A liquid drainage and gas extraction operation system and operation method suitable for engineering ships

A liquid drainage gas recovery and operation system technology, applied in the direction of production fluid, earthwork drilling, drill pipe, etc., can solve the problems that cannot satisfy the liquid drainage gas recovery process, affect the oilfield development benefits, increase the cost of workover operations, etc., to achieve Reduce requirements and cost of liquid drainage and gas production, facilitate on-site operations, and achieve flexible and convenient operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

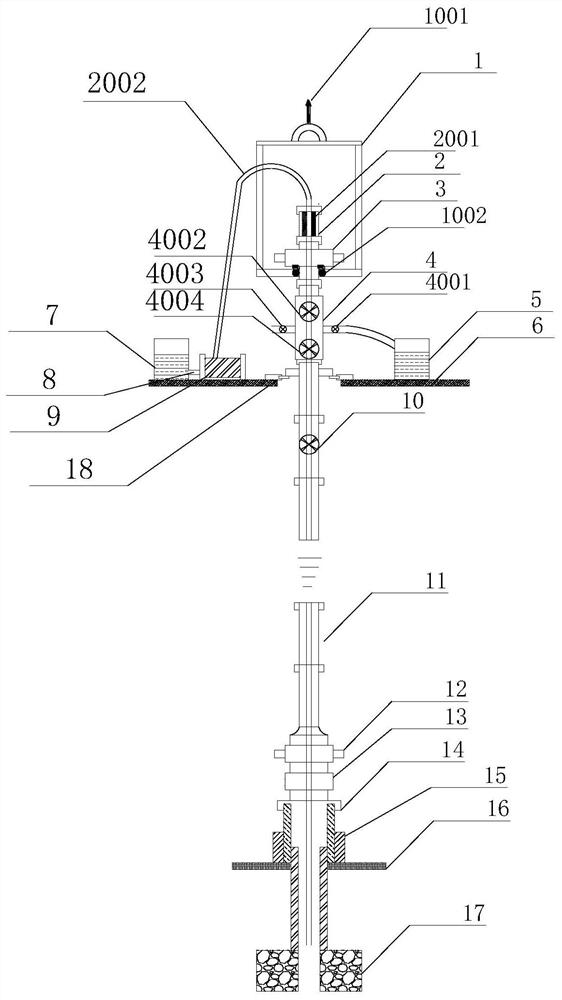

[0046] Such as figure 1 As shown, the liquid drainage and gas recovery operation system suitable for engineering ships provided by the present invention includes a wellhead connector 14, an underwater blowout preventer 12, a high-pressure riser 11, a pressure test valve 10, a cross 4, and a lifting frame 1 , Coiled tubing blowout preventer 3, Coiled tubing feeding tool 2, Coiled tubing drum 9, Fluid storage tank 7, Fluid storage tank 5, etc. The specific structure is as follows:

[0047] One end of the high-pressure riser 11 is connected to the underwater blowout preventer 12 , and then connected to the wellhead 15 through the wellhead connector 14 , and the other end extends to the engineering ship 6 . The high-pressure riser 11 is suspended on the engineering ship 6 through the chuck 18, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com