Numerical-control machine tool retracting protection method

A CNC machine tool and tool retraction technology, applied in the direction of digital control, program control, electrical program control, etc., can solve problems such as economic loss, self-fault, tool damage, etc., and achieve the effect of strong automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0027] The present invention provides a protection method for tool retraction of a numerically controlled machine tool. On the basis of its original functions such as speed control, torque control, and bus control, a tool retraction protection function is added to ensure the integrity of the servo drive device and the safety of the entire machine tool system. .

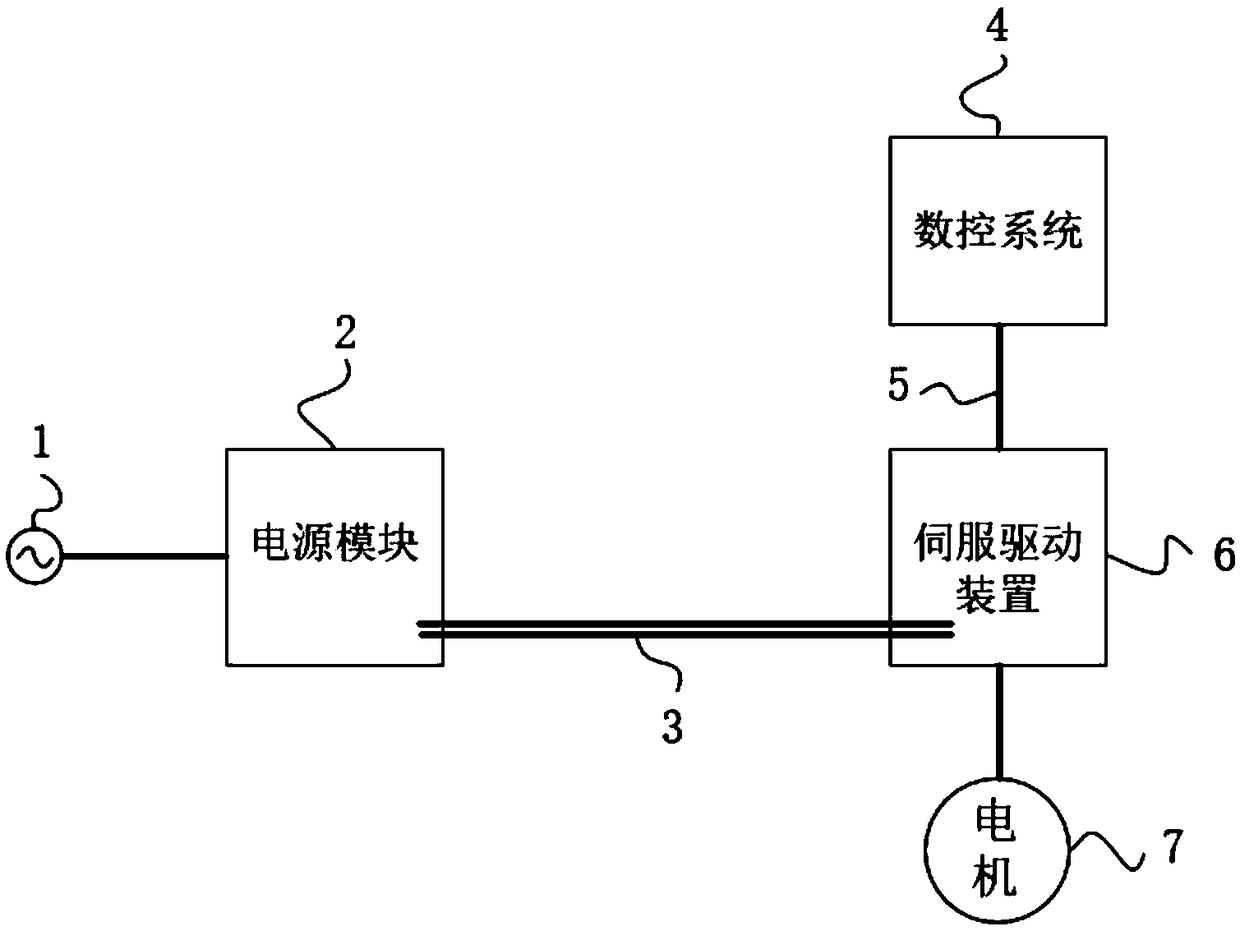

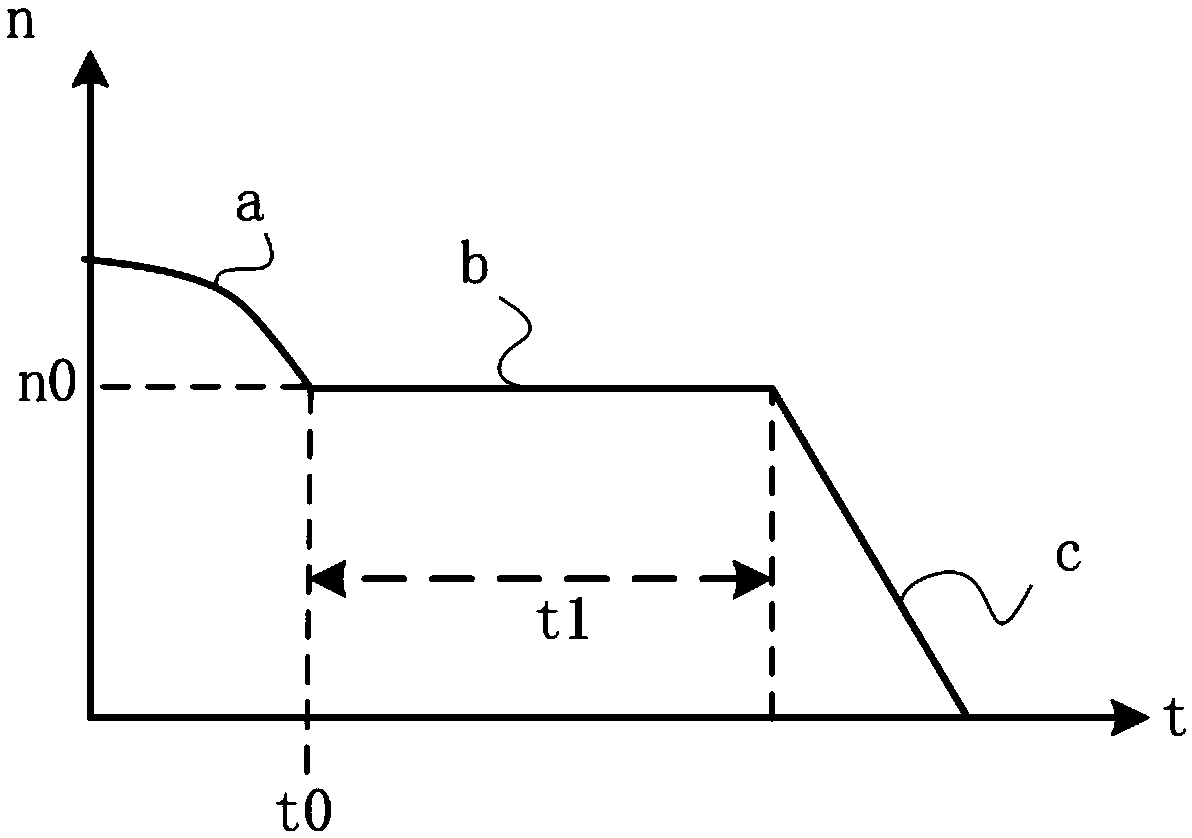

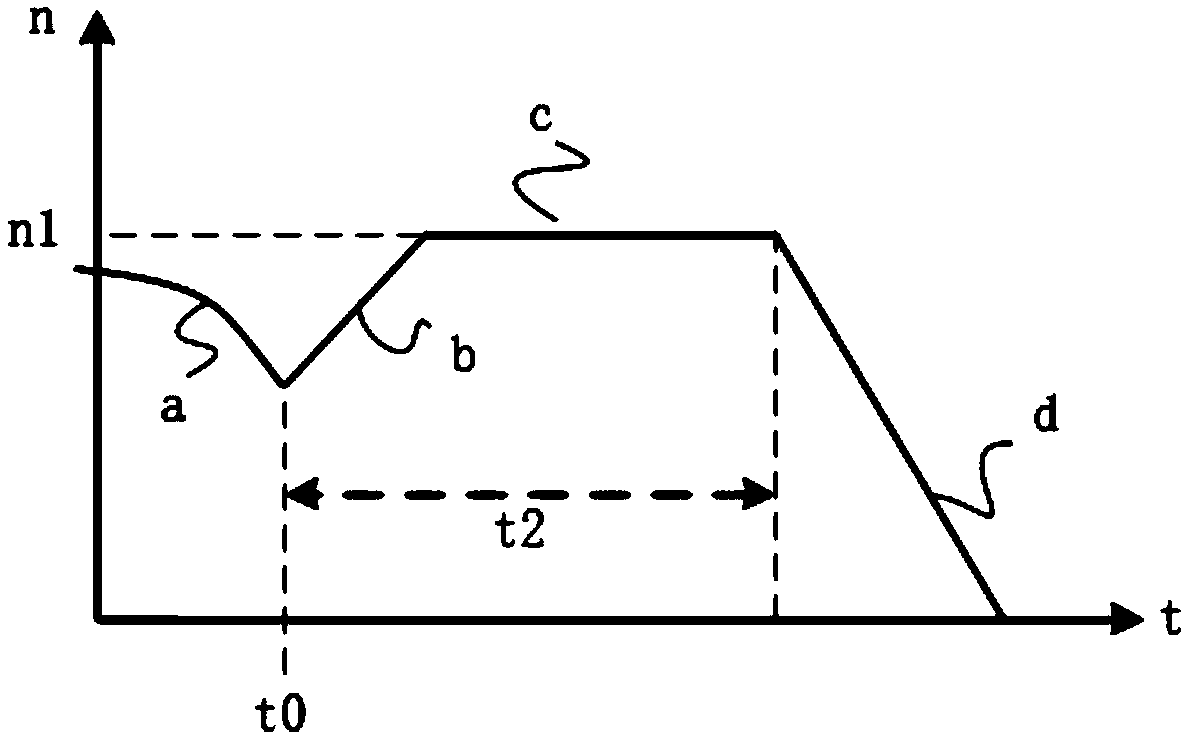

[0028] The tool retract protection function mainly includes trigger source setting and response mode setting. Such as figure 1 As mentioned above, when the system is running, that is, the CNC machine tool is in normal operation, the power supply 1 (380V AC) is input to the power module 2, and the power module 2 is rectified to form a DC bus 3, and the DC bus 3 is connected to the servo drive device 6, and the CNC system 4 passes through The bus 5 is connected to the servo drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com