A high-precision temperature sensor calibration method and circuit

A temperature sensor and calibration circuit technology, used in thermometer testing/calibration, thermometers, instruments, etc., can solve the problem that the test environment is difficult to meet the sensor calibration requirements, reduce test conditions and test costs, and avoid high-precision temperature environments. the effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

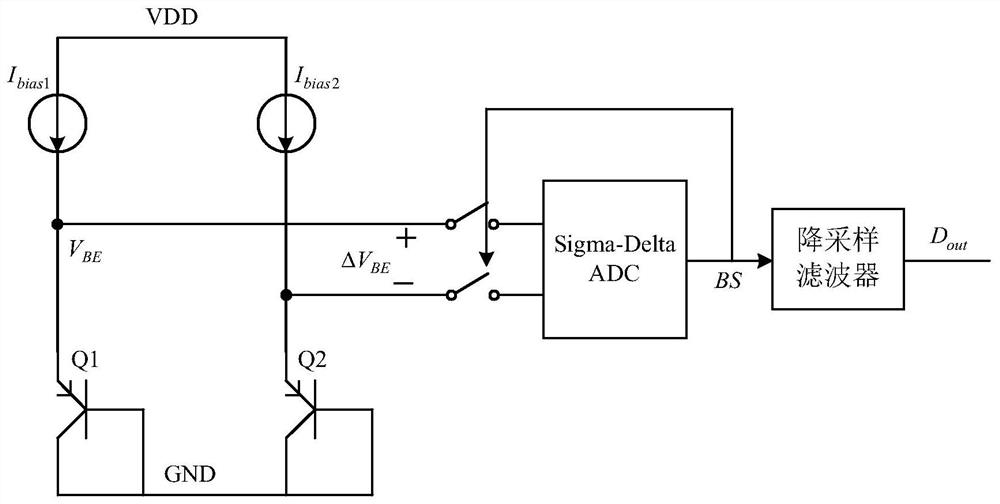

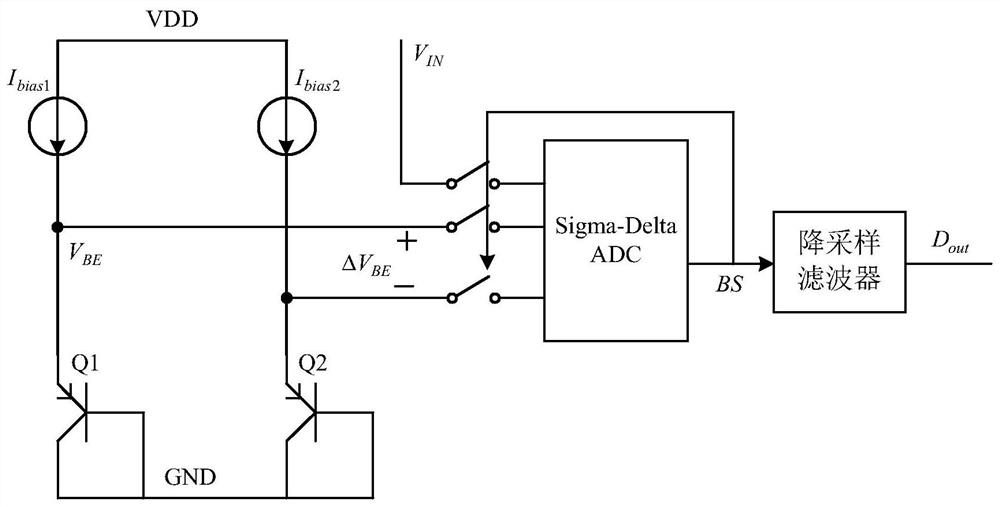

[0045] figure 1 Is a structural schematic diagram of the temperature sensor, the bias current I bias1 Flow to the transistor (bipolar tube) Q1 to generate the voltage V BE ; two bias currents I bias1 and I bias2 flow to transistors Q1 and Q2 respectively, generating two V BE , whose difference is ΔV BE .

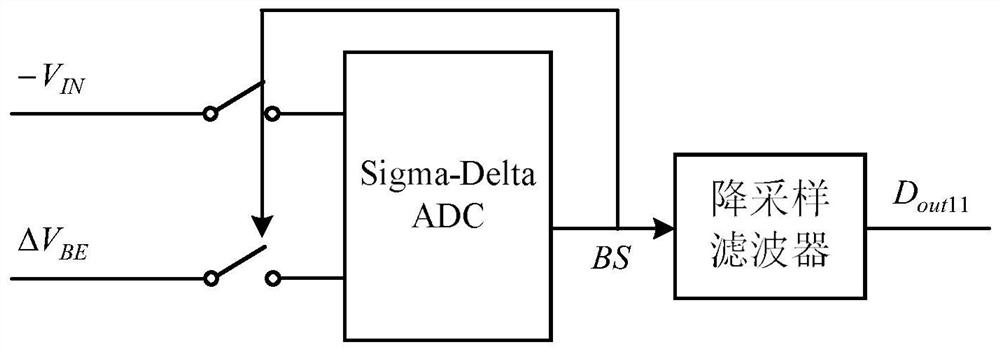

[0046] The Sigma delta ADC is responsible for V BE and ΔV BE Perform sampling, generate BS signal, and feedback control input sampling; when BS=0, input sampling ΔV BE , when BS=1, the input sample -V BE ; After BS is filtered by a downsampling filter (decimation filter), a quantized digital temperature signal D is finally generated out .

[0047] figure 1 The temperature signal output in can be expressed as

[0048]

[0049] where α is ΔV BE The magnification at sampling time, which is implemented in the sigma delta ADC.

[0050] It can be seen from formula (1) that the error of the output temperature mainly comes from three parameters, namely V BE , ΔV BE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com