Shelf type storage equipment capable of automatically recognizing goods and working method

A storage device, automatic identification technology, applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Commodity heating storage or refrigeration storage, low degree of intelligence and other issues, to achieve the effect of improving stocking and storage efficiency, increasing diversity, and reducing difficulty and intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

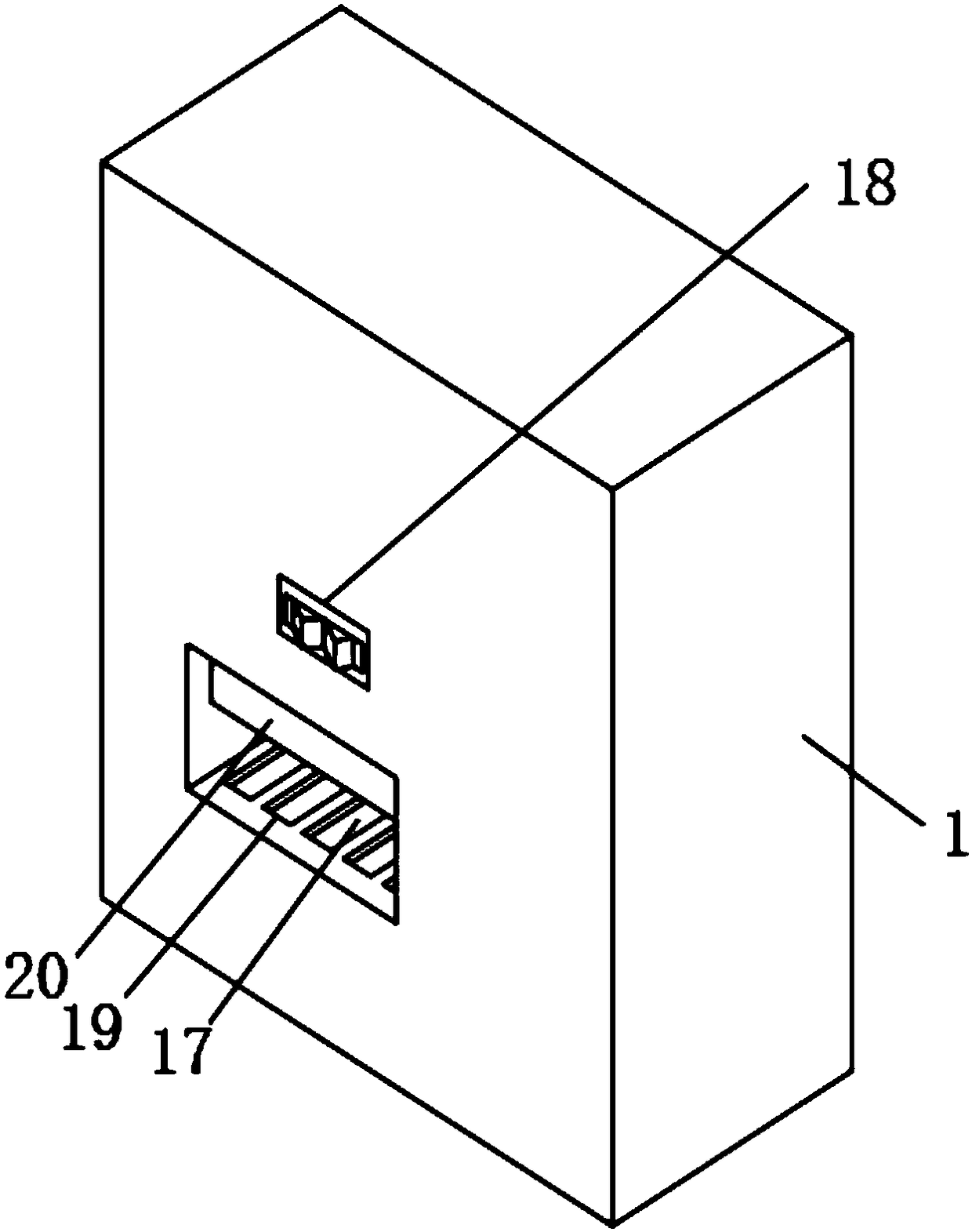

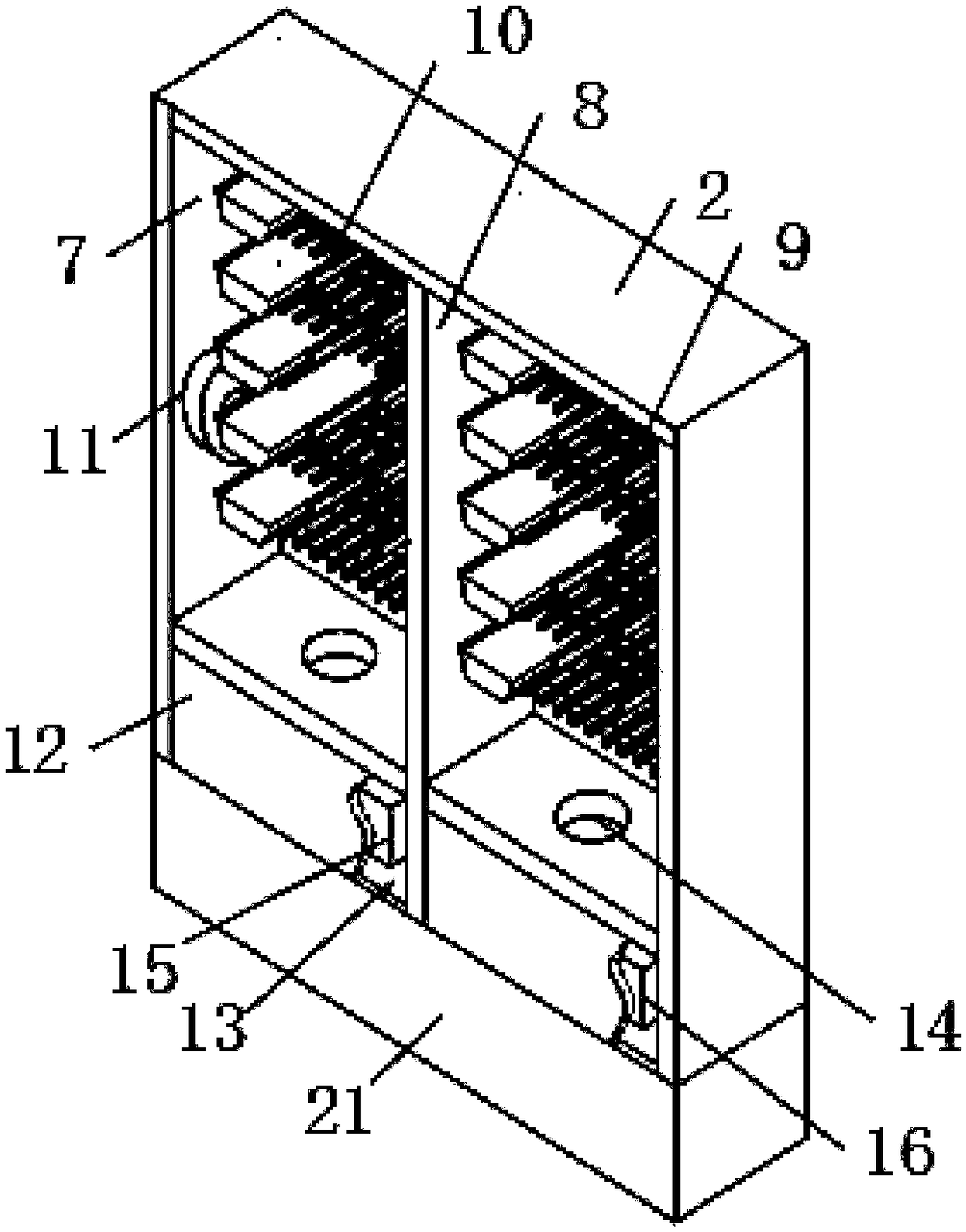

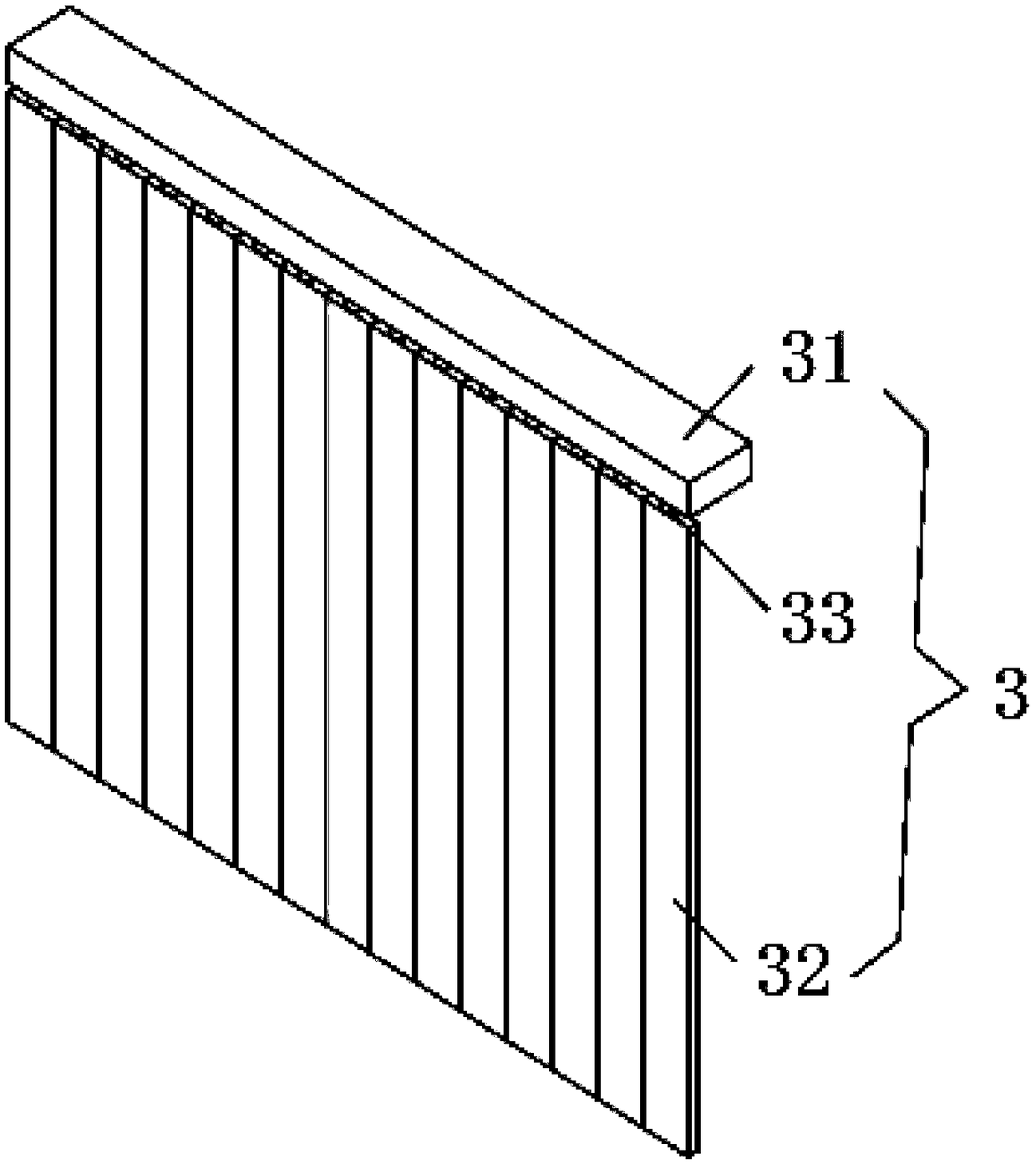

[0032] The present invention provides such Figure 1-7A shelf-type storage device that can automatically identify goods is shown, including a casing 1, a frame 2, a movable airtight door 3 and a sliding table group 4, and the frame 2, the movable airtight door 3 and the sliding table group 4 are all arranged in the casing 1, the outer facade of the frame 2 is fitted and connected to the inner wall of the shell 1, the movable airtight door 3 is arranged on one side of the frame 2, and the top of the movable airtight door 3 is fixedly arranged on the top of one side of the frame 2, and the movable airtight door 3 