Semi-automatic pressure testing machine for indoor bolts and its pressure testing method

An indoor bolt and pressure tester technology, which is applied in liquid tightness measurement using liquid/vacuum degree, fire rescue, etc., can solve problems such as low efficiency of pressure test, complex structure of pressure test machine, complicated pressure test process, etc., and achieve Reduce workload, facilitate rational utilization, compact and reasonable structure arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

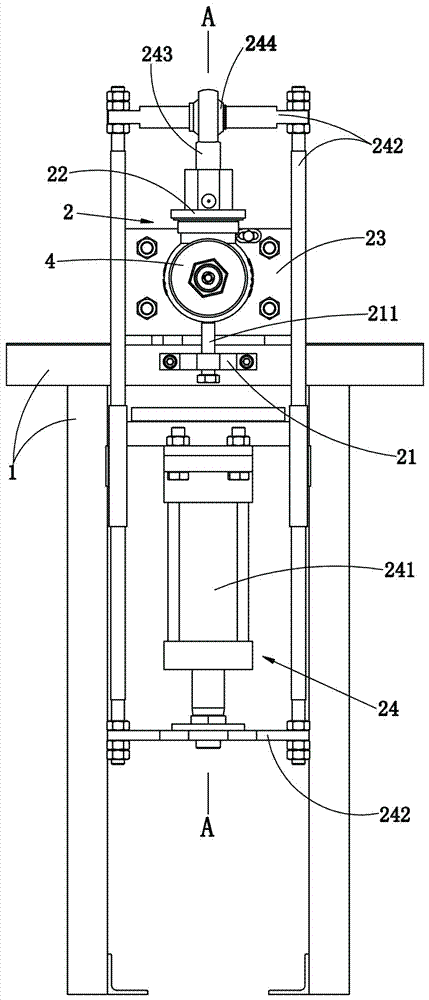

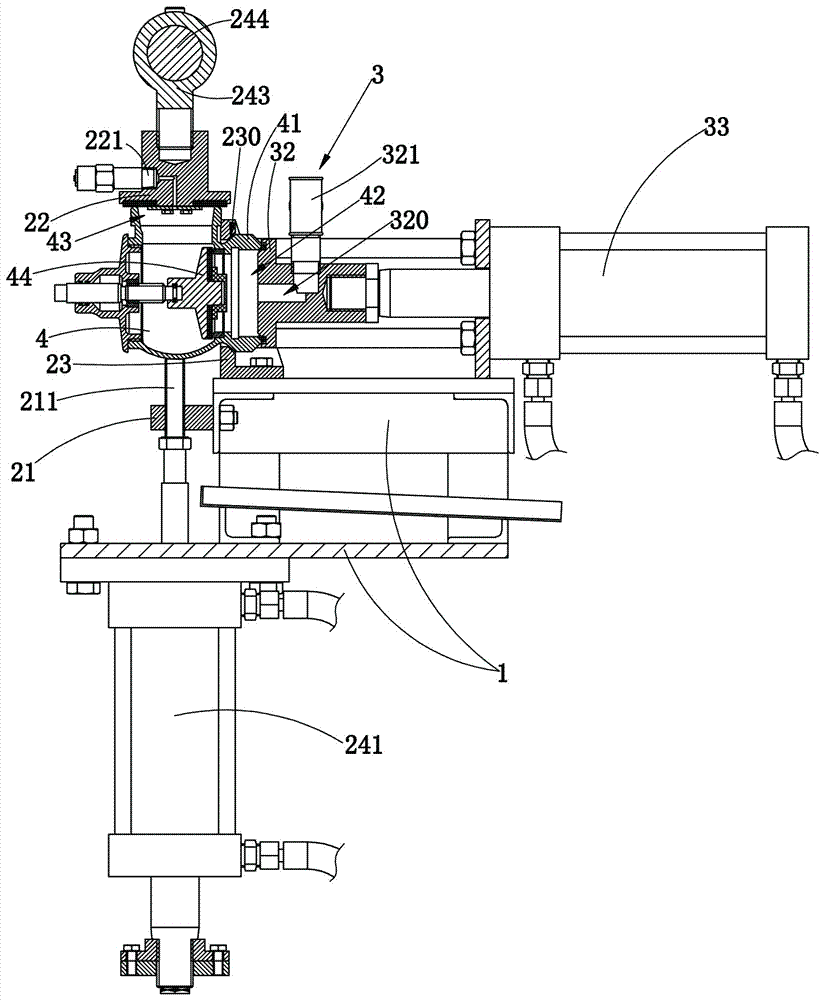

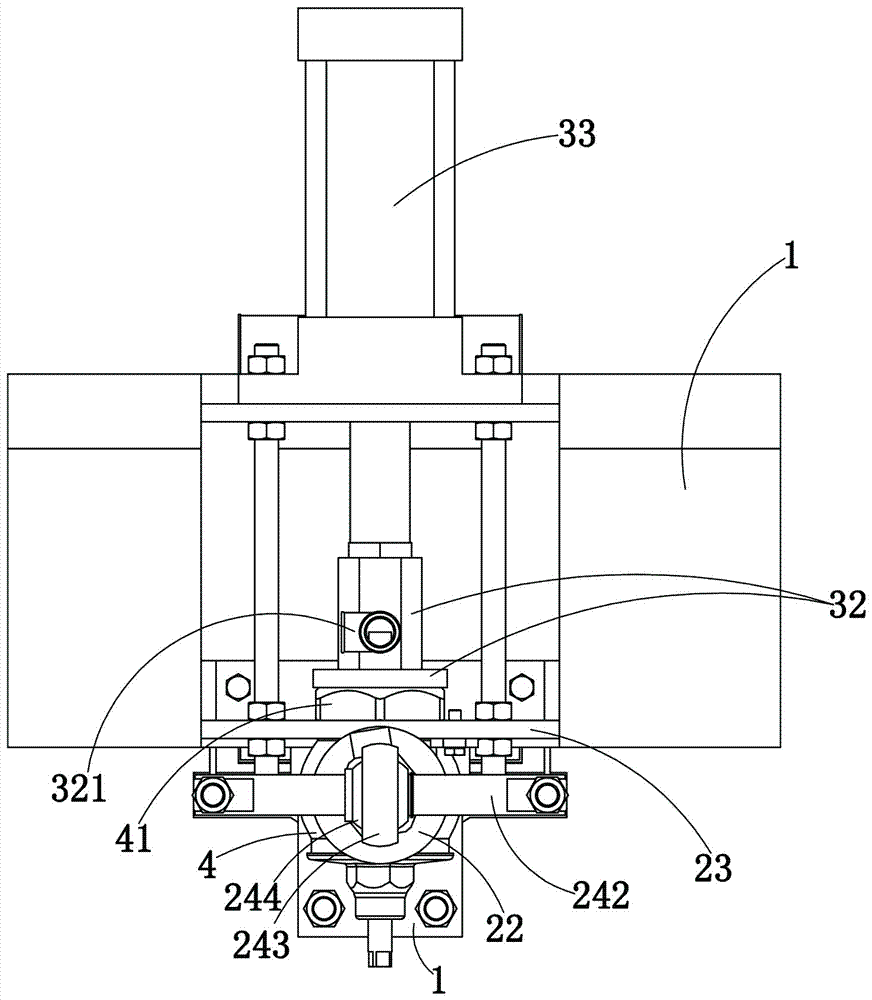

[0027] refer to figure 1 , figure 2 , image 3 , Figure 4 , a semi-automatic pressure testing machine for indoor bolts, including a frame 1 and a fixing mechanism 2 assembled on the frame 1, a pressure testing mechanism 3, a computer control device and an alarm, and the computer control device is used to control the above fixing mechanism 2 and The above-mentioned pressure testing mechanism 3 operates in sequence, and the alarm device is used to give an alarm when the above-mentioned computer control device receives abnormal water pressure data during the pressure measurement process.

[0028] Continue to refer to figure 1 , figure 2 , image 3 , the above-mentioned fixing mechanism 2 includes a base 21 , an upper pressing head 22 , a side plate 23 and a first power device 24 . The base 21 is locked to the frame 1 by bolts, and the base 21 is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com