control system, setting a closed-loop connection with the control system on the drive motor of the bead-feeding structure 1 that grips and transports beads, and detecting the rotation angle of the drive motor 11 or The first detector 2 in the rotating position is provided with the second detector 3 connected to the control system to detect the bead delivery stroke information of the bead delivery structure 1, and the second detector 3 can arbitrarily set detection points within the normal bead delivery stroke, and the control system receives The stroke information of the detection point detected by the second detector 3 is compared with the preset stroke information rotated by the drive motor 11 of the first detector 2 to judge the stroke difference between the bead feeding plate 12 and the drive motor 11, and then judge whether there is a step-out situation, Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com