Heat dissipation distribution cabinet

A distribution box and box body technology, applied in electrical components, substation/switch layout details, substation/switchgear cooling/ventilation, etc., can solve the problem of poor heat dissipation of the distribution box, poor light inside the distribution box, etc. problems, to achieve the effect of stable resistance, convenient installation, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

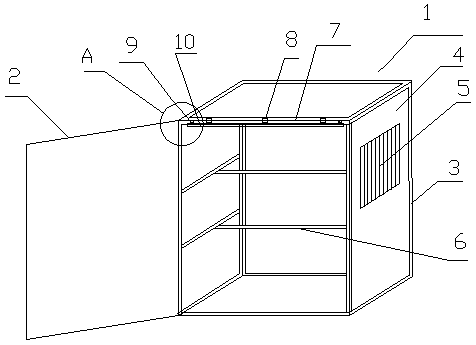

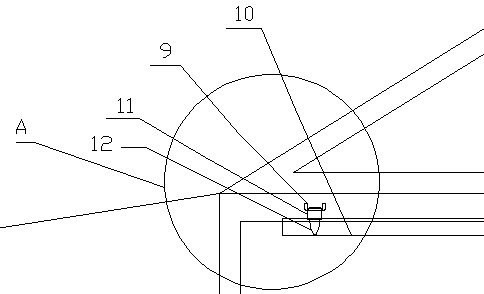

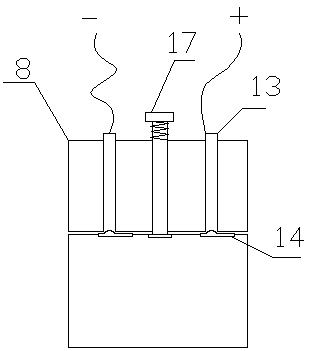

[0036] Such as figure 1 As shown, a heat dissipation distribution box includes a box body 1 and a box door 2. The box body 1 is composed of a frame 3 and a box plate 4. The box door 2 and the box body 1 are connected by a rotating shaft type living hinge; the side of the box body 1 There are vents 5; the box body 1 also has reinforcing ribs 6 inside, and the reinforcing ribs 6 are located in the middle of the frame 3 and are fixedly connected with the frame 3; The joint 8 has a power supply interface inside the fixed joint 8 , the beam 7 is provided with hooks 9 at least on both sides, and the fixed joint is connected with a lighting mechanism 10 . Such as figure 2 As shown, the lighting mechanism 10 is in the shape of a strip, and the lighting mechanism 10 has a buckle 11 at a position corresponding to the hook of the crossbeam 7, and the hook 11 has a tensioning handle 12 thereon.

[0037] Such as Figure 11 As shown, the air vent 5 is composed of a heat-conducting main ...

Embodiment 2

[0046] refer to figure 1 As shown, a heat dissipation distribution box includes a box body 1 and a box door 2. The box body 1 is composed of a frame 3 and a box plate 4. The box door 2 and the box body 1 are connected by a rotating shaft type living hinge; the side of the box body 1 There are vents 5; the box body 1 also has reinforcing ribs 6 inside, and the reinforcing ribs 6 are located in the middle of the frame 3 and are fixedly connected with the frame 3; The joint 8 has a power supply interface inside the fixed joint 8 , the beam 7 is provided with hooks 9 at least on both sides, and the fixed joint is connected with a lighting mechanism 10 . Such as figure 2 As shown, the lighting mechanism 10 is in the shape of a strip, and the lighting mechanism 10 has a buckle 11 at a position corresponding to the hook of the crossbeam 7, and the hook 11 has a tensioning handle 12 thereon. refer to Figure 11 As shown, the air vent 5 is composed of a heat-conducting main copper ...

Embodiment 3

[0049] refer to figure 1 As shown, a heat dissipation distribution box includes a box body 1 and a box door 2. The box body 1 is composed of a frame 3 and a box plate 4. The box door 2 and the box body 1 are connected by a rotating shaft type living hinge; the side of the box body 1 There are vents 5; the box body 1 also has reinforcing ribs 6 inside, and the reinforcing ribs 6 are located in the middle of the frame 3 and are fixedly connected with the frame 3; The joint 8 has a power supply interface inside the fixed joint 8 , the beam 7 is provided with hooks 9 at least on both sides, and the fixed joint is connected with a lighting mechanism 10 . The structures and functions of other components are the same as in Embodiment 1. The difference with embodiment 1 is: as Figure 7 As shown, there are 6 copper tubes 13, which are arranged equidistantly along the circumferential direction, and the angle between every two adjacent copper tubes is 60 degrees; each pair of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com