The door 3 is arranged on one side of the movable airtight door 3, and the top of the movable airtight door 3 is fixedly connected with the top wall of the inner cavity of the casing 1, and the sliding table group 4 is movably provided with a movable comb plate 5, and the movable comb plate 5 A sweeping dock 6 is fixedly arranged at one end, and a heating box 7 and a co...

Embodiment 2

[0035] The difference with embodiment 1 is:

[0036] The bottom of the frame 2 is fixed with an equipment box 12, and both sides of the inner cavity of the equipment box 12 are equipped with equipment compartments 13, and the top ends of the two equipment compartments 13 penetrate the top wall of the frame 2 and extend to the heating box 7 or the refrigeration unit. In the box 8, a heater 15 and a refrigerator 16 are respectively arranged in the equipment compartments 13 on both sides, and the heater 15 is arranged at the bottom of the heating box 7, and the refrigerator 16 is arranged at the bottom of the refrigeration box 8, which is beneficial to the heater. 15 and refrigerator 16 run and generate heat or cold air through the air hole 14 to the heating box 7 or cooling box 8, thus realizing the effect of heating or cooling the commodities in the heating box 7 or cooling box 8.

[0037] One side of the outer wall of the housing 1 is provided with a stocking port 17 and a sto...

Embodiment 3

[0045] The difference with embodiment 1 and embodiment 2 is:

[0046] The present invention also provides an operation process of a shelf-type storage device that can automatically identify commodities, including the following specific operation process:

[0047] Step 1: The stocker presses the stocking operation button 18, the electromagnetic door 20 is powered off and opens, and then the stocker puts the goods on the loading comb plate 19 in the stocking port 17;

[0048] Step 2: Then the sliding table group 4 starts to work, utilizes the operation of the first stepper motor 44, the second stepper motor and the third stepper motor 45 to make the moving comb plate 5 move to the bottom 5mm of the cargo comb plate 19- 10mm, then the telescopic motor 46 runs so that the movable comb plate 5 moves to just below the cargo comb plate 19, and then controls the third stepper motor 45 to run upwards on the vertical slide table 43, so that the movable comb plate 5 The goods are "lifte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com