Clamping-ring-type welding-free pressure test plugging device

A plugging device and welding-free technology, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., to improve efficiency, simplify operation, and solve the effect of long installation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

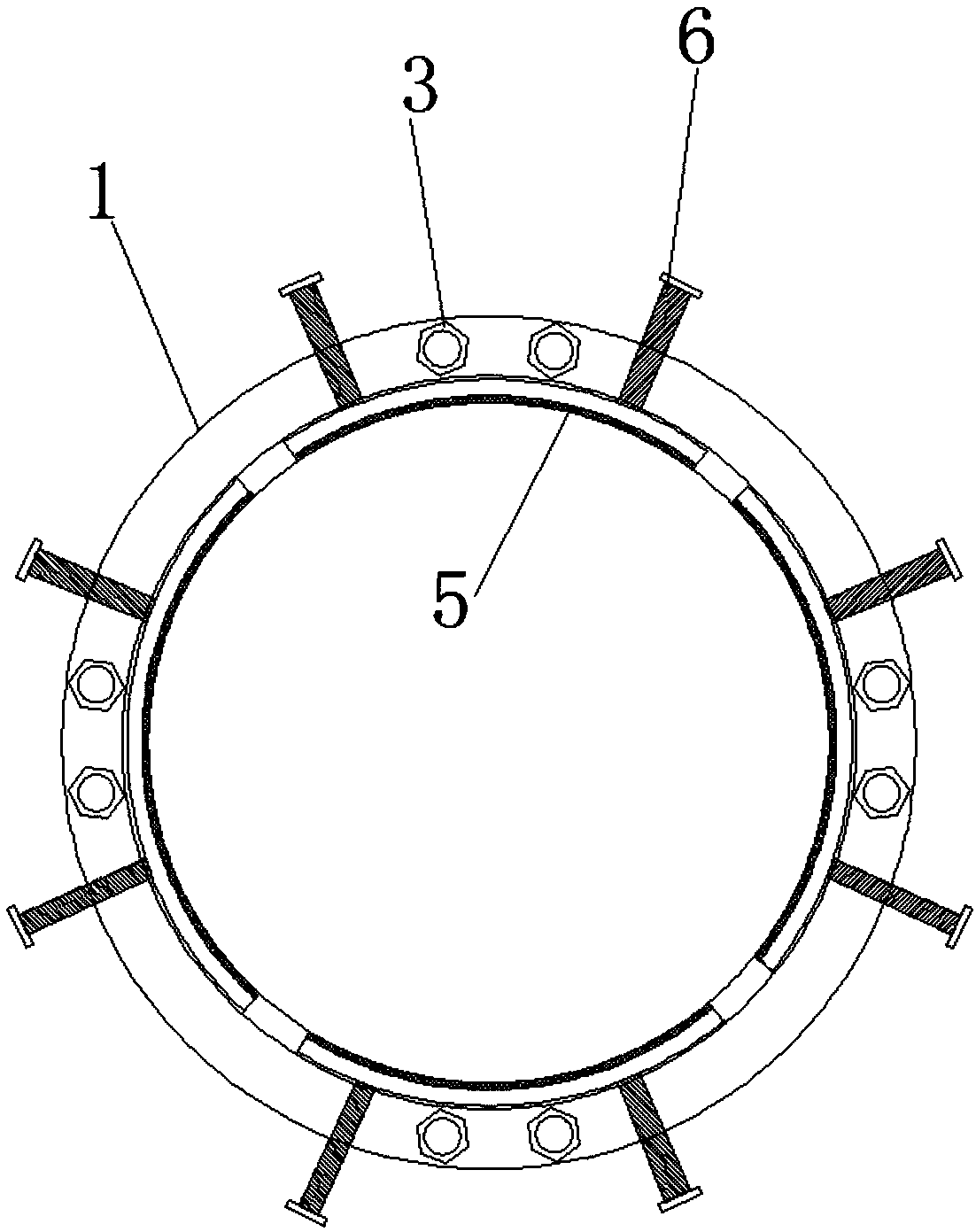

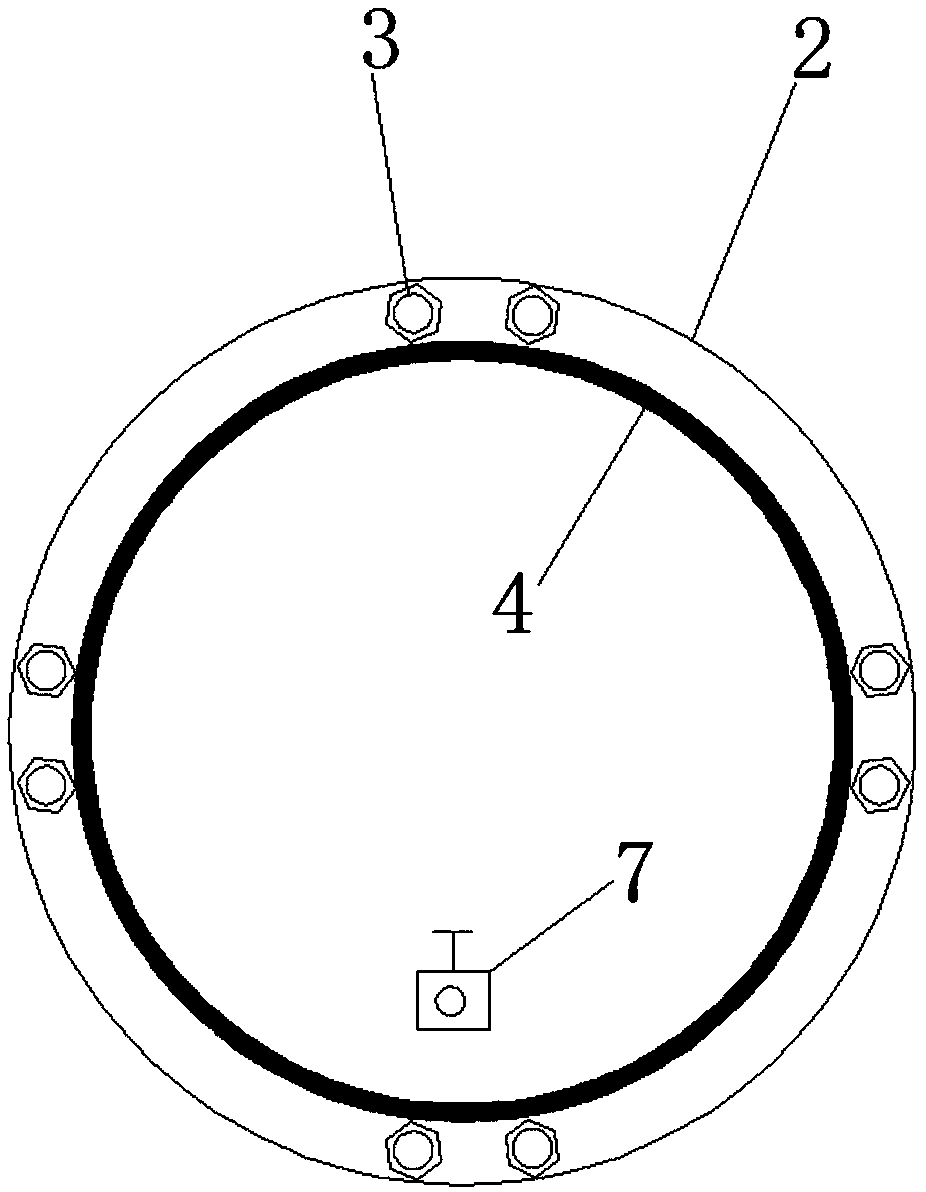

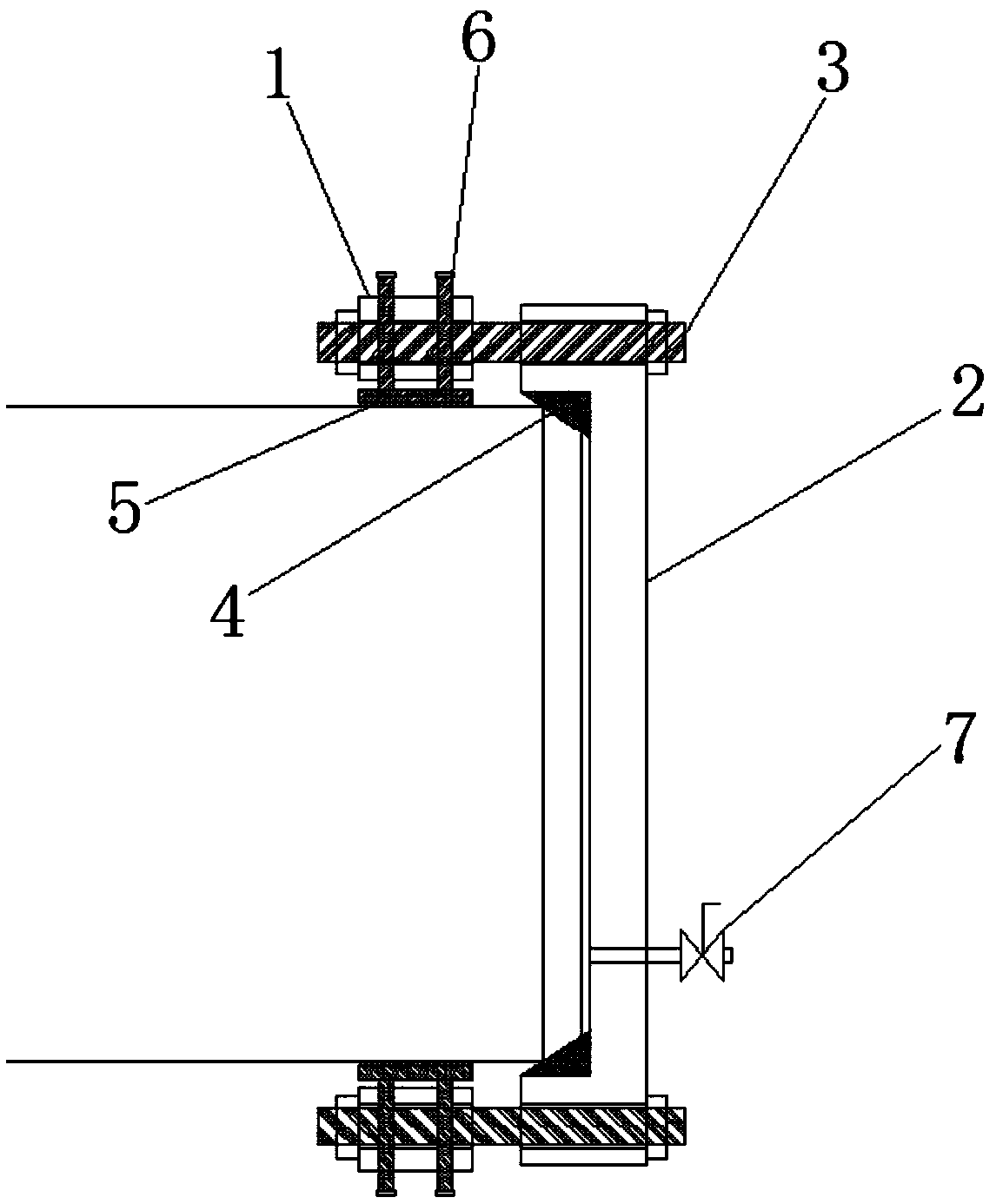

[0013] Such as Figure 1-Figure 3 As shown, the present invention includes: a fixed ring 1 installed at the end of the pipeline, and an anti-slip fastening sheet 5 installed between the fixed ring 1 and the outer surface of the pipeline by means of positioning bolts 6, wherein the end of the pipeline adopts The connection method of the sealing fastening bolt 3 is also equipped with a plugging blind plate 2; and in the plugging blind plate 2, a pressure sealing ring 4 is also installed, so that the plane between the bevel surface at the end of the pipeline and the pressure sealing ring 4 forms a Effective face seal.

[0014] An injection and drainage valve 7 is installed on the above-mentioned blocking blind plate 2; and the blocking blind plate 2 is C-shaped.

[0015] When in use, the present invention is installed on the pipeline, and the pressure test medium enters the interior of the pipeline by opening the injection and drainage valves 7, and then continuously injects to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com